jump start terminals ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4019 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-53

• No L-up solenoid functional failure detection.

• Check Trans “ON”.

• DTC stored.

• MIL request “ON”. (EURO 4 only)

Conditions For Clearing The DTC

• The DTC can be cleared from the TCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warm-up cycles without a

failure reported.

•

After more than 1 second has elapsed after the

ignition key has been turned “ON”, short between

No.11 and No.4 (ground) of DLC (Data Link

Connector). Then, after 1 second, but within 6

seconds, discontinue shorting.

Diagnostic Aids

•

Inspect the wiring for poor electrical connection at the

TCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring. Inspect for a

broken wire inside the insulation.

• W hen diagnosing for a possible intermittent short o

r

open condition, move the wiring harness while

observing test equipment for a change.

• Check oil temperature sensor for proper mounting

and adjustment.

Circuit/System Testing DTC P0713

Step Action Value(s) YES NO

1

W as the On-Board Diagnostic (OBD) System Check

performed ? — Go to

Step 2 Go to OBD

System check

2 Perform the transmission fluid checking procedure. Refer to Checking Transmission Fluid Level and

condition Automatic Transmission 7A section.

W as the fluid checking procedure performed? — Go to

Step 3 Refer to

checking

Transmission

Fluid Level and Condition

Automatic

Transmission

(AW 30-40LE) section

3 1. Lift the driving wheels.

2. Start the engine and place the select lever in D

position.

3. W ait for 15 minutes.

Does a scan tool indicate DTC P0713? — Go to

Step 4 Refer to

Diagnostic Aids

4 Observe the voltage of the oil temperature sensor on the Tech 2 data.

1. Turn “OFF” the ignition.

2. Disconnect the oil temperature sensor connector

E-83

3. Install a fused jumper wire from terminal E83-2 to E83-1 on the transmission harness.

4. Turn “ON” the ignition.

Does a scan tool indicate specified value? About 0V Go to

Step 5 Go to Step 6

5 Replace the transmission fluid temperature sensor.

If the action complete? — Go to

Step 9 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4020 of 6020

7A2-54 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Step Action Value(s) YES NO

6 Measure the resistance of wire by the 5-8840-0285-0

DMM.

1. Turn “OFF” the ignition.

2. Disconnect the TCM connector.

3. Install a fused jumper wire between terminals E83-

1 and E83-2 on the transmission harness.

Does DMM indicate specified value? Less than

1

Ω

Go to Step 8 Go to Step 7

7 An open circuit between TCM from oil temperature

sensor.

Repair the harness.

Is the action complete ? — Go to

Step 9 —

8 Replace the TCM

Important: The replacement TCM must be

programmed. (Refer to SPS for procedure.)

Is the action complete? — Go to

Step 9 —

9 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with a scan tool.

3. Turn “OFF” the ignition.

4. Start the engine.

5. Operate the vehicle within the Conditions For Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame/ Failure Records.

Did the DTC fail this ignition? — Go to

Step 2 Go to Step 10

10 Observe the stored information, Capture Info with a

scan tool.

Are there any DTCs that you have not diagnosed? — Go

to

Diagnostic

Trouble Code (DTC) List Verify repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4305 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-21

Diagnostic Information and Procedures

Diagnostic Starting Point - Transmission Controls

Begin the system diagnosis with Diagnostic System

Check - Transmission Controls. The Diagnostic System

Check - Transmission Controls will provide the

following information:

• The identification of the control modules which command the system.

• The ability of the control modules to communicate through the serial data circuit.

• The identification of any stored diagnostic trouble codes (DTCs) and the their statuses.

