TPMS INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 185 of 5598

AV

DIAGNOSIS SYSTEM (AV CONTROL UNIT)AV-37

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

Vehicle CAN Diagnosis

CAN communication status and error counter is displayed.

The error counter displays “OK” if any malfunction was not

detected in the past and displays “0 ” if a malfunction is detected. It

increases by 1 if the condition is normal at the next ignition switch

ON cycle. The upper limit of the counter is 39.

The error counter is erased if “Reset” is pressed.

NOTE:

“???” indicates UNKWN.

AV COMM Diagnosis

AV COMM CIRCUIT

Switches Connection Error When either one of the following items are

detected:

multifunction switch power supply and

ground circuits were malfunctioning.

AV communication circuits between AV

control unit and multifunction switch are

malfunctioning. Multifunction switch power supply and

ground circuits.

AV communication circuits between AV control unit and multifunction switch.

AV COMM CIRCUIT

AVM Connection Error When either one of the following items are

detected:

around view monitor control unit power

supply and ground circuits are malfunc-

tioning.

AV communication circuits between AV control unit and around view monitor

control unit are malfunctioning. Around view monitor control unit power

supply and ground circuits.

AV communication circuits between AV control unit and around view monitor

control unit.

AV COMM CIRCUIT

Sonar Connection Error When either one of the following items are

detected:

sonar control unit power supply and

ground circuits are malfunctioning.

AV communication circuits between AV control unit and sonar control unit are

malfunctioning. Sonar control unit power supply and

ground circuits.

AV communication circuits between AV control unit and sonar control unit.

AV COMM CIRCUIT

Switches Connection Error

Sonar Connection Error

AVM Connection Error AV communication circuits between AV

control unit and multifunction switch are

malfunctioning.AV communication circuits between AV

control unit and multifunction switch.

AV COMM CIRCUIT

Switches Connection Error

Sonar Connection Error

AVM Connection Error

2nd Display Connection Error Error item Description Possible malfunction factor/Action to take

Items Display (Current)

Malfunction counter

(Past)

Tx(HVAC) OK / ??? OK / 0 – 39

Rx(ECM) OK / ??? OK / 0 – 39

Rx(Cluster) OK / ??? OK / 0 – 39

Rx(HVAC) OK / ??? OK / 0 – 39

Rx(USM) OK / ??? OK / 0 – 39

Rx(TPMS) OK / ??? OK / 0 – 39

Rx(STRG) OK / ??? OK / 0 – 39

Rx(ACC) OK / ??? OK / 0 – 39

RX(VDC) OK / ??? OK / 0 – 39

JSNIA2391ZZ

Revision: 2010 May2011 QX56

Page 390 of 5598

BCS-2

BATTERY SAVER ....................................................29

BATTERY SAVER : CONSULT-III Function (BCM

- BATTERY SAVER) ........................................... ...

29

TRUNK ................................................................... ...30

TRUNK : CONSULT-III Function (BCM - TRUNK) ...30

THEFT ALM ........................................................... ...30

THEFT ALM : CONSULT-III Function (BCM -

THEFT) ...................................................................

30

RETAIND PWR ...................................................... ...31

RETAIND PWR : CONSULT-III Function (BCM -

RETAINED PWR) ...................................................

31

SIGNAL BUFFER ................................................... ...31

SIGNAL BUFFER : CONSULT-III Function (BCM

- SIGNAL BUFFER) ................................................

31

ECU DIAGNOSIS INFORMATION ..............33

BCM ................................................................ ...33

Reference Value .................................................. ...33

Fail-safe ..................................................................54

DTC Inspection Priority Chart ..............................56

DTC Index ..............................................................57

WIRING DIAGRAM .....................................60

BCM ................................................................ ...60

Wiring Diagram .................................................... ...60

BASIC INSPECTION ...................................67

INSPECTION AND ADJUSTMENT ................ ...67

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (BCM) ......................................... ...

67

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (BCM) : Description ....................

67

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (BCM) : Work Procedure ............

67

CONFIGURATION (BCM) ...................................... ...67

CONFIGURATION (BCM) : Description .................67

CONFIGURATION (BCM) : Work Procedure .........68

CONFIGURATION (BCM) : Configuration list ........69

DTC/CIRCUIT DIAGNOSIS ........................70

U1000 CAN COMM ........................................ ...70

Description ........................................................... ...70

DTC Logic ...............................................................70

Diagnosis Procedure ...............................................70

U1010 CONTROL UNIT (CAN) .........................71

DTC Logic ............................................................ ...71

Diagnosis Procedure ...............................................71

U0415 VEHICLE SPEED ...................................72

Description ........................................................... ...72

DTC Logic ...............................................................72

Diagnosis Procedure ...............................................72

B2562 LOW VOLTAGE .....................................73

DTC Logic ............................................................ ...73

Diagnosis Procedure ...............................................73

B26E7 TPMS CAN COMM ............................. ...74

DTC Logic ............................................................ ...74

Diagnosis Procedure ...............................................74

POWER SUPPLY AND GROUND CIRCUIT .....75

Diagnosis Procedure ............................................ ...75

COMBINATION SWITCH OUTPUT CIRCUIT ...76

Diagnosis Procedure ...............................................76

COMBINATION SWITCH INPUT CIRCUIT .......78

Diagnosis Procedure ............................................ ...78

SYMPTOM DIAGNOSIS ............................80

COMBINATION SWITCH SYSTEM SYMP-

TOMS .............................................................. ...

