DTC ISUZU AXIOM 2002 Service Service Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 664 of 2100

5A±45

BRAKE CONTROL SYSTEM

Chart B-16 Rear Dump Solenoid Coil Failure (DTC 46 (Flash out) / C0252, C0254 (Serial

communications))

StepActionYe sNo

1Was the ªEHCU Connector Pin±out Checksº performed?

Go to Step 2

Go to ªEHCU

Connector

Pin±out Checks.º

21. Turn the key switch to off.

2. Disconnect the 2±way EHCU connector (C±5) from the

EHCU.

3. Inspect the connector for damage or corrosion.

Is the connector free from damage or corrosion?

Go to Step 3

Repair the

connector.

Repeat the ªBasic

Diagnostic Flow

Chart.º

31. Replace the Coil Integrated Module.

2. Reconnect all components, ensure all components are

properly mounted.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 3

Chart B-17 FL Speed Sensor Open or Shorted (DTC 51 (Flash out) / C0225 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the resistance between coil integrated module

connector (C-6) terminals 2 and 10.

Is the resistance between 2.0k and 2.8k ohms?Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

Repair, and

perform system

self-check.

No fault found:

Replace coil

integrated

module.

Go to

Step 3Go to Step 2

2Measure the FL speed sensor resistance at the sensor connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 3

Replace sensor.

Go to

Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 3

Page 665 of 2100

5A±46BRAKE CONTROL SYSTEM

Chart B-18 FR Speed Sensor Open or Shorted (DTC 52 (Flash out) / C0221 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the resistance between coil integrated module

connector (C-6) terminals 3 and 11.

Is the resistance between 2.0k and 2.8k ohms?Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

Repair, and

perform system

self-check.

No fault found:

Replace coil

integrated

module.

Go to

Step 3Go to Step 2

2Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 3

Replace sensor.

Go to

Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 3

Page 666 of 2100

5A±47

BRAKE CONTROL SYSTEM

Chart B-19 Rear Speed Sensor Open or Shorted (DTC 53 (Flash out) / C0235 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the resistance between coil integrated module

connector (C-6) terminals 4 and 12.

Is the resistance between 1.0k and 1.7k ohms?Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

Repair, and

perform system

self-check.

No fault found:

Replace EHCU.

Go to

Step 3Go to Step 2

2Measure the Rear speed sensor resistance at the sensor

connector.

Is the resistance between 1.0k and 1.7k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 3

Replace sensor.

Go to

Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 3

Page 667 of 2100

5A±48BRAKE CONTROL SYSTEM

Chart B-20 FL Speed Sensor Missing Signal (DTC 61 (Flash out) / C0226, C0227 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FL speed sensor resistance between coil

integrated module connector (C-6) terminals 2 and 10.

Is the resistance between 2.0k and 2.8k ohms?

Go to Step 2Go to Step 3

2Is there play sensor/sensor rotor?Repair.

Go to

Step 6Go to Step 4

3Measure the FL speed sensor resistance at the sensor connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 6

Replace sensor.

Go to

Step 6

4Damage and powdered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 5

5Is sensor output normal? (Chart C-1-1 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 6

Replace sensor.

Go to

Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 668 of 2100

5A±49

BRAKE CONTROL SYSTEM

Chart B-21 FR Speed Sensor Missing Signal (DTC 62 (Flash out) / C0222, C0223 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FR speed sensor resistance between coil

integrated module connector (C-6) terminals 3 and 11.

Is the resistance between 2.0k and 2.8k ohms?

Go to Step 2Go to Step 3

2Is there play sensor/sensor rotor?Repair.

Go to

Step 6Go to Step 4

3Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 6

Replace sensor.

Go to

Step 6

4Damage and powered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 5

5Is sensor output normal? (Chart C-1-2 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 6

Replace sensor.

Go to

Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 669 of 2100

5A±50BRAKE CONTROL SYSTEM

Chart B-22 Rear Speed Sensor Missing Signal (DTC 63 (Flash out) / C0236, C0237 (Serial

communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the Rear speed sensor resistance between coil

integrated module connector (C-6) terminals 4 and 12.

