tires INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1 of 5598

A

B

D

E

F

G

H

I

J

K

L

M

N

P

O

C

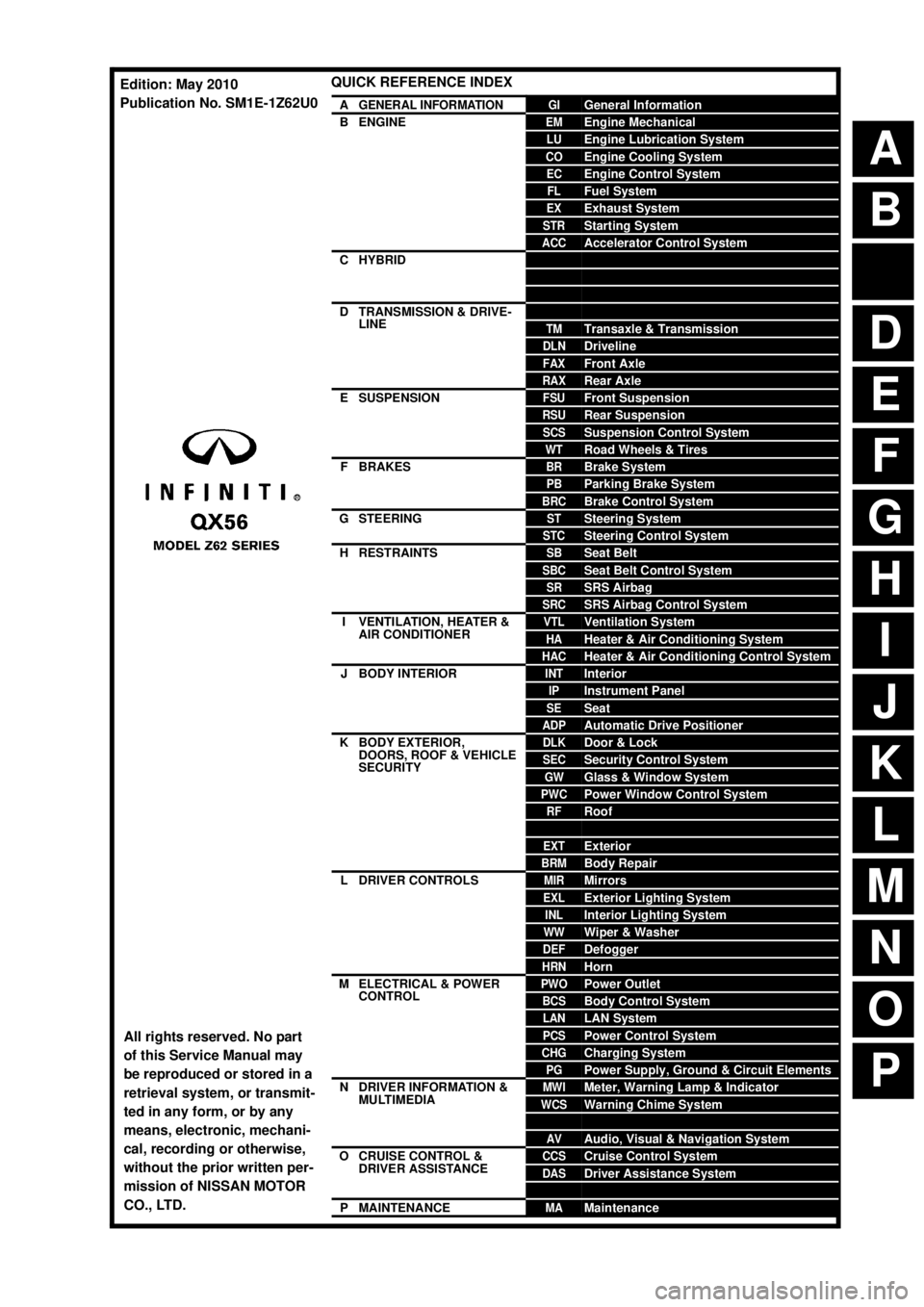

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINECLClutch

TMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Positioner

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

HDHood

EXTExterior

BRMBody Repair

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROL &

DRIVER ASSISTANCECCSCruise Control System

DASDriver Assistance System

DMSDrive Mode System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, recording or otherwise,

without the prior written per-

mission of NISSAN MOTOR

CO., LTD.

