height INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5 of 5598

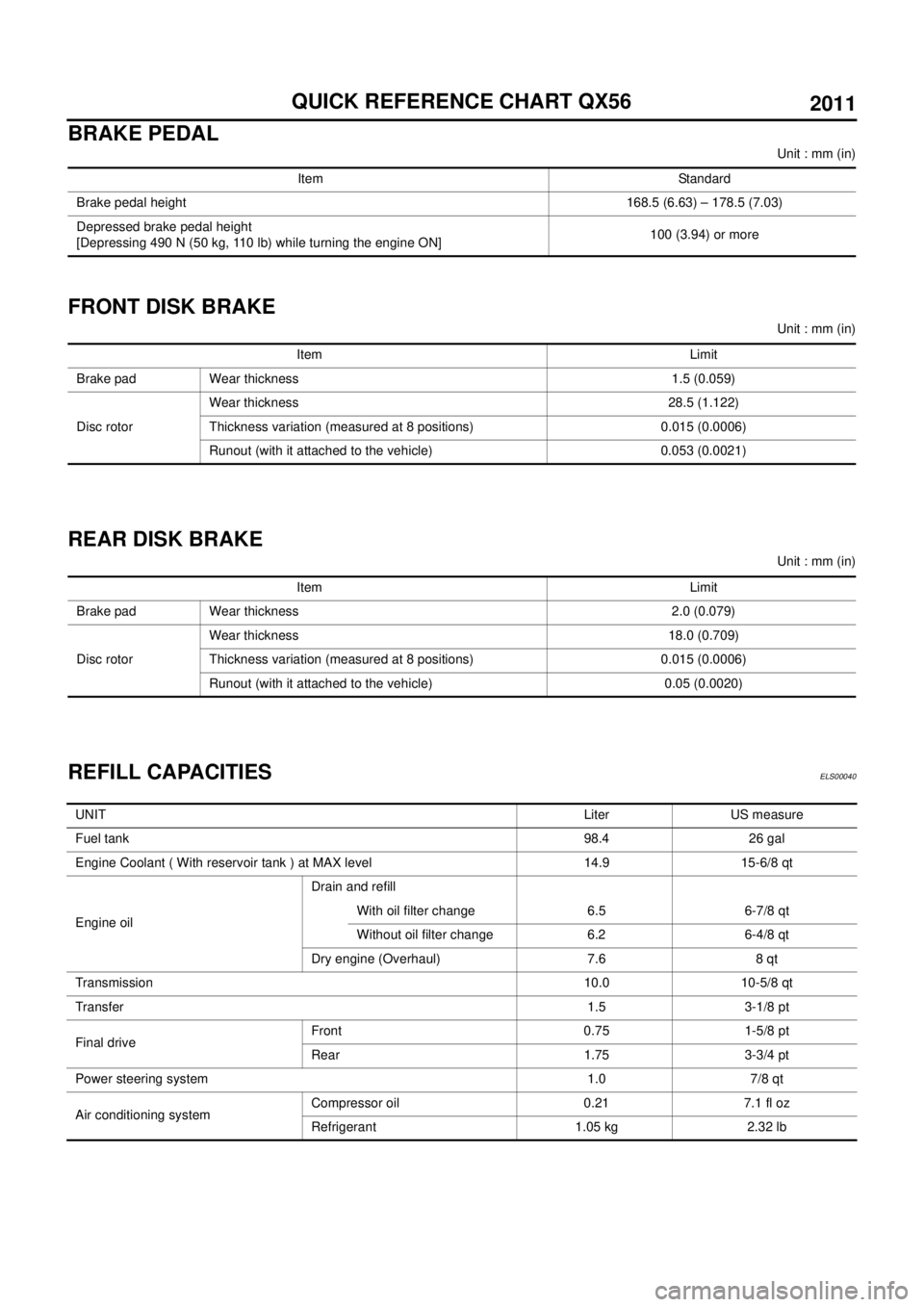

QUICK REFERENCE CHART QX56

BRAKE PEDAL

Unit : mm (in)

FRONT DISK BRAKE

Unit : mm (in)