Is the resistance between 1.0k and 1.7k ohms?

Go to Step 2Go to Step 3

2Is there play sensor/sensor rotor?Repair.

Go to

Step 6Go to Step 4

3Measure the rear speed sensor resistance at the sensor

connector.

Is the resistance between 1.0k and 1.7k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 6

Replace sensor.

Go to

Step 6

4Damage and powered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 5

5Is sensor output normal? (Chart C-1-3 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 6

Replace sensor.

Go to

Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the ªBasic

diagnostic flow

chartº

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 670 of 2100

5A±51

BRAKE CONTROL SYSTEM

Chart B-23 Simultaneous Drop-out of Front Speed Sensor Signal (DTC 64 (Flash out) /

C0229 (Serial communications))

StepActionYe sNo

11. Turn the key off.

2. Disconnect coil integrated module connector.

3. Measure the FL speed sensor resistance between coil

integrated module connector (C-6) terminals 2 and 10.

Is the resistance between 2.0k and 2.8k ohms?

Go to Step 2Go to Step 3

2Measure the FR speed sensor resistance between coil integrated

module connector (C-6) terminals 3 and 11.

Is the resistance between 2.0k and 2.8 k ohms?

Go to Step 5Go to Step 4

3Measure the FL speed sensor resistance at the sensor connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 2

Replace sensor.

Go to

Step 2

4Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 2.0k and 2.8k ohms?Repair harness

abnormality

between sensors

and coil

integrated

module.

Go to

Step 5

Replace sensor.

Go to

Step 5

5Damage and powered iron sticking to sensor/sensor ring?Repair.

Go to

Step 6Go to Step 6

6Is there play sensor/sensor rotor?Repair.

Go to

Step 7Go to Step 7

7Is sensor output normal? (Chart C-1-1&C-1-2 or TC-1)Check for faults

in harness

between speed

sensor and coil

integrated

module.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to

Step 8

Replace sensor.

Go to

Step 8

81. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat ªBasic

diagnostic flow

chartº

Go to Step 8

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

Page 671 of 2100

5A±52BRAKE CONTROL SYSTEM

Chart B-24 Wheel Speed Input Abnormality (DTC 65 (Flash out) / C0238 (Serial

communications))

StepActionYe sNo

1Using TECH 2?Go to Step 2Go to Step 3

21. Connect TECH 2.

2. Select Snap shot manual trigger.

3. With wheel speed data displayed, run the vehicle when speed

has arrived at 30 km/h (18 mph).

4. Check speed data on each wheel (refer to the criterion given

below). * 1

Is the abnormal sensor condition found?

Replace.

Go to

Step 8

Go to Step 3

All the sensors

should follow the

following

flowchart (without

using TECH 2).

3Is there play in sensor/sensor ring?Repair.

Go to

Step 8Go to Step 4

4Is there powdered iron sticking to sensor/sensor ring?Repair.

Go to

Step 8Go to Step 5

5Is there a broken tooth or indentation in sensor ring?Replace sensor

ring.

Go to

Step 8Go to Step 6

6Is there play in wheel bearing?Adjust or repair.

Go to

Step 8Go to Step 7

7Is the check wiring between sensor and coil integrated module

normal?

Replace EHCU.

Go to

Step 8

Repair, and

perform system

self-check.

Go to

Step 8

81. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat `Basic

diagnostic flow

chartº

Go to Step 8

Sensor Signal Abnormality Criteria using TECH 2

1. While driving, the speed of one or two wheels is 25%

or more higher or lower than that of the other wheels.

2. The speed of one or two wheels is 10 km/h (6 mph) or

more higher or lower than that of the other wheels.

3. During steady driving, wheel speed changes abruptly.

*1 The vehicle must run on a level paved road.

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop.

Turn the ignition switch to the ON position and drive the

vehicle at 12 km/h (8 mph) or higher to make sure that the

warning light goes out.