Edition: May 2010

Publication No. SM1E-1Z62U0

Page 182 of 5598

AV-34

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

The steering angle output value detected with the gyroscope is

adjusted.

SPEED CALIBRATION

During normal driving, distance error caused by tire wear and tire

pressure change is automatically adjusted for by the automatic dis-

tance correction function. This function, on the other hand, is for

immediate adjustment, in cases such as driving with tire chain fitted

on tires.

Error History

The self-diagnosis results are judged depending on whether any error occurs from when “Self-diagnosis” is

selected until the self-diagnosis results are displayed.

However, the diagnosis results are judged normal if an error has occurred before the ignition switch is turned

ON and then no error has occurred until the self-diagnosis start. Check the “Error Record” to detect any error

that may have occurred before the self-di agnosis start because of this situation.

The error record displays the time and place of the most recent occurrence of that error. However, take note of

the following points.

If there is a malfunction with the GPS antenna circuit board in the AV control unit, the correct date and time

of occurrence may not be able to be displayed.

Place of the error occurrence is represented by the posit ion of the current location mark at the time an error

occurred. If current location mark has deviated from t he correct position, then the place of the error occur-

rence cannot be located correctly.

The frequency of occurrence is displayed in a count up manner. The actual count up method differs depend- ing on the error item.

Count up method A

The counter resets to 0 if an error occurs when igniti on switch is turned ON. The counter increases by 1 if

the condition is normal at a next ignition ON cycle.

The counter upper limit is 39. Any counts exceeding 39 are ignored.“ The counter can be reset (no error

record display) with the “Delete log” switch or CONSULT-III.

Count up method B

The counter increases by 1 if an error occurs when i gnition switch is ON. The counter will not decrease even

if the condition is normal at the next ignition ON cycle.

The counter upper limit is 50. Any counts exceeding 50 are ignored. “ The counter can be reset (no error

record display) with the “Delete log” switch or CONSULT-III.

JSNIA2179ZZ

JSNIA2180ZZ

Display type of occur-

rence frequency Error history display item

Count up method A CAN communication line, control unit (CAN), AV communication line, control unit (AV)

Count up method B Other than the above

Revision: 2010 May2011 QX56

Page 358 of 5598

AV-210

< SYMPTOM DIAGNOSIS >

NORMAL OPERATING CONDITION

RELATED TO ROUTE CALCULATION AND VISUAL GUIDANCE

The vehicle icon is not displayed in

the correct position.The vehicle was transported after the ignition

switch was pressed off, for example, by a ferry

or car transporter.

Drive the vehicle for a while on a road where

GPS signals can be received.

The position and direction of the vehicle icon

may be incorrect depending on the driving en-

vironments and the levels of positioning accu-

racy of the navigation system. This is not a malfunction. Drive the vehicle for

a while to automatically correct the position

and direction of the vehicle icon.

When the vehicle is traveling on a

new road, the vehicle icon is located

on another road nearby. Because the new road is not stored in the map

data, the system automatically places the vehi-

cle icon on the nearest road available.

Updated road information will be included in

the next version of the map data.

The screen does not switch to the

night screen even after turning on

the headlights. The daytime screen was set the last time the

headlights were turned on.

Set the screen to the night screen mode using

The map does not scroll even when

the vehicle is moving. The current location map screen is not dis-

played.

Press “MAP”.

The vehicle icon is not displayed. The current location map screen is not dis-

played.

Press “MAP”.

The location of the vehicle icon is

misaligned from the actual position. When using tire chains or replacing the tires,

speed calculations based on the speed sensor

may be incorrect. Drive the vehicle for a while [at approximately

30 km/h (19 MPH) for about 30 minutes] to

automatically correct the vehicle icon posi-

tion.

If this does not correct the vehicle icon posi-

tion, contact an INFINITI dealer.

