clutch INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1 of 5598

A

B

D

E

F

G

H

I

J

K

L

M

N

P

O

C

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINECLClutch

TMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Positioner

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

HDHood

EXTExterior

BRMBody Repair

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROL &

DRIVER ASSISTANCECCSCruise Control System

DASDriver Assistance System

DMSDrive Mode System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, recording or otherwise,

without the prior written per-

mission of NISSAN MOTOR

CO., LTD.

Edition: May 2010

Publication No. SM1E-1Z62U0

Page 413 of 5598

BCS

DIAGNOSIS SYSTEM (BCM)BCS-25

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

B A

O P

N

SELF-DIAG RESULT

Refer to

BCS-57, "DTCIndex".

DATA MONITOR

SHORT CRANKING OUTPUT Starter motor can operate during the times below

70 msec

100 msec

200 msec

CONFIRM KEY FOB ID It can be checked wh ether Intelligent Key ID code is registered or not in this mode

AUTO LOCK SET Auto door lock operation time can be changed in this mode

MODE 1: OFF

MODE 2: 30 sec

MODE 3: 1 minute

MODE 4: 2 minutes

MODE 5: 3 minutes

MODE 6: 4 minutes

MODE 7: 5 minutes

HORN WITH KEYLESS LOCK Horn reminder function mode by Intelligent Key button can be selected from the following with

this mode

On: Operate

Off: Non-operation

PW DOWN SET Unlock button pressing time on Intelligent Key button can be selected from the following with

this mode

MODE 1: 3 sec

MODE 2: Non-operation

MODE 3: 5 sec

WELCOME LIGHT SELECT Welcome light function mode can be selected from the following with this mode

Puddle/Outside Handle

Room lamp

Head & Tail Lamps (this item is displayed, but cannot be used)

Heart Beat

WELCOME LIGHT OP SET Welcome light function mode can be changed to operation with this mode

On: Operate

Off: Non-operation

Monitor item Description

Monitor Item Condition

REQ SW -DR Indicates [On/Off] condition of door request switch (driver side)

REQ SW -AS Indicates [On/Off] condition of door request switch (passenger side)

REQ SW -BD/TR Indicates [On/Off] condition of back door request switch

PUSH SW Indicates [On/Off] condition of push-button ignition switch

CLUTCH SW NOTE:

This item is displayed, but cannot be monitored

BRAKE SW 1 Indicates [On/Off]* conditio n of stop lamp switch power supply

BRAKE SW 2 Indicates [On/Off] co ndition of stop lamp switch

DETE/CANCL SW Indicates [On/Off] condition of P position

SFT PN/N SW Indicates [On/Off] condition of P or N position

S/L -LOCK Indicates [On/Off] condition of steering lock unit (LOCK)

S/L -UNLOCK Indicates [On/Off] condition of steering lock unit (UNLOCK)

S/L RELAY -F/B Indicates [On/Off] condition of steering lock relay

UNLK SEN -DR Indicates [On/Off] condition of driver door UNLOCK status

PUSH SW -IPDM Indicates [On/Off] condition of push-button ignition switch

IGN RLY1 -F/B Indicates [On/Off] condition of ignition relay 1

DETE SW -IPDM Indicates [On/Off] condition of P position

Revision: 2010 May2011 QX56

Page 443 of 5598

BCS

BCM

BCS-55

< ECU DIAGNOSIS INFORMATION >

C

D E

F

G H

I

J

K L

B A

O P

N

B2603: SHIFT POSI STATUS Inhibit steering lock

500 ms after any of the following BCM recognition conditions are fulfilled

Status 1

- Ignition switch is in the ON position

- Selector lever P position switch signal: Except P position (12 V)

- Selector lever P/N position signal: Except P and N positions (0 V)

Status 2

- Ignition switch is in the ON position

- Selector lever P position switch signal: P position (0 V)

- Selector lever P/N position signal: P or N positions (12 V)

B2604: PNP/CLUTCH SW Inhibit steering lock 500 ms after any of the following BCM recognition conditions are fulfilled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (12 V)

- Shift position signal (CAN): P or N position

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- Shift position signal (CAN): Except P and N position

B2605: PNP/CLUTCH SW Inhibit steering lock 500 ms after any of the following BCM recognition conditions are fulfilled

Status 1

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (12 V)

