display INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3244 of 5598

![INFINITI QX56 2011 Factory Service Manual

HAC-138

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

INSUFFICIENT COOLING

INSUFFICIENT COOLING

FRONT AIR CONDITIONER

FRONT AIR CONDITIONER : DescriptionINFOID:0000000006275984

Symptom Insuffici INFINITI QX56 2011 Factory Service Manual

HAC-138

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

INSUFFICIENT COOLING

INSUFFICIENT COOLING

FRONT AIR CONDITIONER

FRONT AIR CONDITIONER : DescriptionINFOID:0000000006275984

Symptom Insuffici](/img/42/57033/w960_57033-3243.png)

HAC-138

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

INSUFFICIENT COOLING

INSUFFICIENT COOLING

FRONT AIR CONDITIONER

FRONT AIR CONDITIONER : DescriptionINFOID:0000000006275984

Symptom Insufficient cooling

No cool air comes out. (Air flow volume is normal.)

FRONT AIR CONDITIONER

: Diagnosis ProcedureINFOID:0000000006275985

NOTE:

Perform self-diagnoses with CONSULT-III before perform ing symptom diagnosis. If any DTC is detected, per-

form the corresponding diagnosis.

1.CHECK MAGNET CLUTCH OPERATION

1. Turn ignition switch ON.

2. Operate fan switch.

3. Press A/C switch.

4. Check that A/C indicator turns ON. Check visually and by sound that compressor operates.

5. Press A/C switch again.

6. Check that A/C indicator turns OFF. Check that compressor stops.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Perform diagnosis of “COMPRESSOR DOSE NOT OPERATE” in “SYMPTOM DIAGNOSIS”.

Refer to HAC-142, "

Diagnosis Procedure".

2.CHECK DRIVE BELT

Check tension of drive belt. Refer to EM-20, "

Checking".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Adjust or replace drive belt depending on the inspection results.

3.CHECK REFRIGERANT CYCLE

Connect recovery/recycling recharging equipment to the vehicle and perform pressure inspection with gauge.

Refer to HA-27, "

Symptom Table".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace parts depending on the inspection results.

4.CHECK AIR LEAKAGE FROM EACH DUCT

Check duct and nozzle, etc. of the fr ont air conditioning system for leakage.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace parts depending on the inspection results.

5.CHECK AMBIENT TEMPERATURE DISPLAY

Check that there is not much diference between act ual ambient temperature and indicated temperature on

information display in combination meter.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Perform diagnosis for the A/C auto amp. connection recognition signal circuit. Refer to MWI-74,

"DiagnosisProcedure".

6.CHECK SETTING OF TEMPERATURE SETTING TRIMMER (FRONT)

1. Check setting value of temperature setting trimmer (front). Refer to HAC-68, "

FRONT AUTOMATIC AIR

CONDITIONING SYSTEM : Temperature Setting Trimmer (Front)".

2. Check that temperature setting trimme r (front) is set to “+ direction”.

Revision: 2010 May2011 QX56

Page 3278 of 5598

SYSTEMINL-11

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

AUTO LIGHT ADJUSTMENT SYSTEM : System DiagramINFOID:0000000006216056

AUTO LIGHT ADJUSTMENT SYSTEM : System DescriptionINFOID:0000000006216057

OUTLINE

Auto light adjustment system is controlled by each f unction of BCM, combination meter and AV control unit

Control by BCM Auto light system

Auto light adjustment system

AUTO LIGHT ADJUSTMENT SYSTEM

Description

BCM supplies voltage to the optical sensor when the ignition switch is turned ON or ACC.

Optical sensor converts outside brightness (lux) to voltage and transmits the optical sensor signal to BCM.

BCM judges dimming/brightening of combination meter and display according to brightness outside the vehi- cle, when ignition switch is ON.

BCM transmits dimmer signal to combination meter via CAN communication, according to auto light adjust- ment conditions. Dimmer signal is also transmitted to AV control unit.

