flat tire INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3777 of 5598

MWI-34

< SYSTEM DESCRIPTION >

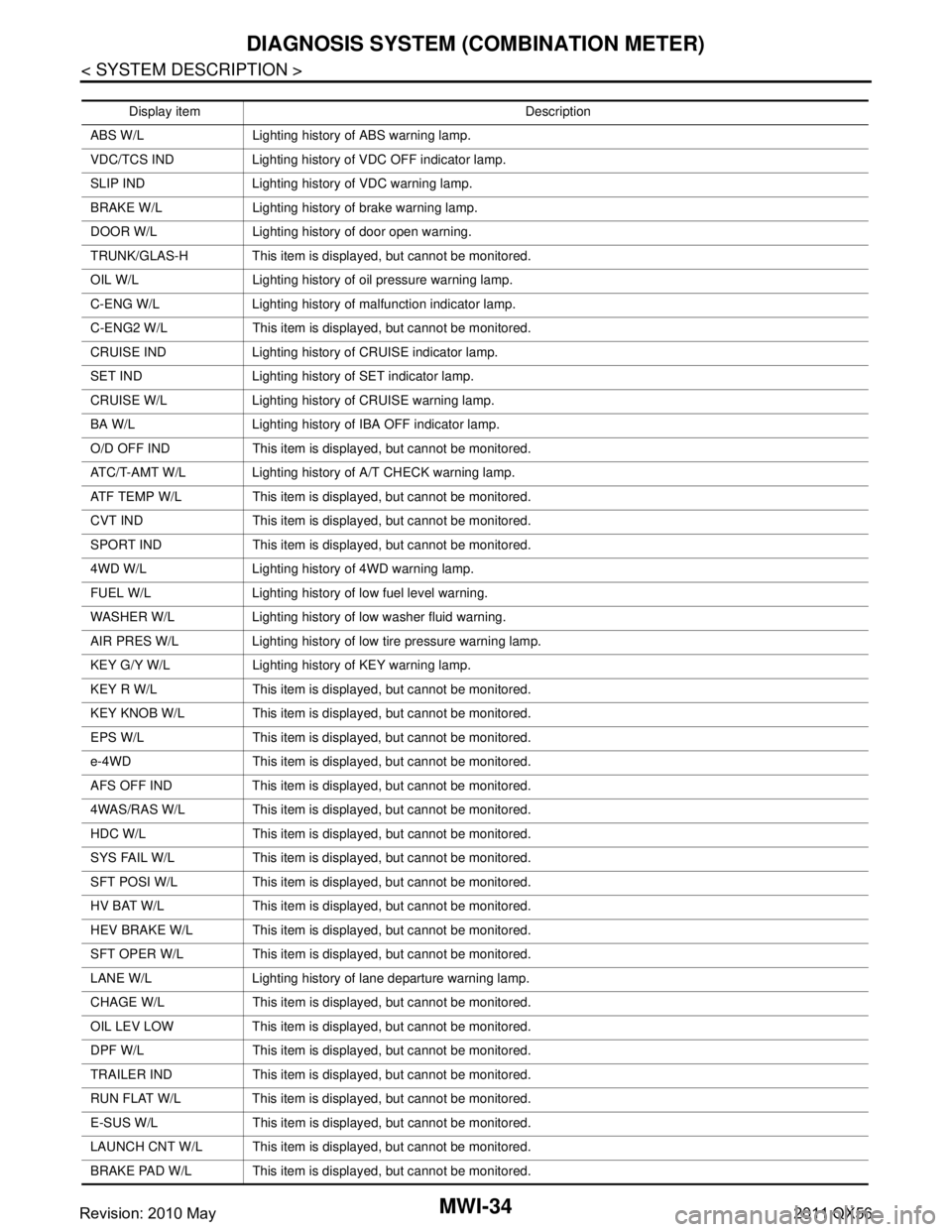

DIAGNOSIS SYSTEM (COMBINATION METER)

Display item Description

ABS W/L Lighting history of ABS warning lamp.