The map data has a mistake or is incomplete

(the vehicle icon position is always misaligned

in the same area). Updated road information will be included in

the next version of the map data.

Symptom Possible cause Possible solution

Symptom Possible cause Possible solution

Waypoints are not included in

the auto reroute calculation. Waypoints that you have already passed are not included in

the auto reroute calculation. If you want to go to that waypoint

again, you need to edit the route.

Route information is not dis-

played. Route calculation has not yet been performed.

Set the destination and perform route

calculation.

You are not driving on the suggested route. Drive on the suggested route.

Route guidance is set to off. Turn on route guidance.

Route information is not provided for certain types of roads

(roads displayed in gray). This is not a malfunction.

The auto reroute calculation (or

detour calculation) suggests

the same route as the one pre-

viously suggested. Route calculations took priority conditions into consider-

ation, but the same route was calculated.

This is not a malfunction.

A waypoint cannot be added. Five waypoints are already set on the route, including ones

that you have already passed. A maximum of 5 waypoints can be set

on the route. If you want to go to 6 or

more waypoints, perform route calcu-

lations multiple times as necessary.

The suggested route is not dis-

played. Roads near the destination cannot be calculated.

Reset the destination to a main or or-

dinary road, and recalculate the route.

The starting point and destination are too close. Set a more distant destination.

The starting point and destination are too far away. Divide your trip by selecting one or two

intermediate destinations, and per-

form route calculations multiple times.

There are time restricted roads (by the day of the week, by

time) near the current vehicle location or destination. Set [Use Time Restricted Roads] to

off.

