clutch INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1818 of 5598

![INFINITI QX56 2011 Factory Owners Manual

DLN-16

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

STRUCTURE AND OPERATION

1. Transfer control unit supplies command current to transfer motor.

2. Transfer motor operates and actuator shaft rotates cloc INFINITI QX56 2011 Factory Owners Manual

DLN-16

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

STRUCTURE AND OPERATION

1. Transfer control unit supplies command current to transfer motor.

2. Transfer motor operates and actuator shaft rotates cloc](/img/42/57033/w960_57033-1817.png)

DLN-16

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

STRUCTURE AND OPERATION

1. Transfer control unit supplies command current to transfer motor.

2. Transfer motor operates and actuator shaft rotates clockwise.

3. Shift fork operates according to rotation of actuator shaft. Sun gear and Hi-Lo sleeve are engaged.

4. Ball ramp lever operates in axial direction via cam fixed on actuator shaft according to traction torque of

transfer motor, presses piston, and thrusts multiple plate clutch.

5. Torque is transmitted to front wheels according to thrusting pressure of multiple plate clutch. NOTE:

Torque transmitted to the front wheel is determined according to the command current.

4L MODE

1. Main shaft 2. Ball lamp lever 3. Piston

4. Clutch 5. Hi-Lo sleeve 6. Sun gear

7. Shift fork 8. Actuator shaft 9. Transfer control actuator

JPDIE0278GB

Revision: 2010 May2011 QX56

Page 1904 of 5598

![INFINITI QX56 2011 Factory Owners Manual

DLN-102

< SYMPTOM DIAGNOSIS >[TRANSFER: ATX90A]

4WD WARNING LAMP BLINKS QUICKLY

4WD WARNING LAMP BLINKS QUICKLY

DescriptionINFOID:0000000006222318

While driving, 4WD warning lamp blinks 2 times in 1 INFINITI QX56 2011 Factory Owners Manual

DLN-102

< SYMPTOM DIAGNOSIS >[TRANSFER: ATX90A]

4WD WARNING LAMP BLINKS QUICKLY

4WD WARNING LAMP BLINKS QUICKLY

DescriptionINFOID:0000000006222318

While driving, 4WD warning lamp blinks 2 times in 1](/img/42/57033/w960_57033-1903.png)

DLN-102

< SYMPTOM DIAGNOSIS >[TRANSFER: ATX90A]

4WD WARNING LAMP BLINKS QUICKLY

4WD WARNING LAMP BLINKS QUICKLY

DescriptionINFOID:0000000006222318

While driving, 4WD warning lamp blinks 2 times in 1 second and it turns OFF after 1 minute.

This symptom protects drivetrain parts when a heavy

load is applied to the electric controlled coupling and

multiple disc clutch temperature increases. Also, opt ional distribution of torque sometimes becomes rigid

before lamp blinks quickly. Both cases are not malfunction.

When this symptom occurs, stop vehicle and allow it to idle for some times. Blinking will stop and system will be restored.

Revision: 2010 May2011 QX56

Page 2737 of 5598

![INFINITI QX56 2011 Factory Owners Manual

DIAGNOSIS SYSTEM (IPDM E/R)EXL-27

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000006368066

AUTO ACTIVE TEST

Descr INFINITI QX56 2011 Factory Owners Manual

DIAGNOSIS SYSTEM (IPDM E/R)EXL-27

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000006368066

AUTO ACTIVE TEST

Descr](/img/42/57033/w960_57033-2736.png)

DIAGNOSIS SYSTEM (IPDM E/R)EXL-27

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000006368066

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure warning lamp

Rear window defogger

Front wiper (LO, HI)

Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp

Headlamp (LO, HI)

A/C compressor (magnet clutch)

Operation Procedure

CAUTION:

Never perform auto active test in the following conditions.

Engine is running.

CONSULT-III is connected.

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, pr ess the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

CAUTION:

Engine starts when ignition switch is turned ON while brake pedal is depressed.

5. The oil pressure warning lamp starts blinking when the auto active test starts.

6. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test has to be cancelled halfw ay through test, turn the ignition switch OFF.

When auto active test is not activated, door swit ch may be the cause. Check door switch. Refer to DLK-117,

"ComponentFunctionCheck".

