AUX ISUZU AXIOM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 21 of 2100

0B±7 MAINTENANCE AND LUBRICATION

Automatic Transmission Fluid

Replacement

Under harsh operating conditions, such as constant

driving in heavy city traffic during hot weather, or in hilly or

mountainous terrain, change the transmission fluid and

service the sump filter after every 20,000 miles (32,000

km) of operation.

More over, the remaining life percentage of ATF can be

estimated by using TECH±II as an auxiliary tool to judge

the right time for ATF replacement.

The remaining life percentage is calculated from ATF'S

heat history. When it is close to 0%, ATF replacement is

recommended.

Auto Cruise Control Inspection

Check to see if the clearance between cruise link and

accelerator link is normal. Also check that the connected

properly.

Accelerator Linkage Inspection

Inspect for interference, binding, and damaged or

missing parts. Check accelerator pedal for smooth

operation and even pedal effort. Replace parts as

needed.

Page 385 of 2100

DRIVE LINE CONTROL SYSTEM (TOD) 4B2±6

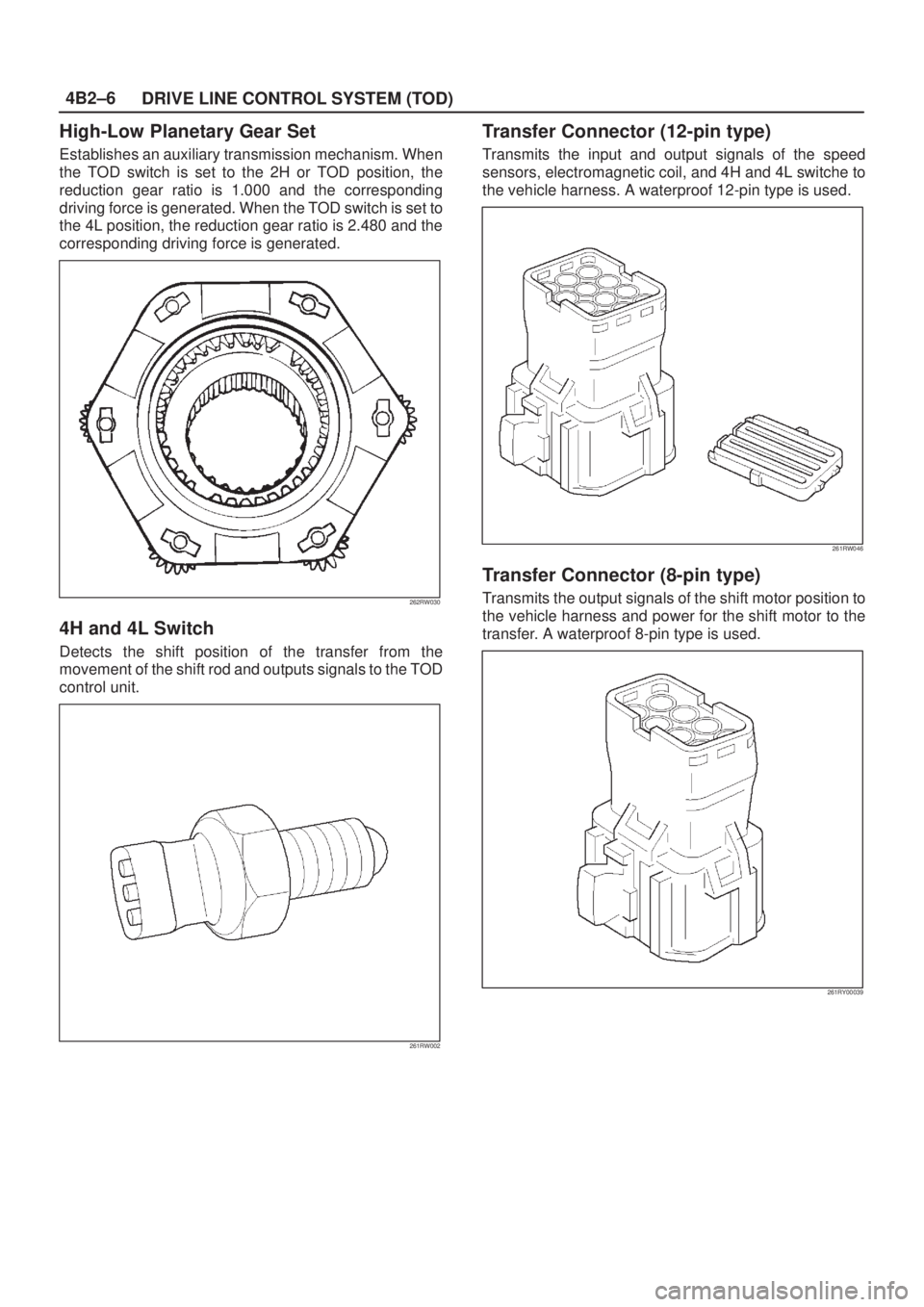

High-Low Planetary Gear Set

Establishes an auxiliary transmission mechanism. When

the TOD switch is set to the 2H or TOD position, the

reduction gear ratio is 1.000 and the corresponding

driving force is generated. When the TOD switch is set to

the 4L position, the reduction gear ratio is 2.480 and the

corresponding driving force is generated.