Revision: 2010 May2011 QX56

Page 493 of 5598

BRAKE PIPINGBR-23

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

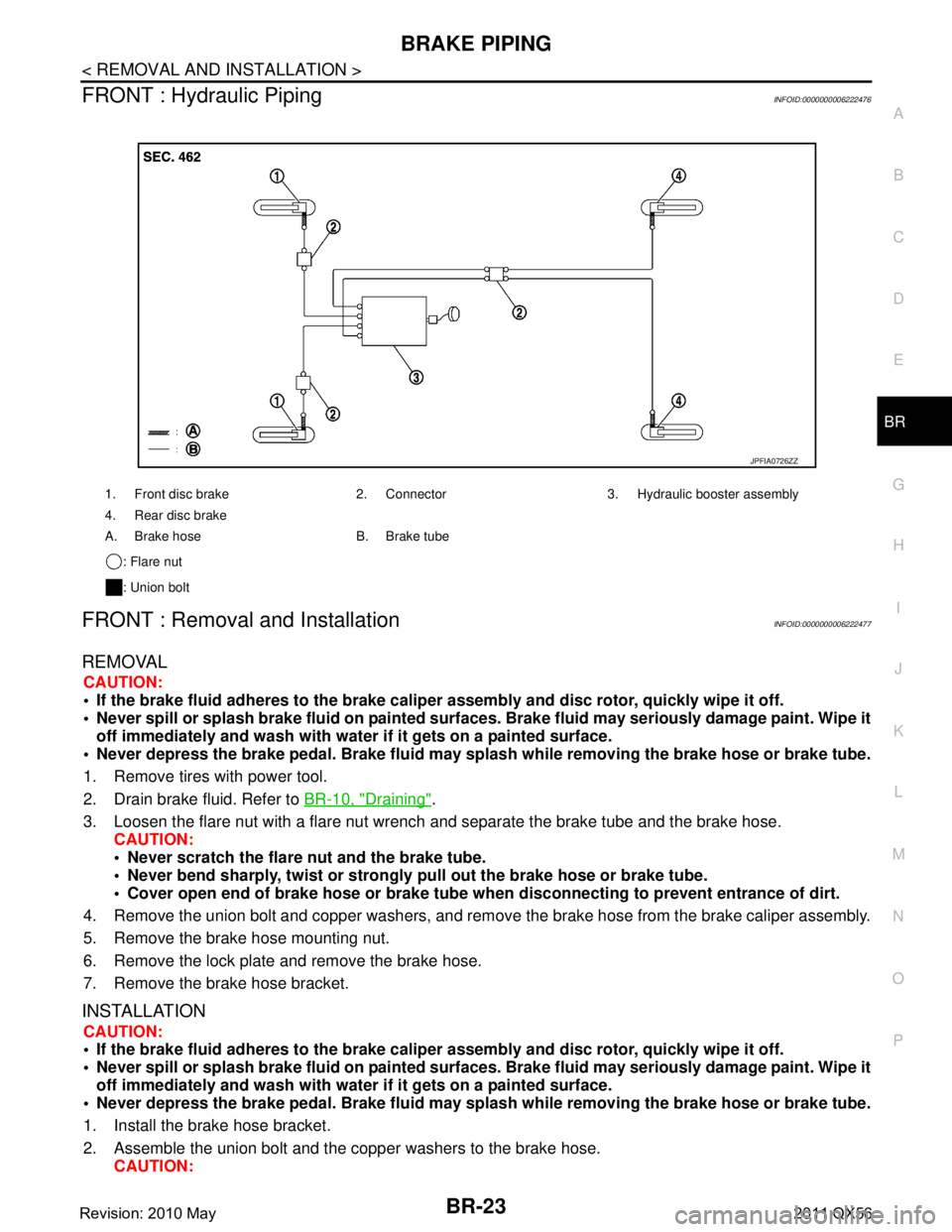

FRONT : Hydraulic PipingINFOID:0000000006222476

FRONT : Removal and InstallationINFOID:0000000006222477

REMOVAL

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Remove tires with power tool.

2. Drain brake fluid. Refer to BR-10, "

Draining".

3. Loosen the flare nut with a flare nut wrench and separate the brake tube and the brake hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strongly pull out the brake hose or brake tube.

Cover open end of brake hose or brake tube wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the brake hose mounting nut.

6. Remove the lock plate and remove the brake hose.

7. Remove the brake hose bracket.

INSTALLATION

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Install the brake hose bracket.

2. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

1. Front disc brake 2. Connector 3. Hydraulic booster assembly

4. Rear disc brake

A. Brake hose B. Brake tube

: Flare nut

: Union bolt

JPFIA0726ZZ

Revision: 2010 May2011 QX56

Page 494 of 5598

BR-24

< REMOVAL AND INSTALLATION >

BRAKE PIPING

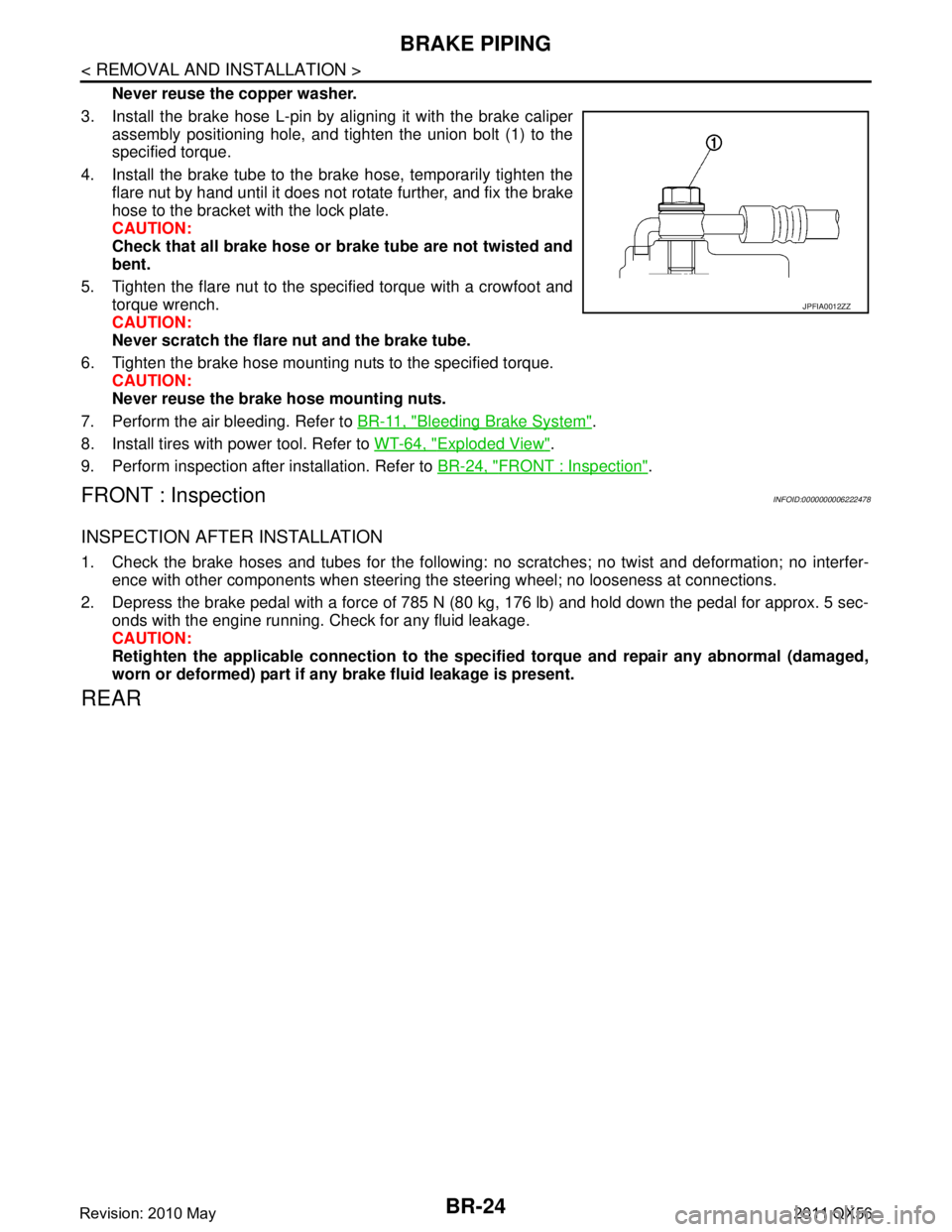

Never reuse the copper washer.

3. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

4. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

5. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

6. Tighten the brake hose mounting nuts to the specified torque. CAUTION:

Never reuse the brake hose mounting nuts.

7. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

8. Install tires with power tool. Refer to WT-64, "

Exploded View".

9. Perform inspection after installation. Refer to BR-24, "

FRONT : Inspection".

FRONT : InspectionINFOID:0000000006222478

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approx. 5 sec- onds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