- Interlock/PNP switch signal (CAN): ON

B2608: STARTER RELAY Inhibit engine cranking 500 ms after the following signal communication status becomes con-

sistent

Starter motor re

lay control signal

Starter relay status signal (CAN)

B2609: S/L STATUS Inhibit engine crank-

ing

Inhibit steering lock When the following steering lock conditions agree

BCM steering lock control status

Steering lock condition No. 1 signal status

Steering lock condition No. 2 signal status

B260B: STEERING LOCK UNIT Inhibit steering lock Erase DTC

B260D: STEERING LOCK UNIT Inhibit steering lock Erase DTC

B260F: ENG STATE SIG LOST Inhibit engine cranking When any of the following conditions are fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B2612: S/L STATUS Inhibit engine crank-

ing

Inhibit steering lock When any of the following conditions are fulfilled

Steering lock unit status signal (CAN) is received normally

The BCM steering lock control status matches the steering lock status

recognized by the steering lock unit status signal (CAN from IPDM E/

R)

B2619: BCM Inhibit engine cranking 1 second after the steering lock unit power supply output control inside

BCM becomes normal

B26EF: STRG LCK RELAY OFF Inhibit engine cranking When the following conditions are fulfilled

Steering lock relay signal (CAN): ON

Steering lock unit status signal (CAN): ON

B26F0: STRG LCK RELAY ON Inhibit engine cranking When the following conditions are fulfilled

Steering lock relay signal (CAN): OFF

Steering lock unit status signal (CAN): OFF

B26F1: IGN RELAY OFF Inhibit engine cranking When the following conditions are fulfilled

Ignition switch ON signal (CAN: Transmitted from BCM): ON

Ignition switch ON signal (CAN: Transmitted from IPDM E/R): ON

B26F2: IGN RELAY ON Inhibit engine cranking When the following conditions are fulfilled

Ignition switch ON signal (CAN: Transmitted from BCM): OFF

Ignition switch ON signal (CAN: Transmitted from IPDM E/R): OFF

Display contents of CONSULT Fail-safe Cancellation

Revision: 2010 May2011 QX56

Page 445 of 5598

BCS

BCM

BCS-57

< ECU DIAGNOSIS INFORMATION >

C

D E

F

G H

I

J

K L

B A

O P

N

DTC IndexINFOID:0000000006274822

NOTE:

The details of time display are as follows.

CRNT: A malfunction is detected now.

PAST: A malfunction was detected in the past.

IGN counter is displayed on Freeze Frame Data. For details of Freeze Frame Data, refer to

BCS-14, "

COM-

MON ITEM : CONSULT-III Function (BCM - COMMON ITEM)".

4 B2013: ID DISCORD BCM-S/L

B2014: CHAIN OF S/L-BCM

B2555: STOP LAMP

B2556: PUSH-BTN IGN SW

B2557: VEHICLE SPEED

B2601: SHIFT POSITION

B2602: SHIFT POSITION

B2603: SHIFT POSI STATUS

B2604: PNP/CLUTCH SW

B2605: PNP/CLUTCH SW

B2608: STARTER RELAY

B2609: S/L STATUS

B260B: STEERING LOCK UNIT

B260C: STEERING LOCK UNIT

B260D: STEERING LOCK UNIT

B260F: ENG STATE SIG LOST

B2612: S/L STATUS

B2614: BCM

B2615: BCM

B2616: BCM

B2618: BCM

B2619: BCM

B261A: PUSH-BTN IGN SW

B26E9: LOCK MALFUNCTION

B26EF: STRG LCK RELAY OFF

B26F0: STRG LCK RELAY ON

B26F1: IGN RELAY OFF

B26F2: IGN RELAY ON

B26F3: START CONT RLY ON

B26F4: START CONT RLY OFF

B26F5: STRG LCK STS SW

B26F6: BCM

B26F7: BCM

B26F8: BCM

B26F9: CRANK REQ CIR SHORT

B26FA: CRANK REQ CIR OPEN

B26FC: KEY REGISTRATION

U0415: VEHICLE SPEED

5 B2621: INSIDE ANTENNA

B2622: INSIDE ANTENNA

B2623: INSIDE ANTENNA

6 B2626: OUTSIDE ANTENNA

B2627: OUTSIDE ANTENNA

B2628: OUTSIDE ANTENNA

7 B26E7: TPMS CAN COMM

Priority DTC

Revision: 2010 May2011 QX56

Page 446 of 5598

BCS-58

< ECU DIAGNOSIS INFORMATION >

BCM

CONSULT display Fail-safeFreeze Frame Data

Vehicle Speed

Odo/Trip Meter

Vehicle Condition Intelligent Key warn-

ing lamp ON Reference

page

No DTC is detected.

