clutch ISUZU AXIOM 2002 Service Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 486 of 2100

4B2┬▒107

DRIVE LINE CONTROL SYSTEM (TOD)

StepActionYe sNo

1Is the trouble code 31(P1721) recorded?Examine the

trouble based on

ªDiagnosis from

Trouble Codes┬║.

Go to Step 2

2Is any of the trouble codes 28(P1760), 32(P1761) and 33(P1762)

recorded?Examine the

trouble based on

ªDiagnosis from

Trouble Codes┬║.

Go to Step 3

3When the TOD switch is selected to the specified position, do the

TOD indicator lamps show the correct status?

Go to Step 4

Examine the

trouble based on

ªTrouble

Diagnosis

Depending on

The Status of

TOD Indicator┬║.

4Select the TOD switch to the 4L position, fully turn the steering to

the left (or right) end, and start the creep run. Does the tight corner

braking occur?

Go to Step 5

Repair the

transfer

assembly.

Go to

Step 7

51. Select the TOD switch to the TOD position.

2. Turn on the starter switch.

Does the voltage between terminals 11 and 22 indicate at least 3V

while the throttle is completely open?

Go to Step 6

The ECU has

failed. Replace

the ECU.

Go to

Step 7

6Does the voltage between terminals 11 and 22 indicate at least

0.1V while the throttle is completely closed?The TOD clutch

is worn. Repair

the transfer

assembly.

Go to

Step 7

The ECU has

failed. Replace

the ECU.

Go to

Step 7

7Check that all the parts are mounted.

Is this step complete?