NOTE:

As to dimming/brightening timing, the sensitivity depends on settings. The settings can be changed with CON-

SULT-III. Refer to EXL-23, "

HEADLAMP : CONSULT-III F unction (BCM - HEAD LAMP)".

Auto Light Adjustment Timing Table

When the ignition switch is ON, the illumination of co mbination meter and display switches dimming/brighten-

ing in the following condition.

BCM switches the illumination of combination me ter and display to dimming when outside brightening

obtained from the optical sensor signal is 1250 lx or le ss for 3 seconds or more. And BCM switches the illumi-

nation of combination meter and display to brightening when outside brightening from the optical sensor signal

is 2500 lx or more for 5 seconds or more.

JMLIA0967GB

Combination meter and display Dimming/brightening timing

Dimming Outside brightness is 1250 lx or less for 3 seconds or more.

Brightening Outside brightness is 2500 lx or more for 5 seconds or more.

Revision: 2010 May2011 QX56

Page 3279 of 5598

INL-12

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000006368143

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate ea ch device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 3404 of 5598

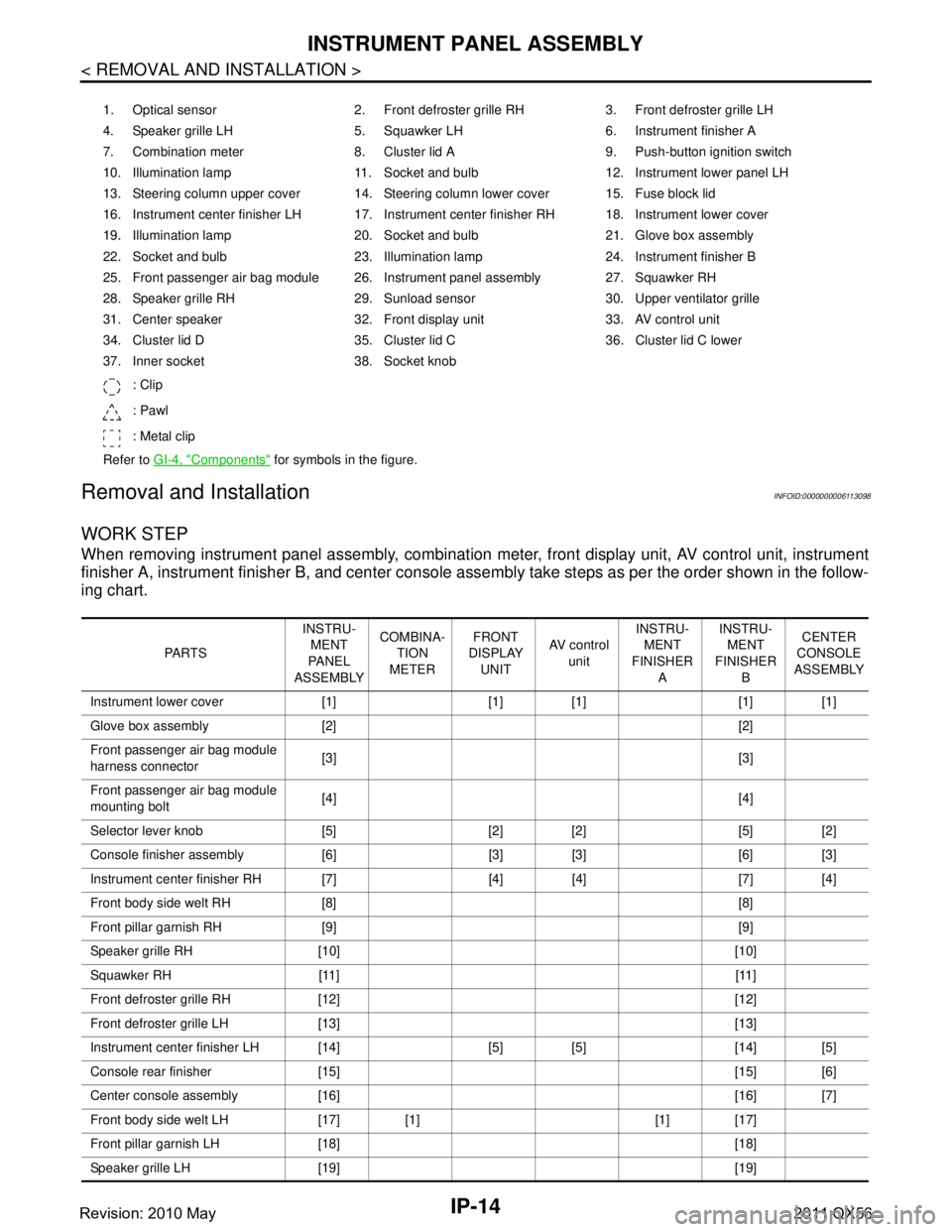

IP-14

< REMOVAL AND INSTALLATION >

INSTRUMENT PANEL ASSEMBLY

Removal and Installation

INFOID:0000000006113098

WORK STEP

When removing instrument panel assembly, combination meter, front display unit, AV control unit, instrument

finisher A, instrument fini sher B, and center console assembly take st eps as per the order shown in the follow-

ing chart.

1. Optical sensor 2. Front defroster grille RH 3. Front defroster grille LH

4. Speaker grille LH 5. Squawker LH 6. Instrument finisher A

7. Combination meter 8. Cluster lid A 9. Push-button ignition switch

10. Illumination lamp 11. Socket and bulb 12. Instrument lower panel LH

13. Steering column upper cover 14. Steering column lower cover 15. Fuse block lid

