ground INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2027 of 5598

EC-3

C

DE

F

G H

I

J

K L

M

EC A

N

O P

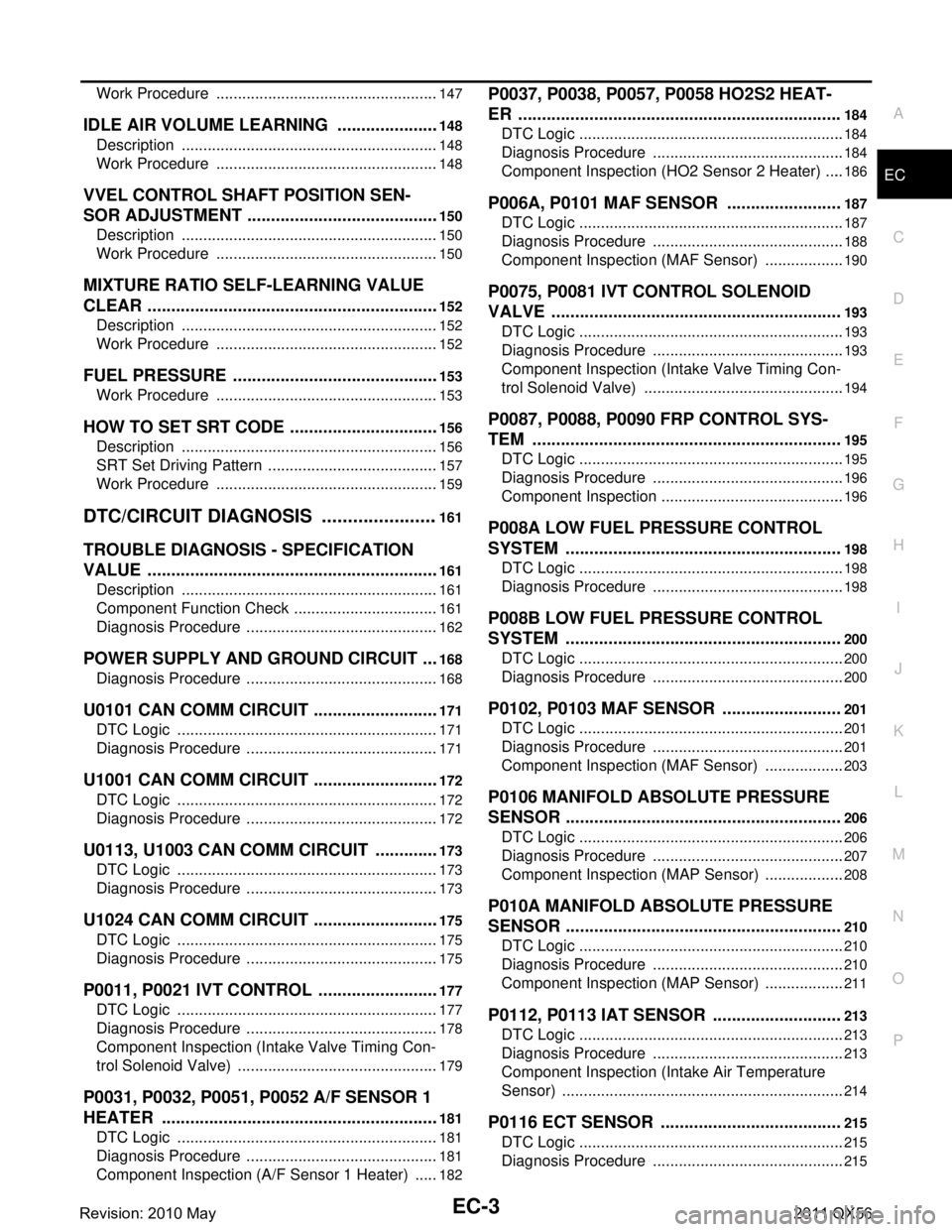

Work Procedure ..................................................

..

147

IDLE AIR VOLUME LEARNING ......................148

Description .......................................................... ..148

Work Procedure ....................................................148

VVEL CONTROL SHAFT POSITION SEN-

SOR ADJUSTMENT .........................................

150

Description .......................................................... ..150

Work Procedure ....................................................150

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ..............................................................