REAR DISK BRAKE

Unit : mm (in)

REFILL CAPACITIESELS00040

Item Standard

Brake pedal height 168.5 (6.63) – 178.5 (7.03)

Depressed brake pedal height

[Depressing 490 N (50 kg, 110 lb) while turning the engine ON] 100 (3.94) or more

Item Limit

Brake pad Wear thickness 1.5 (0.059)

Disc rotor Wear thickness 28.5 (1.122)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.053 (0.0021)

Item Limit

Brake pad Wear thickness 2.0 (0.079)

Disc rotor Wear thickness 18.0 (0.709)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.05 (0.0020)

UNIT

Liter US measure

Fuel tank 98.4 26 gal

Engine Coolant ( With reservoir tank ) at MAX level 14.9 15-6/8 qt

Engine oil Drain and refill

With oil filter change 6.5 6-7/8 qt

Without oil filter change 6.2 6-4/8 qt

Dry engine (Overhaul) 7.6 8 qt

Transmission 10.0 10-5/8 qt

Transfer 1.5 3-1/8 pt

Final drive Front 0.75 1-5/8 pt

Rear 1.75 3-3/4 pt

Power steering system 1.0 7/8 qt

Air conditioning system Compressor oil 0.21 7.1 fl oz

Refrigerant 1.05 kg 2.32 lb

2011

Page 477 of 5598

BRAKE PEDALBR-7

< PERIODIC MAINTENANCE >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

PERIODIC MAINTENANCE

BRAKE PEDAL

Inspection and AdjustmentINFOID:0000000006222462