It is important to verify that the correct tires are installed

on vehicle.

Page 968 of 2100

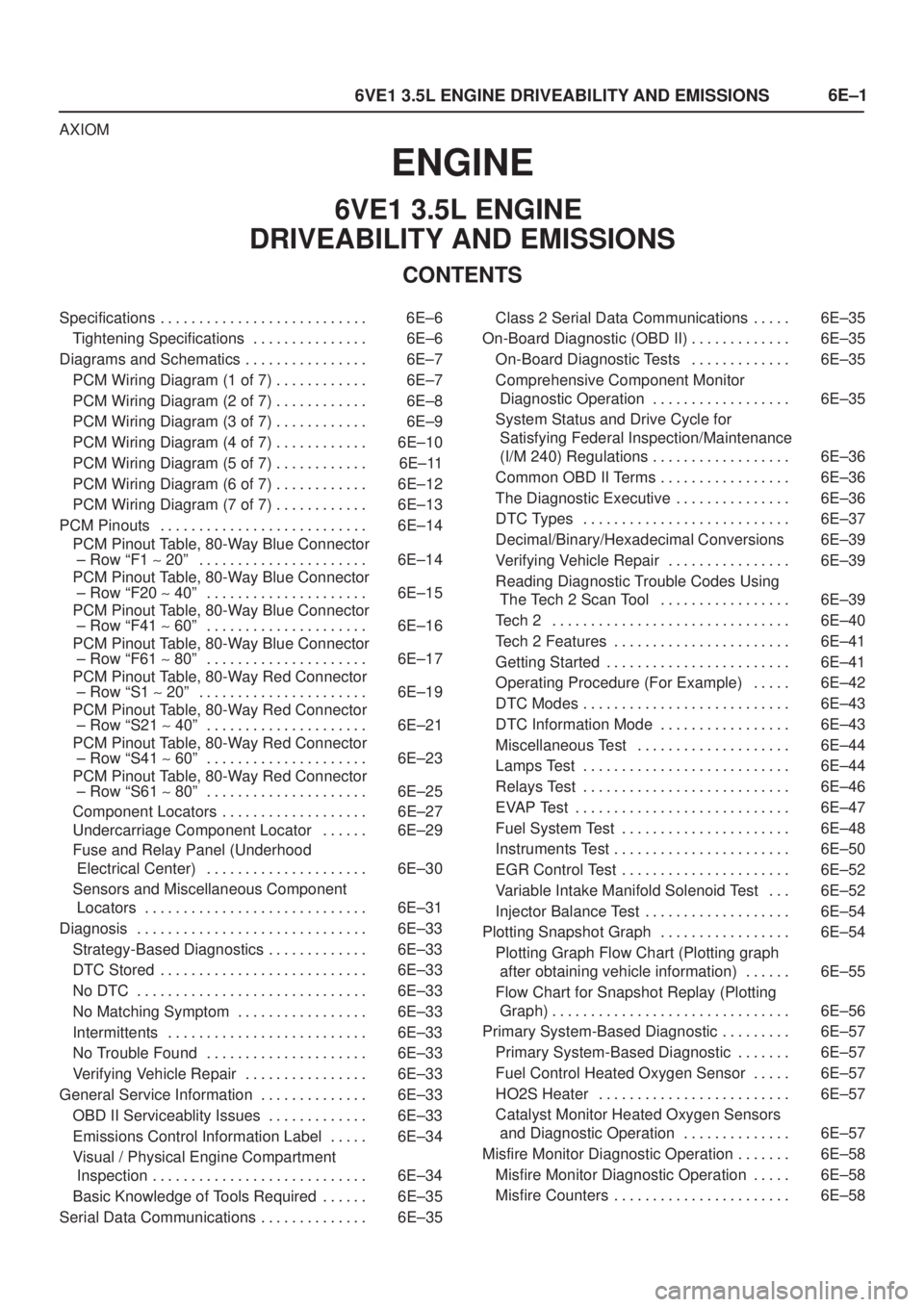

6E±1

6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

AXIOM

ENGINE

6VE1 3.5L ENGINE

DRIVEABILITY AND EMISSIONS

CONTENTS

Specifications 6E±6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Tightening Specifications 6E±6. . . . . . . . . . . . . . .

