engine INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3359 of 5598

INT-10

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing, or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof / headlining area can often be traced to one of the following items:

1. Sunroof lid, rail, linkage, or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note t he position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Causes of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move, or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: 2010 May2011 QX56

Page 3392 of 5598

IP-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006113088

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006113089

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 3394 of 5598

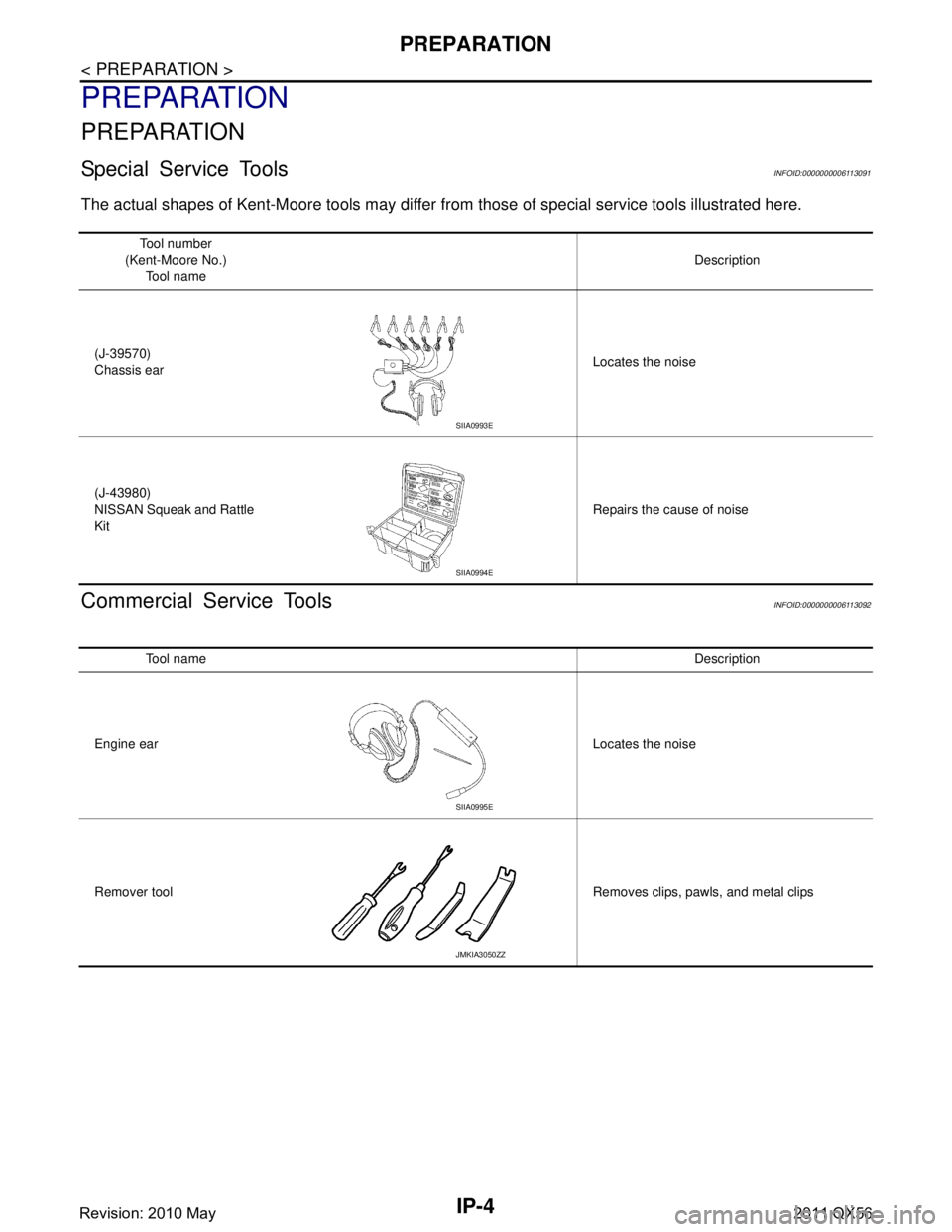

IP-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000006113091

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsINFOID:0000000006113092

Tool number

(Kent-Moore No.) Tool name Description

(J-39570)

Chassis ear Locates the noise

(J-43980)