80

Symptom Table .................................................... ...80

REMOVAL AND INSTALLATION ..............81

BCM ................................................................ ...81

Removal and Installation ...................................... ...81

COMBINATION SWITCH ..................................82

Exploded View ..................................................... ...82

Removal and Installation .........................................82

Revision: 2010 May2011 QX56

Page 445 of 5598

BCS

BCM

BCS-57

< ECU DIAGNOSIS INFORMATION >

C

D E

F

G H

I

J

K L

B A

O P

N

DTC IndexINFOID:0000000006274822

NOTE:

The details of time display are as follows.

CRNT: A malfunction is detected now.

PAST: A malfunction was detected in the past.

IGN counter is displayed on Freeze Frame Data. For details of Freeze Frame Data, refer to

BCS-14, "

COM-

MON ITEM : CONSULT-III Function (BCM - COMMON ITEM)".

4 B2013: ID DISCORD BCM-S/L

B2014: CHAIN OF S/L-BCM

B2555: STOP LAMP

B2556: PUSH-BTN IGN SW

B2557: VEHICLE SPEED

B2601: SHIFT POSITION

B2602: SHIFT POSITION

B2603: SHIFT POSI STATUS

B2604: PNP/CLUTCH SW

B2605: PNP/CLUTCH SW

B2608: STARTER RELAY

B2609: S/L STATUS

B260B: STEERING LOCK UNIT

B260C: STEERING LOCK UNIT

B260D: STEERING LOCK UNIT

B260F: ENG STATE SIG LOST

B2612: S/L STATUS

B2614: BCM

B2615: BCM

B2616: BCM

B2618: BCM

B2619: BCM

B261A: PUSH-BTN IGN SW

B26E9: LOCK MALFUNCTION

B26EF: STRG LCK RELAY OFF

B26F0: STRG LCK RELAY ON

B26F1: IGN RELAY OFF

B26F2: IGN RELAY ON

B26F3: START CONT RLY ON

B26F4: START CONT RLY OFF

B26F5: STRG LCK STS SW

B26F6: BCM

B26F7: BCM

B26F8: BCM

B26F9: CRANK REQ CIR SHORT

B26FA: CRANK REQ CIR OPEN

B26FC: KEY REGISTRATION

U0415: VEHICLE SPEED

5 B2621: INSIDE ANTENNA

B2622: INSIDE ANTENNA

B2623: INSIDE ANTENNA

6 B2626: OUTSIDE ANTENNA

B2627: OUTSIDE ANTENNA

B2628: OUTSIDE ANTENNA

7 B26E7: TPMS CAN COMM

Priority DTC

Revision: 2010 May2011 QX56

Page 446 of 5598

BCS-58

< ECU DIAGNOSIS INFORMATION >

BCM

CONSULT display Fail-safeFreeze Frame Data

Vehicle Speed

Odo/Trip Meter

Vehicle Condition Intelligent Key warn-

ing lamp ON Reference

page

No DTC is detected.

