oil capacity INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1908 of 5598

![INFINITI QX56 2011 Factory Service Manual

DLN-106

< PERIODIC MAINTENANCE >[TRANSFER: ATX90A]

TRANSFER FLUID

PERIODIC MAINTENANCE

TRANSFER FLUID

InspectionINFOID:0000000006222324

FLUID LEAKAGE

Check transfer surrounding area (oil seal, drain INFINITI QX56 2011 Factory Service Manual

DLN-106

< PERIODIC MAINTENANCE >[TRANSFER: ATX90A]

TRANSFER FLUID

PERIODIC MAINTENANCE

TRANSFER FLUID

InspectionINFOID:0000000006222324

FLUID LEAKAGE

Check transfer surrounding area (oil seal, drain](/img/42/57033/w960_57033-1907.png)

DLN-106

< PERIODIC MAINTENANCE >[TRANSFER: ATX90A]

TRANSFER FLUID

PERIODIC MAINTENANCE

TRANSFER FLUID

InspectionINFOID:0000000006222324

FLUID LEAKAGE

Check transfer surrounding area (oil seal, drain plug, and filler plug etc.) for fluid leakage.

FLUID LEVEL

1. Remove filler plug (1) and gasket. Then check that fluid is filled

up from mounting hole for the filler plug.

CAUTION:

Never start engine whil e checking fluid level.

2. Set a new gasket onto filler plug (1), and install it on transfer and then tighten to the specified torque.

CAUTION:

Never reuse gasket.

DrainingINFOID:0000000006222325

1. Run the vehicle to warm up the transfer unit sufficiently.

2. Stop the engine.

3. Remove the drain plug (1) and drain transfer fluid.

4. Set a new gasket onto drain plug (1), and install it to transfer andtighten to the specified torque.

CAUTION:

Never reuse gasket.

RefillingINFOID:0000000006222326

1. Remove filler plug (1). Fill up with new transfer fluid up to mount-ing hole for the filler plug.

CAUTION:

Carefully fill the fluid. (Fill up for approximately 3 minutes.)

2. Leave the vehicle for 3 minutes, and check the fluid level again.

3. Set a new gasket onto filler plug, and install it on transfer and tighten to the specified torque.

CAUTION:

Never reuse gasket.

4. Perform learning of transfer fluid viscosity. Refer to DLN-47, "

Work Procedure".

Specified torque : 33 N·m (3.4 kg-m, 24 ft-lb)

JPDIE0295ZZ

Specified torque : 33 N-m (3.4 kg-m, 24 ft-lb)

JPDIE0245ZZ

Fluid grade and Viscosity : Refer to

MA-10, "Fluids

and Lubricants".

Fluid capacity : Refer to DLN-124, "

Gen-

eral Specifications".

Specified torque : 33 N-m (3.4 kg-m, 24 ft-lb)

JPDIE0295ZZ

Revision: 2010 May2011 QX56

Page 1957 of 5598

![INFINITI QX56 2011 Factory Service Manual

FRONT DIFFERENTIAL GEAR OILDLN-155

< PERIODIC MAINTENANCE > [FRONT FINAL DRIVE: R180A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

PERIODIC MAINTENANCE

FRONT DIFFERENTIAL GEAR OIL

InspectionINFOID:0000000006222 INFINITI QX56 2011 Factory Service Manual

FRONT DIFFERENTIAL GEAR OILDLN-155

< PERIODIC MAINTENANCE > [FRONT FINAL DRIVE: R180A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

PERIODIC MAINTENANCE

FRONT DIFFERENTIAL GEAR OIL

InspectionINFOID:0000000006222](/img/42/57033/w960_57033-1956.png)

FRONT DIFFERENTIAL GEAR OILDLN-155

< PERIODIC MAINTENANCE > [FRONT FINAL DRIVE: R180A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

PERIODIC MAINTENANCE

FRONT DIFFERENTIAL GEAR OIL

InspectionINFOID:0000000006222378

OIL LEAKAGE

Check that oil is not leaking from the front final drive assembly or around it.

OIL LEVEL

Remove filler plug (1) and check oil level from filler plug mounting

hole as shown in the figure.

CAUTION:

Never start engine while checking oil level.

Set a gasket on filler plug (1) and install it on final drive assembly. Refer to DLN-167, "

Exploded View".

CAUTION:

Never reuse gasket.