16. Instrument center finisher LH 17. Instrument center finisher RH 18. Instrument lower cover

19. Illumination lamp 20. Socket and bulb 21. Glove box assembly

22. Socket and bulb 23. Illumination lamp 24. Instrument finisher B

25. Front passenger air bag module 26. Instrument panel assembly 27. Squawker RH

28. Speaker grille RH 29. Sunload sensor 30. Upper ventilator grille

31. Center speaker 32. Front display unit 33. AV control unit

34. Cluster lid D 35. Cluster lid C 36. Cluster lid C lower

37. Inner socket 38. Socket knob

: Clip

: Pawl

: Metal clip

Refer to GI-4, "

Components" for symbols in the figure.

PA R T S INSTRU-

MENT

PA N E L

ASSEMBLY COMBINA-

TION

METER FRONT

DISPLAY

UNIT AV c o n t r o l

unit INSTRU-

MENT

FINISHER A INSTRU-

MENT

FINISHER B CENTER

CONSOLE

ASSEMBLY

Instrument lower cover [1] [1] [1] [1] [1]

Glove box assembly [2] [2]

Front passenger air bag module

harness connector [3] [3]

Front passenger air bag module

mounting bolt [4] [4]

Selector lever knob [5] [2] [2] [5] [2]

Console finisher assembly [6] [3] [3] [6] [3]

Instrument center finisher RH [7] [4] [4] [7] [4]

Front body side welt RH [8] [8]

Front pillar garnish RH [9] [9]

Speaker grille RH [10] [10]

Squawker RH [11] [11]

Front defroster grille RH [12] [12]

Front defroster grille LH [13] [13]

Instrument center finisher LH [14] [5] [5] [14] [5]

Console rear finisher [15] [15] [6]

Center console assembly [16] [16] [7]

Front body side welt LH [17] [1] [1] [17]

Front pillar garnish LH [18] [18]

Speaker grille LH [19] [19]

Revision: 2010 May2011 QX56

Page 3405 of 5598

![INFINITI QX56 2011 Factory Service Manual

INSTRUMENT PANEL ASSEMBLYIP-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

[ ]:Number indicates step in removal procedures.

WARNING:

Before servicing, turn igni tion switch OFF, disc INFINITI QX56 2011 Factory Service Manual

INSTRUMENT PANEL ASSEMBLYIP-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

[ ]:Number indicates step in removal procedures.