Inspection in Auto Active Test

When auto active test is actuated, the following operation sequence is repeated 3 times.

Operation

sequence Inspection location Operation

1 Oil pressure warning lamp Blinks continuously during operation of auto active test

2 Rear window defogger 10 seconds

3 Front wiper LO for 5 seconds → HI for 5 seconds

4 Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp 10 seconds

Revision: 2010 May2011 QX56

Page 2738 of 5598

![INFINITI QX56 2011 Factory Owners Manual

EXL-28

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of auto active test

IPDM E/R starts the auto active test with the door

switch signals transmitted by BCM via CAN commu INFINITI QX56 2011 Factory Owners Manual

EXL-28

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of auto active test

IPDM E/R starts the auto active test with the door

switch signals transmitted by BCM via CAN commu](/img/42/57033/w960_57033-2737.png)

EXL-28

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of auto active test

IPDM E/R starts the auto active test with the door

switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test

5 Headlamp LO for 10 seconds →HI ON ⇔ OFF 5 times

6 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

Operation

sequence Inspection location Operation

JMMIA0492GB

Symptom Inspection contents Possible cause

Rear window defogger does not operate Perform auto active test.

Does the rear window defog-

ger operate?YES BCM signal input circuit

NO Rear window defogger

Rear window defogger

ground circuit

Harness or connector be- tween IPDM E/R and rear

window defogger

IPDM E/R

Any of the following components do not operate

Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp

Headlamp (HI, LO)

Front wiper (HI, LO) Perform auto active test.

Does the applicable system

operate?YES BCM signal input circuit

NO Lamp or motor

Lamp or motor ground cir-

cuit

Harness or connector be- tween IPDM E/R and appli-

cable system

IPDM E/R

A/C compressor does not operate Perform auto active test.

Does the magnet clutch oper-

ate?YES

A/C auto amp. signal input

circuit

CAN communication signal

between A/C auto amp. and

ECM

CAN communication signal

between ECM and IPDM E/

R

NO Magnet clutch

Harness or connector be-

tween IPDM E/R and mag-

net clutch

IPDM E/R

Revision: 2010 May2011 QX56

Page 2978 of 5598

GI-14

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

ABBREVIATIONS

Abbreviation ListINFOID:0000000006280882

The following ABBREVIATIONS are used:

A

B

C

D

ABBREVIATION DESCRIPTION

A/C Air conditioner

A/C Air conditioning

A/F sensor Air fuel ratio sensor A/T Automatic transaxle/transmission

ABS Anti-lock braking system

ACCS Advance climate control system ACL Air cleaner

AP Accelerator pedal

APP Accelerator pedal position ATF Automatic transmission fluid AV Audio visual

AWD All wheel drive

ABBREVIATION DESCRIPTION BARO Barometric pressureBCM Body control module

BLSD Brake limited slip differential BPP Brake pedal positionBSI Blind spot intervention

BSW Blind spot warning

ABBREVIATION DESCRIPTION CKP Crankshaft positionCL Closed loop

CMP Camshaft position CPP Clutch pedal positionCTP Closed throttle position

CVT Continuously Variable transaxle/transmission

ABBREVIATION DESCRIPTION D

1Drive range first gear

D

2Drive range second gear

D

3Drive range third gear

D

4Drive range fourth gear

DCA Distance control assist DFI Direct fuel injection system

DLC Data link connector

DTC Diagnostic trouble code

Revision: 2010 May2011 QX56

Page 3057 of 5598

HA-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION HA

A

B

HA

N

O P

CONTENTS

HEATER & AIR CONDITIONING SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

Precautions For Refrigerant System Service ............4

Service Equipment ....................................................6

PREPARATION ............................................9

PREPARATION .............................................. .....9

Special Service Tool ........................................... ......9

Commercial Service Tool ........................................12

Sealant or/and Lubricant .........................................12

SYSTEM DESCRIPTION .............................13

COMPONENT PARTS ................................... ....13

Component Parts Location .................................. ....13

Component Description ...........................................13

SYSTEM .............................................................14

System Diagram .................................................. ....14

System Description .................................................14

BASIC INSPECTION ...................................16

DIAGNOSIS AND REPAIR WORKFLOW ..... ....16

Work Flow ........................................................... ....16

REFRIGERANT ..................................................18

Description .......................................................... ....18

Leak Test ................................................................18

Recycle Refrigerant .................................................20

Charge Refrigerant ..................................................20

LUBRICANT ................................................... ....22

Description .......................................................... ....22

Inspection ............................................................ ....22

Perform Lubricant Return Operation .......................22

Lubricant Adjusting Procedure for Components

Replacement Except Compressor ...........................