DrainingINFOID:0000000006222379

1. Stop engine.

2. Remove drain plug (1) and drain gear oil.

3. Set a gasket on drain plug (1) and install it to final drive assem- bly and tighten to the specified torque. Refer to DLN-167,

"Exploded View".

CAUTION:

Never reuse gasket.

RefillingINFOID:0000000006222380

1. Remove filler plug (1). Fill with new gear oil until oil level reaches the specified level near filler plug mounting hole.

2. After refilling oil, check oil level. Set a gasket to filler plug (1), then install it to final drive assembly. Refer to DLN-167,

"Exploded View".

CAUTION:

Never reuse gasket.

JPDID0312ZZ

JPDID0313ZZ

Oil grade and Viscosity : Refer to MA-10, "Fluids

and Lubricants".

Oil capacity : Refer to DLN-185, "

Gen-

eral Specifications".

JPDID0312ZZ

Revision: 2010 May2011 QX56

Page 1987 of 5598

![INFINITI QX56 2011 Factory Service Manual

SERVICE DATA AND SPECIFICATIONS (SDS)

DLN-185

< SERVICE DATA AND SPECIFICATIONS (SDS) [FRONT FINAL DRIVE: R180A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA A INFINITI QX56 2011 Factory Service Manual

SERVICE DATA AND SPECIFICATIONS (SDS)

DLN-185

< SERVICE DATA AND SPECIFICATIONS (SDS) [FRONT FINAL DRIVE: R180A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA A](/img/42/57033/w960_57033-1986.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

DLN-185

< SERVICE DATA AND SPECIFICATIONS (SDS) [FRONT FINAL DRIVE: R180A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationsINFOID:0000000006222401

Drive Gear RunoutINFOID:0000000006222402

Unit: mm (in)

Preload TorqueINFOID:0000000006222403

Unit: N·m (kg-m, in-lb)

BacklashINFOID:0000000006222404

Unit: mm (in)

Companion Flange RunoutINFOID:0000000006222405

Unit: mm (in)

Applied model 4WD

VK56VD A/T

Final drive model R180A

Gear ratio 2.937

Number of teeth (Drive gear/Drive pinion) 47/16

Oil capacity (Approx.) (US pt, lmp pt)0.75 (1-5/8, 1-3/8)

Number of pinion gears 4

Drive pinion adjustment spacer type Collapsible

Item Limit

Drive gear back face runout 0.05 (0.0020)

Item Standard

Pinion bearing (P

1) 1.08 – 1.66 (0.11 – 0.16, 10 – 14)

Side bearing (P

2) 0.59 – 1.08 (0.06 – 0.11, 6 – 9)

Side bearing to pinion bearing (Total preload)

(Total preload = P

1 + P2) 1.67 – 2.74 (0.17 – 0.27, 15 – 24)

Item Standard

Drive gear to drive pinion gear 0.10 – 0.15 (0.0039 – 0.0059)

Item Limit

Companion flange face 0.10 (0.004)

Inner side of the companion flange 0.10 (0.004)

Revision: 2010 May2011 QX56

Page 1995 of 5598

![INFINITI QX56 2011 Factory Service Manual

REAR DIFFERENTIAL GEAR OILDLN-193

< PERIODIC MAINTENANCE > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

PERIODIC MAINTENANCE

REAR DIFFERENTIAL GEAR OIL

InspectionINFOID:0000000006222411

INFINITI QX56 2011 Factory Service Manual

REAR DIFFERENTIAL GEAR OILDLN-193

< PERIODIC MAINTENANCE > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

PERIODIC MAINTENANCE

REAR DIFFERENTIAL GEAR OIL

InspectionINFOID:0000000006222411](/img/42/57033/w960_57033-1994.png)

REAR DIFFERENTIAL GEAR OILDLN-193

< PERIODIC MAINTENANCE > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

PERIODIC MAINTENANCE

REAR DIFFERENTIAL GEAR OIL

InspectionINFOID:0000000006222411

OIL LEAKAGE

Check that differential gear oil is not leaking fr om the rear final drive assembly or around it.

OIL LEVEL

Remove filler plug (1) and check oil level from filler plug mounting

hole as shown in the figure.

CAUTION:

Never start engine while checking oil level.

Set a gasket on filler plug (1) and install it on final drive assembly. Refer to DLN-203, "

Exploded View".

CAUTION:

Never reuse gasket.