VDC/TCS IND Lighting history of VDC OFF indicator lamp.

SLIP IND Lighting history of VDC warning lamp.

BRAKE W/L Lighting history of brake warning lamp.

DOOR W/L Lighting history of door open warning.

TRUNK/GLAS-H This item is displa yed, but cannot be monitored.

OIL W/L Lighting history of oil pressure warning lamp.

C-ENG W/L Lighting history of malfunction indicator lamp.

C-ENG2 W/L This item is displayed, but cannot be monitored.

CRUISE IND Lighting history of CRUISE indicator lamp.

SET IND Lighting history of SET indicator lamp.

CRUISE W/L Lighting history of CRUISE warning lamp.

BA W/L Lighting history of IBA OFF indicator lamp.

O/D OFF IND This item is displayed, but cannot be monitored.

ATC/T-AMT W/L Lighting history of A/T CHECK warning lamp.

ATF TEMP W/L This item is displayed, but cannot be monitored.

CVT IND This item is displayed, but cannot be monitored.

SPORT IND This item is displayed, but cannot be monitored.

4WD W/L Lighting history of 4WD warning lamp.

FUEL W/L Lighting history of low fuel level warning.

WASHER W/L Lighting history of low washer fluid warning.

AIR PRES W/L Lighting history of low tire pressure warning lamp.

KEY G/Y W/L Lighting history of KEY warning lamp.

KEY R W/L This item is displaye d, but cannot be monitored.

KEY KNOB W/L This item is displa yed, but cannot be monitored.

EPS W/L This item is displayed, but cannot be monitored.

e-4WD This item is displayed, but cannot be monitored.

AFS OFF IND This item is displayed, but cannot be monitored.

4WAS/RAS W/L This item is displayed, but cannot be monitored.

HDC W/L This item is displayed, but cannot be monitored.

SYS FAIL W/L This item is displa yed, but cannot be monitored.

SFT POSI W/L This item is displayed, but cannot be monitored.

HV BAT W/L This item is displayed, but cannot be monitored.

HEV BRAKE W/L This item is displayed, but cannot be monitored.

SFT OPER W/L This item is displayed, but cannot be monitored.

LANE W/L Lighting history of lane departure warning lamp.

CHAGE W/L This item is displayed, but cannot be monitored.

OIL LEV LOW This item is displayed, but cannot be monitored.

DPF W/L This item is displayed, but cannot be monitored.

TRAILER IND This item is displayed, but cannot be monitored.

RUN FLAT W/L This item is displa yed, but cannot be monitored.

E-SUS W/L This item is displayed, but cannot be monitored.

LAUNCH CNT W/L This item is displayed, but cannot be monitored.

BRAKE PAD W/L This item is displa yed, but cannot be monitored.

Revision: 2010 May2011 QX56

Page 4799 of 5598

SRC-6

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006219946

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

ServiceINFOID:0000000006219947

Never use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

Before servicing the SRS, turn ignition switch OF F, disconnect battery negative terminal and wait 3 minutes

or more.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt pre-

tensioner to deploy. Therefore, never work on any SR S connectors or wires until at least 3 minutes have

passed.

Diagnosis sensor unit must always be installed with their arrow marks “ ⇐” pointing towards the front of the

vehicle for proper operation. Also chec k diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

The spiral cable must be aligned with the neutral position since its rotations are limited. Never turn steering

wheel and column after removal of steering gear.

Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Always replace instrument panel pad following front passenger air bag deployment.

Never solder the harness when making repairs. Check that harness is not pinched and that there is no con-

tact with other components.

Never allow harness to come in contact with oil, grease, waste oil, or water.

Never insert foreign materials, such as a screwdriver , into the harness connector. (This is to prevent acci-

dental activation caused by static electricity.)