152

Description .......................................................... ..152

Work Procedure ....................................................152

FUEL PRESSURE .......................................... ..153

Work Procedure .................................................. ..153

HOW TO SET SRT CODE ................................156

Description .......................................................... ..156

SRT Set Driving Pattern ........................................157

Work Procedure ....................................................159

DTC/CIRCUIT DIAGNOSIS .......................161

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE ............................................................ ..

161

Description .......................................................... ..161

Component Function Check ..................................161

Diagnosis Procedure .............................................162

POWER SUPPLY AND GROUND CIRCUIT ....168

Diagnosis Procedure ........................................... ..168

U0101 CAN COMM CIRCUIT ...........................171

DTC Logic ........................................................... ..171

Diagnosis Procedure .............................................171

U1001 CAN COMM CIRCUIT ...........................172

DTC Logic ........................................................... ..172

Diagnosis Procedure .............................................172

U0113, U1003 CAN COMM CIRCUIT ..............173

DTC Logic ........................................................... ..173

Diagnosis Procedure .............................................173

U1024 CAN COMM CIRCUIT ...........................175

DTC Logic ........................................................... ..175

Diagnosis Procedure .............................................175

P0011, P0021 IVT CONTROL ..........................177

DTC Logic ........................................................... ..177

Diagnosis Procedure .............................................178

Component Inspection (Intake Valve Timing Con-

trol Solenoid Valve) ...............................................

179

P0031, P0032, P0051, P0052 A/F SENSOR 1

HEATER ...........................................................

181

DTC Logic ........................................................... ..181

Diagnosis Procedure .............................................181

Component Inspection (A/F Sensor 1 Heater) ......182

P0037, P0038, P0057, P0058 HO2S2 HEAT-

ER ....................................................................

184

DTC Logic ............................................................ ..184

Diagnosis Procedure .............................................184

Component Inspection (HO2 Sensor 2 Heater) .....186

P006A, P0101 MAF SENSOR ........................187

DTC Logic ..............................................................187

Diagnosis Procedure .............................................188

Component Inspection (MAF Sensor) ...................190

P0075, P0081 IVT CONTROL SOLENOID

VALVE .............................................................

193

DTC Logic ..............................................................193

Diagnosis Procedure .............................................193

Component Inspection (Intake Valve Timing Con-

trol Solenoid Valve) ...............................................

194

P0087, P0088, P0090 FRP CONTROL SYS-

TEM .................................................................

195

DTC Logic ..............................................................195

Diagnosis Procedure .............................................196

Component Inspection ...........................................196

P008A LOW FUEL PRESSURE CONTROL

SYSTEM ..........................................................

198

DTC Logic ............................................................ ..198

Diagnosis Procedure .............................................198

P008B LOW FUEL PRESSURE CONTROL

SYSTEM ..........................................................

200

DTC Logic ............................................................ ..200

Diagnosis Procedure .............................................200

P0102, P0103 MAF SENSOR .........................201

DTC Logic ..............................................................201

Diagnosis Procedure .............................................201

Component Inspection (MAF Sensor) ...................203

P0106 MANIFOLD ABSOLUTE PRESSURE

SENSOR ..........................................................

206

DTC Logic ..............................................................206

Diagnosis Procedure .............................................207

Component Inspection (MAP Sensor) ...................208

P010A MANIFOLD ABSOLUTE PRESSURE

SENSOR ..........................................................

210

DTC Logic ..............................................................210

Diagnosis Procedure .............................................210

Component Inspection (MAP Sensor) ...................211

P0112, P0113 IAT SENSOR ...........................213

DTC Logic ..............................................................213

Diagnosis Procedure .............................................213

Component Inspection (Intake Air Temperature

Sensor) ..................................................................

214

P0116 ECT SENSOR ......................................215

DTC Logic ..............................................................215

Diagnosis Procedure .............................................215

Revision: 2010 May2011 QX56

Page 2034 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-10

< PRECAUTION >[VK56VD]

PRECAUTIONS

CAUTION:

Comply with the following cautions to

prevent any error and malfunction.

Install the xenon bulb securely. (Ins ufficient bulb socket installation INFINITI QX56 2011 Factory Service Manual

EC-10

< PRECAUTION >[VK56VD]

PRECAUTIONS

CAUTION:

Comply with the following cautions to

prevent any error and malfunction.