Verify the repair.Go to Step 7

Page 516 of 2100

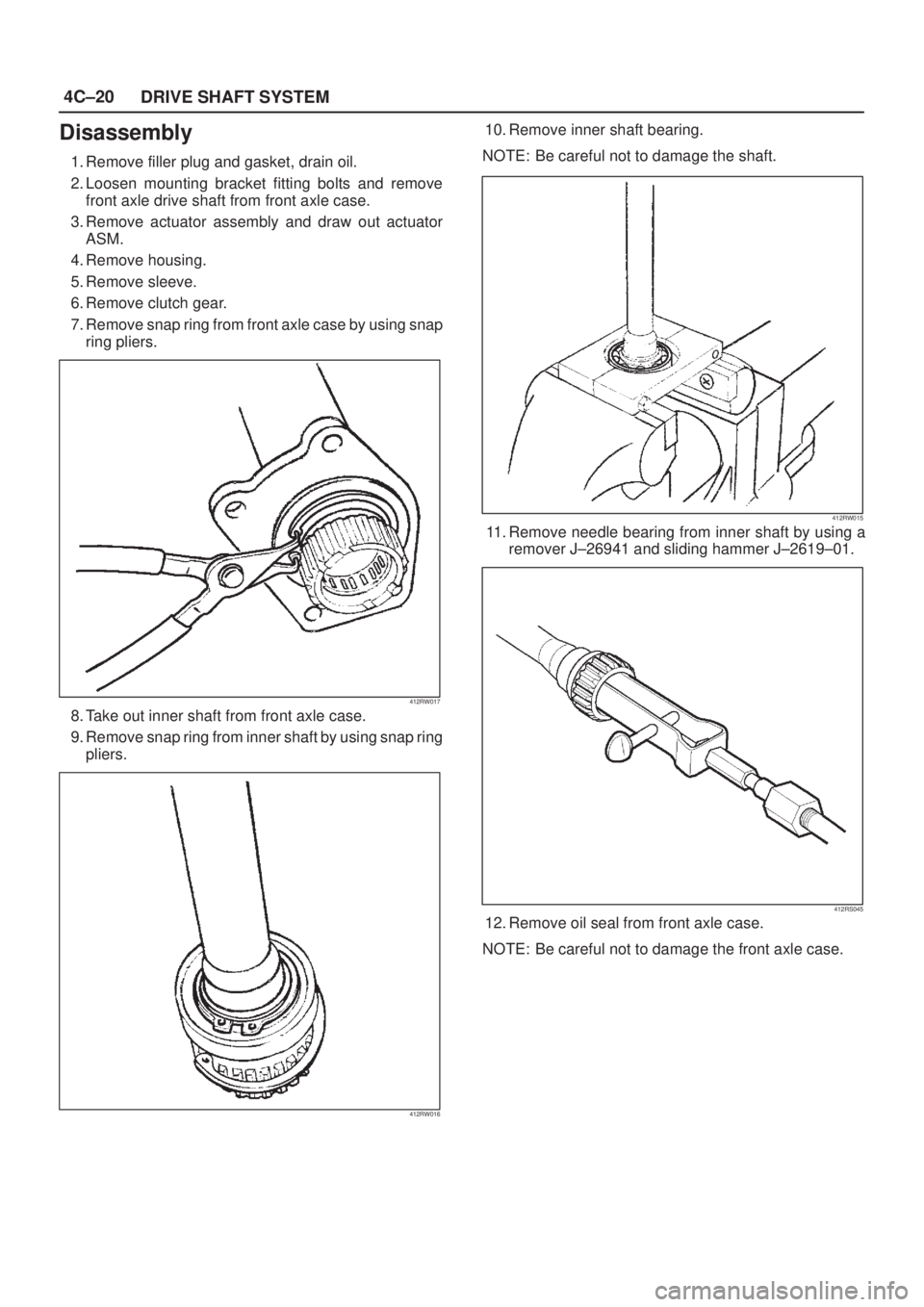

4C┬▒19 DRIVE SHAFT SYSTEM

Shift On The Fly System

Shift On The Fly System and Associated Parts

412RY00007

Legend

(1) Filler Plug

(2) Bolt

(3) Oil Seal

(4) Snap Ring(External)

(5) Inner Shaft Bearing

(6) Snap Ring(Internal)