further testing

may be required. ————

U1000: CAN COMM — — — BCS-70

U1010: CONTROL UNIT (CAN) — — —BCS-71

U0415: VEHICLE SPEED×— ×BCS-72

B2013: ID DISCORD BCM-S/L ××× SEC-69

B2014: CHAIN OF S/L-BCM××× SEC-70

B2192: ID DISCORD BCM-ECM×—— SEC-60

B2193: CHAIN OF BCM-ECM ×—— SEC-61

B2195: ANTI-SCANNING ×—— SEC-62

B2196: DONGLE NG ×—— SEC-63

B2198: NATS ANTENNA AMP ×—— SEC-65

B2555: STOP LAMP — ××SEC-73

B2556: PUSH-BTN IGN SW — ××SEC-76

B2557: VEHICLE SPEED ××× SEC-78

B2562: LOW VOLTAGE — ×—BCS-73

B2601: SHIFT POSITION ××× SEC-79

B2602: SHIFT POSITION××× SEC-82

B2603: SHIFT POSI STATUS××× SEC-85

B2604: PNP/CLUTCH SW××× SEC-89

B2605: PNP/CLUTCH SW××× SEC-91

B2608: STARTER RELAY××× SEC-93

B2609: S/L STATUS××× SEC-95

B260B: STEERING LOCK UNIT××× SEC-98

B260C: STEERING LOCK UNIT — ××SEC-99

B260D: STEERING LOCK UNIT ××× SEC-100

B260F: ENG STATE SIG LOST××× SEC-101

B2612: S/L STATUS××× SEC-102

B2614: BCM — ××PCS-56

B2615: BCM — ××PCS-59

B2616: BCM — ××PCS-61

B2618: BCM — ××PCS-63

B2619: BCM ××× SEC-105

B261A: PUSH-BTN IGN SW — ××PCS-64

B2621: INSIDE ANTENNA — ×—DLK-104

B2622: INSIDE ANTENNA — ×—DLK-106

B2623: INSIDE ANTENNA — ×—DLK-108

B2626: OUTSIDE ANTENNA — ×—DLK-110

B2627: OUTSIDE ANTENNA — ×—DLK-112

B2628: OUTSIDE ANTENNA — ×—DLK-114

B26E7: TPMS CAN COMM — — — BCS-74

Revision: 2010 May2011 QX56

Page 457 of 5598

BCS

INSPECTION AND ADJUSTMENTBCS-69

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

B A

O P

N

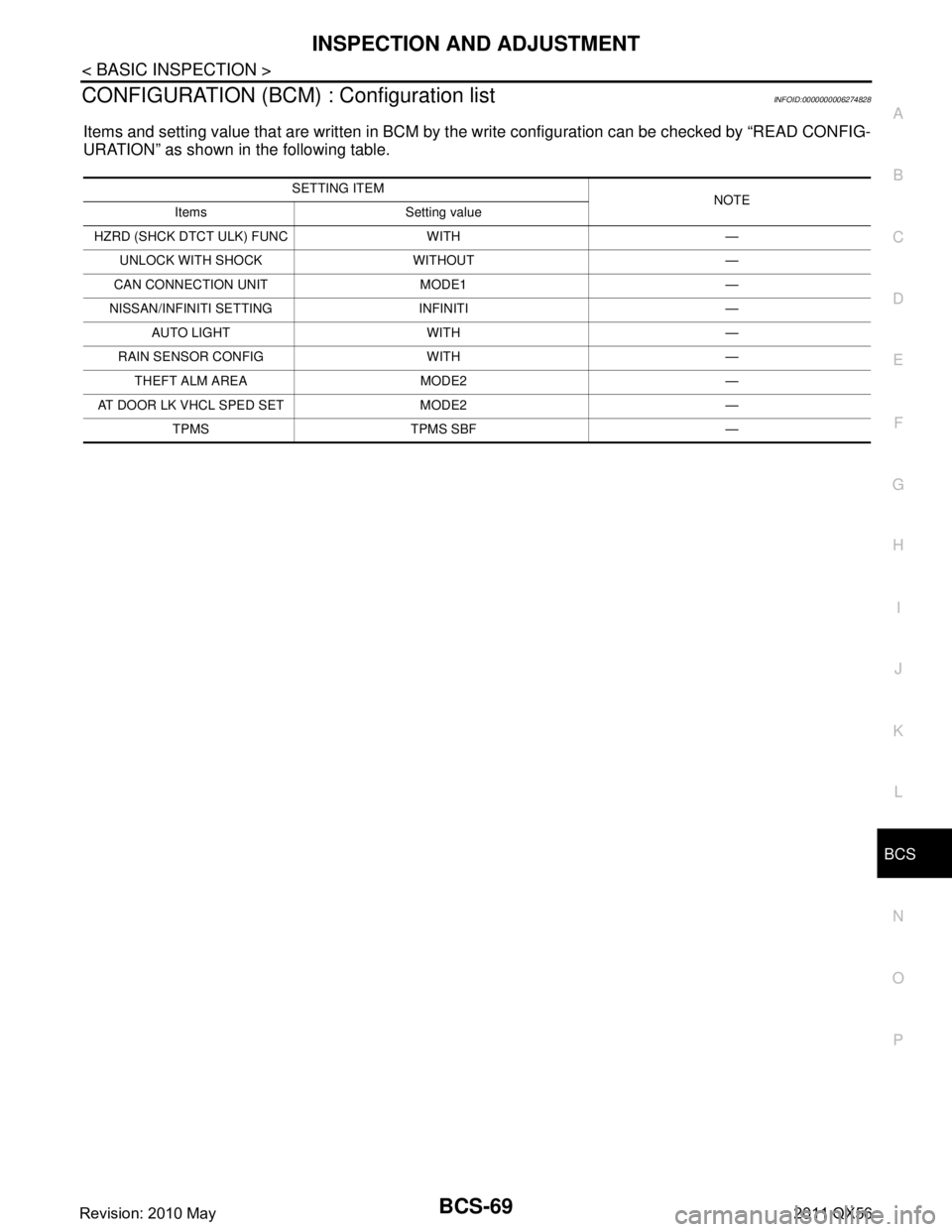

CONFIGURATION (BCM)

: Configuration listINFOID:0000000006274828

Items and setting value that are written in BCM by t he write configuration can be checked by “READ CONFIG-

URATION” as shown in the following table.