Always use CONSULT-III or SRS air bag warning lamp to perform the circuit diagnosis. (Never use an elec- tric tester such as a circuit tester.)

Never enter in the deployment area of the pop-up roll bar. Never put an object in the deployment area of the

pop-up roll bar. (This is to prevent injury in case of an unintentional deployment.)

Revision: 2010 May2011 QX56

Page 5001 of 5598

ST-14

< BASIC INSPECTION >

STEERING WHEEL

STEERING WHEEL

InspectionINFOID:0000000006225584

NEUTRAL POSITION STEERING WHEEL

1. Check that steering gear assembly, steering column assembly and steering wheel are installed in the cor-

rect position.

2. Perform neutral position inspection after wheel alignment. Refer to FSU-7, "

Inspection".

3. Set vehicle to the straight-ahead position and c onfirm steering wheel is in the neutral position.

4. Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if steering wheel is not in the neutral position.

STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Tires need to be inflated the specified pressure. Refer to WT-69, "

Tire Air Pressure".

3. Start the engine.

4. Bring power steering fluid up to adequate operating temperature.

5. Check steering wheel turning force when steering wheel has been turned 540 ° from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring balance to the

center of steering wheel by the measurement value with a spring

balance.

6. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer to ST-52, "

Inspection".

RACK SLIDING FORCE

1. Disconnect lower joint and steering knuckle from steering gear assembly. Refer to ST-41, "Exploded

View".

2. Start and run engine at idle to make sure steer ing fluid has reached normal operating temperature.

3. While pulling outer socket slowly in ±11.5 mm ( ±0.453 in) range

from neutral position, make sure rack sliding force is within

specification.

4. If rack sliding force is not within specification, overhaul steering gear assembly.

FRONT WHEEL TURNING ANGLE

1. Check front wheel turning angle after toe-in inspection. Refer to FSU-7, "Inspection".

Fluid temperature : 50 – 80

°C (122 – 176 °F)

Steering wheel turning

force : Refer to

ST-57, "

Steering

Wheel Turning Force".

JSGIA0027ZZ

Fluid temperature : 50 – 80 °C (122 – 176 °F)

Rack sliding force : Refer to ST-58, "

Rack

Sliding Force".

SST090B

Revision: 2010 May2011 QX56

Page 5179 of 5598

![INFINITI QX56 2011 Factory Service Manual

ADDITIONAL SERVICE WHEN REPLACING TRANSMISSION ASSEMBLY

TM-91

< BASIC INSPECTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ADDITIONAL SERVICE WHEN REPL ACING TRANSMISSION ASSEMBLY

DescriptionI INFINITI QX56 2011 Factory Service Manual

ADDITIONAL SERVICE WHEN REPLACING TRANSMISSION ASSEMBLY

TM-91

< BASIC INSPECTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ADDITIONAL SERVICE WHEN REPL ACING TRANSMISSION ASSEMBLY

DescriptionI](/img/42/57033/w960_57033-5178.png)

ADDITIONAL SERVICE WHEN REPLACING TRANSMISSION ASSEMBLY

TM-91

< BASIC INSPECTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ADDITIONAL SERVICE WHEN REPL ACING TRANSMISSION ASSEMBLY

DescriptionINFOID:0000000006233270

Decel G sensor calibration must be performed when replacing A/T assembly.

Special Repair RequirementINFOID:0000000006233271

1.PREPARATION BEFORE CALIBRATION PROCEDURE

1. Park the vehicle on a flat road.

2. Adjust pressure in all tires to the specified value. Refer to WT-69, "

Tire Air Pressure".

>> GO TO 2.

2.PERFORM CALIBRATION

With CONSULT-III

1. Turn ignition switch ON.

CAUTION:

Never start the engine.

2. Select “G SENSOR CALIBRATION” in “Work Support” in “TRANSMISSION”.

3. Touch “START”. CAUTION:

Never give any motion to the vehicle during the calibration.