INSPECTION

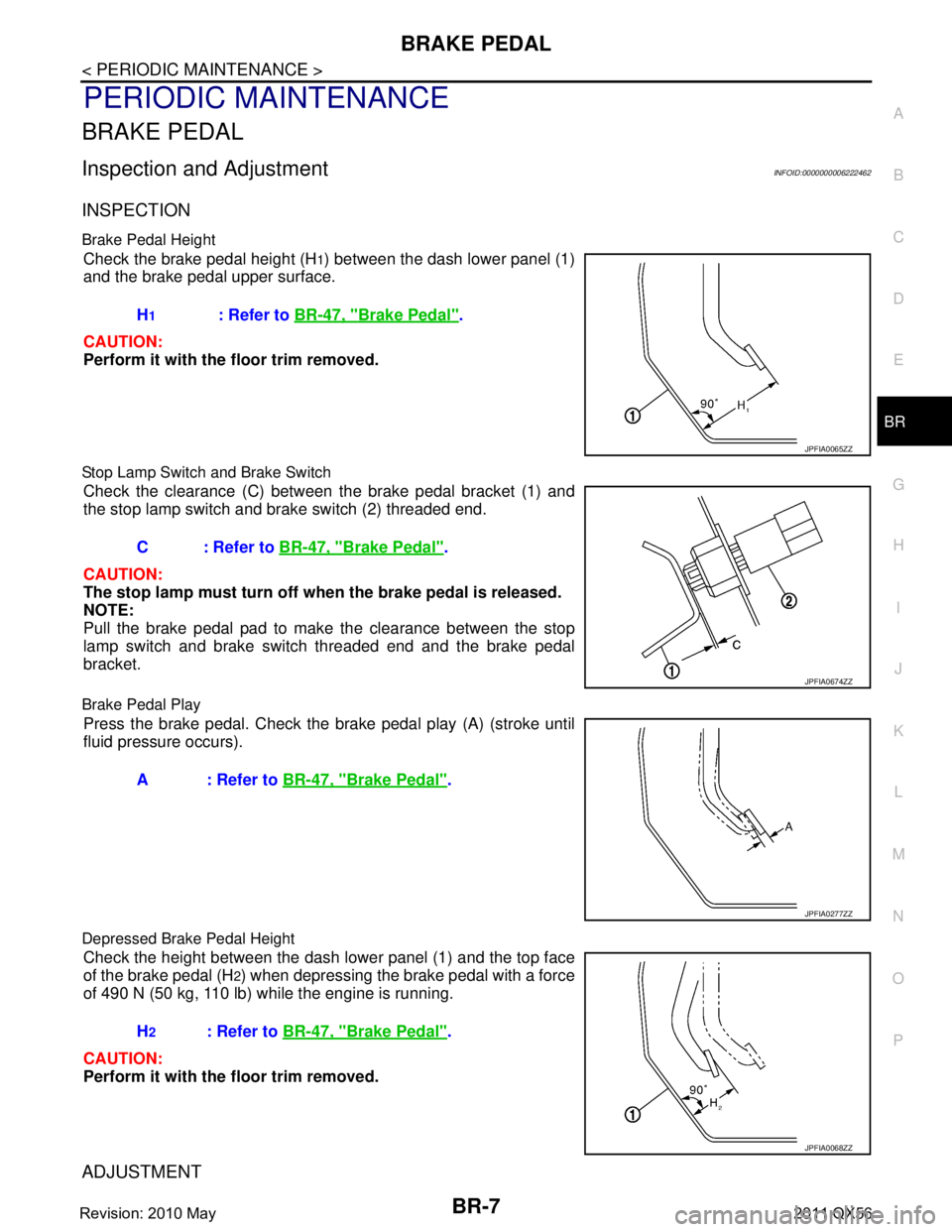

Brake Pedal Height

Check the brake pedal height (H1) between the dash lower panel (1)

and the brake pedal upper surface.

CAUTION:

Perform it with the floor trim removed.

Stop Lamp Switch and Brake Switch

Check the clearance (C) between the brake pedal bracket (1) and

the stop lamp switch and brake switch (2) threaded end.

CAUTION:

The stop lamp must turn off when the brake pedal is released.

NOTE:

Pull the brake pedal pad to make the clearance between the stop

lamp switch and brake switch threaded end and the brake pedal

bracket.

Brake Pedal Play

Press the brake pedal. Check the brake pedal play (A) (stroke until

fluid pressure occurs).

Depressed Brake Pedal Height

Check the height between the dash lower panel (1) and the top face

of the brake pedal (H

2) when depressing the brake pedal with a force

of 490 N (50 kg, 110 lb) while the engine is running.

CAUTION:

Perform it with the floor trim removed.

ADJUSTMENT

H1: Refer to BR-47, "Brake Pedal".

JPFIA0065ZZ

C : Refer to BR-47, "Brake Pedal".

JPFIA0674ZZ

A : Refer to BR-47, "Brake Pedal".

JPFIA0277ZZ

H2: Refer to BR-47, "Brake Pedal".