(7) Inner Shaft(8) Needle Bearing

(9) Clutch Gear

(10) Sleeve

(11) Housing

(12) Front Axle Drive Shaft(LH side) with Bracket

(13) Bolt

(14) Actuator Assembly

(15) Bolt

Page 517 of 2100

4C┬▒20

DRIVE SHAFT SYSTEM

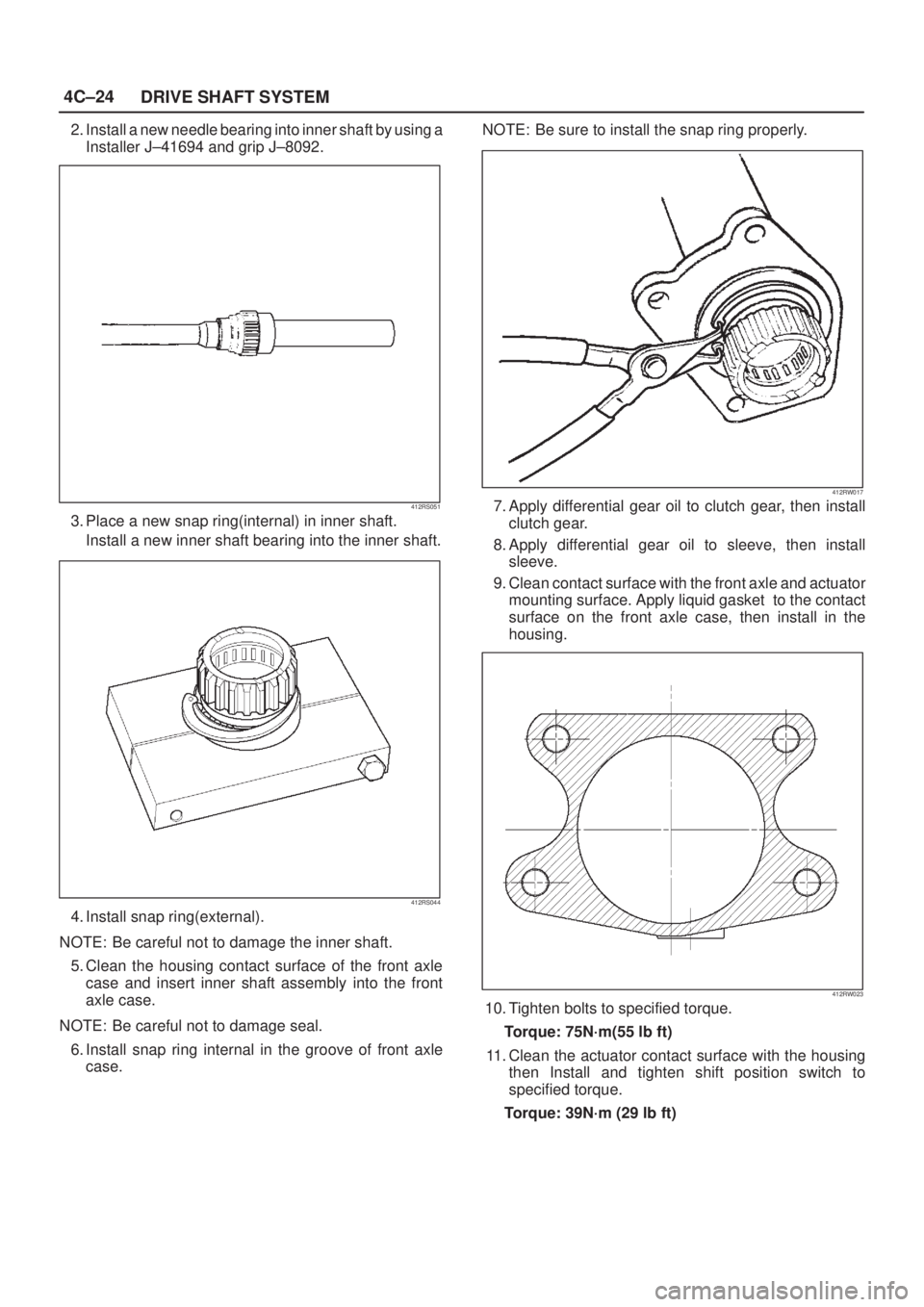

Disassembly

1. Remove filler plug and gasket, drain oil.

2. Loosen mounting bracket fitting bolts and remove

front axle drive shaft from front axle case.

3. Remove actuator assembly and draw out actuator

ASM.

4. Remove housing.

5. Remove sleeve.

6. Remove clutch gear.

7. Remove snap ring from front axle case by using snap

ring pliers.

412RW017

8. Take out inner shaft from front axle case.

9. Remove snap ring from inner shaft by using snap ring

pliers.

412RW016

10. Remove inner shaft bearing.

NOTE: Be careful not to damage the shaft.

412RW015

11. Remove needle bearing from inner shaft by using a

remover J┬▒26941 and sliding hammer J┬▒2619┬▒01.

412RS045

12. Remove oil seal from front axle case.

NOTE: Be careful not to damage the front axle case.

Page 518 of 2100

4C┬▒21 DRIVE SHAFT SYSTEM

Inspection And Repair

Inspect the removed parts. If there are abnormalities

such as wear and damage, take corrective action or

replace.

Visual Check

1. Check and see if the inner shaft has such

abnormalities as wear and damage.

412RW014

2. Replace the shaft if any signs of deterioration in the

gear is present.

420RS008

Inner Shaft Run┬▒Out