Install the xenon bulb securely. (Ins ufficient bulb socket installation](/img/42/57033/w960_57033-2033.png)

EC-10

< PRECAUTION >[VK56VD]

PRECAUTIONS

CAUTION:

Comply with the following cautions to

prevent any error and malfunction.

Install the xenon bulb securely. (Ins ufficient bulb socket installation may melt the bulb, the connec-

tor, the housing, etc. by high-v oltage leakage or corona discharge.)

Never perform HID circuit in spection with a tester.

Never touch the xenon bulb glass with ha nds. Never put oil and grease on it.

Dispose of the used xenon bulb after packing it in thick vinyl without breaking it.

Never wipe out dirt and cont amination with organic solven t (thinner, gasoline, etc.).

On Board Diagnostic (OBD) System of Engine and A/TINFOID:0000000006217652

The ECM has an on board diagnostic system. It will illuminate the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Always turn the ignition switch OFF and disconnect the negative battery cable before any repair or

inspection work. The open/short circuit of related sw itches, sensors, solenoid valves, etc. will cause

the MIL to illuminate.

Always connect and lock the conn ectors securely after work. A loose (unlocked) connector will

cause the MIL to illuminate due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For descripti on and how to disconnect, refer to EC-51, "

Diagnosis

Description".

Always route and secure the harnesses properly afte r work. The interference of the harness with a

bracket, etc. may cause the MIL to illu minate due to the short circuit.

Always connect rubber tubes properly after work. A misconnected or disconnected rubber tube may

cause the MIL to illuminate due to the malfunction of the EVAP system or fuel injection system, etc.

Always erase the unnecessary malfunction information (repairs completed) from the ECM and TCM

(Transmission control module) before re turning the vehicle to the customer.

General PrecautionsINFOID:0000000006217653

Always use a 12 volt battery as power source.

Never attempt to disconnect battery cables while engine is

running.

Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

Before removing parts, turn ig nition switch OFF and then dis-

connect battery ground cable.

Never disassemble ECM.

If a battery cable is disconnected, the memory will return to

the ECM value.

The ECM will now start to self-control at its initial value. Thus,

engine operation can vary slight ly in this case. However, this

is not an indication of a ma lfunction. Never replace parts

because of a slight variation.

If the battery is disconnected, the following emission-related

diagnostic information will be lost within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

SEF289H

JMBIA0057ZZ

Revision: 2010 May2011 QX56

Page 2037 of 5598

![INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSEC-13

< PRECAUTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

con INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSEC-13

< PRECAUTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

con](/img/42/57033/w960_57033-2036.png)

PRECAUTIONSEC-13

< PRECAUTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possi ble from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Never let them run parallel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

ratio can be kept smaller.

- Be sure to ground the radio to vehicle body.

SEF708Y

Revision: 2010 May2011 QX56

Page 2058 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-34

< SYSTEM DESCRIPTION >[VK56VD]

STRUCTURE AND OPERATION

On Board Refueling V apor Recovery (ORVR)

INFOID:0000000006217696

From the beginning of refueling, the air and vapor insi de the fuel tank INFINITI QX56 2011 Factory Service Manual

EC-34

< SYSTEM DESCRIPTION >[VK56VD]

STRUCTURE AND OPERATION

On Board Refueling V apor Recovery (ORVR)

INFOID:0000000006217696

From the beginning of refueling, the air and vapor insi de the fuel tank](/img/42/57033/w960_57033-2057.png)

EC-34

< SYSTEM DESCRIPTION >[VK56VD]

STRUCTURE AND OPERATION

On Board Refueling V apor Recovery (ORVR)

INFOID:0000000006217696

From the beginning of refueling, the air and vapor insi de the fuel tank go through refueling EVAP vapor cut

valve and EVAP/ORVR line to the EVAP canister. The vapor is absorbed by the EVAP canister and the air is

released to the atmosphere.

When the refueling has reached the full level of the fuel tank, the refueling EVAP vapor cut valve is closed and

refueling is stopped because of auto shut-off. The vapor which was absorbed by the EVAP canister is purged

during driving.

WARNING:

When conducting inspections below, be sure to observe the following:

Put a “CAUTION: FLAMMABLE” sign in workshop.

Never smoke while servicing fuel system. Keep open flames and sparks away from work area.