JPFIA0068ZZ

Revision: 2010 May2011 QX56

Page 478 of 5598

BR-8

< PERIODIC MAINTENANCE >

BRAKE PEDAL

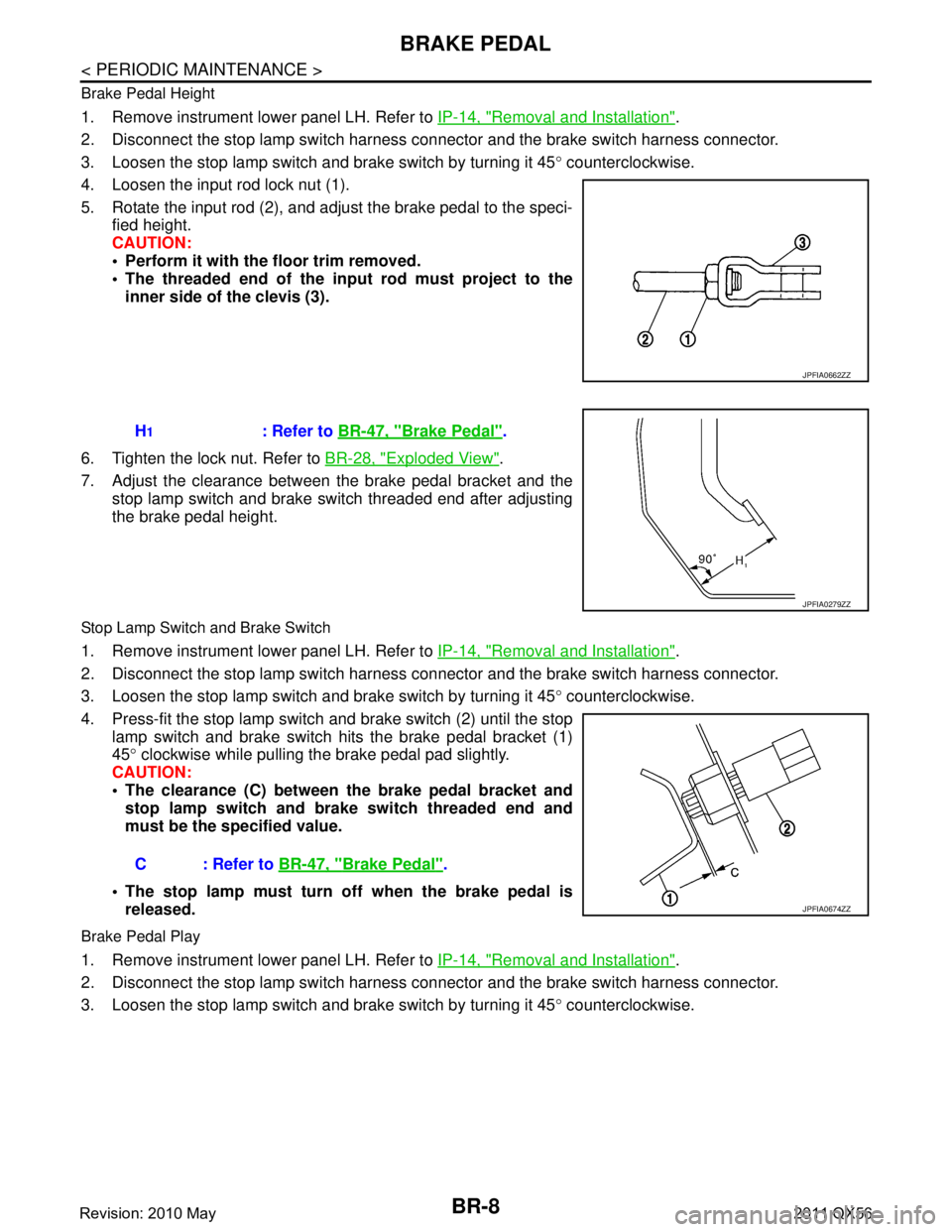

Brake Pedal Height

1. Remove instrument lower panel LH. Refer to IP-14, "Removal and Installation".

2. Disconnect the stop lamp switch harness c onnector and the brake switch harness connector.

3. Loosen the stop lamp switch and brake switch by turning it 45 ° counterclockwise.

4. Loosen the input rod lock nut (1).

5. Rotate the input rod (2), and adjust the brake pedal to the speci- fied height.

CAUTION:

Perform it with the floor trim removed.

The threaded end of the in put rod must project to the

inner side of the clevis (3).

6. Tighten the lock nut. Refer to BR-28, "

Exploded View".

7. Adjust the clearance between the brake pedal bracket and the stop lamp switch and brake switch threaded end after adjusting

the brake pedal height.

Stop Lamp Switch and Brake Switch

1. Remove instrument lower panel LH. Refer to IP-14, "Removal and Installation".

2. Disconnect the stop lamp switch harness c onnector and the brake switch harness connector.

3. Loosen the stop lamp switch and brake switch by turning it 45 ° counterclockwise.

4. Press-fit the stop lamp switch and brake switch (2) until the stop

lamp switch and brake switch hits the brake pedal bracket (1)

45 ° clockwise while pulling the brake pedal pad slightly.

CAUTION:

The clearance (C) between the brake pedal bracket and

stop lamp switch and brake switch threaded end and

must be the specified value.

The stop lamp must turn off when the brake pedal is released.

Brake Pedal Play

1. Remove instrument lower panel LH. Refer to IP-14, "Removal and Installation".

2. Disconnect the stop lamp switch harness c onnector and the brake switch harness connector.

3. Loosen the stop lamp switch and brake switch by turning it 45 ° counterclockwise.

JPFIA0662ZZ

H1: Refer to BR-47, "Brake Pedal".