With both end centers supported, rotate the shaft slowly

and measure deflection with a dial gauge.

Limit: 0.5 mm (0.02 in)

NOTE: Do not heat the shaft to correct its bend.

412RS026

Inner Shaft Bearing

412RW006

Legend

(1) Inner Shaft Bearing

(2) Inner Shaft

(3) Clutch Gear

1. Inspect the inner shaft bearing for any signs of

deterioration, replace if uneven.

2. Insert the clutch gear and inspect the needle bearing.

3. Replace the needle bearing if found to be uneven.

Page 519 of 2100

4C┬▒22

DRIVE SHAFT SYSTEM

Sleeve Condition

Check and see that there is not wear damage, or cracking

in the sleeve.

NOTE: Close inspection of the groove and inner gear are

required because those are important parts.

Sleeve Function

412RY00039Test the sleeve for smoothness by sliding it between the

inner shaft and the clutch gear, replace the sleeve if its

difficult to slide.

NOTE: Gear oil should be applied to the contact surface

of gear.

Check the width of sleeve center groove.

Limit: 7.1 mm (0.28 in)

412RW022

Clutch Gear Condition

Check for wear, damage, crack or any other deterioration

in the clutch gear.

Clutch Gear Function

412RY00038Test the sleeve for smoothness by sliding it across the

clutch gear, replace the clutch gear if its difficult to slide.

NOTE: When inspecting, gear oil should be applied to the

contact surface of gear.

Clutch Gear Journal Diameter

Make sure of the size illustrated.