REAR

JPFIA0012ZZ

Revision: 2010 May2011 QX56

Page 496 of 5598

BR-26

< REMOVAL AND INSTALLATION >

BRAKE PIPING

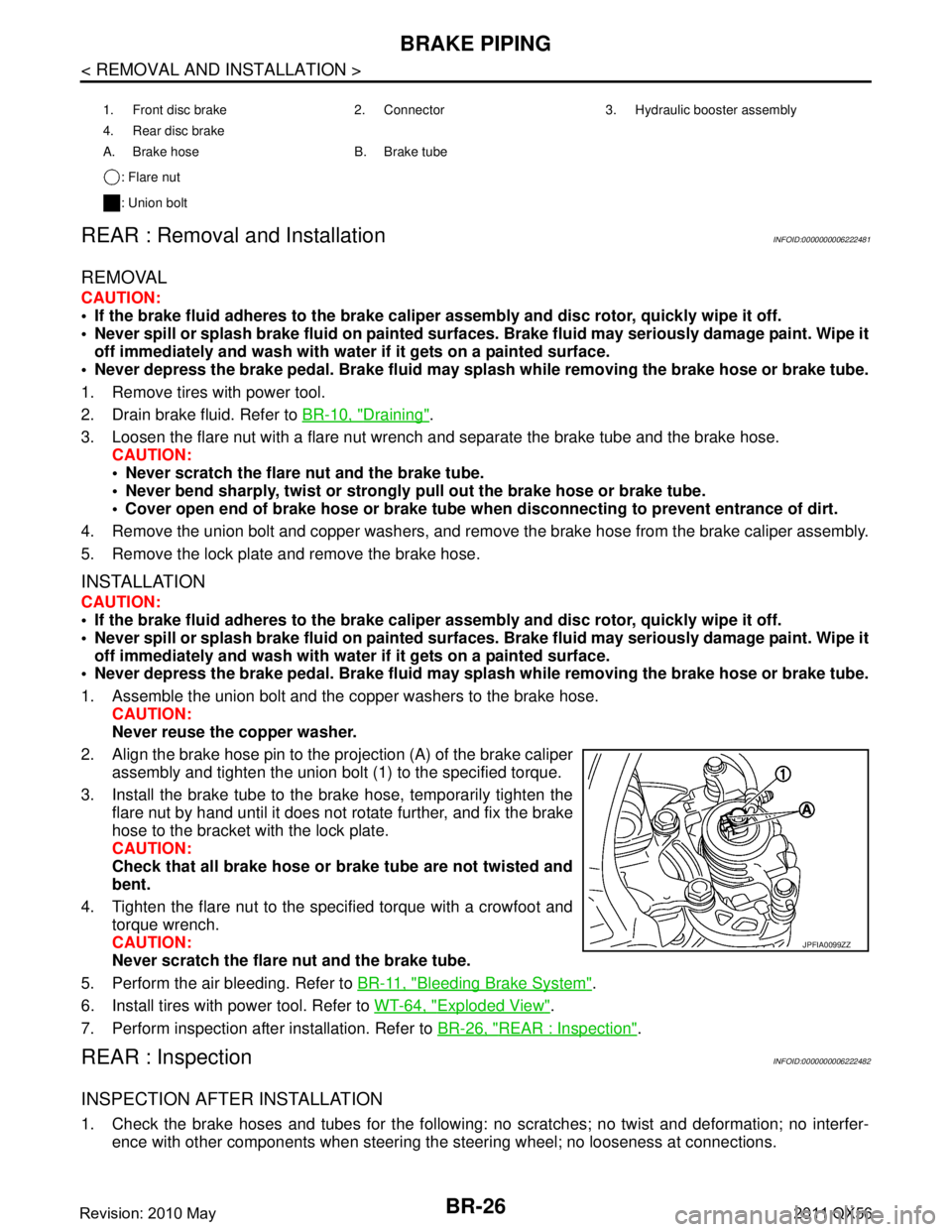

REAR : Removal and Installation

INFOID:0000000006222481

REMOVAL

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Remove tires with power tool.

2. Drain brake fluid. Refer to BR-10, "

Draining".

3. Loosen the flare nut with a flare nut wrench and separate the brake tube and the brake hose. CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strongly pull out the brake hose or brake tube.

Cover open end of brake hose or brake tube wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

2. Align the brake hose pin to the projection (A) of the brake caliper

assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

6. Install tires with power tool. Refer to WT-64, "

Exploded View".

7. Perform inspection after installation. Refer to BR-26, "

REAR : Inspection".