Is

“completed” displayed?

YES >> GO TO 3.

NO >> Perform the calibration again.

3.CHECK DTC

With CONSULT-III

1. Turn ignition switch OFF and wait 10 seconds or more.

2. Turn ignition switch ON.

3. Select “Self Diagnostic Results” in “ABS”.

Is

“C1145” or “C1146” detected?

YES >> Refer to BRC-51, "DTC Index".

NO >> Calibration end.

Revision: 2010 May2011 QX56

Page 5180 of 5598

![INFINITI QX56 2011 Factory Service Manual

TM-92

< BASIC INSPECTION >[7AT: RE7R01B]

ADDITIONAL SERVICE WHEN RE

PLACING CONTROL VALVE & TCM

ADDITIONAL SERVICE WHEN REPLACING CONTROL VALVE & TCM

DescriptionINFOID:0000000006233274

Decel G sensor INFINITI QX56 2011 Factory Service Manual

TM-92

< BASIC INSPECTION >[7AT: RE7R01B]

ADDITIONAL SERVICE WHEN RE

PLACING CONTROL VALVE & TCM

ADDITIONAL SERVICE WHEN REPLACING CONTROL VALVE & TCM

DescriptionINFOID:0000000006233274

Decel G sensor](/img/42/57033/w960_57033-5179.png)

TM-92

< BASIC INSPECTION >[7AT: RE7R01B]

ADDITIONAL SERVICE WHEN RE

PLACING CONTROL VALVE & TCM

ADDITIONAL SERVICE WHEN REPLACING CONTROL VALVE & TCM

DescriptionINFOID:0000000006233274

Decel G sensor calibration must be performed when replacing control valve & TCM.

Special Repair RequirementINFOID:0000000006233275

1.PREPARATION BEFORE CALIBRATION PROCEDURE

1. Park the vehicle on a flat road.

2. Adjust pressure in all tires to the specified value. Refer to WT-69, "

Tire Air Pressure".

>> GO TO 2.

2.PERFORM CALIBRATION

With CONSULT-III

1. Turn ignition switch ON.

CAUTION:

Never start the engine.

2. Select “G SENSOR CALIBRATION” in “Work Support” in “TRANSMISSION”.

3. Touch “START”. CAUTION:

Never give any motion to the vehicle during the calibration.

Is

“completed” displayed?

YES >> GO TO 3.

NO >> Perform the calibration again.

3.CHECK DTC

With CONSULT-III

1. Turn ignition switch OFF and wait 10 seconds or more.

2. Turn ignition switch ON.

3. Select “Self Diagnostic Results” in “ABS”.

Is

“C1145” or “C1146” detected?

YES >> Refer to BRC-51, "DTC Index".

NO >> Calibration end.

Revision: 2010 May2011 QX56

Page 5181 of 5598

![INFINITI QX56 2011 Factory Service Manual

CALIBRATION OF DECEL G SENSORTM-93

< BASIC INSPECTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

CALIBRATION OF DECEL G SENSOR

DescriptionINFOID:0000000006233272

Decel G sensor calibration must INFINITI QX56 2011 Factory Service Manual

CALIBRATION OF DECEL G SENSORTM-93

< BASIC INSPECTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

CALIBRATION OF DECEL G SENSOR

DescriptionINFOID:0000000006233272

Decel G sensor calibration must](/img/42/57033/w960_57033-5180.png)

CALIBRATION OF DECEL G SENSORTM-93

< BASIC INSPECTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

CALIBRATION OF DECEL G SENSOR

DescriptionINFOID:0000000006233272

Decel G sensor calibration must be performed when the following operation is performed.

Removal and installation or replacem ent of yaw rate/side/decel G sensor

Replacement of A/T assembly

Replacement of ABS actuator and electric unit (control unit)

CAUTION:

After removing/replacing the yaw rate/side/decal G sensor or replaci ng the ABS actuator and electric

unit (control unit), the decel G sensor of the ABS act uator and electric unit (control unit) must be cali-

brated first. Refer to BRC-66, "

Description".