DrainingINFOID:0000000006222412

1. Stop the engine.

2. Remove drain plug (1) and drain gear oil.

3. Set a gasket on drain plug (1) and install it to final drive assem- bly and tighten to the specified torque. Refer to DLN-203,

"Exploded View".

CAUTION:

Never reuse gasket.

RefillingINFOID:0000000006222413

1. Remove filler plug (1). Fill with new gear oil until oil level reaches the specified level near filler plug mounting hole.

2. After refilling oil, check oil level. Set a gasket to filler plug (1), then install it to final drive assembly. Refer to DLN-203,

"Exploded View".

CAUTION:

Never reuse gasket.

JPDID0415ZZ

JPDID0392ZZ

Oil grade and viscosity : Refer to MA-10, "Fluids and

Lubricants".

Oil capacity : Refer to DLN-222, "

General

Specification".

JPDID0415ZZ

Revision: 2010 May2011 QX56

Page 2024 of 5598

![INFINITI QX56 2011 Factory Service Manual

DLN-222

< SERVICE DATA AND SPECIFICATIONS (SDS) [REAR FINAL DRIVE: R230]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Spec INFINITI QX56 2011 Factory Service Manual

DLN-222

< SERVICE DATA AND SPECIFICATIONS (SDS) [REAR FINAL DRIVE: R230]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Spec](/img/42/57033/w960_57033-2023.png)

DLN-222

< SERVICE DATA AND SPECIFICATIONS (SDS) [REAR FINAL DRIVE: R230]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000006222430

Drive Gear RunoutINFOID:0000000006222431

Unit: mm (in)

Side Gear ClearanceINFOID:0000000006222432

Unit: mm (in)

Preload TorqueINFOID:0000000006222433

BacklashINFOID:0000000006222434

Unit: mm (in)

Companion Flange RunoutINFOID:0000000006222435

Unit: mm (in)

Applied model 2WD 4WD

VK56VDA/T

Final drive model R230

Gear ratio 2.937

Number of teeth (Drive gear/Drive pinion) 47/16

Oil capacity (Approx.) (US pt, lmp pt)1.75 (3-3/4, 3-1/8)

Number of pinion gears 2

Drive pinion adjustment spacer type Collapsible

Item Runout limit

Drive gear back face 0.05 (0.0020) or less

Item Specification

Side gear back clearance

(Clearance limit between side gear and differential case for adjusting

side gear backlash) 0.20 (0.0079) or less

(Each gear should rotate smoothly without excessive resis-

tance during differential motion.)

Item Specification

Drive pinion bearing preload torque 1.76 − 2.65 N·m (0.18 − 0.27 kg −m, 16 − 23 in-lb)

Side bearing preload torque (reference value determined by drive

gear bolt pulling force) 0.29

− 1.47 N·m (0.03 − 0.14 kg −m, 3 − 13 in-lb)

Total preload torque

(Total preload torque = drive pinion bearing preload torque + Side

bearing preload torque) 2.06

− 4.12 N·m (0.21 − 0.42 kg −m, 19 − 36 in-lb)

Item Specification

Drive gear to drive pinion gear 0.13 − 0.18 (0.0051 − 0.0070)