REAR : InspectionINFOID:0000000006222482

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

1. Front disc brake 2. Connector 3. Hydraulic booster assembly

4. Rear disc brake

A. Brake hose B. Brake tube

: Flare nut

: Union bolt

JPFIA0099ZZ

Revision: 2010 May2011 QX56

Page 504 of 5598

BR-34

< REMOVAL AND INSTALLATION >

FRONT DISC BRAKE

FRONT DISC BRAKE

BRAKE PAD

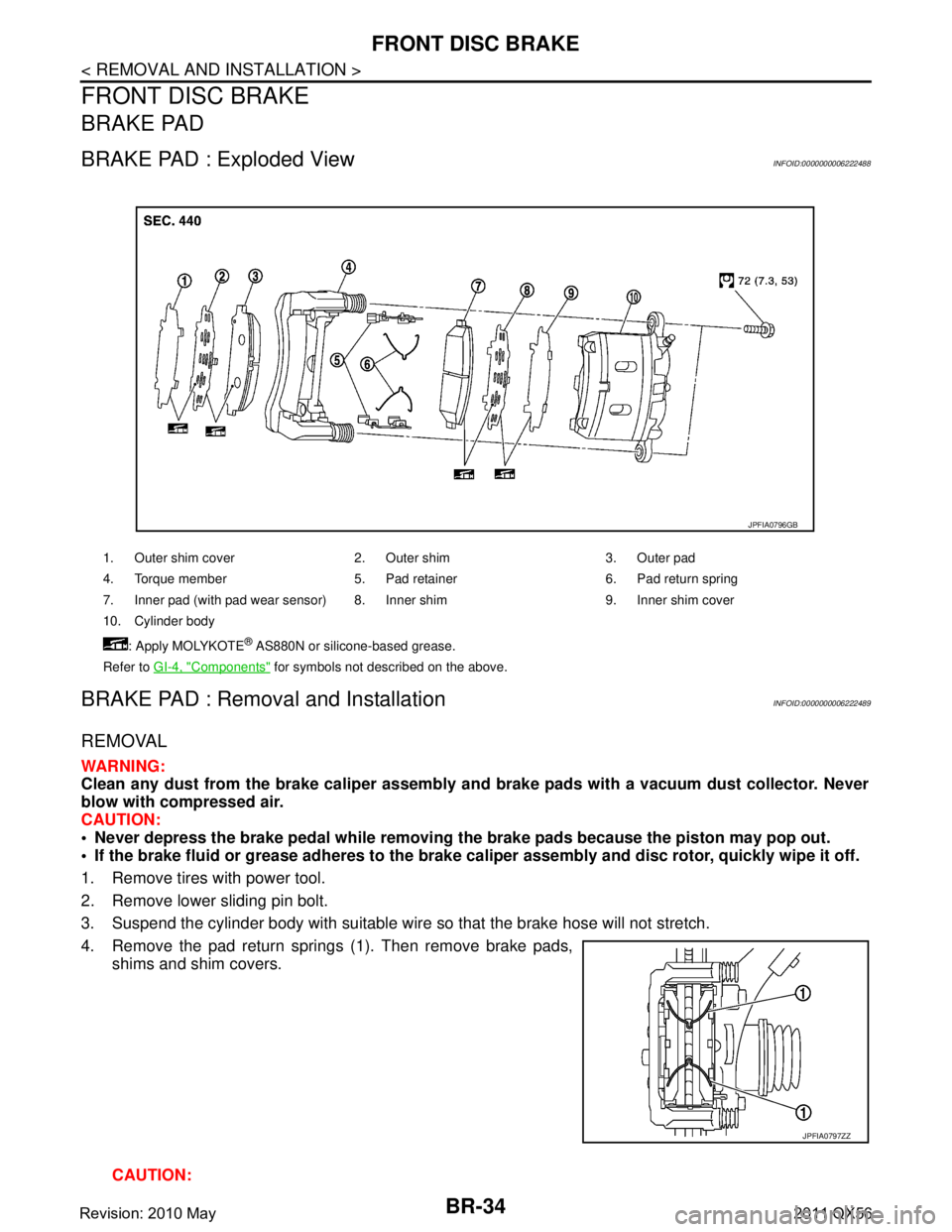

BRAKE PAD : Exploded ViewINFOID:0000000006222488

BRAKE PAD : Removal and InstallationINFOID:0000000006222489

REMOVAL

WARNING:

Clean any dust from the brake caliper assembly and brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never depress the brake pedal while removing th e brake pads because the piston may pop out.

If the brake fluid or grease adheres to the brake calip er assembly and disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Remove lower sliding pin bolt.

3. Suspend the cylinder body with suitable wire so that the brake hose will not stretch.

4. Remove the pad return springs (1). Then remove brake pads, shims and shim covers.

CAUTION:

1. Outer shim cover 2. Outer shim 3. Outer pad

4. Torque member 5. Pad retainer 6. Pad return spring

7. Inner pad (with pad wear sensor) 8. Inner shim 9. Inner shim cover

10. Cylinder body

: Apply MOLYKOTE

® AS880N or silicone-based grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0796GB

JPFIA0797ZZ

Revision: 2010 May2011 QX56

Page 506 of 5598

BR-36

< REMOVAL AND INSTALLATION >

FRONT DISC BRAKE

7. Depress the brake pedal several times to check that no drag feel is present for the front disc brake. Refer

to BR-36, "

BRAKE PAD : Inspection".