JPFIA0279ZZ

C : Refer to BR-47, "Brake Pedal".

JPFIA0674ZZ

Revision: 2010 May2011 QX56

Page 479 of 5598

BRAKE PEDALBR-9

< PERIODIC MAINTENANCE >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

4. Press-fit the stop lamp switch and brake switch (2) until the stop

lamp switch and brake switch hits the brake pedal bracket (1)

45 ° clockwise while pulling the brake pedal pad slightly.

CAUTION:

The clearance (C) between the brake pedal bracket and stop lamp switch and brake switch threaded end and

must be the specified value.

The stop lamp must turn off when the brake pedal is released.

Depressed Brake Pedal Height

1. Perform the air bleeding. Refer to BR-11, "Bleeding Brake System".

2. Check the height between the dash lower panel (1) and the top face of the brake pedal (H

2) when depressing the brake pedal

with a force of 490 N (50 kg, 110 lb) while the engine is running.

CAUTION:

Perform it with the floor trim removed.

3. Adjust the brake pedal play after adjusting the brake pedal height, clearance between the brake pedal bracket and the stop

lamp switch and brake switch threaded end.C : Refer to

BR-47, "

Brake Pedal".

JPFIA0674ZZ

H2: Refer to BR-47, "Brake Pedal".

JPFIA0068ZZ

Revision: 2010 May2011 QX56

Page 517 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-47

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

G H

I

J

K L

M A

B

BR

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000006222502

Unit: mm (in)

Brake PedalINFOID:0000000006222503

Unit: mm (in)

Brake BoosterINFOID:0000000006222504

Unit: mm (in)

Front Disc BrakeINFOID:0000000006222505

Unit: mm (in)

Rear Disc BrakeINFOID:0000000006222506

Unit: mm (in)

Front brake Cylinder bore diameter 50.8 (2.000)

× 2

Pad length × width × thickness 151.6 (5.97) × 56.5 (2.224) × 12.0 (0.472)

Rotor outer diameter × thickness 350 (13.78) × 30.0 (1.181)

Rear brake Cylinder bore diameter 48.1 (10894)

Pad length

× width × thickness 110.0 (4.43) × 41.0 (1.614) × 9.0 (0.354)

Rotor outer diameter × thickness 350 (13.78) × 20.0 (0.787)

Control valve Valve type Electric brake force distribution

Recommended brake fluid Refer to MA-10, "

Fluids and Lubricants".

Item Standard

Brake pedal height 168.5 (6.63) – 178.5 (7.03)

Depressed brake pedal height

[Depressing 490 N (50 kg, 110 lb) while turning the engine ON] 100 (3.94) or more

Clearance between stop lamp switch and brake switch threaded end and the

brake pedal bracket 0.2 (0.008) – 1.96 (0.0772)

Brake pedal play 3 (0.12) – 11 (0.43)

Item Standard

Input rod length 202.2 (7.96)

Item Limit

Brake pad Wear thickness 1.5 (0.059)

Disc rotor Wear thickness 28.5 (1.122)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.053 (0.0021)

Item Limit

Brake pad Wear thickness 2.0 (0.079)

Disc rotor Wear thickness 18.0 (0.709)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.05 (0.0020)

Revision: 2010 May2011 QX56

Page 645 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-128

< SYMPTOM DIAGNOSIS >[WITH VDC]

UNEXPECTED BRAKE PEDAL REACTION

UNEXPECTED BRAKE PEDAL REACTION

DescriptionINFOID:0000000006222659

A malfunction of brake pedal feel (height or ot

hers) is det INFINITI QX56 2011 Factory Service Manual

BRC-128

< SYMPTOM DIAGNOSIS >[WITH VDC]

UNEXPECTED BRAKE PEDAL REACTION

UNEXPECTED BRAKE PEDAL REACTION

DescriptionINFOID:0000000006222659

A malfunction of brake pedal feel (height or ot

hers) is det](/img/42/57033/w960_57033-644.png)

BRC-128

< SYMPTOM DIAGNOSIS >[WITH VDC]

UNEXPECTED BRAKE PEDAL REACTION

UNEXPECTED BRAKE PEDAL REACTION

DescriptionINFOID:0000000006222659

A malfunction of brake pedal feel (height or ot

hers) is detected when brake pedal is depressed.