Limit: 36.98 mm (1.456 in)

412RY00037

Page 521 of 2100

4C┬▒24

DRIVE SHAFT SYSTEM

2. Install a new needle bearing into inner shaft by using a

Installer J┬▒41694 and grip J┬▒8092.

412RS051

3. Place a new snap ring(internal) in inner shaft.

Install a new inner shaft bearing into the inner shaft.

412RS044

4. Install snap ring(external).

NOTE: Be careful not to damage the inner shaft.

5. Clean the housing contact surface of the front axle

case and insert inner shaft assembly into the front

axle case.

NOTE: Be careful not to damage seal.

6. Install snap ring internal in the groove of front axle

case.NOTE: Be sure to install the snap ring properly.

412RW017

7. Apply differential gear oil to clutch gear, then install

clutch gear.

8. Apply differential gear oil to sleeve, then install

sleeve.

9. Clean contact surface with the front axle and actuator

mounting surface. Apply liquid gasket to the contact

surface on the front axle case, then install in the

housing.

412RW023

10. Tighten bolts to specified torque.

Torque: 75N┬┤m(55 lb ft)

11. Clean the actuator contact surface with the housing

then Install and tighten shift position switch to

specified torque.

Torque: 39N┬┤m (29 lb ft)

Page 556 of 2100

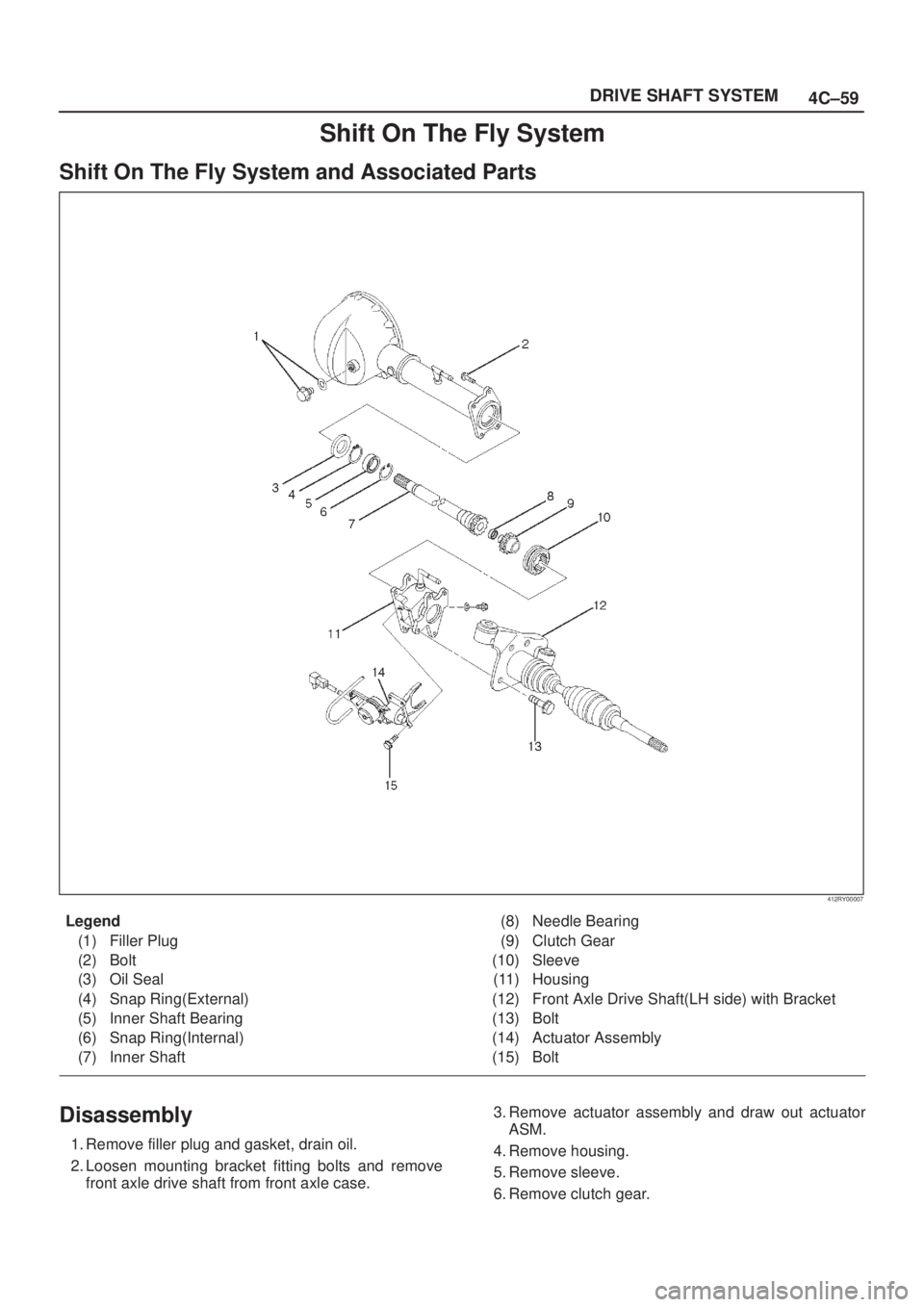

4C┬▒59 DRIVE SHAFT SYSTEM

Shift On The Fly System

Shift On The Fly System and Associated Parts

412RY00007

Legend

(1) Filler Plug

(2) Bolt

(3) Oil Seal

(4) Snap Ring(External)

(5) Inner Shaft Bearing

(6) Snap Ring(Internal)

(7) Inner Shaft(8) Needle Bearing

(9) Clutch Gear

(10) Sleeve

(11) Housing

(12) Front Axle Drive Shaft(LH side) with Bracket

(13) Bolt

(14) Actuator Assembly

(15) Bolt

Disassembly

1. Remove filler plug and gasket, drain oil.

2. Loosen mounting bracket fitting bolts and remove

front axle drive shaft from front axle case.3. Remove actuator assembly and draw out actuator

ASM.