SETTING ITEM NOTE

Items Setting value

HZRD (SHCK DTCT ULK) FUNC WITH — UNLOCK WITH SHOCK WITHOUT —

CAN CONNECTION UNIT MODE1 —

NISSAN/INFINITI SETTING INFINITI — AUTO LIGHT WITH —

RAIN SENSOR CONFIG WITH — THEFT ALM AREA MODE2 —

AT DOOR LK VHCL SPED SET MODE2 — TPMS TPMS SBF —

Revision: 2010 May2011 QX56

Page 462 of 5598

BCS-74

< DTC/CIRCUIT DIAGNOSIS >

B26E7 TPMS CAN COMM

B26E7 TPMS CAN COMM

DTC LogicINFOID:0000000006274839

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.DTC CONFIRMATION

1. Erase the DTC.

2. Turn ignition switch OFF.

3. Perform the “Self Diagnostic Result” of BCM with CONS ULT-III, when passed 2 seconds or more after the

ignition switch is turned ON.

Is any DTC detected?

YES >> Refer to BCS-74, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006274840

NOTE:

If DTC “B26E7” detected along with DTC “U1000” , first diagnose the DTC “U1000”. Refer to BCS-70, "

Diagno-

sis Procedure".

1.LOW TIRE PRESSURE WARNING CONTRO L UNIT SELF DIAGNOSTIC RESULT

Perform “Self Diagnostic Result” of low tire pressu re warning control unit with CONSULT-III. Refer to WT-12,

"CONSULT-III Function".

Is any DTC detected?

YES >> GO TO 2.

NO >> GO TO 4.

2.LOW TIRE PRESSURE WARNING CONTROL UNIT DIAGNOSIS

Perform low tire pressure warning control uni t component diagnosis of detected DTC. Refer to WT-18, "

DTC

Index".

>> GO TO 3.

3.BCM SELF DIAGNOSTIC RESULT

Erase DTC of BCM, and perform “Self Diagnostic Result” again.

Is DTC

“B26E7” detected?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> INSPECTION END

4.REPLACE LOW TIRE PRESSURE WA RNING CONTROL UNIT TEMPORARILY

Remove low tire pressure warning control unit, and in stall normal low tire pressure warning control unit.

>> GO TO 5.

5.BCM SELF-DIAGNOSTIC RESULT

Erase DTC of BCM, and perform “S elf Diagnostic Result” of BCM again.

Is DTC

“B26E7” detected?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> Replace low tire pressure warning control unit. Refer to WT-65, "

Removal and Installation".

DTC CONSULT-III display description DTC Detection Condition Probable cause

B26E7 TPMS CAN COMM When ignition switch is ON, BCM cannot re-

ceived CAN communication signal from low

tire pressure warn

ing control unit. CAN communication system

Low tire pressure warning control unit

BCM

Revision: 2010 May2011 QX56

Page 1788 of 5598

DLK-252

< REMOVAL AND INSTALLATION >

CAB MOUNTING INSULATOR

Drain brake fluid from brake line. Refer to BR-10, "Draining".

Release fuel pressure. Refer to EC-153, "

Work Procedure".

Disconnect both battery cables. Refer to PG-164, "

Removal and Installation".

Drain engine coolant from radiator. Refer to CO-8, "

Draining".

Discharge refrigerant from A/C circuit. Refer to HA-20, "

Recycle Refrigerant".

Drain power steering fluid from reservoir tank.

4. Remove parts relating to connection of body assembly and frame assembly. Tire and wheel: Refer to WT-64, "

Removal and Installation" (with TPMS).

Front fender protector (LH and RH): Refer to EXT-23, "

FENDER PROTECTOR : Removal and Installa-

tion".

Front bumper: Refer to EXT-13, "

Removal and Installation".

Radiator core support upper: Refer to DLK-220, "

Removal and Installation".

Fan shroud: Refer to CO-16, "

Removal and Installation".

Battery and battery case: Refer to PG-164, "

Removal and Installation".

Air cleaner case (upper and lower): Refer to EM-27, "

Removal and Installation".

Engine cover: Refer to EM-25, "

Removal and Installation".

Rear wheel house protector (LH and RH): EXT-24, "

REAR WHEEL HOUSE PROTECTOR : Removal

and Installation".

Rear bumper: Refer to EXT-17, "

Removal and Installation".

Fuel filler tube: Remove to FL-8, "

Exploded View".

Spare tire

Towing hook bracket.

5. Separate parts relating to connection of body assembly and frame assembly. Vehicle front

Disconnect ICC sensor connector. (models with ICC) Refer to CCS-176, "

Removal and Installation".