Item Runout limit

Inner side of the companion flange 0.08 (0.0031) or less

Revision: 2010 May2011 QX56

Page 2665 of 5598

ENGINE STAND SETTINGEM-103

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

UNIT DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

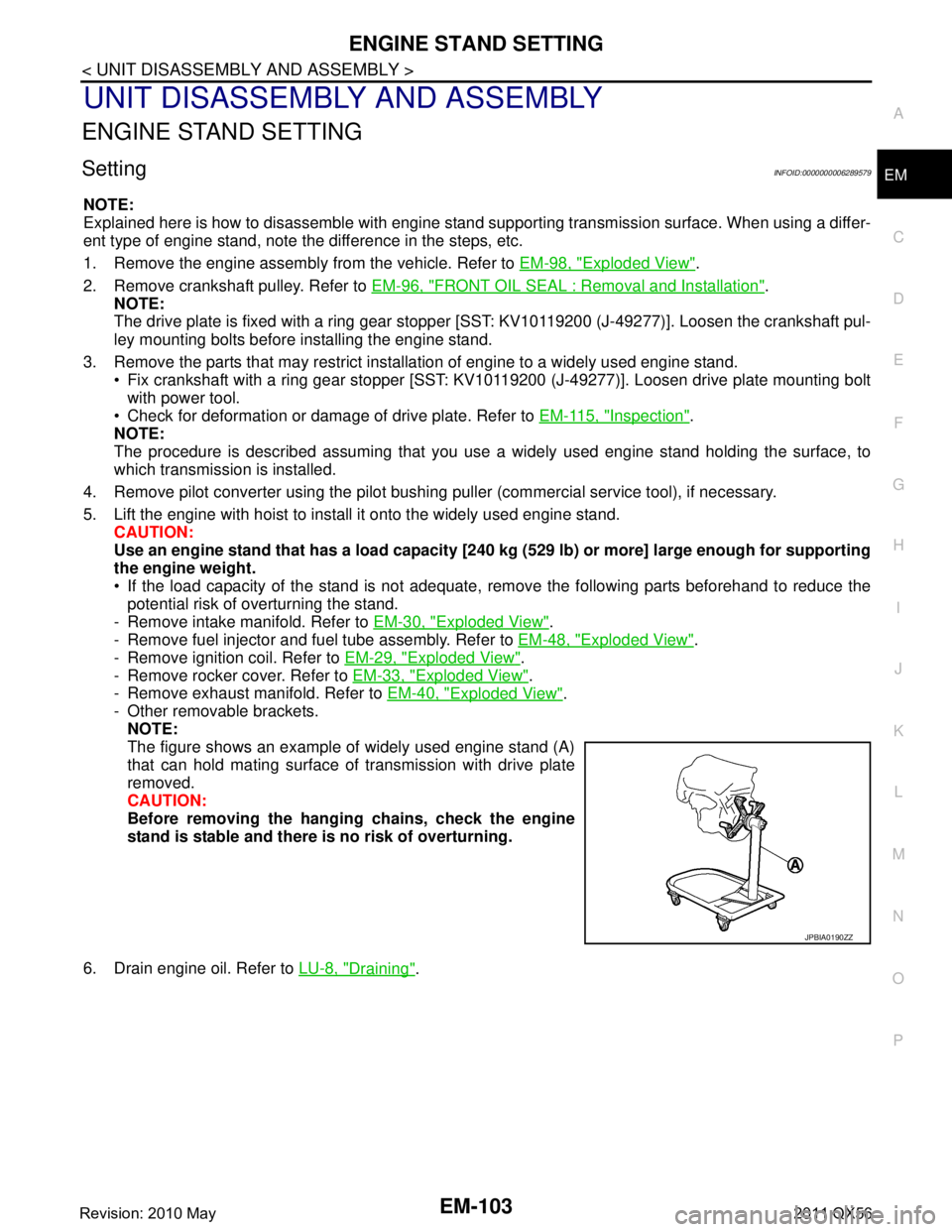

SettingINFOID:0000000006289579

NOTE:

Explained here is how to disassemble with engine stand s

upporting transmission surface. When using a differ-

ent type of engine stand, note the difference in the steps, etc.

1. Remove the engine assembly from the vehicle. Refer to EM-98, "

Exploded View".

2. Remove crankshaft pulley. Refer to EM-96, "

FRONT OIL SEAL : Removal and Installation".

NOTE:

The drive plate is fixed with a ring gear stopper [SST: KV10119200 (J-49277)]. Loosen the crankshaft pul-

ley mounting bolts before installing the engine stand.

3. Remove the parts that may restrict installation of engine to a widely used engine stand. Fix crankshaft with a ring gear stopper [SST: KV10119200 (J-49277)]. Loosen drive plate mounting bolt

with power tool.

Check for deformation or damage of drive plate. Refer to EM-115, "

Inspection".

NOTE:

The procedure is described assuming that you us e a widely used engine stand holding the surface, to

which transmission is installed.

4. Remove pilot converter using the pilot bushing puller (commercial service tool), if necessary.

5. Lift the engine with hoist to inst all it onto the widely used engine stand.

CAUTION:

Use an engine stand that has a load capacity [240 kg (529 lb) or more] large enough for supporting

the engine weight.

If the load capacity of the stand is not adequate, remove the following parts beforehand to reduce the potential risk of overturning the stand.

- Remove intake manifold. Refer to EM-30, "

Exploded View".

- Remove fuel injector and fuel tube assembly. Refer to EM-48, "

Exploded View".

- Remove ignition coil. Refer to EM-29, "

Exploded View".