262RW030

4H and 4L Switch

Detects the shift position of the transfer from the

movement of the shift rod and outputs signals to the TOD

control unit.

261RW002

Transfer Connector (12-pin type)

Transmits the input and output signals of the speed

sensors, electromagnetic coil, and 4H and 4L switche to

the vehicle harness. A waterproof 12-pin type is used.

261RW046

Transfer Connector (8-pin type)

Transmits the output signals of the shift motor position to

the vehicle harness and power for the shift motor to the

transfer. A waterproof 8-pin type is used.

261RY00039

Page 933 of 2100

ENGINE ELECTRICAL (6VE1 3.5L)6D1±3

Battery Charging

Observe the following safety precautions when charging

the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during charging

procedure.

Battery charging should be discontinued or the rate of

charge reduced if the battery feels hot to the touch.

Battery charging should be discontinued or the rate of

charge reduced if the battery begins to gas or spew

electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue dot

or ring, it may be necessary to jiggle or tilt the battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be either

quick charged or slow charged in the same manner as

other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

Jump Starting

Jump Starting with an Auxiliary (Booster)

Battery

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.

Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: FAILURE TO CAREFULLY FOLLOW THE

JUMP STARTING PROCEDURE COULD RESULT IN

THE FOLLOWING:

1. Serous personal injury, particularly to your eyes.

2. Property damage from a battery explosion, battery

acid, or an electrical fire.

3. Damage to the electronic components of one or both

vehicles particularly.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode.

Remove any rings, watches, or other jewelry before

working around the battery. Protect your eyes by wearing

an approved set of goggles.

Never allow battery fluid to come in contact with your eyes

or skin.Never allow battery fluid to come in contact with fabrics or

painted surfaces.

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly

rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector level in the ªPARKº

position.

If the vehicle is equipped with a manual transmission,

place the shift lever in the ªNEUTRALº position.

Turn ªOFFº the ignition.

Turn ªOFFº all lights and any other accessory

requiring electrical power.

2. Look at the built±in hydrometer.

If the indication area of the built±in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will

cause a ground connection, effectively neutralizing

the charging procedure.

Be sure that the booster battery has a 12 volt rating.

4. Attach one end of the remaining cable to the negative

terminal of the booster battery.

Attach the other end of the same cable to a solid

engine ground (such as the air conditioning

compressor bracket or the generator mounting

bracket) of the vehicle with the discharged battery.

The ground connection must be at least 450 mm (18

in.) from the battery of the vehicle whose battery is

being charged.

WARNING: NEVER ATTACH THE END OF THE

JUMPER CABLE DIRECTLY TO THE NEGATIVE

TERMINAL OF THE DEAD BATTERY.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical accessories

have been turned ªOFFº.

6. Start the engine of the vehicle with the dead battery.

Page 1587 of 2100

7A±3 AUTOMATIC TRANSMISSION (4L30±E)

Construction

A07R100002

Legend

(1) Torque Converter Clutch (TCC)

(2) Overdrive Free Wheel (One Way Clutch)

(OFW)

(3) Fourth Clutch (C4)

(4) Overrun Clutch (OC)

(5) Overdrive Unit(6) Reverse Clutch (RC)

(7) Second Clutch (C2)

(8) Third Clutch (C3)

(9) Principle Sprag Assembly (One Way Clutch)

(PFW)

(10) Ravigneaux Planetary Gear Set

(11) Brake Band (B)

Page 1673 of 2100

7A±89 AUTOMATIC TRANSMISSION (4L30±E)