Remove radiator upper hose and radiator lower hose from radiator assembly. Refer to CO-13,

"Exploded View".

Remove A/T fluid cooler hose B and A/T fluid cooler hose E from A/T fluid cooler tubes. Refer to TM-

202, "Exploded View".

Remove power steering return hose from oil cooler, and then power steering return hose clamp bolt from frame assembly. Refer to ST-54, "

Exploded View".

Remove power steering suction hose from reservoir tank. Refer to ST-54, "

Exploded View".

CAUTION:

Never spill power steering fluid in engine room.

Remove A/C low-presser flexible hose from A/C low-presser pipe. Refer to HA-35, "

LOW-PRESSURE

FLEXIBLE HOSE : Removal and Installation".

Remove A/C hi-presser flexible hose from condenser. Refer to HA-34, "

HIGH-PRESSURE FLEXIBLE

HOSE : Removal and Installation".

Remove all engine Control Harness connectors, har ness clips and others that are connected to the

body assembly side of the engine room. (engine room LH and RH side). Refer to PG-148, "

Engine Con-

trol Harness".

NOTE:

Separate harness connectors from ECM (engine control module). Refer to EC-10, "

General Precau-

tions".

CAUTION:

When pulling out harnesses, never damage harnesses or connectors.

After temporarily securing connectors, cover th em with vinyl or similar material to protect

against adhesion of foreign materials.

Disconnect engine room harness connectors and remo ve harness clips from engine assembly (engine

RH side). Refer to PG-146, "

Engine Room Harness".

Remove heater hoses from front water outlet tube (engine room RH side). Refer to HA-33, "

Exploded

View".

Disconnect front wheel sensor connectors (LH and RH). Refer to BRC-134, "

FRONT WHEEL SENSOR

: Exploded View".

Disconnect fuel feed tube and EVAP hos e (front wheel well LH side).

Remove steering lower shaft from steering gear side assembly. Refer to ST-37, "

Removal and Installa-

tion"

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and

steering gear assembly.