Diagnosis ProcedureINFOID:0000000006222660

1.CHECK FRONT AND REAR AXLE

Check that there is no excessive looseness in front and rear axle.

Front axle: Refer to FAX-7, "

Inspection" (2WD), FAX-16, "Inspection" (4WD).

Rear axle: Refer to RAX-5, "

Inspection"

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

2.CHECK DISC ROTOR

Check disc rotor runout.

Front: Refer to BR-16, "

DISC ROTOR : Inspection and Adjustment".

Rear: Refer to BR-18, "

DISC ROTOR : Inspection and Adjustment".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Refinish or replace disc rotor. Front: Refer to BR-16, "

DISC ROTOR : Inspection and Adjustment".

Rear: Refer to BR-18, "

DISC ROTOR : Inspection and Adjustment".

3.CHECK BRAKE FLUID LEACKAGE

Check fluid leakage.

Front: Refer to BR-24, "

FRONT : Inspection".

Rear: Refer to BR-26, "

REAR : Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK BRAKE PEDAL

Check each item of brake pedal. Refer to BR-7, "

Inspection and Adjustment".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Adjust each item of brake pedal. Refer to BR-7, "

Inspection and Adjustment".

5.CHECK BRAKING FORCE

Check brake force using a brake tester.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Check each components of brake system.

6.CHECK BRAKE PERFORMANCE

Disconnect ABS actuator and electric unit (control unit) connector so that ABS does not operate. Check that

brake force is normal in this condition. Connect harness connectors after checking.

Is the inspection result normal?

YES >> Normal

NO >> Check each components of brake system.

Revision: 2010 May2011 QX56

Page 776 of 5598

![INFINITI QX56 2011 Factory Service Manual

CCS

DIAGNOSIS SYSTEM (ICC SENSOR)CCS-41

< SYSTEM DESCRIPTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

DIAGNOSIS SYSTEM (ICC SENSOR)

CONSULT-III Function (LASER)INFOID:0000000006224280

APPLICATION ITEMS

INFINITI QX56 2011 Factory Service Manual

CCS

DIAGNOSIS SYSTEM (ICC SENSOR)CCS-41

< SYSTEM DESCRIPTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

DIAGNOSIS SYSTEM (ICC SENSOR)

CONSULT-III Function (LASER)INFOID:0000000006224280

APPLICATION ITEMS](/img/42/57033/w960_57033-775.png)

CCS

DIAGNOSIS SYSTEM (ICC SENSOR)CCS-41

< SYSTEM DESCRIPTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

DIAGNOSIS SYSTEM (ICC SENSOR)

CONSULT-III Function (LASER)INFOID:0000000006224280

APPLICATION ITEMS

CONSULT-III performs the following functions via CAN communication with ADAS control unit and the com-

munication with ICC sensor.

WORK SUPPORT

Laser Beam Adjust

Refer to CCS-72, "Description".

SELF DIAGNOSTIC RESULT

Refer to CCS-55, "DTC Index".

DATA MONITOR

Diagnosis mode Description

Work Support It can monitor the adjustment direction indication in order to perform the laser beam aiming operation

smoothly

Self Diagnostic Result Displays malfunctioning system memorized in ICC sensor

Data Monitor Displays real-time input/output data of ICC sensor

Ecu Identification Displays ICC sensor part number

CAN Diag Support Monitor The results of transmit/receive diagnosis of ITS communication can be read

Work support items Description

LASER BEAM ADJUST Outputs laser beam, calculates dislocation of the beam, and indicates adjustment direction

Monitored item

[Unit] Description

VHCL SPEED SE

[km/h] or [mph] Vehicle speed judged from a vehicle speed signal read by the ICC sensor via ITS communica-

tion is displayed [ADAS control unit receives a vehicle speed signal from ABS actuator and

electric unit (control unit) via CAN communication and transmits the calculated vehicle speed

to ICC sensor via ITS communication]