- Remove rocker cover. Refer to EM-33, "

Exploded View".

- Remove exhaust manifold. Refer to EM-40, "

Exploded View".

- Other removable brackets. NOTE:

The figure shows an example of widely used engine stand (A)

that can hold mating surface of transmission with drive plate

removed.

CAUTION:

Before removing the hang ing chains, check the engine

stand is stable and there is no risk of overturning.

6. Drain engine oil. Refer to LU-8, "

Draining".

JPBIA0190ZZ

Revision: 2010 May2011 QX56

Page 3067 of 5598

PREPARATIONHA-11

< PREPARATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

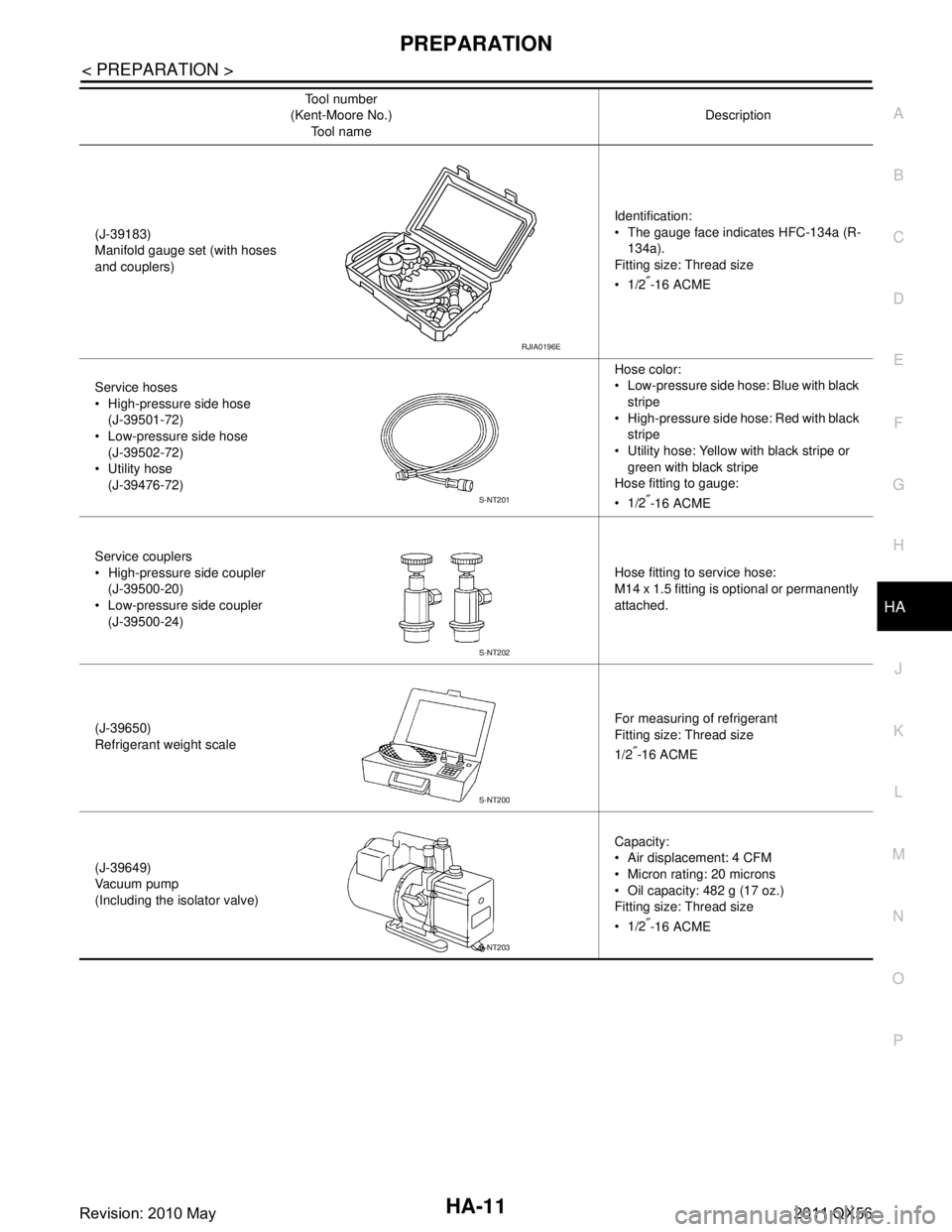

(J-39183)

Manifold gauge set (with hoses

and couplers) Identification:

The gauge face indicates HFC-134a (R-

134a).