Revision: 2010 May2011 QX56

Page 2981 of 5598

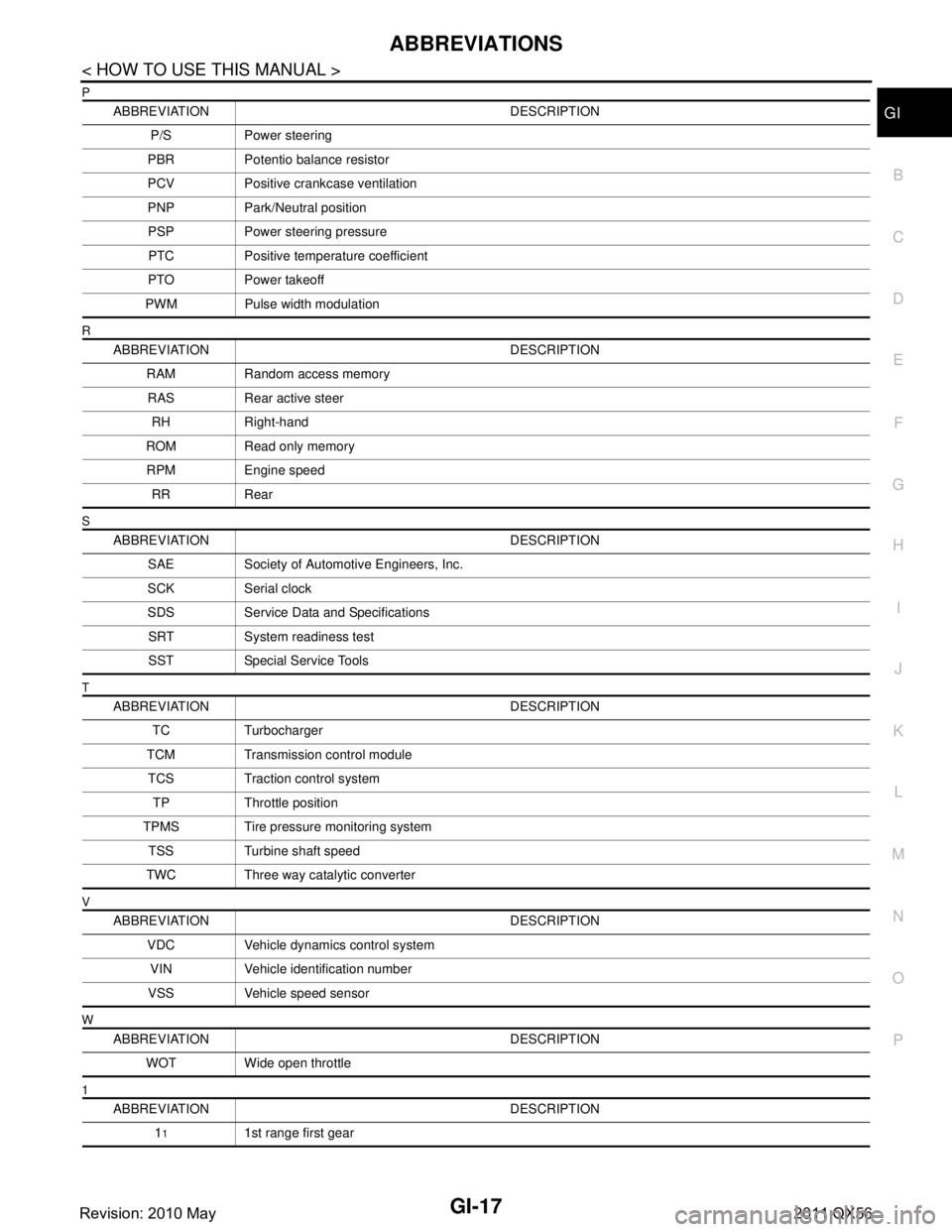

ABBREVIATIONSGI-17

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

P

R

S

T

V

W

1

ABBREVIATION DESCRIPTION P/S Power steering

PBR Potentio balance resistor

PCV Positive crankcase ventilation

PNP Park/Neutral position PSP Power steering pressurePTC Positive temperature coefficient

PTO Power takeoff

PWM Pulse width modulation

ABBREVIATION DESCRIPTION RAM Random access memoryRAS Rear active steer RH Right-hand

ROM Read only memory RPM Engine speed RR Rear

ABBREVIATION DESCRIPTION SAE Society of Automoti ve Engineers, Inc.

SCK Serial clock

SDS Service Data and Specifications SRT System readiness testSST Special Service Tools

ABBREVIATION DESCRIPTION TC Turbocharger

TCM Transmission control module TCS Traction control system TP Throttle position

TPMS Tire pressure monitoring system TSS Turbine shaft speed

TWC Three way catalytic converter

ABBREVIATION DESCRIPTION VDC Vehicle dynamics control systemVIN Vehicle identification number

VSS Vehicle speed sensor

ABBREVIATION DESCRIPTION WOT Wide open throttle

ABBREVIATION DESCRIPTION 1

11st range first gear

Revision: 2010 May2011 QX56

Page 3422 of 5598

LAN-2

ITS Communication Circuit .....................................58

MAIN LINE BETWEEN ABS AND DLC CIR-

CUIT ...................................................................

60

Diagnosis Procedure ........................................... ...60

MAIN LINE BETWEEN DLC AND E-SUS CIR-

CUIT ...................................................................

61

Diagnosis Procedure ........................................... ...61

MAIN LINE BETWEEN E-SUS AND ADP CIR-

CUIT ...................................................................

62

Diagnosis Procedure ........................................... ...62

MAIN LINE BETWEEN ADP AND PWBD CIR-

CUIT ...................................................................

63

Diagnosis Procedure ........................................... ...63

MAIN LINE BETWEEN RDR-R AND RDR-L

CIRCUIT .............................................................

64

Diagnosis Procedure ........................................... ...64

MAIN LINE BETWEEN RDR-L AND LANE

CIRCUIT .............................................................

65

Diagnosis Procedure ........................................... ...65

MAIN LINE BETWEEN LANE AND APA CIR-

CUIT ...................................................................

67

Diagnosis Procedure ........................................... ...67

ECM BRANCH LINE CIRCUIT ..........................68

Diagnosis Procedure ........................................... ...68

4WD BRANCH LINE CIRCUIT ..........................69

Diagnosis Procedure ........................................... ...69

ABS BRANCH LINE CIRCUIT ..........................70

Diagnosis Procedure ........................................... ...70

TCM BRANCH LINE CIRCUIT ..........................71

Diagnosis Procedure ........................................... ...71

A-BAG BRANCH LINE CIRCUIT ......................72

Diagnosis Procedure ........................................... ...72

AFS BRANCH LINE CIRCUIT ...........................73

Diagnosis Procedure ........................................... ...73

AV BRANCH LINE CIRCUIT .............................74

Diagnosis Procedure ........................................... ...74

BCM BRANCH LINE CIRCUIT ..........................75

Diagnosis Procedure ........................................... ...75

CGW BRANCH LINE CIRCUIT (CAN COM-

MUNICATION CIRCUIT 1) .................................

76

Diagnosis Procedure ........................................... ...76

CGW BRANCH LINE CIRCUIT (CAN COM-

MUNICATION CIRCUIT 2) .................................