Diagrams and Schematics 6E±7. . . . . . . . . . . . . . . .

PCM Wiring Diagram (1 of 7) 6E±7. . . . . . . . . . . .

PCM Wiring Diagram (2 of 7) 6E±8. . . . . . . . . . . .

PCM Wiring Diagram (3 of 7) 6E±9. . . . . . . . . . . .

PCM Wiring Diagram (4 of 7) 6E±10. . . . . . . . . . . .

PCM Wiring Diagram (5 of 7) 6E±11. . . . . . . . . . . .

PCM Wiring Diagram (6 of 7) 6E±12. . . . . . . . . . . .

PCM Wiring Diagram (7 of 7) 6E±13. . . . . . . . . . . .

PCM Pinouts 6E±14. . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Blue Connector

± Row ªF1 ~ 20º 6E±14. . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Blue Connector

± Row ªF20 ~ 40º 6E±15. . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Blue Connector

± Row ªF41 ~ 60º 6E±16. . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Blue Connector

± Row ªF61 ~ 80º 6E±17. . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Red Connector

± Row ªS1 ~ 20º 6E±19. . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Red Connector

± Row ªS21 ~ 40º 6E±21. . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Red Connector

± Row ªS41 ~ 60º 6E±23. . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 80-Way Red Connector

± Row ªS61 ~ 80º 6E±25. . . . . . . . . . . . . . . . . . . . .

Component Locators 6E±27. . . . . . . . . . . . . . . . . . .

Undercarriage Component Locator 6E±29. . . . . .

Fuse and Relay Panel (Underhood

Electrical Center) 6E±30. . . . . . . . . . . . . . . . . . . . .

Sensors and Miscellaneous Component

Locators 6E±31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 6E±33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy-Based Diagnostics 6E±33. . . . . . . . . . . . .

DTC Stored 6E±33. . . . . . . . . . . . . . . . . . . . . . . . . . .

No DTC 6E±33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Matching Symptom 6E±33. . . . . . . . . . . . . . . . .

Intermittents 6E±33. . . . . . . . . . . . . . . . . . . . . . . . . .

No Trouble Found 6E±33. . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E±33. . . . . . . . . . . . . . . .

General Service Information 6E±33. . . . . . . . . . . . . .

OBD II Serviceablity Issues 6E±33. . . . . . . . . . . . .

Emissions Control Information Label 6E±34. . . . .

Visual / Physical Engine Compartment

Inspection 6E±34. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge of Tools Required 6E±35. . . . . .

Serial Data Communications 6E±35. . . . . . . . . . . . . . Class 2 Serial Data Communications 6E±35. . . . .

On-Board Diagnostic (OBD II) 6E±35. . . . . . . . . . . . .

On-Board Diagnostic Tests 6E±35. . . . . . . . . . . . .

Comprehensive Component Monitor

Diagnostic Operation 6E±35. . . . . . . . . . . . . . . . . .

System Status and Drive Cycle for

Satisfying Federal Inspection/Maintenance

(I/M 240) Regulations 6E±36. . . . . . . . . . . . . . . . . .

Common OBD II Terms 6E±36. . . . . . . . . . . . . . . . .

The Diagnostic Executive 6E±36. . . . . . . . . . . . . . .

DTC Types 6E±37. . . . . . . . . . . . . . . . . . . . . . . . . . .

Decimal/Binary/Hexadecimal Conversions 6E±39

Verifying Vehicle Repair 6E±39. . . . . . . . . . . . . . . .

Reading Diagnostic Trouble Codes Using

The Tech 2 Scan Tool 6E±39. . . . . . . . . . . . . . . . .