Fitting size: Thread size

1/2

″-16 ACME

Service hoses

High-pressure side hose (J-39501-72)

Low-pressure side hose

(J-39502-72)

Utility hose (J-39476-72) Hose color:

Low-pressure side hose: Blue with black

stripe

High-pressure side hose: Red with black stripe

Utility hose: Yellow with black stripe or

green with black stripe

Hose fitting to gauge:

1/2

″-16 ACME

Service couplers

High-pressure side coupler (J-39500-20)

Low-pressure side coupler (J-39500-24) Hose fitting to service hose:

M14 x 1.5 fitting is optional or permanently

attached.

(J-39650)

Refrigerant weight scale For measuring of refrigerant

Fitting size: Thread size

1/2

″-16 ACME

(J-39649)

Va c u u m p u m p

(Including the isolator valve) Capacity:

Air displacement: 4 CFM

Micron rating: 20 microns

Oil capacity: 482 g (17 oz.)

Fitting size: Thread size

1/2

″-16 ACME

Tool number

(Kent-Moore No.)

Tool name Description

RJIA0196E

S-NT201

S-NT202

S-NT200

S-NT203

Revision: 2010 May2011 QX56

Page 3068 of 5598

HA-12

< PREPARATION >

PREPARATION

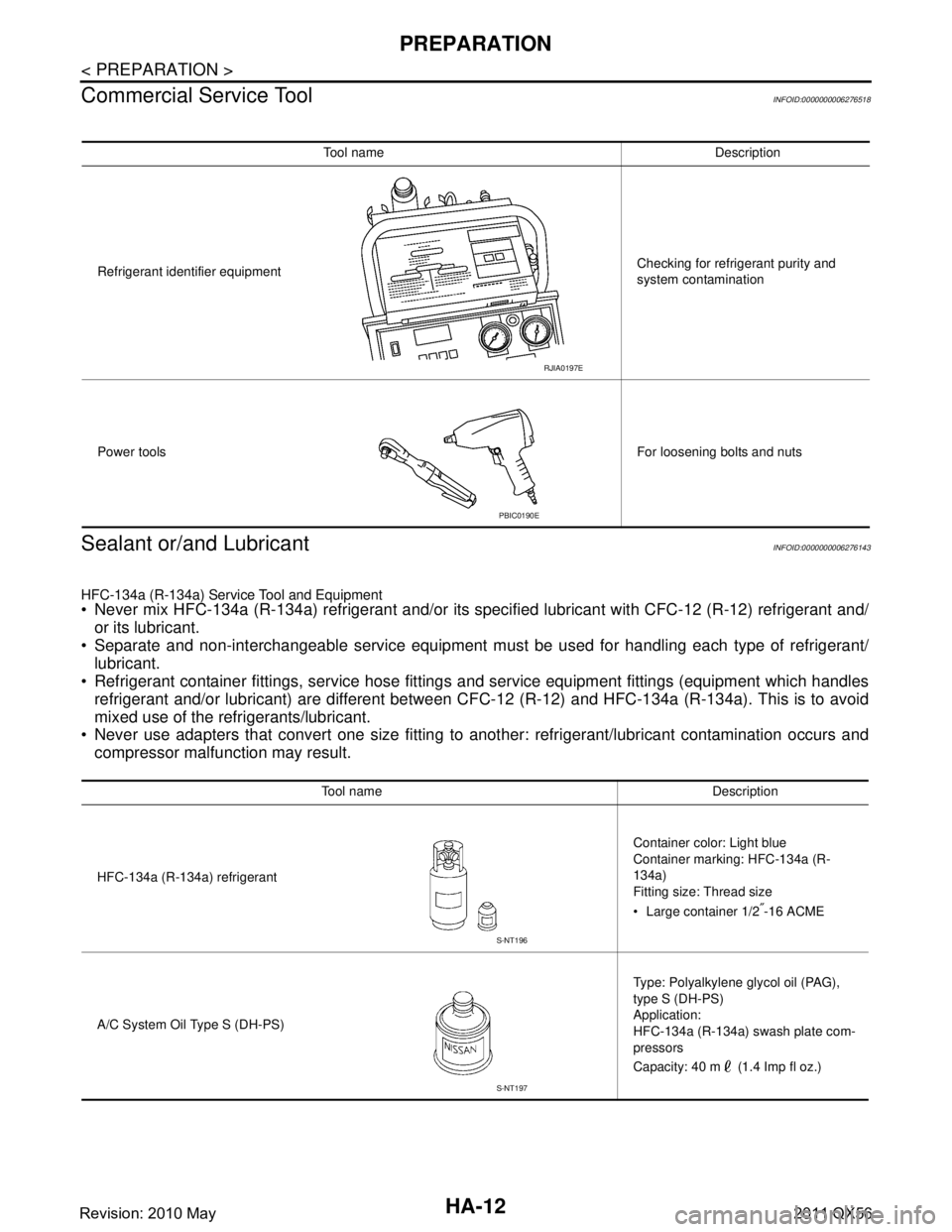

Commercial Service Tool

INFOID:0000000006276518

Sealant or/and LubricantINFOID:0000000006276143

HFC-134a (R-134a) Service Tool and Equipment

Never mix HFC-134a (R-134a) refrigerant and/or its s pecified lubricant with CFC-12 (R-12) refrigerant and/

or its lubricant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/ lubricant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CF C-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Never use adapters that convert one size fitting to another: refrigerant/lubricant contamination occurs and

compressor malfunction may result.

Tool name Description

Refrigerant identifier equipment Checking for refrigerant purity and

system contamination

Power tools For loosening bolts and nuts

RJIA0197E

PBIC0190E

Tool name Description

HFC-134a (R-134a) refrigerant Container color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

Large container 1/2

″-16 ACME

A/C System Oil Type S (DH-PS) Type: Polyalkylene glycol oil (PAG),

type S (DH-PS)

Application:

HFC-134a (R-134a) swash plate com-

pressors

Capacity: 40 m (1.4 Imp fl oz.)

S-NT196

S-NT197

Revision: 2010 May2011 QX56

Page 3106 of 5598

HA-50

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

CompressorINFOID:0000000006276197

LubricantINFOID:0000000006276198