further testing

may be required. ————

U1000: CAN COMM — — — BCS-70

U1010: CONTROL UNIT (CAN) — — —BCS-71

U0415: VEHICLE SPEED×— ×BCS-72

B2013: ID DISCORD BCM-S/L ××× SEC-69

B2014: CHAIN OF S/L-BCM××× SEC-70

B2192: ID DISCORD BCM-ECM×—— SEC-60

B2193: CHAIN OF BCM-ECM ×—— SEC-61

B2195: ANTI-SCANNING ×—— SEC-62

B2196: DONGLE NG ×—— SEC-63

B2198: NATS ANTENNA AMP ×—— SEC-65

B2555: STOP LAMP — ××SEC-73

B2556: PUSH-BTN IGN SW — ××SEC-76

B2557: VEHICLE SPEED ××× SEC-78

B2562: LOW VOLTAGE — ×—BCS-73

B2601: SHIFT POSITION ××× SEC-79

B2602: SHIFT POSITION××× SEC-82

B2603: SHIFT POSI STATUS××× SEC-85

B2604: PNP/CLUTCH SW××× SEC-89

B2605: PNP/CLUTCH SW××× SEC-91

B2608: STARTER RELAY××× SEC-93

B2609: S/L STATUS××× SEC-95

B260B: STEERING LOCK UNIT××× SEC-98

B260C: STEERING LOCK UNIT — ××SEC-99

B260D: STEERING LOCK UNIT ××× SEC-100

B260F: ENG STATE SIG LOST××× SEC-101

B2612: S/L STATUS××× SEC-102

B2614: BCM — ××PCS-56

B2615: BCM — ××PCS-59

B2616: BCM — ××PCS-61

B2618: BCM — ××PCS-63

B2619: BCM ××× SEC-105

B261A: PUSH-BTN IGN SW — ××PCS-64

B2621: INSIDE ANTENNA — ×—DLK-104

B2622: INSIDE ANTENNA — ×—DLK-106

B2623: INSIDE ANTENNA — ×—DLK-108

B2626: OUTSIDE ANTENNA — ×—DLK-110

B2627: OUTSIDE ANTENNA — ×—DLK-112

B2628: OUTSIDE ANTENNA — ×—DLK-114

B26E7: TPMS CAN COMM — — — BCS-74

Revision: 2010 May2011 QX56

Page 1502 of 5598

DEF-10

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

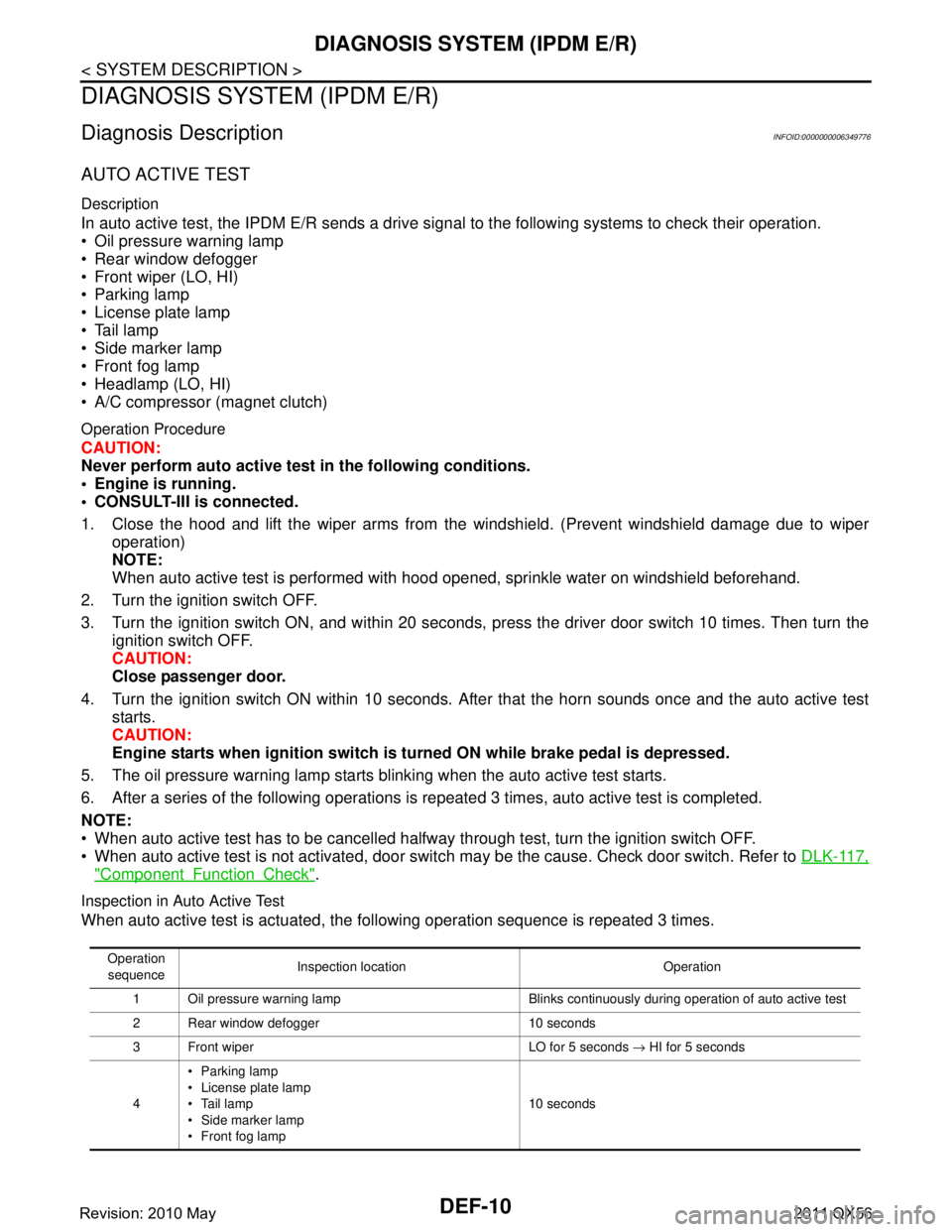

Diagnosis DescriptionINFOID:0000000006349776

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure warning lamp

Rear window defogger

Front wiper (LO, HI)

Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp

Headlamp (LO, HI)

A/C compressor (magnet clutch)

Operation Procedure

CAUTION:

Never perform auto active test in the following conditions.

Engine is running.

CONSULT-III is connected.

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, pr ess the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

CAUTION:

Engine starts when igniti on switch is turned ON while brake pedal is depressed.

5. The oil pressure warning lamp starts blinking when the auto active test starts.

6. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test has to be cancelled halfway through test, turn the ignition switch OFF.

When auto active test is not activated, door swit ch may be the cause. Check door switch. Refer to DLK-117,

"ComponentFunctionCheck".

Inspection in Auto Active Test

When auto active test is actuated, the following operation sequence is repeated 3 times.

Operation

sequence Inspection location Operation

1 Oil pressure warning lamp Blinks continuously during operation of auto active test

2 Rear window defogger 10 seconds

3 Front wiper LO for 5 seconds → HI for 5 seconds

4 Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp 10 seconds

Revision: 2010 May2011 QX56

Page 1503 of 5598

DIAGNOSIS SYSTEM (IPDM E/R)DEF-11

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

Concept of auto active test

IPDM E/R starts the auto active test with the door

switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test

5 Headlamp LO for 10 seconds →HI ON ⇔ OFF 5 times

6 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

Operation

sequence Inspection location Operation

JMMIA0492GB

Symptom Inspection contents Possible cause

Rear window defogger does not operate Perform auto active test.

Does the rear window defog-

ger operate?YES BCM signal input circuit

NO Rear window defogger

Rear window defogger

ground circuit

Harness or connector be- tween IPDM E/R and rear

window defogger

IPDM E/R

Any of the following components do not operate

Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp

Headlamp (HI, LO)

Front wiper (HI, LO) Perform auto active test.

Does the applicable system

operate?YES BCM signal input circuit

NO Lamp or motor

Lamp or motor ground cir-

cuit

Harness or connector be- tween IPDM E/R and appli-

cable system

IPDM E/R

A/C compressor does not operate Perform auto active test.