Tech 2 6E±40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Features 6E±41. . . . . . . . . . . . . . . . . . . . . . .

Getting Started 6E±41. . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure (For Example) 6E±42. . . . .

DTC Modes 6E±43. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Information Mode 6E±43. . . . . . . . . . . . . . . . .

Miscellaneous Test 6E±44. . . . . . . . . . . . . . . . . . . .

Lamps Test 6E±44. . . . . . . . . . . . . . . . . . . . . . . . . . .

Relays Test 6E±46. . . . . . . . . . . . . . . . . . . . . . . . . . .

EVAP Test 6E±47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System Test 6E±48. . . . . . . . . . . . . . . . . . . . . .

Instruments Test 6E±50. . . . . . . . . . . . . . . . . . . . . . .

EGR Control Test 6E±52. . . . . . . . . . . . . . . . . . . . . .

Variable Intake Manifold Solenoid Test 6E±52. . .

Injector Balance Test 6E±54. . . . . . . . . . . . . . . . . . .

Plotting Snapshot Graph 6E±54. . . . . . . . . . . . . . . . .

Plotting Graph Flow Chart (Plotting graph

after obtaining vehicle information) 6E±55. . . . . .

Flow Chart for Snapshot Replay (Plotting

Graph) 6E±56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Primary System-Based Diagnostic 6E±57. . . . . . . . .

Primary System-Based Diagnostic 6E±57. . . . . . .

Fuel Control Heated Oxygen Sensor 6E±57. . . . .

HO2S Heater 6E±57. . . . . . . . . . . . . . . . . . . . . . . . .

Catalyst Monitor Heated Oxygen Sensors

and Diagnostic Operation 6E±57. . . . . . . . . . . . . .

Misfire Monitor Diagnostic Operation 6E±58. . . . . . .

Misfire Monitor Diagnostic Operation 6E±58. . . . .

Misfire Counters 6E±58. . . . . . . . . . . . . . . . . . . . . . .

Page 969 of 2100

6E±2

6VE1 3.5L ENGINE DRIVEABILITY AND EMISSIONS

Fuel Trim System Monitor Diagnostic

Operation 6E±59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Trim System Monitor Diagnostic

Operation 6E±59. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Trim Cell Diagnostic Weights 6E±59. . . . . . .

On-Board Diagnostic (OBD II) System Check 6E±60

Circuit Description 6E±60. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±60. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E±60. . . . . . . . . . . . . . . . . . . . . . .

A/C Clutch Control Circuit Diagnosis 6E±63. . . . . . .

Circuit Description 6E±63. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±63. . . . . . . . . . . . . . . . . . . . . . . .

A/C Clutch Diagnosis 6E±64. . . . . . . . . . . . . . . . . .

Electronic Ignition System Diagnosis 6E±68. . . . . . .

EVAP Canister Purge Solenoid and EVAP

Vent Solenoid Valve 6E±68. . . . . . . . . . . . . . . . . . . . .

Visual Check of The Evaporative Emission

Canister 6E±68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Metering System Check 6E±68. . . . . . . . . . . . .

Fuel System Pressure Test 6E±68. . . . . . . . . . . . . . .

Fuel Injector Coil Test Procedure and Fuel

Injector Balance Test Procedure 6E±68. . . . . . . . . .

Test Description 6E±68. . . . . . . . . . . . . . . . . . . . . . .

Injector Coil Test Procedure (Steps 1-6)

and Injector Balance Test Procedure

(Steps 7-11) 6E±69. . . . . . . . . . . . . . . . . . . . . . . . . .

Powertrain Control Module (PCM) Diagnosis 6E±73

Multiple PCM Information Sensor DTCs Set 6E±73

Circuit Description 6E±73. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±73. . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Gas Recirculation (EGR) Diagnosis 6E±76

Engine Tech 2 Data Definitions and Ranges 6E±76

Typical Scan Data Values 6E±78. . . . . . . . . . . . . . . .

Test Conditions 6E±78. . . . . . . . . . . . . . . . . . . . . . . .