77

Diagnosis Procedure ........................................... ...77

DLC BRANCH LINE CIRCUIT ..........................78

Diagnosis Procedure ............................................ ...78

HVAC BRANCH LINE CIRCUIT ........................79

Diagnosis Procedure ............................................ ...79

M&A BRANCH LINE CIRCUIT ..........................80

Diagnosis Procedure ............................................ ...80

STRG BRANCH LINE CIRCUIT ........................81

Diagnosis Procedure ............................................ ...81

TPMS BRANCH LINE CIRCUIT ........................82

Diagnosis Procedure ............................................ ...82

IPDM-E BRANCH LINE CIRCUIT .....................83

Diagnosis Procedure ............................................ ...83

ADP BRANCH LINE CIRCUIT ..........................84

Diagnosis Procedure ............................................ ...84

PSB BRANCH LINE CIRCUIT ..........................85

Diagnosis Procedure ............................................ ...85

E-SUS BRANCH LINE CIRCUIT .......................86

Diagnosis Procedure ............................................ ...86

ICC BRANCH LINE CIRCUIT ............................87

Diagnosis Procedure ............................................ ...87

PWBD BRANCH LINE CIRCUIT .......................88

Diagnosis Procedure ............................................ ...88

RDR-R BRANCH LINE CIRCUIT ......................89

Diagnosis Procedure ............................................ ...89

RDR-L BRANCH LINE CIRCUIT .......................90

Diagnosis Procedure ............................................ ...90

LANE BRANCH LINE CIRCUIT ........................91

Diagnosis Procedure ............................................ ...91

APA BRANCH LINE CIRCUIT ..........................92

Diagnosis Procedure ............................................ ...92

LASER BRANCH LINE CIRCUIT ......................93

Diagnosis Procedure ............................................ ...93

CAN COMMUNICATION CIRCUIT ...................94

Diagnosis Procedure ............................................ ...94

CAN COMMUNICATION CIRCUIT 1 ................96

Diagnosis Procedure ............................................ ...96

CAN COMMUNICATION CIRCUIT 2 ................98

Diagnosis Procedure ............................................ ...98

ITS COMMUNICATION CIRCUIT .....................100

Diagnosis Procedure ............................................ .100

CAN GATEWAY

PRECAUTION ............... ............................