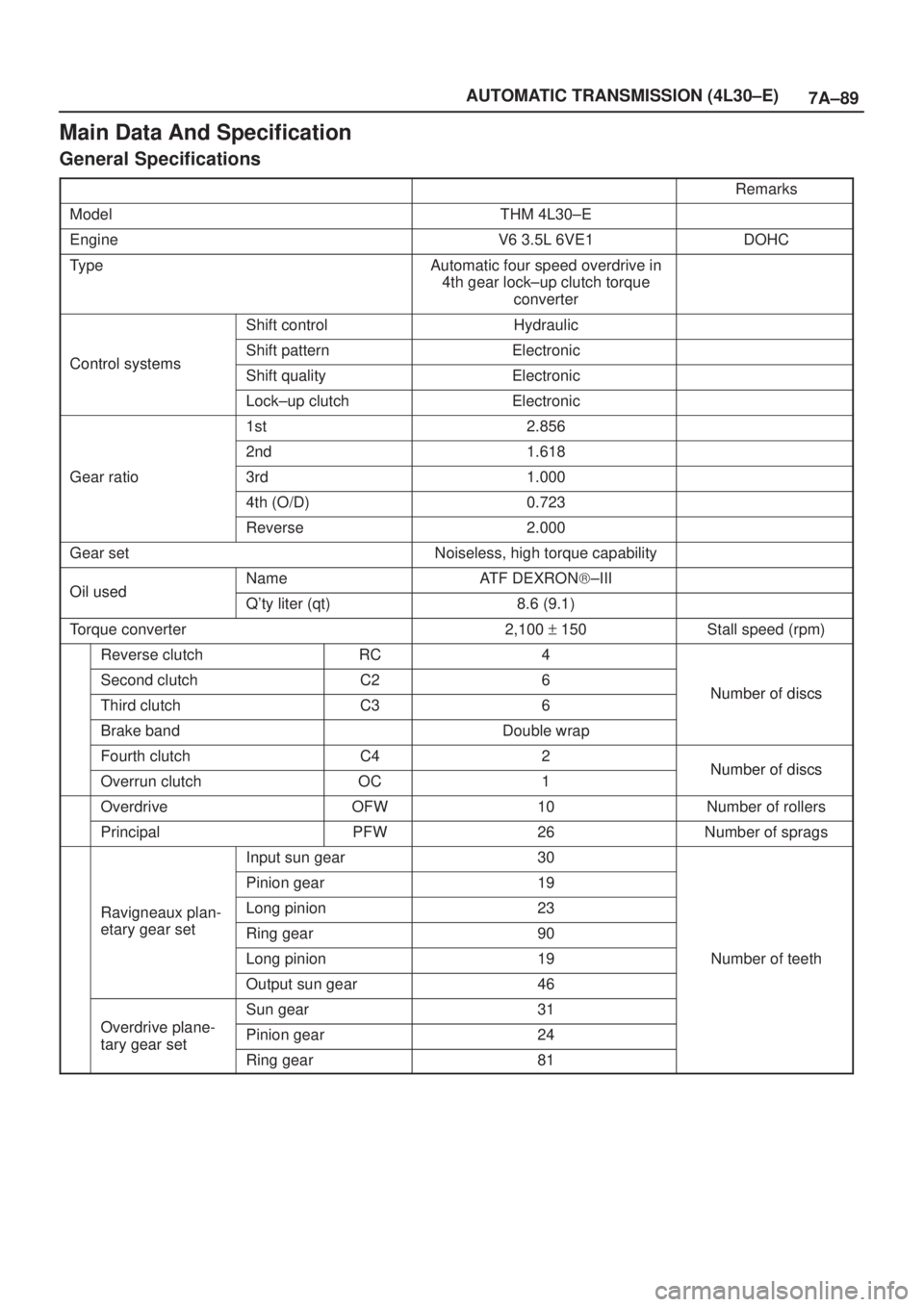

Main Data And Specification

General Specifications

Remarks

ModelTHM 4L30±E

EngineV6 3.5L 6VE1DOHC

TypeAutomatic four speed overdrive in

4th gear lock±up clutch torque

converter

Shift controlHydraulic

Control systemsShift patternElectronicControl systemsShift qualityElectronic

Lock±up clutchElectronic

1st2.856

2nd1.618

Gear ratio3rd1.000

4th (O/D)0.723

Reverse2.000

Gear setNoiseless, high torque capability

Oil usedNameATF DEXRON)±IIIOil usedQ'ty liter (qt)8.6 (9.1)

Torque converter2,100 + 150Stall speed (rpm)

Reverse clutchRC4

Second clutchC26Number of discsThird clutchC36Number of discs

Brake bandDouble wrap

Fourth clutchC42Number of discsOverrun clutchOC1Number of discs

OverdriveOFW10Number of rollers

PrincipalPFW26Number of sprags

Input sun gear30

Pinion gear19

Ravigneaux plan-Long pinion23g

etary gear setRing gear90

Long pinion19Number of teeth

Output sun gear46

Odi l

Sun gear31

Overdrive plane-

tary gear setPinion gear24tary gear set

Ring gear81