Always furnish the workshop with a CO

2 fire extinguisher.

CAUTION:

Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-pr oof container and put lid on securely.

- Release fuel pressure from fuel line. Refer to EC-153, "

Work Procedure".

- Disconnect battery ground cable.

Always replace O-ring when the fuel gauge retainer is removed.

Never kink or twist hose and tube when they are installed.

Never tighten hose and clamps excessively to avoid damaging hoses.

After installation, run engine an d check for fuel leaks at connections.

Never attempt to top off the fuel tank after the fuel pump nozzle shuts off automatically.

Continued refueling may cause fu el overflow, resulting in fuel spray and possibly a fire.

PBIB1068E

Revision: 2010 May2011 QX56

Page 2102 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-78

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

1

(R)

2

(R) 175

(B) Fuel injector No. 8 (HI) INFINITI QX56 2011 Factory Service Manual

EC-78

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

1

(R)

2

(R) 175

(B) Fuel injector No. 8 (HI)](/img/42/57033/w960_57033-2101.png)

EC-78

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

1

(R)

2

(R) 175

(B) Fuel injector No. 8 (HI)

Fuel injector No. 5 (HI)

Output[Engine is running]

Warm-up condition

Idle speed

NOTE:

The pulse cycle changes depending

on rpm at idle BATTERY VOLTAGE

(11 - 14 V)

[Engine is running]

Warm-up condition

Engine speed: 2,000 rpm BATTERY VOLTAGE

(11 - 14 V)

3

(G)

4

(G) 175

(B) Fuel injector No. 3 (LO)

Fuel injector No. 2 (LO)

Input[Engine is running]

Warm-up condition

Idle speed

NOTE:

The pulse cycle changes depending

on rpm at idle BATTERY VOLTAGE

(11 - 14 V)

[Engine is running]

Warm-up condition

Engine speed: 2,000 rpm BATTERY VOLTAGE

(11 - 14 V)

5

(B/R) — ECM ground — — —

JPBIA3345ZZ

JPBIA3347ZZ

JPBIA3355ZZ

JPBIA3356ZZ

Revision: 2010 May2011 QX56

Page 2103 of 5598

![INFINITI QX56 2011 Factory Service Manual

ECM

EC-79

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6

(R) 7

(R) 175

(B) Fuel injector No. 3 (HI)

Fuel injector No. 2 (HI)

Output[Engine is running]

Warm-up condition

INFINITI QX56 2011 Factory Service Manual

ECM

EC-79

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6

(R) 7

(R) 175

(B) Fuel injector No. 3 (HI)

Fuel injector No. 2 (HI)

Output[Engine is running]

Warm-up condition

](/img/42/57033/w960_57033-2102.png)

ECM

EC-79

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6

(R) 7

(R) 175

(B) Fuel injector No. 3 (HI)

Fuel injector No. 2 (HI)

Output[Engine is running]

Warm-up condition

Idle speed

NOTE:

The pulse cycle changes depending

on rpm at idle BATTERY VOLTAGE

(11 - 14 V)

[Engine is running]

Warm-up condition

Engine speed: 2,000 rpm BATTERY VOLTAGE

(11 - 14 V)

8

(G) 9

(G) 175

(B) Fuel injector No. 8 (LO)

Fuel injector No. 5 (LO)

Input[Engine is running]

Warm-up condition

Idle speed

NOTE:

The pulse cycle changes depending

on rpm at idle BATTERY VOLTAGE

(11 - 14 V)

[Engine is running]

Warm-up condition

Engine speed: 2,000 rpm BATTERY VOLTAGE

(11 - 14 V)

10

(B) — ECM ground — — —

11

(BR) 175

(B) PNP switch Input [Ignition switch: ON]

Selector lever: P or N position

BATTERY VOLTAGE

(11 - 14 V)

[Ignition switch: ON]

Selector lever: Except above posi- tion 0 V

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

OutputJPBIA3345ZZ

JPBIA3347ZZ

JPBIA3355ZZ

JPBIA3356ZZ

Revision: 2010 May2011 QX56

Page 2105 of 5598

![INFINITI QX56 2011 Factory Service Manual

ECM

EC-81

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

23

(V) 45

(L/O) Low fuel pressure sensor Input [Engine is running]