102

PRECAUTIONS .............................................. ..102

Revision: 2010 May2011 QX56

Page 3423 of 5598

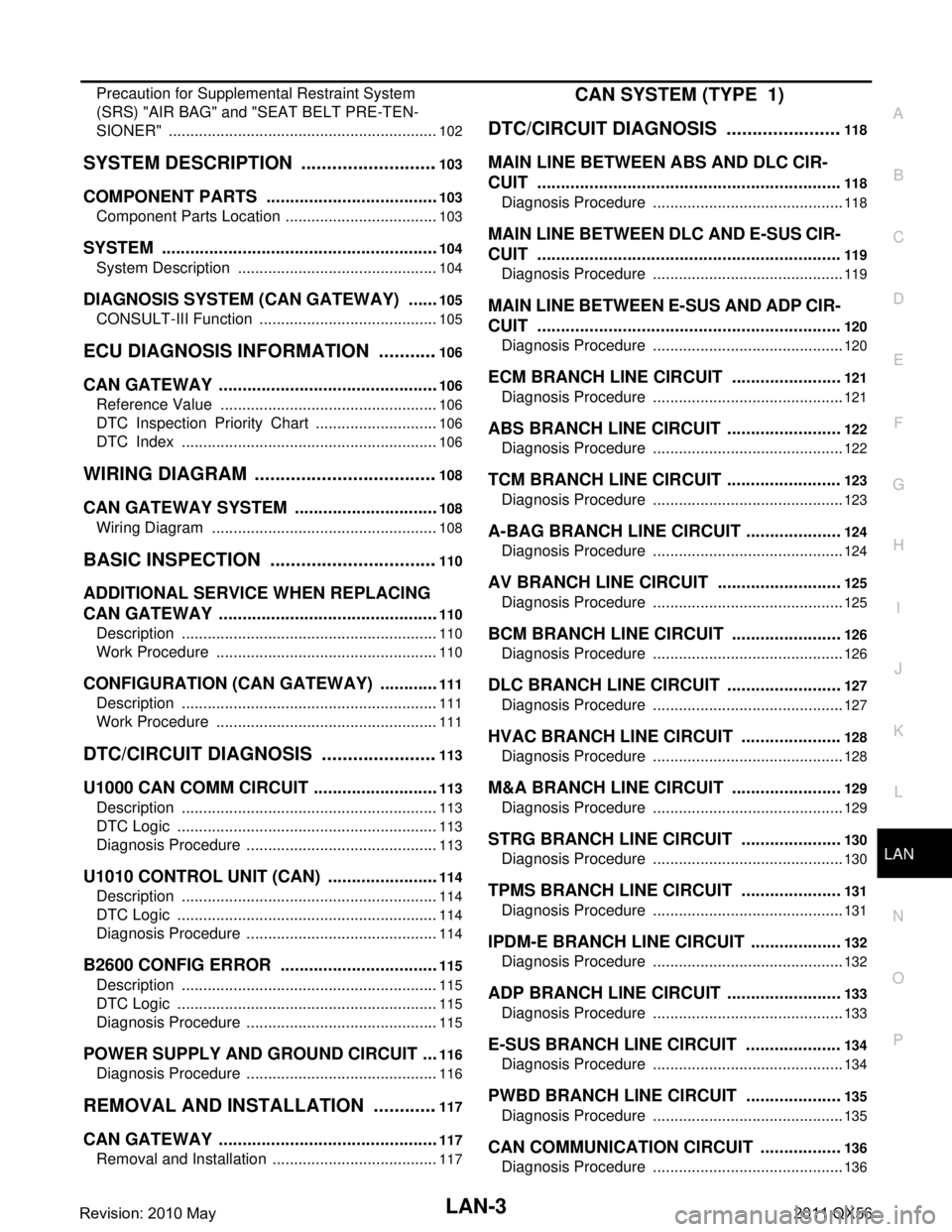

LAN

LAN-3

C

DE

F

G H

I

J

K L

B

A

O P

N

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................

..

102

SYSTEM DESCRIPTION ...........................103

COMPONENT PARTS ................................... ..103

Component Parts Location .................................. ..103

SYSTEM ...........................................................104

System Description ............................................. ..104

DIAGNOSIS SYSTEM (CAN GATEWAY) .......105

CONSULT-III Function ........................................ ..105

ECU DIAGNOSIS INFORMATION ............106

CAN GATEWAY ............................................. ..106

Reference Value ................................................. ..106

DTC Inspection Priority Chart .............................106

DTC Index ............................................................106

WIRING DIAGRAM ....................................108

CAN GATEWAY SYSTEM ............................. ..108

Wiring Diagram ................................................... ..108

BASIC INSPECTION .................................110

ADDITIONAL SERVICE WHEN REPLACING

CAN GATEWAY ............................................. ..

110

Description .......................................................... ..110

Work Procedure ....................................................110

CONFIGURATION (CAN GATEWAY) .............111

Description .......................................................... ..111

Work Procedure ....................................................111

DTC/CIRCUIT DIAGNOSIS .......................113

U1000 CAN COMM CIRCUIT ......................... ..113

Description .......................................................... ..113

DTC Logic .............................................................113

Diagnosis Procedure .............................................113

U1010 CONTROL UNIT (CAN) ........................114

Description .......................................................... ..114

DTC Logic .............................................................114

Diagnosis Procedure .............................................114

B2600 CONFIG ERROR ..................................115

Description .......................................................... ..115

DTC Logic .............................................................115

Diagnosis Procedure .............................................115

POWER SUPPLY AND GROUND CIRCUIT ....116

Diagnosis Procedure ........................................... ..116

REMOVAL AND INSTALLATION .............117

CAN GATEWAY ............................................. ..117

Removal and Installation ..................................... ..117

CAN SYSTEM (TYPE 1)

DTC/CIRCUIT DIAGNOSIS .......................

118

MAIN LINE BETWEEN ABS AND DLC CIR-

CUIT ................................................................

118

Diagnosis Procedure ........................................... ..118

MAIN LINE BETWEEN DLC AND E-SUS CIR-

CUIT ................................................................

119

Diagnosis Procedure .............................................119

MAIN LINE BETWEEN E-SUS AND ADP CIR-

CUIT ................................................................

120

Diagnosis Procedure .............................................120

ECM BRANCH LINE CIRCUIT .......................121

Diagnosis Procedure .............................................121

ABS BRANCH LINE CIRCUIT ........................122

Diagnosis Procedure .............................................122

TCM BRANCH LINE CIRCUIT ........................123

Diagnosis Procedure .............................................123

A-BAG BRANCH LINE CIRCUIT ....................124

Diagnosis Procedure .............................................124

AV BRANCH LINE CIRCUIT ..........................125

Diagnosis Procedure .............................................125

BCM BRANCH LINE CIRCUIT .......................126

Diagnosis Procedure .............................................126

DLC BRANCH LINE CIRCUIT ........................127

Diagnosis Procedure .............................................127

HVAC BRANCH LINE CIRCUIT .....................128

Diagnosis Procedure .............................................128

M&A BRANCH LINE CIRCUIT .......................129

Diagnosis Procedure .............................................129

STRG BRANCH LINE CIRCUIT .....................130

Diagnosis Procedure .............................................130

TPMS BRANCH LINE CIRCUIT .....................131

Diagnosis Procedure .............................................131

IPDM-E BRANCH LINE CIRCUIT ...................132

Diagnosis Procedure .............................................132

ADP BRANCH LINE CIRCUIT ........................133

Diagnosis Procedure .............................................133

E-SUS BRANCH LINE CIRCUIT ....................134

Diagnosis Procedure .............................................134

PWBD BRANCH LINE CIRCUIT ....................135

Diagnosis Procedure .............................................135

CAN COMMUNICATION CIRCUIT .................136

Diagnosis Procedure .............................................136

Revision: 2010 May2011 QX56