Special Repair RequirementINFOID:0000000006233273

CAUTION:

After removing/replacing the yaw rate/side/decal G sensor or replaci ng the ABS actuator and electric

unit (control unit), the decel G sensor of the ABS act uator and electric unit (control unit) must be cali-

brated first. Refer to BRC-66, "

Description".

1.PREPARATION BEFORE CALIBRATION PROCEDURE

1. Park the vehicle on a flat road.

2. Adjust pressure in all tires to the specified value. Refer to WT-69, "

Tire Air Pressure".

>> GO TO 2.

2.PERFORM CALIBRATION

With CONSULT-III

1. Turn ignition switch ON. CAUTION:

Never start the engine.

2. Select “G SENSOR CALIBRATION” in “Work Support” in “TRANSMISSION”.

3. Touch “START”. CAUTION:

Never give any motion to the vehicle during the calibration.

Is

“completed” displayed?

YES >> GO TO 3.

NO >> Perform the calibration again.

3.CHECK DTC

With CONSULT-III

1. Turn ignition switch OFF and wait 10 seconds or more.

2. Turn ignition switch ON.

3. Select “Self Diagnostic Results” in “ABS”.

Is

“C1145” or “C1146” detected?

YES >> Refer to BRC-51, "DTC Index".

NO >> Calibration end.

Revision: 2010 May2011 QX56

Page 5422 of 5598

WCS-18

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (COMBINATION METER)

4WD W/L Lighting history of 4WD warning lamp.

FUEL W/L Lighting history of low fuel level warning.

WASHER W/L Lighting history of low washer fluid warning.

AIR PRES W/L Lighting history of low tire pressure warning lamp.

KEY G/Y W/L Lighting history of KEY warning lamp.

KEY R W/L This item is displayed, but cannot be monitored.

KEY KNOB W/L This item is displa yed, but cannot be monitored.

EPS W/L This item is displayed, but cannot be monitored.

e-4WD This item is displayed, but cannot be monitored.

AFS OFF IND This item is displayed, but cannot be monitored.

4WAS/RAS W/L This item is displayed, but cannot be monitored.

HDC W/L This item is displayed, but cannot be monitored.

SYS FAIL W/L This item is displa yed, but cannot be monitored.

SFT POSI W/L This item is displayed, but cannot be monitored.

HV BAT W/L This item is displayed, but cannot be monitored.

HEV BRAKE W/L This item is displayed, but cannot be monitored.

SFT OPER W/L This item is displayed, but cannot be monitored.

LANE W/L Lighting history of lane departure warning lamp.

CHAGE W/L This item is displayed, but cannot be monitored.

OIL LEV LOW This item is displayed, but cannot be monitored.

DPF W/L This item is displayed, but cannot be monitored.

TRAILER IND This item is displayed, but cannot be monitored.

RUN FLAT W/L This item is displa yed, but cannot be monitored.

E-SUS W/L This item is displayed, but cannot be monitored.

LAUNCH CNT W/L This item is displayed, but cannot be monitored.

BRAKE PAD W/L This item is displa yed, but cannot be monitored.

Display item Description

Revision: 2010 May2011 QX56

Page 5451 of 5598

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

ROAD WHEELS & TIRES

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Service Notice or Precautions for TPMS ...................4

Service Notice or Precautions for Road Wheel .........4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tools .......................................... ......5

Commercial Service Tools ........................................5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................7

Low Tire Pressure Warning Control Unit ...................7

Transmitter ................................................................7

Tire Pressure Receiver .............................................8

Low Tire Pressure Warning Lamp .............................8

SYSTEM ..............................................................9

System Description ............................................. ......9

Tire Inflation Indicator Function ...............................10

DIAGNOSIS SYSTEM (LOW TIRE PRES-

SURE WARNING CONTROL UNIT) ..................