22

Lubricant Adjusting Procedure for Compressor

Replacement ...........................................................

23

PERFORMANCE TEST ....................................25

Inspection ................................................................25

SYMPTOM DIAGNOSIS ..............................27

REFRIGERATION SYSTEM SYMPTOMS ........27

Trouble Diagnosis For Unusual Pressure ............ ....27

Symptom Table .......................................................27

NOISE ................................................................29

Symptom Table .......................................................29

REMOVAL AND INSTALLATION ...............30

COMPRESSOR .................................................30

Exploded View ..................................................... ....30

COMPRESSOR ..........................................................30

COMPRESSOR : Removal and Installation ............30

MAGNET CLUTCH ................................................ ....31

MAGNET CLUTCH : Removal and Installation of

Compressor Clutch ..................................................

31

Inspection ................................................................32

COOLER PIPE AND HOSE ..............................33

Exploded View .........................................................33

HIGH-PRESSURE FLEXIBLE HOSE ........................34

HIGH-PRESSURE FLEXIBLE HOSE : Removal

and Installation .................................................... ....

34

LOW-PRESSURE FLEXIBLE HOSE ..................... ....35

LOW-PRESSURE FLEXIBLE HOSE : Removal

and Installation ........................................................

35

HIGH-PRESSURE PIPE ............................................35

Revision: 2010 May2011 QX56

Page 3061 of 5598

PRECAUTIONSHA-5

< PRECAUTION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

- Never allow lubricant (A/C System Oil Type R) to come in contact with styrene foam parts. Damage

may result.

REFRIGERANT CONNECTION

A new type refrigerant connection has been introduced to a ll refrigerant lines except the following location.

Expansion valve to evaporator

Refrigerant pressure sensor to liquid tank

WARNING:

Check that all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loo sen the discharge side hose fitting and remove it.

CAUTION:

Observe the following when replacing or cleaning refrigerant cycle components.

Store it in the same way at it is when mounted on the car when the compressor is removed. Failure

to do so will cause lubricant to enter the low-pressure chamber.

Use always a torque wrench and a b ack-up wrench when connecting tubes.

Plug immediately all openings to prevent entry of dust and mois ture after disconnecting tubes.

Connect the pipes at the final stag e of the operation when installing an air conditioner in the vehicle.

Never remove the seal caps of pipes and other compon ents until just before required for connection.

Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

Remove thoroughly moisture from the refriger ation system before charging the refrigerant.

Replace always used O-rings.

Apply lubricant to circle of th e O-rings shown in illustration when connecting tube. Be careful not to

apply lubricant to threaded portion.

O-ring must be closely attached to the groove portion of tube.

Be careful not to damage O-ring and tube when replacing the O-ring.

Connect tube until a click can be heard. Then tighten the nut or bolt by hand. Check that the O-ring is

installed to tube correctly.

Perform leakage test and make sure that there is no leakage from connections after connecting line.

Disconnect that line and replace the O-ring when the refrigerant leaking point is found. Then tighten

connections of seal seat to the specified torque.

COMPRESSOR

CAUTION:

Plug all openings to prevent moisture and foreign matter from entering.

Store it in the same way at it is when moun ted on the car when the compressor is removed.

Follow “MAINTENANCE OF LUBRICANT LEVEL IN CO MPRESSOR” exactly when replacing or repair-

ing compressor. Refer to HA-22, "

Description".

Keep friction surfaces between clutch and pulley cl ean. Wipe it off by using a clean waste cloth

moistened with thinner if the surface is contaminated with lubricant.

Name A/C System Oil Type S

RHA861F

Revision: 2010 May2011 QX56

Page 3062 of 5598

HA-6

< PRECAUTION >

PRECAUTIONS

Turn the compressor shaft by hand more than five turns in both directions after compressor service

operation. This distributes equall y lubricant inside the compressor. Let the engine idle and operate

the compressor for one hour after the compressor is installed.

Apply voltage to the new one and check for norma l operation after replacing the compressor magnet

clutch.