WARNING:

Before servicing, turn igni tion switch OFF, disc](/img/42/57033/w960_57033-3404.png)

INSTRUMENT PANEL ASSEMBLYIP-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

[ ]:Number indicates step in removal procedures.

WARNING:

Before servicing, turn igni tion switch OFF, disconnect battery ne gative terminal, and wait 3 minutes or

more.

CAUTION:

When removing, always use a remover tool that is made of plastic.

REMOVAL

1. Remove instrument lower cover.

1. Pull disengaged pawls downward.

2. Pull back instrument lower cover.

3. Disconnect harness connectors.

Squawker LH [20] [20]

Instrument lower panel LH [21] [2] [2] [21]

Disconnect meter control switch

harness connector [22] [3] [3] [22]

Driver air bag module [23] [23]

Steering wheel [24] [24]

Steering column cover [25] [25]

Combination switch [26] [26]

Spiral cable [27] [27]

Cluster lid A [28] [4] [4] [28]

Combination meter [29] [5] [29]

Instrument finisher A [5]

Upper ventilator grille [30] [30]

Center speaker [31] [31]

Cluster lid C [32] [6] [6] [32]

Cluster lid C lower [33] [7] [33]

AV control unit [34] [8] [34]

Cluster lid D [35] [7] [35]

Front display unit [36] [8] [36]

instrument panel assembly

mounting screws and bolts [37] [37]

Squawker LH harness clip [38] [38]

Instrument panel assembly [39] [39]

Instrument finisher B [40]