12

CONSULT-III Function ........................................ ....12

ECU DIAGNOSIS INFORMATION ..............14

LOW TIRE PRESSURE WARNING CON-

TROL UNIT ..................................................... ....

14

Reference Value ................................................. ....14

DTC Inspection Priority Chart .................................17

DTC Index ...............................................................18

WIRING DIAGRAM ......................................19

TIRE PRESSURE MONITORING SYSTEM ......19

Wiring Diagram .................................................... ....19

BASIC INSPECTION ...................................25

DIAGNOSIS AND REPAIR WORK FLOW .......25

Work Flow ............................................................ ....25

ADDITIONAL SERVICE WHEN REPLACING

LOW TIRE PRESSURE WARNING CON-

TROL UNIT ........................................................

27

Description ...............................................................27

Work Procedure .......................................................27

TRANSMITTER WAKE UP OPERATION .........28

Description ...............................................................28

Work Procedure .......................................................28

ID REGISTRATION ...........................................29

Description ...............................................................29

Work Procedure .......................................................29

DTC/CIRCUIT DIAGNOSIS .........................31

C1704, C1705, C1706, C1707 LOW TIRE

PRESSURE .......................................................

31

DTC Logic ............................................................ ....31

Diagnosis Procedure ...............................................31

C1708, C1709, C1710, C1711 TRANSMITTER

(NO DATA) ........................................................

33

DTC Logic ............................................................ ....33

Diagnosis Procedure ...............................................33

C1716, C1717, C1718, C1719 TRANSMITTER

(PRESSURE DATA) ..........................................

37

DTC Logic ............................................................ ....37

Diagnosis Procedure ...............................................37

C1728 RECEIVER ID ........................................39

Revision: 2010 May2011 QX56

Page 5452 of 5598

WT-2

DTC Logic ...............................................................39

Diagnosis Procedure ..............................................39

C1729 VEHICLE SPEED SIGNAL ....................41

DTC Logic ............................................................ ...41

Diagnosis Procedure ..............................................41

C1750, C1751, C1752, C1753 RECEIVER ........42

DTC Logic ............................................................ ...42

Diagnosis Procedure ..............................................42

C1754 LOW TIRE PRESSURE WARNING

CONTROL UNIT ................................................

45

DTC Logic ............................................................ ...45

Diagnosis Procedure ..............................................45

C1755, C1756, C1757, C1758 POOR RE-

CEIVING CONDITIONS .....................................

47

DTC Logic ............................................................ ...47

Diagnosis Procedure ..............................................47

U1000 CAN COMM CIRCUIT ............................49

Description ........................................................... ...49

DTC Logic ...............................................................49

Diagnosis Procedure ..............................................49

U1010 CONTROL UNIT (CAN) .........................50

Description ........................................................... ...50

DTC Logic ...............................................................50

Diagnosis Procedure ..............................................50

POWER SUPPLY AND GROUND CIRCUIT .....51

Diagnosis Procedure ........................................... ...51

LOW TIRE PRESSURE WARNING LAMP .......52

Component Function Check ................................ ...52

Diagnosis Procedure ..............................................52

SYMPTOM DIAGNOSIS .............................53

TPMS SYMPTOMS ......................................... ...53

Symptom Table ................................................... ...53

LOW TIRE PRESSURE WARNING LAMP

DOES NOT TURN ON .......................................

56

Description ........................................................... ...56

Diagnosis Procedure ..............................................56

LOW TIRE PRESSURE WARNING LAMP

DOES NOT TURN OFF .....................................

57

Description ........................................................... ...57

Diagnosis Procedure ..............................................57

LOW TIRE PRESSURE WARNING LAMP

BLINKS ..............................................................

58

Description ........................................................... ...58

Diagnosis Procedure ............................................ ...58

TIRE INFLATION INDICATOR DOES NOT

ACTIVATE .........................................................