4. Remove housing.

5. Remove sleeve.

6. Remove clutch gear.

Page 558 of 2100

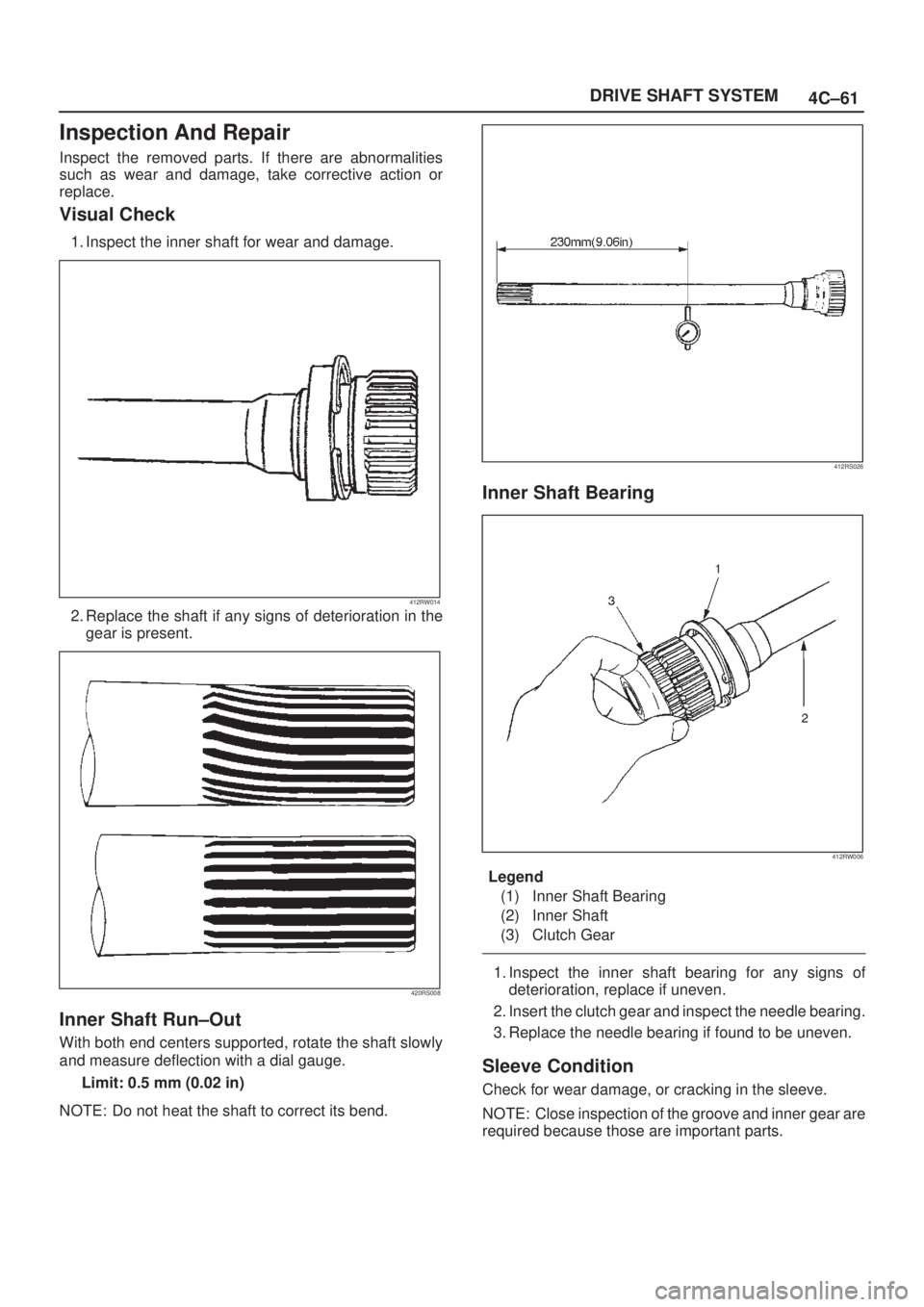

4C┬▒61 DRIVE SHAFT SYSTEM

Inspection And Repair

Inspect the removed parts. If there are abnormalities

such as wear and damage, take corrective action or

replace.

Visual Check

1. Inspect the inner shaft for wear and damage.

412RW014

2. Replace the shaft if any signs of deterioration in the

gear is present.

420RS008

Inner Shaft Run┬▒Out

With both end centers supported, rotate the shaft slowly

and measure deflection with a dial gauge.

Limit: 0.5 mm (0.02 in)

NOTE: Do not heat the shaft to correct its bend.

412RS026

Inner Shaft Bearing

412RW006

Legend

(1) Inner Shaft Bearing

(2) Inner Shaft

(3) Clutch Gear

1. Inspect the inner shaft bearing for any signs of

deterioration, replace if uneven.

2. Insert the clutch gear and inspect the needle bearing.

3. Replace the needle bearing if found to be uneven.

Sleeve Condition

Check for wear damage, or cracking in the sleeve.

NOTE: Close inspection of the groove and inner gear are

required because those are important parts.

Page 559 of 2100

4C┬▒62

DRIVE SHAFT SYSTEM

Sleeve Function

412RY00039Test the sleeve for smoothness by sliding it between the

inner shaft and the clutch gear, replace the sleeve if its

difficult to slide.

NOTE: Gear oil should be applied to the contact surface

of gear.

Check the width of sleeve center groove.

Limit: 7.1 mm (0.28 in)

412RW022

Clutch Gear Condition

Check for wear, damage, crack or any other deterioration

in the clutch gear.

Clutch Gear Function

412RY00038Test the sleeve for smoothness by sliding it across the

clutch gear, replace the clutch gear if its difficult to slide.

NOTE: When inspecting, gear oil should be applied to the

contact surface of gear.

Clutch Gear Journal Diameter

Make sure of the size illustrated.

Limit: 36.98 mm (1.456 in)

412RY00037

Actuator

Check for damage, cracking, or other abnormality.