PA R T S

INSTRU-

MENT

PA N E L

ASSEMBLY COMBINA-

TION

METER FRONT

DISPLAY UNIT AV c o n t r o l

unit INSTRU-

MENT

FINISHER A INSTRU-

MENT

FINISHER B CENTER

CONSOLE

ASSEMBLY

: Pawl

JMJIA3828ZZ

Revision: 2010 May2011 QX56

Page 3411 of 5598

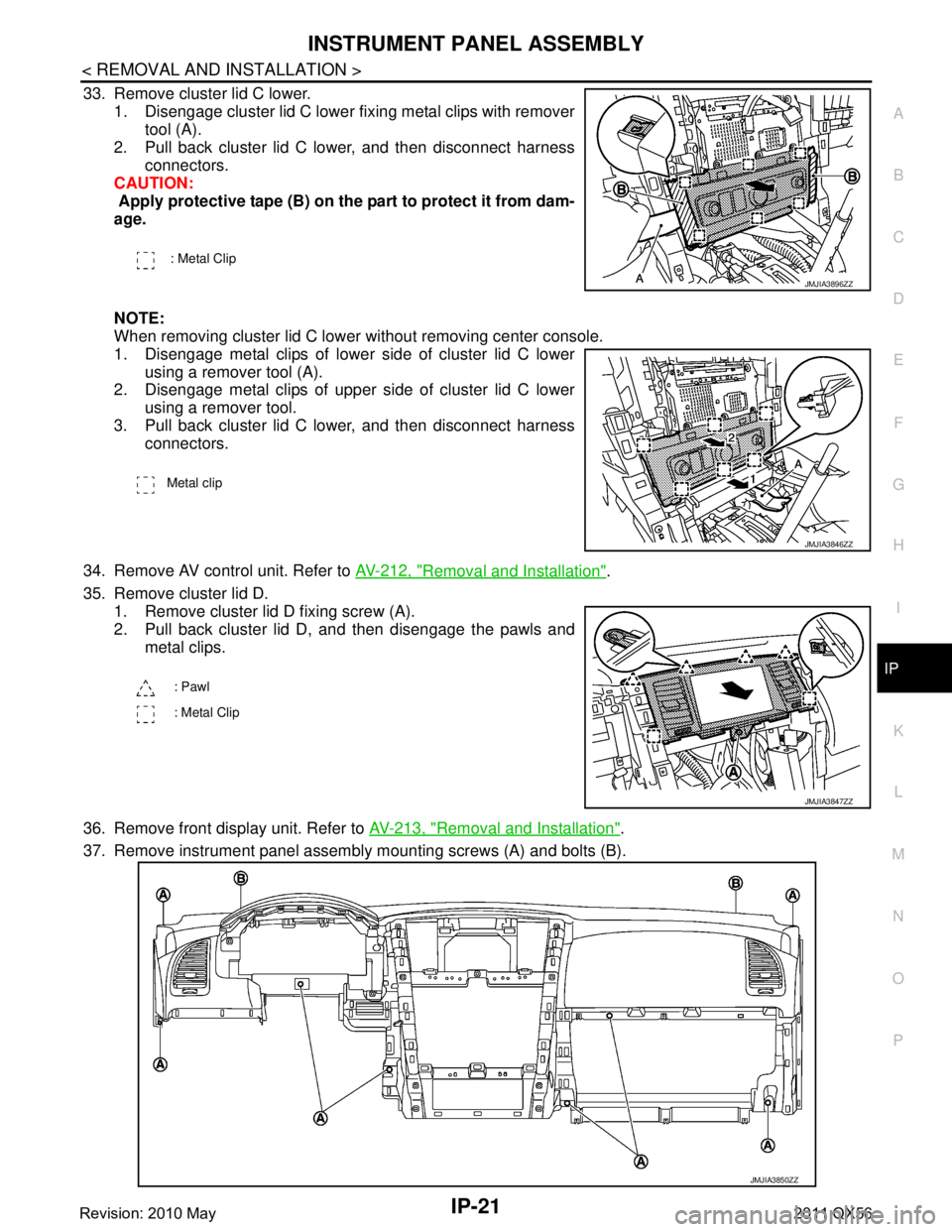

INSTRUMENT PANEL ASSEMBLYIP-21

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

33. Remove cluster lid C lower. 1. Disengage cluster lid C lower fixing metal clips with remover tool (A).

2. Pull back cluster lid C lower, and then disconnect harness

connectors.

CAUTION:

Apply protective tape (B) on the part to protect it from dam-

age.

NOTE:

When removing cluster lid C lower without removing center console.

1. Disengage metal clips of lower side of cluster lid C lower

using a remover tool (A).

2. Disengage metal clips of upper side of cluster lid C lower

using a remover tool.

3. Pull back cluster lid C lower, and then disconnect harness connectors.

34. Remove AV control unit. Refer to AV-212, "

Removal and Installation".

35. Remove cluster lid D. 1. Remove cluster lid D fixing screw (A).

2. Pull back cluster lid D, and then disengage the pawls and metal clips.

36. Remove front display unit. Refer to AV-213, "

Removal and Installation".

37. Remove instrument panel assembly mounting screws (A) and bolts (B).

: Metal Clip

JMJIA3896ZZ

Metal clip

JMJIA3846ZZ

: Pawl

: Metal Clip

JMJIA3847ZZ

JMJIA3850ZZ

Revision: 2010 May2011 QX56

Page 3436 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-16

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

With PAST

MONITOR ITEM (ON-BOARD DIAGNOSIS)

NOTE:

For some models, CAN communication diagnosis result is received from the vehicle mon INFINITI QX56 2011 Factory Service Manual

LAN-16

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

With PAST

MONITOR ITEM (ON-BOARD DIAGNOSIS)

NOTE:

For some models, CAN communication diagnosis result is received from the vehicle mon](/img/42/57033/w960_57033-3435.png)

LAN-16

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

With PAST

MONITOR ITEM (ON-BOARD DIAGNOSIS)

NOTE:

For some models, CAN communication diagnosis result is received from the vehicle monitor.

Example: Vehicle Display

Item PRSNT Description

Initial diagnosis OK Normal at present

NG Control unit error (Excep t for some control units)

Transmission diagnosis OK Normal at present

UNKWN Unable to transmit signals for 2 seconds or more.