NISSAN Squeak and Rattle

Kit Repairs the cause of noise

SIIA0993E

SIIA0994E

Tool name

Description

Engine ear Locates the noise

Remover tool Removes clips, pawls, and metal clips

SIIA0995E

JMKIA3050ZZ

Revision: 2010 May2011 QX56

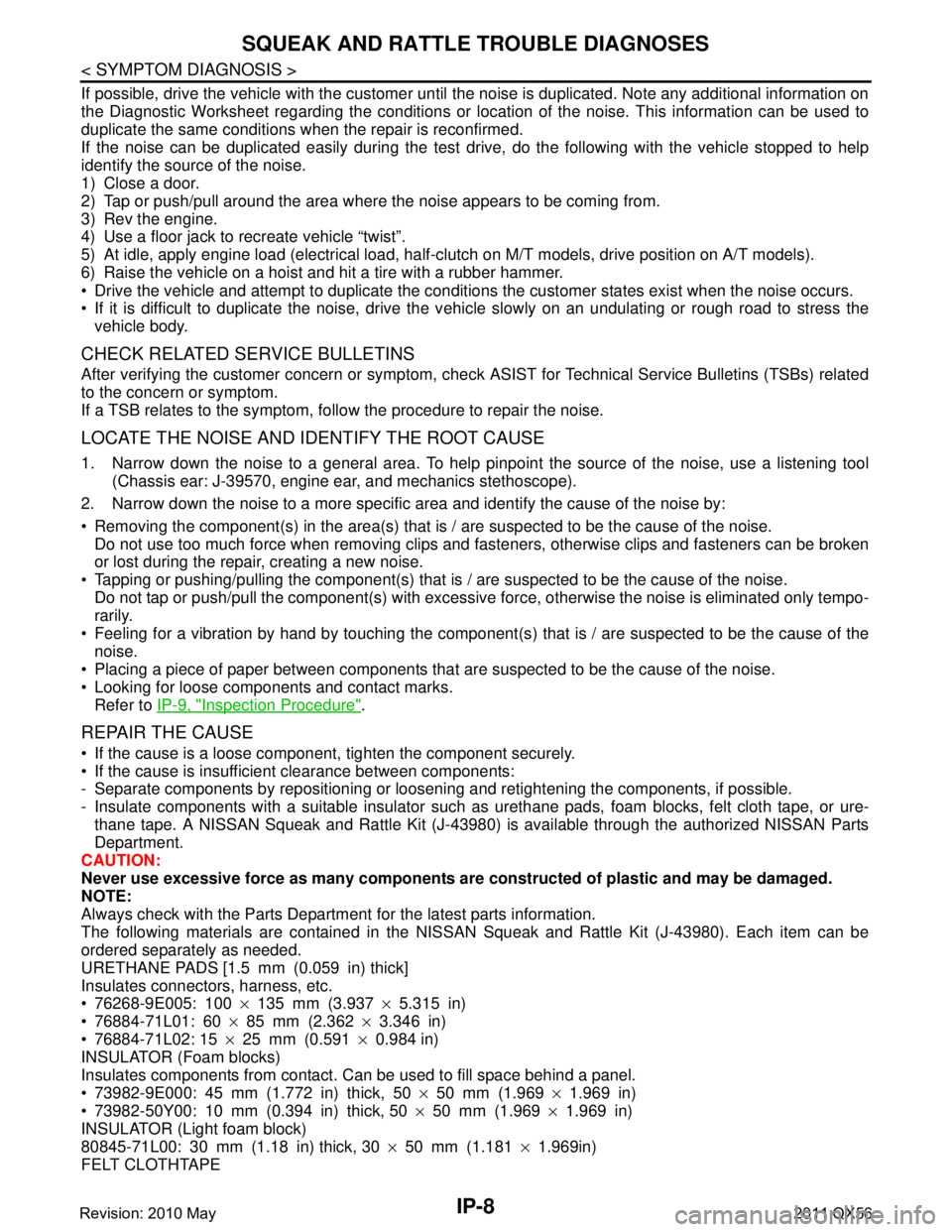

Page 3398 of 5598

IP-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when the repair is reconfirmed.

If the noise can be duplicated easily during the test dr ive, do the following with the vehicle stopped to help

identify the source of the noise.

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to the concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis ear: J-39570, engine ear, and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the component(s) in the area(s) that is / are suspected to be the cause of the noise.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, creating a new noise.

Tapping or pushing/pulling the component(s) that is / are suspected to be the cause of the noise.

Do not tap or push/pull the component(s) with excessive force, otherwise the noise is eliminated only tempo-

rarily.

Feeling for a vibration by hand by touching the component(s ) that is / are suspected to be the cause of the

noise.

Placing a piece of paper between components that are suspected to be the cause of the noise.

Looking for loose components and contact marks. Refer to IP-9, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loos ening and retightening the components, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape, or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through the authorized NISSAN Parts

Department.

CAUTION:

Never use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Departm ent for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.937 ×5.315 in)

76884-71L01: 60 ×85 mm (2.362 ×3.346 in)

76884-71L02: 15 ×25 mm (0.591 ×0.984 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.772 in) thick, 50 ×50 mm (1.969 ×1.969 in)

73982-50Y00: 10 mm (0.394 in) thick, 50 ×50 mm (1.969 ×1.969 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.181 ×1.969in)

FELT CLOTHTAPE

Revision: 2010 May2011 QX56

Page 3400 of 5598

IP-10

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing, or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof / headlining area can often be traced to one of the following items:

1. Sunroof lid, rail, linkage, or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note t he position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Causes of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move, or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: 2010 May2011 QX56

Page 3432 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-12

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: TCM branch line open circuit

Example: Data link connector branch line open circuit

SKIB8738E

Unit name Major symptom

ECM Engi INFINITI QX56 2011 Factory Service Manual

LAN-12

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: TCM branch line open circuit

Example: Data link connector branch line open circuit

SKIB8738E

Unit name Major symptom

ECM Engi](/img/42/57033/w960_57033-3431.png)

LAN-12

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: TCM branch line open circuit

Example: Data link connector branch line open circuit

SKIB8738E

Unit name Major symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM Reverse warning chime does not sound.