YAW R AT E

[deg/s] Indicates yaw rate read from ADAS control unit through ITS communication (ADAS control unit

receives yaw rate signal from ABS actuator and electric unit (control unit) via CAN communi-

cation and transmits yaw rate calculated by the ADAS control unit)

Yaw rate judged from a yaw rate signal read by ICC sensor via ITS communication is displayed

[ADAS control unit receives a yaw

rate signal from ABS actuator and electric unit (control unit)

via CAN communication and transmits the calculated yaw rate to ICC sensor via ITS commu-

nication]

PWR SUP MONI

[V] Indicates IGN voltage input by ICC sensor

DISTANCE

[m] Indicates the distance from the vehicle ahead

RELATIVE SPD

[m/s] Indicates the relative speed of the vehicle ahead

LASER OFFSET

[m] NOTE:

The item is indicated, but not used

LASER HEIGHT

[m] NOTE:

The item is indicated, but not used

STEERING ANGLE

[deg] The steering angle is displayed

STRG ANGLE SPEED

[deg/s] The steering angle speed is displayed

Revision: 2010 May2011 QX56

Page 789 of 5598

![INFINITI QX56 2011 Factory Service Manual

CCS-54

< ECU DIAGNOSIS INFORMATION >[ICC]

ICC SENSOR

ICC SENSOR

Reference ValueINFOID:0000000006224285

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

PHYSICAL VALUES

Monitor item Condition Value/Status INFINITI QX56 2011 Factory Service Manual

CCS-54

< ECU DIAGNOSIS INFORMATION >[ICC]

ICC SENSOR

ICC SENSOR

Reference ValueINFOID:0000000006224285

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

PHYSICAL VALUES

Monitor item Condition Value/Status](/img/42/57033/w960_57033-788.png)

CCS-54

< ECU DIAGNOSIS INFORMATION >[ICC]

ICC SENSOR

ICC SENSOR

Reference ValueINFOID:0000000006224285

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

PHYSICAL VALUES

Monitor item Condition Value/Status

VHCL SPEED SE While driving Value of vehicle

speed signal

(wheel speed)

YAW RATE While driving Vehicle stopped 0.0

Vehicle turning right Positive value

Vehicle turning left Negative value

PWR SUP MONI Ignition switch ON Power supply

voltage value of ICC sensor

DISTANCE Drive the vehicle and activate

the vehicle-to-vehicle distance

control mode When a vehicle ahead is detected

Displays the dis-

tance from the

preceding vehi- cle

When a vehicle ahead is not detected 0.0

RELATIVE SPD Drive the vehicle and activate

the vehicle-to-vehicle distance

control mode When a vehicle ahead is detected

Displays the rel-

ative speed

When a vehicle ahead is not detected 0.0

LASER OFFSET NOTE:

The item is indicated, but not used

—

LASER HEIGHT NOTE:

The item is indicated, but not used —

STEERING ANGLE Ignition switch ON When setting the steering wheel in straight-ahead posi-

tion

0.0

When turning the steering wheel 90 ° rightward +90

When turning the steering wheel 90 ° leftward -90

STRG ANGLE

SPEED Ignition switch ON At the time of turning the steering wheel Steering wheel

turning speed is

displayed

L/R ADJUST Ignition switch ON At the completion of laser beam adjustment Horizontal cor-

rection value is

displayed

U/D ADJUST Ignition switch ON At the completion of laser beam adjustment Vertical correc-

tion value is dis-

played

JPOIA0105ZZ

Revision: 2010 May2011 QX56

Page 807 of 5598

![INFINITI QX56 2011 Factory Service Manual

CCS-72

< BASIC INSPECTION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

DescriptionINFOID:0000000006224293

OUTLINE OF LASER BEAM AIMING ADJUSTMENT

Always adjust the laser beam aimi INFINITI QX56 2011 Factory Service Manual

CCS-72

< BASIC INSPECTION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

DescriptionINFOID:0000000006224293

OUTLINE OF LASER BEAM AIMING ADJUSTMENT

Always adjust the laser beam aimi](/img/42/57033/w960_57033-806.png)

CCS-72

< BASIC INSPECTION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

DescriptionINFOID:0000000006224293

OUTLINE OF LASER BEAM AIMING ADJUSTMENT

Always adjust the laser beam aiming after removing and installing or replacing the ICC sensor.