LEAK DETECTION DYE

CAUTION:

The A/C system contains a fluorescent leak detect ion dye used for locating refrigerant leakages. An

ultraviolet (UV) lamp is required to il luminate the dye when inspecting for leakages.

Wear always fluorescence enhancing UV safety goggles to protect eyes and enhance the visibility of

the fluorescent dye.

The fluorescent dye leak detector is not a replacem ent for an electrical leak detector. The fluorescent

dye leak detector should be used in conjunction with an electrical leak detector to pin-point refriger-

ant leakages.

Read and follow all manufacture’ s operating instructions and precau tions prior to performing the

work for the purpose of safet y and customer’s satisfaction.

A compressor shaft seal should not necessarily be repaired because of dye seepage. The compres-

sor shaft seal should only be repaired after conf irming the leakage with an electrical leak detector.

Remove always any remaining dye from the leakage area after repairs are completed to avoid a mis-

diagnosis during a future service.

Never allow dye to come into contact with painted body panels or interior components. Clean imme-

diately with the approved dye cl eaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

Never spray the fluorescent dye cleaning agent on hot surfaces (eng ine exhaust manifold, etc.).

Never use more than one refrigerant dye bottle [1/4 ounce (7.4 cc)] per A/C system.

Leak detection dyes for HFC-134a (R-134a) and CFC- 12 (R-12) A/C systems are different. Never use

HFC-134a (R-134a) leak detection dye in CFC-12 (R- 12) A/C system, or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system, or A/C system damage may result.

The fluorescent properties of the dye remains fo r three or more years unless a compressor malfunc-

tion occurs.

NOTE:

Identification

Vehicles with factory installed fluorescent dye have a green label.

Vehicles without factory installed fluorescent dye have a blue label.

Service EquipmentINFOID:0000000006276140

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRICAL LEAK DETECTOR

Be certain to follow the manufacturer’s instruct ions for tester operation and tester maintenance.