Does the magnet clutch oper-

ate?YES

A/C auto amp. signal input

circuit

CAN communication signal

between A/C auto amp. and

ECM

CAN communication signal

between ECM and IPDM E/

R

NO Magnet clutch

Harness or connector be-

tween IPDM E/R and mag-

net clutch

IPDM E/R

Revision: 2010 May2011 QX56

Page 1538 of 5598

DLK-2

DOOR LOCK .............................................................39

DOOR LOCK : CONSULT-III Function (BCM -

DOOR LOCK) .........................................................

39

INTELLIGENT KEY ................................................ ...40

INTELLIGENT KEY : CONSULT-III Function

(BCM - INTELLIGENT KEY) ...................................

41

TRUNK ................................................................... ...44

TRUNK : CONSULT-III Function (BCM - TRUNK) ...44

DIAGNOSIS SYSTEM (AUTOMATIC BACK

DOOR CONTROL UNIT) ...................................

45

CONSULT-III Function (AUTOMATIC BACK

DOOR CONTROL UNIT) ..................................... ...

45

ECU DIAGNOSIS INFORMATION ..............46

BCM ................................................................ ...46

List of ECU Reference ......................................... ...46

AUTOMATIC BACK DOOR CONTROL MOD-

ULE ....................................................................

47

Reference Value .................................................. ...47

Fail Safe .................................................................49

DTC Inspection Priority Chart ..............................49

DTC Index ..............................................................50

WIRING DIAGRAM .....................................51

DOOR & LOCK SYSTEM ............................... ...51

Wiring Diagram - DOOR & LOCK SYSTEM - ...... ...51

AUTOMATIC BACK DOOR SYSTEM ...............66

Wiring Diagram - AUTOMATIC BACK DOOR

SYSTEM - ............................................ ...................

66

INTEGRATED HOMELINK TRANSMITTER

SYSTEM ............ .............................................. ...

75

Wiring Diagram - INTEGRATED HOMELINK

TRANSMITTER SYSTEM - ....................................

75

BASIC INSPECTION ...... .............................77

DIAGNOSIS AND REPAIR WORK FLOW ..... ...77

Work Flow ............................................................ ...77

INSPECTION AND ADJUSTMENT ...................80

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ...

80

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Description ....

80

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Work Proce-

dure ........................................................................

80

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (BCM) ......................................... ...

80

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (BCM) : Description ....................

80

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (BCM) : Work Procedure .......... ...

80

ADDITIONAL SERVICE WHEN REPLACING (AU-

TOMATIC BACK DOOR CONTROL MODULE) .......

80

ADDITIONAL SERVICE WHEN REPLACING

(AUTOMATIC BACK DOOR CONTROL MOD-

ULE) : Description ................................................ ...

80

ADDITIONAL SERVICE WHEN REPLACING

(AUTOMATIC BACK DOOR CONTROL MOD-

ULE) : Work Procedure ........................................ ...

80

DTC/CIRCUIT DIAGNOSIS ........................82

U1000 CAN COMM CIRCUIT ......................... ...82

Description ........................................................... ...82

DTC Logic ...............................................................82

Diagnosis Procedure ...............................................82

U1010 CONTROL UNIT (CAN) .........................83

DTC Logic ............................................................ ...83

Diagnosis Procedure ...............................................83

B2401 IGNITION POWER SUPPLY CIRCUIT ...84

DTC Logic ............................................................ ...84

Diagnosis Procedure ...............................................84

B2403 ENCODER ..............................................85

DTC Logic ............................................................ ...85

Diagnosis Procedure ...............................................85

B2409 HALF LATCH SWITCH ..........................86

DTC Logic ............................................................ ...86

Diagnosis Procedure ...............................................86

Component Inspection ............................................87

B2416 TOUCH SENSOR RH ............................88

DTC Logic ............................................................ ...88

Diagnosis Procedure ...............................................88

Component Inspection ............................................89

B2417 TOUCH SENSOR LH .............................90

DTC Logic ............................................................ ...90

Diagnosis Procedure ...............................................90

Component Inspection ............................................91

B2419 OPEN SWITCH ......................................92

DTC Logic ............................................................ ...92

Diagnosis Procedure ...............................................92

Component Inspection ............................................93

B2420 CLOSE SWITCH ....................................95

DTC Logic ............................................................ ...95

Diagnosis Procedure ...............................................95

Component Inspection ............................................96

B2421 CLUTCH OPERATION TIME .................97

DTC Logic ............................................................ ...97

Diagnosis Procedure ...............................................97

B2422 BACK DOOR STATE .............................98

DTC Logic ............................................................ ...98

Revision: 2010 May2011 QX56

Page 1551 of 5598

COMPONENT PARTSDLK-15

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

AUTOMATIC BACK DOOR SYST EM : Component DescriptionINFOID:0000000006225836

7. Touch sensor LH 8. Back door request switch 9. Back door lock assembly

10. Back door opener switch 11. Automatic back door close switch 12. Automatic back door warning buzzer

13. Touch sensor RH

A. View with luggage side finisher up-

per removed B. View with back door finisher inner re-

moved

Item Function

Automatic back door control mod-

ule Automatic back door control unit, encoder, automatic back door motor and clutch are in-