Warm-up condition

Idle speed

2.4 - 3.6 V

[Engin INFINITI QX56 2011 Factory Service Manual

ECM

EC-81

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

23

(V) 45

(L/O) Low fuel pressure sensor Input [Engine is running]

Warm-up condition

Idle speed

2.4 - 3.6 V

[Engin](/img/42/57033/w960_57033-2104.png)

ECM

EC-81

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

23

(V) 45

(L/O) Low fuel pressure sensor Input [Engine is running]

Warm-up condition

Idle speed

2.4 - 3.6 V

[Engine is running]

Warm-up condition

Engine speed: 2,000 rpm 2.4 - 3.6 V

25

(LG) —Sensor ground

[Mass air flow sensor/ Intake air

temperature sensor] —— —

27

(P) 45

(L/O) Sensor power supply

(Power steering pressure sen-

sor/ Low fuel pressure sensor/

Electrically-controlled cooling

fan coupling)

— [Ignition switch: ON] 5 V

28

(SB) 40

(W/L) Sensor power supply

(Fuel rail pressure sensor/En-

gine oil pressure sensor)

— [Ignition switch: ON] 5 V

29

(W) 35

(—) Knock sensor (bank 1) Input [Engine is running]

Idle speed

2.0 V*

1

31

(V/W) 40

(W/L) Fuel rail pressure sensor Input [Engine is running]

Warm-up condition

Idle speed

0.98 - 1.2 V

[Engine is running]

Warm-up condition

Revving engine from idle to 4,000 rpm quickly 1.1 - 2.9 V

32

(R) 40

(W/L) Engine coolant temperature

sensor

Input [Engine is running] 0 - 4.8 V

Output voltage varies with engine

coolant temperature.

33

(W) 35

(—) Knock sensor (bank 2) Input [Engine is running]

Idle speed

2.0 V*

1

35

(—) —Sensor ground

(Knock sensor)

—— —

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

JPBIA3357ZZ

JPBIA3358ZZ

Revision: 2010 May2011 QX56

Page 2106 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-82

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

37

(V) 175

(B) Cooling fan speed Input [Ignition switch: ON]

Engine stopped

5 V

[Engine is running]

Idle speed

After warm-up condition BATTERY VO INFINITI QX56 2011 Factory Service Manual

EC-82

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

37

(V) 175

(B) Cooling fan speed Input [Ignition switch: ON]

Engine stopped

5 V

[Engine is running]

Idle speed

After warm-up condition BATTERY VO](/img/42/57033/w960_57033-2105.png)

EC-82

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

37

(V) 175

(B) Cooling fan speed Input [Ignition switch: ON]

Engine stopped

5 V

[Engine is running]

Idle speed

After warm-up condition BATTERY VOLTAGE

(11 - 14 V)

[Engine is running]

Idle speed

Before warm-up condition BATTERY VOLTAGE

(11 - 14 V)

39

(P/B) 45

(L/O) Power steering pressure sensor Input [Engine is running]

Steering wheel: Being turned

0.5 - 4.5 V

[Engine is running]

Steering wheel: Not being turned 0.4 - 0.8 V

40

(W/L) —Sensor ground

(Fuel rail pressure sensor/En-

gine coolant temperature sen-

sor/Engine oil temperature

sensor) —— —

42

(L/Y) 40

(W/L) Engine oil temperature sensor Input [Engine is running] 0 - 4.8 V

Output voltage varies with engine

oil temperature.

45

(L/O) —Sensor ground

(Power steering pressure sen-

sor/ Low fuel pressure sensor/

Electrically-controlled cooling

fan coupling) —— —

46

(SB) 175

(B) Fuel injector driver power supply Input [Ignition switch: ON]

BATTERY VOLTAGE

(11 - 14 V)

[Ignition switch: OFF] 1.5 V

47

(G) 175

(B) Heated oxygen sensor 2 heater

(bank 1)

Input[Engine is running]

Engine speed: Below 3,600 rpm af-

ter the following conditions are met

- Engine: after warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute

and at idle for 1 minute under no

load 10 V

[Ignition switch: ON]

Engine: Stopped

[Engine is running]

Engine speed: Above 3,600 rpm BATTERY VOLTAGE

(11 - 14 V)