EPS control unit No rmal operation.

Combination meter Shift position indicator and OD OFF indicator turn OFF.

Warning lamps turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R Normal operation.

SKIB8739E

Revision: 2010 May2011 QX56

Page 3433 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

TROUBLE DIAGNOSISLAN-13

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

NOTE:

When data link connector branch line is open, transmi

ssion and reception of CAN communicati INFINITI QX56 2011 Factory Service Manual

LAN

TROUBLE DIAGNOSISLAN-13

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

NOTE:

When data link connector branch line is open, transmi

ssion and reception of CAN communicati](/img/42/57033/w960_57033-3432.png)

LAN

TROUBLE DIAGNOSISLAN-13

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

NOTE:

When data link connector branch line is open, transmi

ssion and reception of CAN communication signals

are not affected. Therefore, no symptoms occur. However, be sure to repair malfunctioning circuit.

The model (all units on CAN communication system are Diag on CAN) cannot perform CAN diagnosis with

CONSULT-III if the following error occurs. The error is judged by the symptom.

Example: Main Line Between Data Link Connector and ABS Actuator and Electr ic Unit (Control Unit) Open Circuit

Unit name Major symptom

ECM

Normal operation.

BCM

EPS control unit

Combination meter

ABS actuator and electric

unit (control unit)

TCM

IPDM E/R

Error Difference of symptom

Data link connector branch line open circuit Normal operation.

CAN-H, CAN-L harness short-circuit Most of the units which are connected to the CAN communication

system enter fail-safe mode or are deactivated.

SKIB8740E

Unit name Major symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front wip-

er switch being in the intermittent position.

EPS control unit The steering effort increases.

Combination meter The shift position indicator and OD OFF indicator turn OFF.

The speedometer is inoperative.

The odo/trip meter stops.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

Revision: 2010 May2011 QX56

Page 3434 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extract INFINITI QX56 2011 Factory Service Manual

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extract](/img/42/57033/w960_57033-3433.png)

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extracts the root

cause by receiving the following information.

Response to the system call

Control unit diagnosis information

Self-diagnosis

CAN diagnostic support monitor

SKIB8741E

Unit name Major symptom

ECM Engine torque limiting is affected, and shift harshness increases.

Engine speed drops.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

The room lamp does not turn ON.

The engine does not start (if an error or malfunction occurs while turning the igni- tion switch OFF.)

The steering lock does not release (if an error or malfunction occurs while turning the ignition switch OFF.)

EPS control unit The steeri ng effort increases.

Combination meter The tachometer and the speedometer do not move.

Warning lamps turn ON.

Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

Revision: 2010 May2011 QX56

Page 3444 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-24

< PRECAUTION >[CAN]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006238426

The Supplemental Res INFINITI QX56 2011 Factory Service Manual

LAN-24

< PRECAUTION >[CAN]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006238426

The Supplemental Res](/img/42/57033/w960_57033-3443.png)

LAN-24

< PRECAUTION >[CAN]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006238426

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precautions for Trouble DiagnosisINFOID:0000000006220528

CAUTION:

Never apply 7.0 V or more to the measurement terminal.

Use a tester with open terminal voltage of 7.0 V or less.

Turn the ignition switch OFF and disconnect th e battery cable from the negative terminal when

checking the harness.

Precautions for Harness RepairINFOID:0000000006220529

Solder the repaired area and wrap tape around the soldered area.

NOTE:

A fray of twisted lines must be within 110 mm (4.33 in).

SKIB8766E

Revision: 2010 May2011 QX56

Page 3447 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine INFINITI QX56 2011 Factory Service Manual

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine](/img/42/57033/w960_57033-3446.png)

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine CAN system type from the following specification chart.

NOTE:

Refer to LAN-18, "

Trouble Diagnosis Procedure" for how to use CAN system specification chart.

×: Applicable

VEHICLE EQUIPMENT IDENTIFICATION INFORMATION

NOTE:

Body type Wagon

Axle 2WD 4WD

Engine VK56VD

Transmission A/T

Brake control VDC

ICC system ××

CAN system type 1 2 3 4 CAN communication unit

ECM ××××

Transfer control unit ××

ABS actuator and electric unit (control unit) ××××

TCM ××××

Air bag diagnosis sensor unit ××××

AFS control unit ××

AV control unit ××××

BCM ××××

CAN gateway ××

Data link connector ××××

A/C auto amp. ××××

Combination meter ××××

Steering angle sensor ××××

Low tire pressure warning control unit ××××

IPDM E/R ××××

Driver seat control unit ××××

Pre-crash seat belt control unit (driver side) ××

Air levelizer control module ××××

ADAS control unit ××

Automatic back door control module ××××

ITS communication unit

ADAS control unit ××

Side radar RH ××

Side radar LH ××

Lane camera unit ××

Accelerator pedal actuator ××

ICC sensor ××

Revision: 2010 May2011 QX56