stalled

Automatic back door control unit: Controls the automatic back door system

Encoder: Automatic back door control unit receives the pulse signals from encoders A

and B that occurred due to synchronization with the back door operation. The automatic

back door control unit calculates the back door position, operation direction, and opera-

tion speed according to the received pulse signals.

Automatic back door motor: Inputs open/close signal from automatic back door control

unit and activates the automatic back door open/close operation.

Clutch: Performs the duty control of the power supply to control the operation speed of the back door.

BCM Transmits and receives signals to the automatic back door control module

ABS actuator and electric unit Transmits vehi cle speed signal to CAN communication line

Combination meter Transmits vehicle speed signal to CAN communication line

Automatic back door warning buzz-

er Warns the user of the automatic back door condition and inappropriate operations with the

buzzer sounds

Touch sensor LH/RH During back door close operation, the touch sensor detects any trapped foreign material

Back door opener switch Detects if back door opener switch is press/release

Back door request switch Detects if back door request switch is press/release

Automatic back door switch Detects if automatic back door switch is press/release

Automatic back door main switch Detects if automatic back door main switch is press/release

Automatic back door close switch Detects if automatic back door close switch is press/release

Back door lock assembly Back door closure motor, half latch switch, open switch, close switch and back door switch

are installed

Closure motor: Inputs open/close signal from automatic back door control unit and acti-

vates the back door auto closure operation

Half latch switch: Starts the closure motor close operation

Open switch: Stops the closure motor open operation

Close switch: Stops the closure motor close operation

Back door switch: Inputs back door open/ close condition to BCM

Revision: 2010 May2011 QX56

Page 1569 of 5598

SYSTEM (AUTOMATIC BACK DOOR SYSTEM)

DLK-33

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

INTERMITTENT CLUTCH FUNCTION

If the main switch is turned to OFF during auto operation, the back door may be closed suddenly because the

operation is interrupted immediately when the operati on cannot be continued because of the detection of a

system malfunction. Therefore, operat e the clutch intermittently to stabilize the back door behavior and ensure

safety.

AUTOMATIC BACK DOOR OPEN/CLOSE OPERATION CONDITION

*: If the registered Intelligent Key is used, the operation can be performed even if the back door is in the LOCK position

CONTROL IF NOT WITHIN THE OPERAT ION CONDITIONS DURING THE OPERATION

If the back door is not within the operation conditions dur ing the operation, the automatic back door control unit

performs the control as follows.

Non-reverse area Just after starting the mo-

tor operation

Full range of closure oper- ation

Driving Back door open operation

Closure [open (return the latch to the neutral position)]

Switch operation during reverse op-

eration Receive

Number of allowable reverse opera-

tions Perform the intermittent clutch function after 2 reverse operations regardless of the oper-

ation direction

Detection method Encoder pulse Touch sensor

Automatic back door switch Intelligent Key

Automat-

ic back

door close switch Back door opener

switch

Operating direction Fully closed → Open Fully open

→ Closed Fully

closed →

Open Fully open

→ Closed Fully open

→ Closed Fully closed

→ Open

Main switch — — — — ON ON

Ignition position ON ACC/

LOCK ———ON

ACC/

LOCK

Shift selector lever P position — — — — — P position —

Vehicle speed 0 km/h

Back door lock condition — — — — — Unlock*

Touch sensor Normal

Power supply

(Automatic power back

door control unit) Approx. 11 V or more

Item

(Condition) Back door condition

Main Switch (ON → OFF) Motor: OFF

Clutch: OFF (Intermittent clutch function)

Vehicle stop condition (open operation)

IGN ON and shift P position →IGN ON and

other than P position

IGN OFF and shift N position → IGN ON and

N position The operation is continued

Operation condition release during the opera-

tion start announcement condition Automatic back door function does not operate

Revision: 2010 May2011 QX56