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

JPBIA3332ZZ

JPBIA3733ZZ

JMBIA0037GB

Revision: 2010 May2011 QX56

Page 2109 of 5598

![INFINITI QX56 2011 Factory Service Manual

ECM

EC-85

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

64

(V/W) 175

(B) EVAP canister purge volume

control solenoid valve

Output[Engine is running]

Idle speed

Accelerat INFINITI QX56 2011 Factory Service Manual

ECM

EC-85

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

64

(V/W) 175

(B) EVAP canister purge volume

control solenoid valve

Output[Engine is running]

Idle speed

Accelerat](/img/42/57033/w960_57033-2108.png)

ECM

EC-85

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

64

(V/W) 175

(B) EVAP canister purge volume

control solenoid valve

Output[Engine is running]

Idle speed

Accelerator pedal: Not depressed

even slightly, after engine starting BATTERY VOLTAGE

(11 - 14 V)

[Engine is running]

Engine speed: About 2,000 rpm (More than 100 seconds after start-

ing engine) BATTERY VOLTAGE

(11 - 14 V)

67

(V) 175

(B) Manifold absolute pressure sen-

sor

Input[Engine is running]

Warm-up condition

Idle speed

1.2 V

[Engine is running]

Warm-up condition

Engine speed: 2,000 rpm 1.5 V

68

(BR/

W) —

Sensor ground

[Camshaft position sensor (bank

1)] —— —

70

(W/L) —Sensor ground

(Manifold absolute pressure

sensor)

—— —

73

(P) 99

(LG/ B) Camshaft position sensor (bank

2)

Input[Engine is running]

Warm-up condition

Idle speed

NOTE:

The pulse cycle changes depending

on rpm at idle 3.0 - 5.0 V

[Engine is running]

Engine speed: 2,000 rpm 3.0 - 5.0 V

74

(L) 175

(B) A/F sensor 1 (bank 2) Input [Ignition switch: ON] 2.5 V

76

(W/

G) 98

(G/

W) Sensor power supply

(Crankshaft position sensor)

— [Ignition switch: ON] 5 V

77

(Y/R) 68

(BR/ W) Sensor power supply

[Camshaft position sensor (bank

1)]

— [Ignition switch: ON] 5 V

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

OutputJMBIA0039GB

JMBIA0040GB

JMBIA0045GB

JMBIA0046GB

Revision: 2010 May2011 QX56

Page 2111 of 5598

![INFINITI QX56 2011 Factory Service Manual

ECM

EC-87

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

91

(R) 97

(W) Throttle position sensor 1 Input [Ignition switch: ON]

Engine: Stopped

Selector lever: D position

INFINITI QX56 2011 Factory Service Manual

ECM

EC-87

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

91

(R) 97

(W) Throttle position sensor 1 Input [Ignition switch: ON]

Engine: Stopped

Selector lever: D position

](/img/42/57033/w960_57033-2110.png)

ECM

EC-87

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

91

(R) 97

(W) Throttle position sensor 1 Input [Ignition switch: ON]

Engine: Stopped

Selector lever: D position

Accelerator pedal: Fully released

More than 0.36 V

[Ignition switch: ON]

Engine: Stopped

Selector lever: D position

Accelerator pedal: Fully depressed Less than 4.75 V

94

(R) 175

(B) A/F sensor 1 (bank 1) Input [Ignition switch: ON] 2.0 V

95

(L/R) 68

(BR/

W) Camshaft position sensor (bank

1)

Input[Engine is running]

Warm-up condition

Idle speed

NOTE:

The pulse cycle changes depending

on rpm at idle 3.0 - 5.0 V

[Engine is running]

Engine speed: 2,000 rpm 3.0 - 5.0 V

96

(W/ R) 100

(R) Heated oxygen sensor 2 (bank

1)

Input[Engine is running]

Revving engine from idle to 3,000

rpm quickly after the following condi-

tions are met

- Engine: after warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute

and at idle for 1 minute under no

load 0 - 1.0 V

97

(W) —Sensor ground

[Throttle position sensor (bank

1)] —— —

98

(G/ W) —

Sensor ground

(Crankshaft position sensor)

—— —

99

(LG/ B) —Sensor ground

[Camshaft position sensor (bank

2)] —— —

100 (R) —Sensor ground

(Heated oxygen sensor 2) —— —

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

JMBIA0045GB

JMBIA0046GB

Revision: 2010 May2011 QX56