No Malfunction Indicator Lamp (MIL) 6E±84. . . . . . .

Circuit Description 6E±84. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±84. . . . . . . . . . . . . . . . . . . . . . . .

Malfunction Indicator Lamp (MIL) ªONº

Steady 6E±87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit description 6E±87. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±87. . . . . . . . . . . . . . . . . . . . . . . .

No Reduced Power Lamp (RPL) 6E±89. . . . . . . . . .

Circuit Description 6E±89. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±89. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E±89. . . . . . . . . . . . . . . . . . . . . . .

Reduced Power Lamp (RPL) ªONº Steady 6E±93. .

Circuit Description 6E±93. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±93. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E±93. . . . . . . . . . . . . . . . . . . . . . .

Starter Control System Check 6E±96. . . . . . . . . . . . .

Circuit Description 6E±96. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±96. . . . . . . . . . . . . . . . . . . . . . . .

Engine Cranks But Will Not Run 6E±100. . . . . . . . . . .

Circuit Description 6E±102. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±102. . . . . . . . . . . . . . . . . . . . . . . . Test Description 6E±102. . . . . . . . . . . . . . . . . . . . . . .

Fuel System Electrical Test 6E±107. . . . . . . . . . . . . . .

Circuit Description 6E±108. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±108. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E±108. . . . . . . . . . . . . . . . . . . . . . .

Fuel Pressure Relief Procedure 6E±108. . . . . . . . .

Electric Throttle Control (ETC) System

Check 6E±111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E±112. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±112. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E±112. . . . . . . . . . . . . . . . . . . . . . .

Fuel System Diagnosis 6E±115. . . . . . . . . . . . . . . . . . .

Circuit Description 6E±116. . . . . . . . . . . . . . . . . . . . .

Test Description 6E±116. . . . . . . . . . . . . . . . . . . . . . .

Fuel Pressure Relief Procedure 6E±117. . . . . . . . .

Exhaust Gas Recirculation (EGR) System

Check 6E±120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E±120. . . . . . . . . . . . . . . . . . . . .

Manifold Absolute Pressure (MAP) Output

Check 6E±122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E±122. . . . . . . . . . . . . . . . . . . . .

Evaporative (EVAP) Emissions Canister

Purge Valve Check 6E±124. . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E±124. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E±124. . . . . . . . . . . . . . . . . . . . . . . .

PCM Diagnostic Trouble Codes 6E±127. . . . . . . . . . .

DTC P0101 MAF System Performance 6E±131. . . .

DTC P0102 MAF Sensor Circuit Low

Frequency 6E±134. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0103 MAF Sensor Circuit High

Frequency 6E±137. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0106 MAP System Performance 6E±140. . . .

DTC P0107 MAP Sensor Circuit Low

Voltage 6E±143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0108 MAP Sensor Circuit High

Voltage 6E±146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0112 IAT Sensor Circuit Low

Voltage 6E±149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0113 IAT Sensor Circuit High

Voltage 6E±152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0117 ECT Sensor Circuit Low

Voltage 6E±155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0118 ECT Sensor Circuit High

Voltage 6E±158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0125 ECT Excessive Time to Closed

Loop Fuel Control 6E±161. . . . . . . . . . . . . . . . . . . . . . .

DTC P0128 Thermostat Insufficient

Temperature for Stable Operation 6E±164. . . . . . . . .

DTC P0131 HO2S Circuit Low Voltage

Bank 1 Sensor 1 6E±166. . . . . . . . . . . . . . . . . . . . . . . .

DTC P0132 HO2S Circuit High Voltage

Bank 1 Sensor 1 6E±169. . . . . . . . . . . . . . . . . . . . . . . .

DTC P0133 HO2S Slow Response

Bank 1 Sensor 1 6E±172. . . . . . . . . . . . . . . . . . . . . . . .

DTC P0134 HO2S Circuit Insufficient

Activity Bank 1 Sensor 1 6E±176. . . . . . . . . . . . . . . . .