Page 561 of 2100

4C┬▒64

DRIVE SHAFT SYSTEM

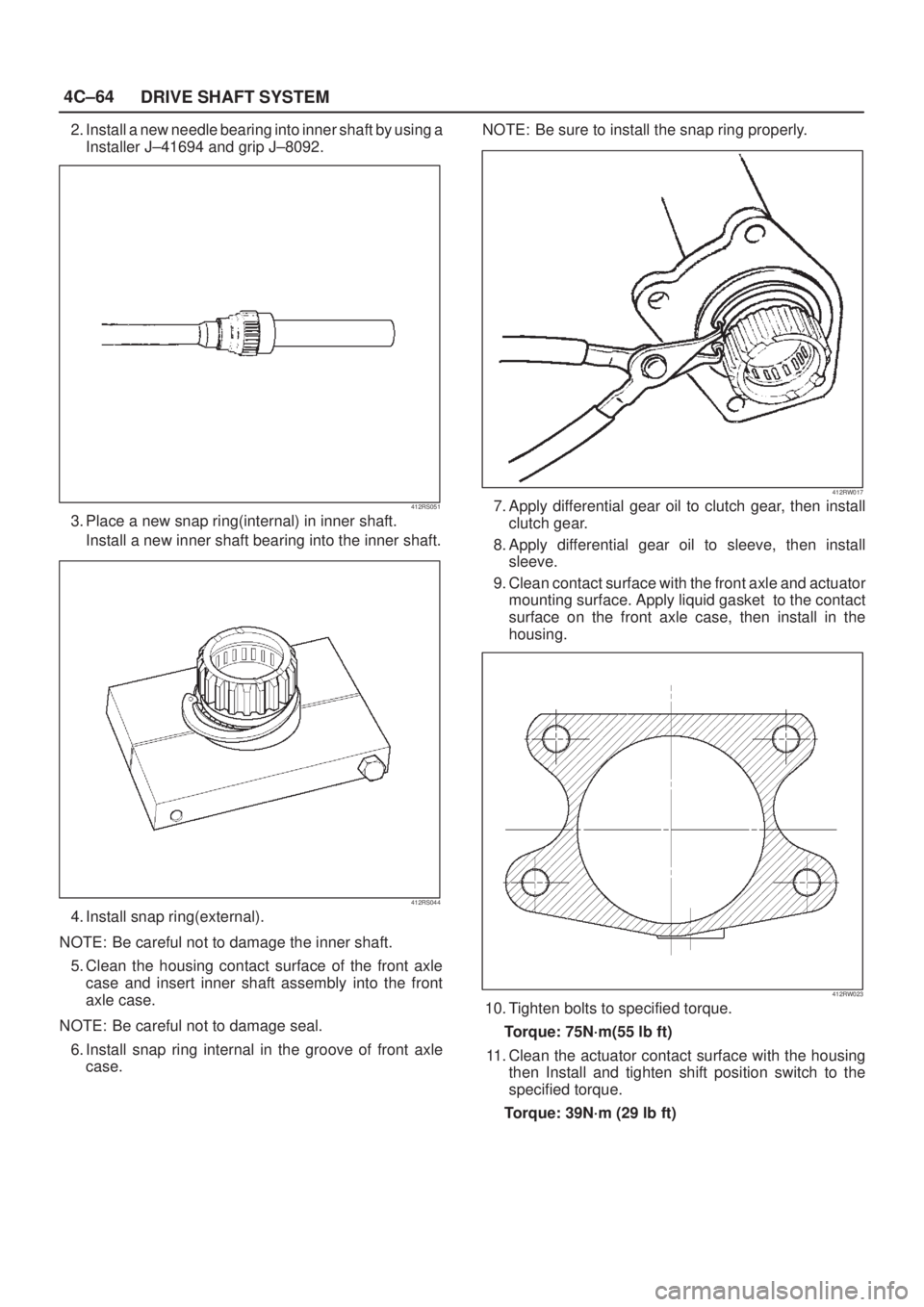

2. Install a new needle bearing into inner shaft by using a

Installer J┬▒41694 and grip J┬▒8092.

412RS051

3. Place a new snap ring(internal) in inner shaft.

Install a new inner shaft bearing into the inner shaft.

412RS044

4. Install snap ring(external).

NOTE: Be careful not to damage the inner shaft.

5. Clean the housing contact surface of the front axle

case and insert inner shaft assembly into the front

axle case.

NOTE: Be careful not to damage seal.

6. Install snap ring internal in the groove of front axle

case.NOTE: Be sure to install the snap ring properly.

412RW017

7. Apply differential gear oil to clutch gear, then install

clutch gear.

8. Apply differential gear oil to sleeve, then install

sleeve.

9. Clean contact surface with the front axle and actuator

mounting surface. Apply liquid gasket to the contact

surface on the front axle case, then install in the

housing.

412RW023

10. Tighten bolts to specified torque.

Torque: 75N┬┤m(55 lb ft)

11. Clean the actuator contact surface with the housing

then Install and tighten shift position switch to the

specified torque.

Torque: 39N┬┤m (29 lb ft)