VACUUM PUMP

Revision: 2010 May2011 QX56

Page 3079 of 5598

LUBRICANTHA-23

< BASIC INSPECTION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

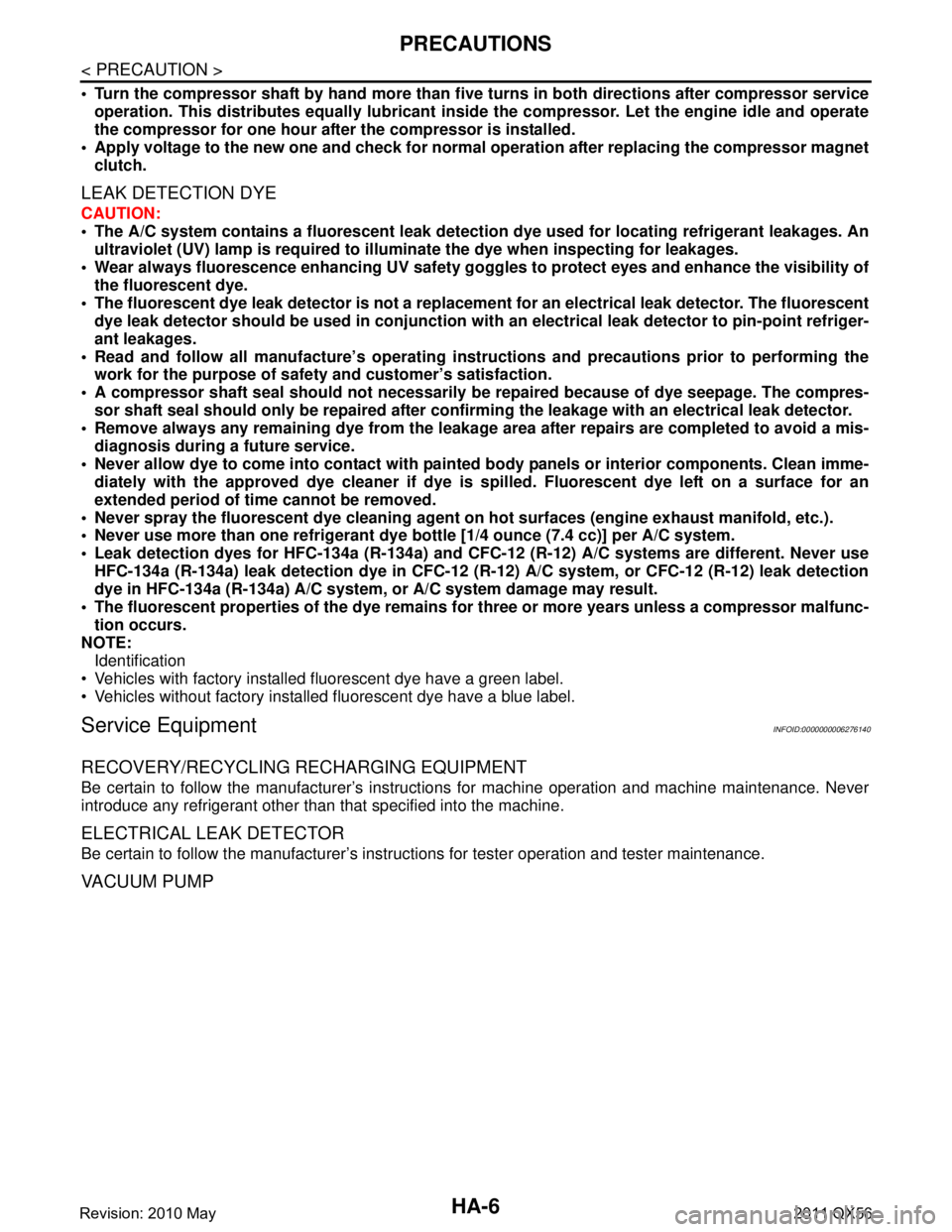

Lubricant Adjusting Procedur e for Compressor ReplacementINFOID:0000000006276157

1. Drain lubricant from removed compressor and measure lubricant amount.

1. Drain lubricant from high-pressure port (A) and low-pres-

sure port (B) while rotating magnet clutch.

2. Measure total amount of lubricant that is drained from removed compressor.

2. Drain lubricant from a new compressor that is calculated accord- ing to the following conditions.

CAUTION:

If lubricant amount that is drained from removed compressor is less than 60 m (2.1 Imp fl oz.),

perform calculation by setting “D” as 40 m (1.4 Imp fl oz.).

Conditions Lubricant amount to be added to A/C system

m (Imp fl oz.)

Replace evaporator A/C unit 75 (2.6)

Rear A/C unit 75 (2.6)

Replace condenser 75 (2.6)

Replace liquid tank 5 (0.2)

Refrigerant leakage is detected Large amount leakage 30 (1.1)

Small amount leakage —

Lubricant amount that is recycled together with refrigerant during recycle operation α

JMIIA0675ZZ

Amount to be drained (A) [m (Imp fl oz.)] = F − (D

+ S + R + α)

F : Lubricant amount that a new compressor contains [210 (7.1)]

D : Lubricant amount that is drained from re- moved compressor

S : Lubricant amount that remains inside of re-

moved compressor [20 (0.7)]

R : Lubricant amount to be added according to components that are removed except com-

pressor

α : Lubricant amount that is recycled together

with refrigerant during recycle operation

Conditions Lubricant amount to be added to A/C system

m (Imp fl oz.)

Replace evaporator Front 75 (2.6)

Rear 75 (2.6)

Replace condenser 75 (2.6)

Replace liquid tank 5 ( 0.2)