59

Description ........................................................... ...59

Diagnosis Procedure ...............................................59

ID REGISTRATION CANNOT BE COMPLET-

ED ......................................................................

60

Description ........................................................... ...60

Diagnosis Procedure ..............................................60

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

61

NVH Troubleshooting Chart ................................. ...61

PERIODIC MAINTENANCE .......................62

ROAD WHEEL ................................................ ...62

Adjustment ........................................................... ...62

Tire Rotation ...........................................................63

REMOVAL AND INSTALLATION ..............64

ROAD WHEEL TIRE ASSEMBLY ................. ...64

Exploded View ..................................................... ...64

Removal and Installation .........................................64

Inspection ................................................................64

LOW TIRE PRESSURE WARNING CON-

TROL UNIT ........................................................

65

Exploded View ..................................................... ...65

Removal and Installation .........................................65

TRANSMITTER .................................................66

Exploded View ..................................................... ...66

Removal and Installation .........................................66

TIRE PRESSURE RECEIVER ...........................68

Exploded View ..................................................... ...68

FRONT TIRE PRESSURE RECEIVER .................. ...68

FRONT TIRE PRESSURE RECEIVER : Removal

and Installation ........................................................

68

REAR TIRE PRESSURE RECEIVER .......................68

REAR TIRE PRESSURE RECEIVER : Removal

and Installation ..................................................... ...

68

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................................

69

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

69

Road Wheel ......................................................... ...69

Tire Air Pressure .....................................................69

Revision: 2010 May2011 QX56

Page 5454 of 5598

WT-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Service Notice or Precautions for TPMSINFOID:0000000006225485

Low tire pressure warning lamp blinks for 1min, then turns ON when occurring any malfunction except low tire pressure. Erase the self-diagnosis memories for low tire pressure warning control unit, or register the ID

to turn low tire pressure warning lamp OFF. For ID registration, refer to WT-29, "

Work Procedure".

ID registration is required when replacing or rotating wheel s, replacing transmitter or low tire pressure warn-

ing control unit. Refer to WT-29, "

Work Procedure".

Replace grommet seal, valve core and cap of transmitter in TPMS, when replacing each tire by reaching the

wear limit. Refer to WT-66, "

Exploded View".

For tire inflation indicator function, refer to the following.

- When inflating the tires, park the vehicle in the safe area and ensure the safety of the working area.

- Read and understand the tire inflation indicator function prior to use.

- Inflate the tires one at a time.

- If there is no response for approximately 15 seconds or mo re after inflating the tires, cancel the use of the

tire inflation indicator function or move the vehicle approximately 1 m (3.2 ft) backward or forward to try

again. The air filler pressure may be weak or out of service area.

- Despite the high-precision TPMS pressure sensor, an i ndicated value may differ from that of the pressure

gauge.

- Air pressure is measured rather high due to the rise in tire air temperature after driving.

- If TPMS is malfunctioning, the tire inflation indicator is unusable.

Service Notice or Precautions for Road WheelINFOID:0000000006225486

Genuine NISSAN aluminum wheel is designed for each type of vehicle. Use it on the specified vehicle only.

Use Genuine NISSAN parts for the wheel nuts.

Always use them after adjusting the wheel balance. For the balance weights, use Genuine NISSAN alumi-

num wheel weights.

Use caution when handling the aluminum wheels, because they can be easily scratched. When removing

dirt, do not use any abrasives, a wire brush, or other it ems that may scratch the coating. Use a neutral deter-

gent if a detergent is needed.

After driving on roads scattered with anti-ici ng salts, wash off the wheels completely.

When installing road wheels onto the vehicle, always wipe of f any dirt or foreign substances to prevent them

from being trapped between the contact surfaces of wheel.

Never apply oil to nut and bolt threads.

Revision: 2010 May2011 QX56