8. Install tires with power tool. Refer to WT-64, "

Exploded View".

BRAKE PAD : InspectionINFOID:0000000006222490

INSPECTION AFTER REMOVAL

Replace the shims and shim covers if rust is excessively attached.

Eliminate rust on the pad retainers and the torque mem ber. Replace them if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads. Refer to BR-34, "

BRAKE PAD : Removal and Installation".

3. Press the pistons. Refer to BR-34, "

BRAKE PAD : Removal and Installation".

4. Install brake pads. Refer to BR-34, "

BRAKE PAD : Removal and Installation".

5. Depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the caliper. Refer to BR-38,

"BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces brake pads and disc rotor after refinishing or replacing brake pads, or if a soft pedal occurs at very low mileage. Refer to BR-16, "

BRAKE PAD : Inspection and Adjustment".

BRAKE CALIPER ASSEMBLY

BRAKE CALIPER ASSEMBLY : Exploded ViewINFOID:0000000006222491

REMOVAL

DISASSEMBLY

1. Brake caliper assembly

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0799GB

Revision: 2010 May2011 QX56

Page 507 of 5598

FRONT DISC BRAKEBR-37

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE CALIPER ASSEMBLY : Removal and InstallationINFOID:0000000006222492

REMOVAL

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid m ay splash while removing the brake hose.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-10, "

Draining".

4. Separate brake hose from brake caliper assembly. Refer to BR-23, "

FRONT : Removal and Installation".

5. Remove torque member mounting bolts, and remove brake caliper assembly. CAUTION:

Never drop brake pad and brake caliper assembly.

6. Remove disc rotor. Refer to FA X - 8 , "

Removal and Installation" (2WD), FAX-18, "Removal and Installation"

(AWD).

INSTALLATION

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid m ay splash while removing the brake hose.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Torque member 2. Sliding pin boot 3. Sliding pin

4. Piston boot 5. Piston 6. Piston seal

7. Cylinder body 8. Bleeder valve 9. Cap

: Apply rubber grease.

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0800GB

Revision: 2010 May2011 QX56

Page 508 of 5598

BR-38

< REMOVAL AND INSTALLATION >

FRONT DISC BRAKE

1. Install disc rotor. Refer to FA X - 8 , "Removal and Installation" (2WD), FAX-18, "Removal and Installation"

(AWD).

2. Install the brake caliper assembly to the steeri ng knuckle and tighten the torque member mounting bolts to

the specified torque.

CAUTION:

Never spill or splash any grease and moisture on the torque member mounting face, threads,

mounting bolts. Wipe out any grease and moisture.

3. Install brake hose to brake caliper assembly. Refer to BR-23, "

FRONT : Removal and Installation".

4. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

5. Check a drag of front disc brake. If any drag is found, refer to BR-39, "

BRAKE CALIPER ASSEMBLY :

Inspection".

6. Install tires with power tool. Refer to WT-64, "

Exploded View".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000006222493

DISASSEMBLY

NOTE:

Never remove the torque member, brake pads and pad retainers when disassembling and assembling the cyl-

inder body.

1. Remove the sliding pin bolt, and remove the cylinder body from the torque member.

CAUTION:

Fix the brake pad at suitable tape so that the brake pad will not drop.

2. Remove sliding pin boots from torque member.

3. Place a wooden block as shown in the figure, and blow air from brake hose mounting hole to remove pistons and piston boots.

CAUTION:

Never get fingers caught in the pistons.

4. Remove piston seals from cylinder body using suitable tool. CAUTION:

Be careful not to damage a cylinder inner wall.

5. Remove bleeder valve and cap.

6. Perform inspection after disassembly. Refer to BR-39, "

BRAKE

CALIPER ASSEMBLY : Inspection".

ASSEMBLY

1. Install bleeder valve and cap.

BRB0032D

JPFIA0781ZZ

Revision: 2010 May2011 QX56