Diagnosis not performed

Control unit name

(Reception diagnosis) OK Normal at present

UNKWN Unable to receive signals for 2 seconds or more.

Diagnosis not performed

No control unit for receiving signals. (No applicable optional parts)

Item PRSNT PAST Description

Transmission diagnosis OKOK Normal at present and in the past

1 – 39 Normal at present, but unable to transmit signals for 2 seconds or more

in the past. (The number indicates the number of ignition switch cycles

from OFF to ON.)

UNKWN 0 Unable to transmit signals for 2 seconds or more at present.

Control unit name

(Reception diagnosis) OK

OK Normal at present and in the past

1 – 39 Normal at present, but unable to receive signals for 2 seconds or more

in the past. (The number indicates the number of ignition switch cycles

from OFF to ON.)

UNKWN 0 Unable to receive signals for 2 seconds or more at present.

–– Diagnosis not performed.

No control unit for receiving signals. (No applicable optional parts)

Item

Result indi-

cated Error counter Description

CAN_COMM

(Initial diagnosis) OK 0 Normal at present

NG 1 – 50 Control unit error

(The number indicates how many times diagnosis has been

run.)

CAN_CIRC_1

(Transmission diagnosis) OK 0 Normal at present

UNKWN 1 – 50 Unable to transmit for 2 seconds or more at present.

(The number indicates how many times diagnosis has been

run.)

CAN_CIRC_2 – 9

(Reception diagnosis of each unit) OK 0 Normal at present

UNKWN 1 – 50 Unable to transmit for 2 seconds or more at present.

(The number indicates how many times diagnosis has been

run.)

Diagnosis not performed.

No control unit for receiving signals. (No applicable optional

parts)

Revision: 2010 May2011 QX56

Page 3451 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

SYSTEMLAN-31

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Meter display signal

TR

RT

Oil pressure switch signal TR

RT

Position light request signal T R R

Rear fog light status signa INFINITI QX56 2011 Factory Service Manual

LAN

SYSTEMLAN-31

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Meter display signal

TR

RT

Oil pressure switch signal TR

RT

Position light request signal T R R

Rear fog light status signa](/img/42/57033/w960_57033-3450.png)

LAN

SYSTEMLAN-31

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Meter display signal

TR

RT

Oil pressure switch signal TR

RT

Position light request signal T R R

Rear fog light status signal T R

Rear window defogger con-

trol signal TR

RT

Sleep wake up signal T R R R R R R

Starter control relay signal T R

Starter relay status signal TRR

RT

Starting mode signal T R

Steering lock relay signal TRR

RT

Theft warning horn request

signal TR

Turn indicator signal R T R R

A/C display signal R T

A/C ON signal R T

Ambient temperature signal T R

Blower fan ON signal R T

Distance to empty signal R T

Fuel level low warning sig-

nal RT

Fuel level sensor signal R T

Manual mode shift down

signal RT

Manual mode shift up sig-

nal RT

Manual mode signal R T

Non-manual mode signal R T

Odometer signal R T

Parking brake switch signal R R T R R

Sleep-ready signal RT

RT

RT

Tow mode switch signal R T

Wake up signal RT

RT

Steering angle sensor mal-

function signal RR T R R

Steering angle sensor sig-

nal RR RR T R R

Steering angle speed signal R T R R Signal name

ECM

4WD

ABS

TCM

A-BAG AFS

AV

BCM

CGW

HVAC M&A

STRG

TPMS

IPDM-E

ADPPSB

E-SUS ICC

PWBD

Revision: 2010 May2011 QX56

Page 3525 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

DIAGNOSIS SYSTEM (CAN GATEWAY)LAN-105

< SYSTEM DESCRIPTION > [CAN GATEWAY]

C

D

E

F

G H

I

J

K L

B A

O P

N

DIAGNOSIS SYSTEM (CAN GATEWAY)