CAUTION:

The system does not operate normally

unless the laser beam aiming adjustment is performed. Always

perform it.

1. Set the ICC target board [SST: KV99110100 (J-45718)] to the correct position in front of the vehicle.

2. Set the laser beam aiming mode (“LASER BEAM AD JUST” on “Work support”) with CONSULT-III, and

then perform the adjustment according to the displa y. (Manually turn the up-down direction adjusting

screw for vertical adjustment. ICC sensor adjusts the automatic aiming for the horizontal direction.)

CAUTIONARY POINT FOR LASER BEAM AIMING ADJUSTMENT

CAUTION:

For laser beam aiming adjustment, choose a level location where a view can be obtained without any

obstruction as far as 12 m (39 ft) or more in the forward direction.

Adjust laser beam aiming for 5 second s or more after starting engine.

Adjust the laser beam aiming with CONSULT-III. (The laser beam aiming cannot be adjusted without

CONSULT-III.)

Never enter the vehicle during laser beam aiming adjustment.

Never look directly into the laser beam sour ce (ICC sensor body window) during laser beam aiming

adjustment.

Laser beam aiming adjustment is performed at idle. At this time, turn the headlamps OFF.

Work Procedure (Preparation)INFOID:0000000006224294

1.ADVANCE PREPARATION FOR LASER BEAM AIMING ADJUSTMENT

1. Adjust all tire pressure to the specified value.

2. Empty the vehicle. (Remove any luggage from the passenger compartment, luggage room, etc.)

3. Shift the selector lever to “P” pos ition, and release the parking brake.

4. Fully fill the fuel tank, and then check that t he coolant and oils are filled up to correct level.

5. Clean off the ICC sensor body window with a soft cloth.

>> Go to CCS-72, "

Work Procedure (Setting The ICC Tar-

get Board)".

Work Procedure (Setting The ICC Target Board)INFOID:0000000006224295

DESCRIPTION

Accurate adjustment of the laser beam requires t hat the ICC target board be accurately positioned.

CAUTION:

If the laser beam is adjusted with the ICC target board in the incorrect position, the ICC system does

not function normally.

1.ICC TARGET BOARD HEIGHT ADJUSTMENT

1 : ICC sensor

JSOIA0372ZZ

Revision: 2010 May2011 QX56

Page 808 of 5598

![INFINITI QX56 2011 Factory Service Manual

CCS

LASER BEAM AIMING ADJUSTMENTCCS-73

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

1. Attach the ruler (2) at 14 mm (0.55 in) (H) below the center (A) of\

the ICC target board (1).

2. INFINITI QX56 2011 Factory Service Manual

CCS

LASER BEAM AIMING ADJUSTMENTCCS-73

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

1. Attach the ruler (2) at 14 mm (0.55 in) (H) below the center (A) of\

the ICC target board (1).

2.](/img/42/57033/w960_57033-807.png)

CCS

LASER BEAM AIMING ADJUSTMENTCCS-73

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

1. Attach the ruler (2) at 14 mm (0.55 in) (H) below the center (A) of\

the ICC target board (1).

2. Adjust the ICC target board height to the position aligning the ruler (1) upper side tip with the center of laser beam axis (A).

NOTE:

The center of laser beam axis (A) is located at 38 mm (1.5 in) (W)

from the left end of ICC sensor and 22 mm (H) (0.87 in) from above

when viewed from the front of the vehicle.

To identify the laser beam axis center (A) easily, prepare a piece of paper (B) cut to the size of 38 mm (1.5 in) (W) × 22 mm (0.87 in)

(H) and attach it on the lower left point of the ICC sensor (1).

>> GO TO 2.

2.ADJUSTING SIDE POSITION OF ICC TARGET BOARD

3: Adjust nut

b: 90 °

JPOIA0215ZZ

2 : ICC sensor

JSOIA0351ZZ

B : Up-down direction adjusting screw

JSOIA0216ZZ

JSOIA0217ZZ

Revision: 2010 May2011 QX56