The use of the Diagnostic System Check -

Transmission Controls will identify the correct

procedure for diagnosing the system and where the

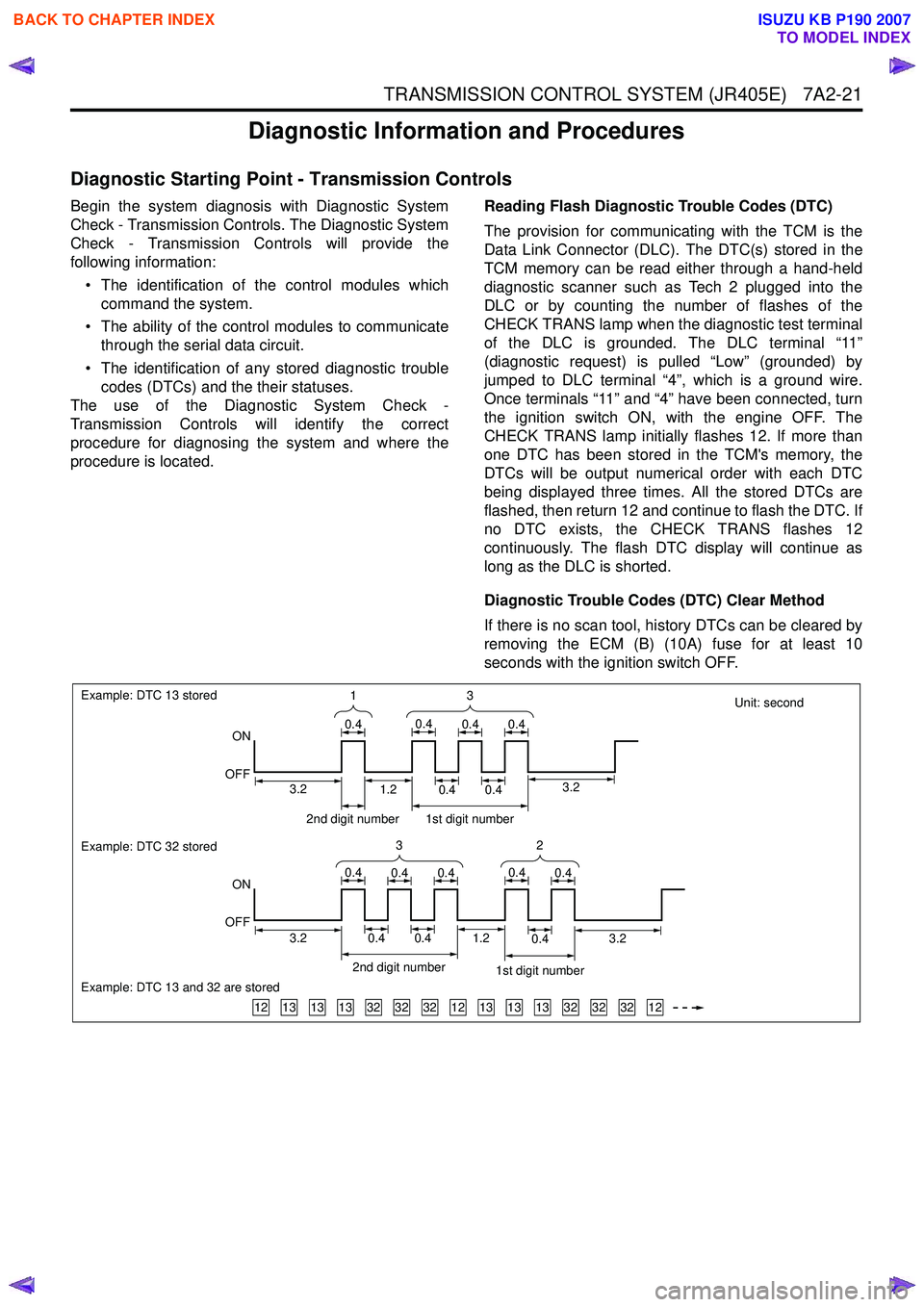

procedure is located. Reading Flash Diagnostic Trouble Codes (DTC)

The provision for communicating with the TCM is the

Data Link Connector (DLC). The DTC(s) stored in the

TCM memory can be read either through a hand-held

diagnostic scanner such as Tech 2 plugged into the

DLC or by counting the number of flashes of the

CHECK TRANS lamp when the diagnostic test terminal

of the DLC is grounded. The DLC terminal “11”

(diagnostic request) is pulled “Low” (grounded) by

jumped to DLC terminal “4”, which is a ground wire.

Once terminals “11” and “4” have been connected, turn

the ignition switch ON, with the engine OFF. The

CHECK TRANS lamp initially flashes 12. If more than

one DTC has been stored in the TCM's memory, the

DTCs will be output numerical order with each DTC

being displayed three times. All the stored DTCs are

flashed, then return 12 and continue to flash the DTC. If

no DTC exists, the CHECK TRANS flashes 12

continuously. The flash DTC display will continue as

long as the DLC is shorted.

Diagnostic Trouble Codes (DTC) Clear Method

If there is no scan tool, history DTCs can be cleared by

removing the ECM (B) (10A) fuse for at least 10

seconds with the ignition switch OFF.

Unit: second

131313323232121313133232321212

Example: DTC 13 stored

ON

OFF

Example: DTC 32 stored

Example: DTC 13 and 32 are stored

ON

OFF 3

1

0.40.40.40.4

32

0.40.40.40.40.4

2nd digit number1st digit number

3.23.20.40.40.41.2

2nd digit number 1st digit number

0.40.41.23.23.2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4957 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-19

Battery-1

BATTERY

Inspection

1. Check the battery terminals 1 for corrosion.

2. Check the battery cables

2 for looseness.

3. Check the battery case

3 for cracks and other damage.

4. Check the battery electrolyte level.

Battery-2

Battery Replacement

1. Disconnect the battery ground cable 1.

2. Disconnect the battery positive cable

2.

3. Remove the battery clamp

3.

4. Remove the battery

Caution:

It is important that the battery ground cable be removed

first.

Removing the battery positive cable first can result in a

short circuit.

Jump Starting the Engine with a Booster Battery

The following description assumes that you are using a booster

battery mounted on a second vehicle.

The listed steps (with some minor modifications) are also

applicable if you are using a naked booster battery or special

battery charging equipment.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007