CONSULT-III FunctionINFOID:0000000006220576

APPLICATION ITE INFINITI QX56 2011 Factory Service Manual

LAN

DIAGNOSIS SYSTEM (CAN GATEWAY)LAN-105

< SYSTEM DESCRIPTION > [CAN GATEWAY]

C

D

E

F

G H

I

J

K L

B A

O P

N

DIAGNOSIS SYSTEM (CAN GATEWAY)

CONSULT-III FunctionINFOID:0000000006220576

APPLICATION ITE](/img/42/57033/w960_57033-3524.png)

LAN

DIAGNOSIS SYSTEM (CAN GATEWAY)LAN-105

< SYSTEM DESCRIPTION > [CAN GATEWAY]

C

D

E

F

G H

I

J

K L

B A

O P

N

DIAGNOSIS SYSTEM (CAN GATEWAY)

CONSULT-III FunctionINFOID:0000000006220576

APPLICATION ITEM

CONSULT-III performs the following functi

ons via CAN communication with CAN gateway.

SELF DIAGNOSTIC RESULT

Refer to LAN-106, "DTCIndex".

Diagnosis mode Function Description

Ecu Identification The CAN gateway part number is displayed.

Self Diagnostic Result Displays the diagnosis results judged by CAN gateway.

CAN Diag Support Monitor The results of transmit/receive diagnosis of CAN communication can be read.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing CAN gateway.

Revision: 2010 May2011 QX56

Page 3526 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-106

< ECU DIAGNOSIS INFORMATION >[CAN GATEWAY]

CAN GATEWAY

ECU DIAGNOSIS INFORMATION

CAN GATEWAY

Reference ValueINFOID:0000000006220577

TERMINAL LAYOUT

PHYSICAL VALUES

DTC Inspection Priority Cha INFINITI QX56 2011 Factory Service Manual

LAN-106

< ECU DIAGNOSIS INFORMATION >[CAN GATEWAY]

CAN GATEWAY

ECU DIAGNOSIS INFORMATION

CAN GATEWAY

Reference ValueINFOID:0000000006220577

TERMINAL LAYOUT

PHYSICAL VALUES

DTC Inspection Priority Cha](/img/42/57033/w960_57033-3525.png)

LAN-106

< ECU DIAGNOSIS INFORMATION >[CAN GATEWAY]

CAN GATEWAY

ECU DIAGNOSIS INFORMATION

CAN GATEWAY

Reference ValueINFOID:0000000006220577

TERMINAL LAYOUT

PHYSICAL VALUES

DTC Inspection Priority ChartINFOID:0000000006220578

If some DTCs are displayed at the same time, perfo

rm inspections one by one based on the following priority

chart.

DTC IndexINFOID:0000000006220579

NOTE:

JSGIA0023ZZ

Te r m i n a l N o .

(Wire color) Description

Condition Va l u e

(Approx.)

Signal name Input/

Output

+–

1

(L) —CAN-H (CAN commu-

nication circuit 1) Input/

Output ——

3

(Y) Ground Battery power supply Input Ignition switch OFF Battery voltage

4

(L) —

CAN-H (CAN commu-

nication circuit 2) Input/

Output ——

5

(B) Ground Ground — Ignition switch ON 0 V

6

(L) —CAN-H (CAN commu-

nication circuit 2) Input/

Output ——

7

(P) —

CAN-L (CAN commu-

nication circuit 1) Input/

Output ——

9

(GR) Ground Ignition power supply Input Ignition switch ON Battery voltage

10

(R) —CAN-L (CAN commu-

nication circuit 2) Input/

Output ——

11

(B) Ground Ground — Ignition switch ON 0 V

12

(R) —CAN-L (CAN commu-

nication circuit 2) Input/

Output ——

Priority DTC

1 B2600: CONFIG ERROR

U1010: CONTROL UNIT(CAN)

2 U1000: CAN COMM CIRCUIT

Revision: 2010 May2011 QX56