JPIIA1455GB

Revision: 2010 May2011 QX56

Page 3085 of 5598

NOISEHA-29

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

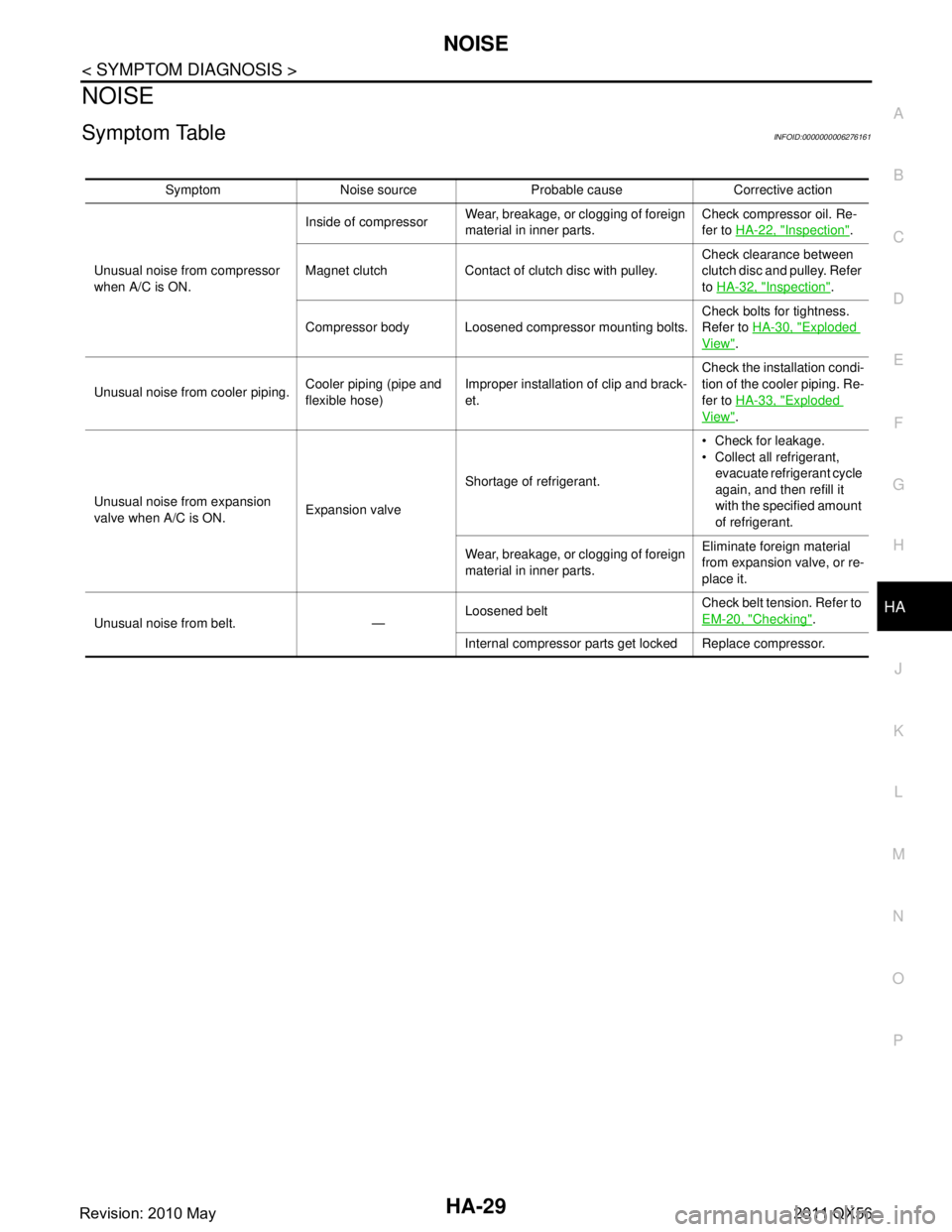

NOISE

Symptom TableINFOID:0000000006276161

Symptom Noise source Probable cause Corrective action

Unusual noise from compressor

when A/C is ON. Inside of compressor

Wear, breakage, or clogging of foreign

material in inner parts. Check compressor oil. Re-

fer to

HA-22, "

Inspection".

Magnet clutch Contact of clutch disc with pulley. Check clearance between

clutch disc and pulley. Refer

to

HA-32, "

Inspection".

Compressor body Loosened compressor mounting bolts. Check bolts for tightness.

Refer to

HA-30, "

Exploded

View".

Unusual noise from cooler piping. Cooler piping (pipe and

flexible hose)Improper installation of clip and brack-

et. Check the installation condi-

tion of the cooler piping. Re-

fer to

HA-33, "

Exploded

View".

Unusual noise from expansion

valve when A/C is ON. Expansion valveShortage of refrigerant. Check for leakage.

Collect all refrigerant,

evacuate refrigerant cycle

again, and then refill it

with the specified amount

of refrigerant.

Wear, breakage, or clogging of foreign

material in inner parts. Eliminate foreign material

from expansion valve, or re-

place it.

Unusual noise from belt. — Loosened belt

Check belt tension. Refer to

EM-20, "

Checking".

Internal compressor parts ge t locked Replace compressor.

Revision: 2010 May2011 QX56