RefrigerantINFOID:0000000006276199

Engine Idling SpeedINFOID:0000000006276200

Refer to EC-538, "Idle Speed".

Belt TensionINFOID:0000000006276201

Refer to EM-20, "TensionAdjustment".

Model VALEO THERMAL SYSTEMS JAPAN make

DSK-17D

Ty p e Fixation displacement swash plate

Displacement

cm

3 (cu in)/rev Maximum 175 (10.7)

Direction of rotation Clockwise (viewed from clutch)

Drive belt Poly V

Disc to pulley clearance

mm (in) Standard 0.3 – 0.6 (0.012 – 0.024)

Name

UV Luminaus Oil Type S (DH-PS)

Capacity

m (Imp fl oz) Total in system 210 (7.1)

Compressor (service part) charging

amount

210 (7.1)

Ty p e

HFC-134a (R-134a)

Capacity

kg (lb) 1.05 (2.32)

Revision: 2010 May2011 QX56

Page 3119 of 5598

![INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSHAC-13

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Rear Blower MotorINFOID:0000000006275858

The rear blower motor utilizes a brush-less motor INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSHAC-13

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Rear Blower MotorINFOID:0000000006275858

The rear blower motor utilizes a brush-less motor](/img/42/57033/w960_57033-3118.png)

COMPONENT PARTSHAC-13

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Rear Blower MotorINFOID:0000000006275858

The rear blower motor utilizes a brush-less motor with a rotating

magnet. Quietness is improved comp aring to a conventional motor

(brush motor) that rotates coil while brush functions as contact

points.

Refrigerant Pressure SensorINFOID:0000000006275859

Description

Refrigerant pressure sensor is installed to upper porti on of liquid tank. The refrigerant pressure sensor con-

verts high-pressure side refrigerant pressure into vo ltage and outputs it to ECM. ECM operates cooling system

protection and idle speed control according to voltage value that is input.

Structure and operation

The refrigerant pressure sensor is a capacitance type sensor. It consists of a pressure detection area and a

signal processing area. The pressure detection area, wh ich is a variable capacity condenser, changes internal

static capacitance according to pressure force. The signal processing area detects the static capacitance of

the pressure detection area, converts the static capacitance into a voltage value, and transmits the voltage

value to ECM.

RJIA2467J

ZHA152H

PBIB2657E

Revision: 2010 May2011 QX56