power steering fluid ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 280 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-19

Disassembly

1. Clean the oil pump with solvent (plug the discharge

and suction ports to prevent the entry of solvent).

Be careful not to expose the oil seal of shaft

assembly to solvent.

2. Remove the bolt, suction pipe and O-ring.

3. Remove the connector, O-ring, relief valve and spring.

4. Remove the bolt, rear housing and O-ring.

5. Remove the snap ring.

6. Remove the shaft assembly.

7. Remove the oil seal.

CAUTION: When removing the oil seal, be careful

not to damage the housing.

8. Remove the pump cartridge assembly from the front housing.

9. Remove two O-rings.

Inspection and Repair

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspection.

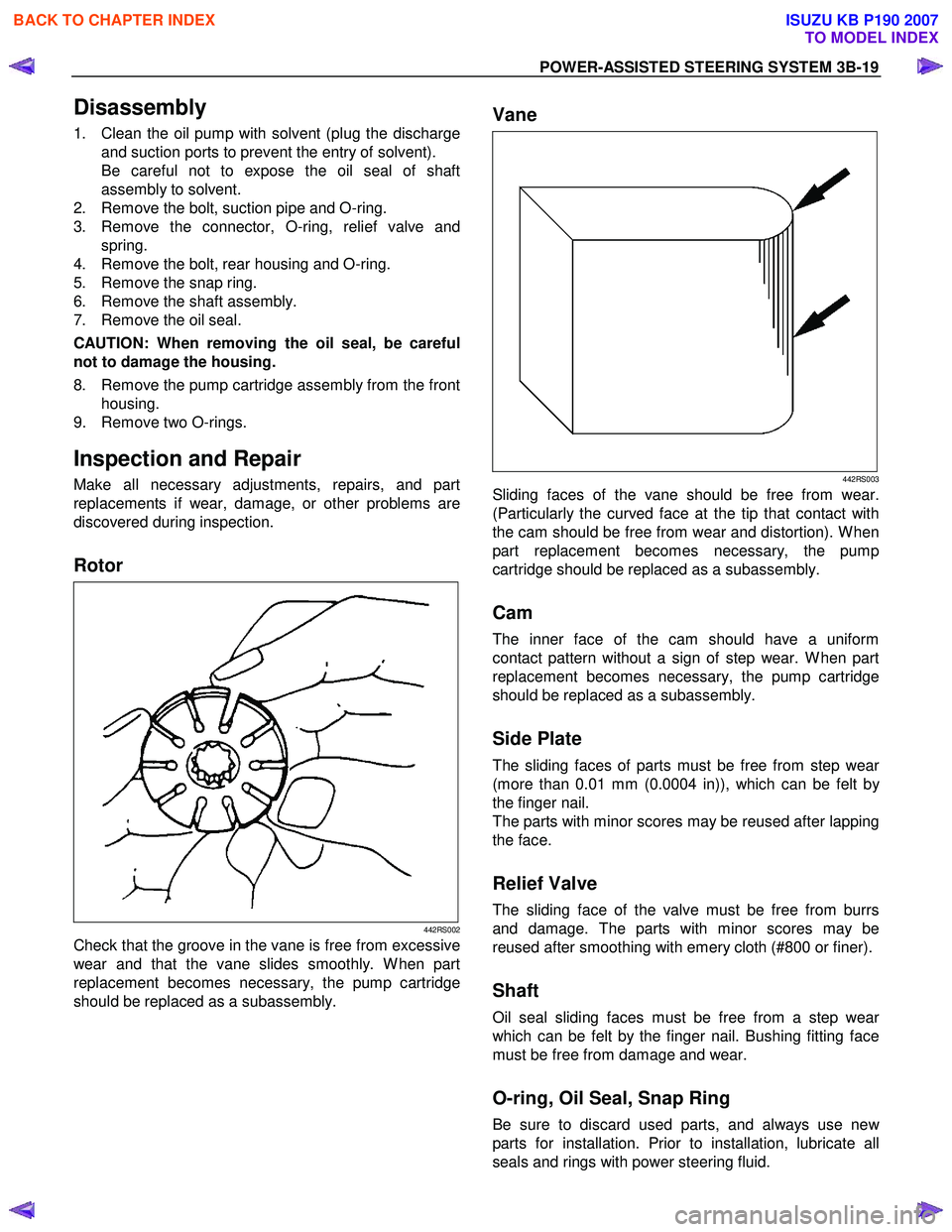

Rotor

442RS002

Check that the groove in the vane is free from excessive

wear and that the vane slides smoothly. W hen part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

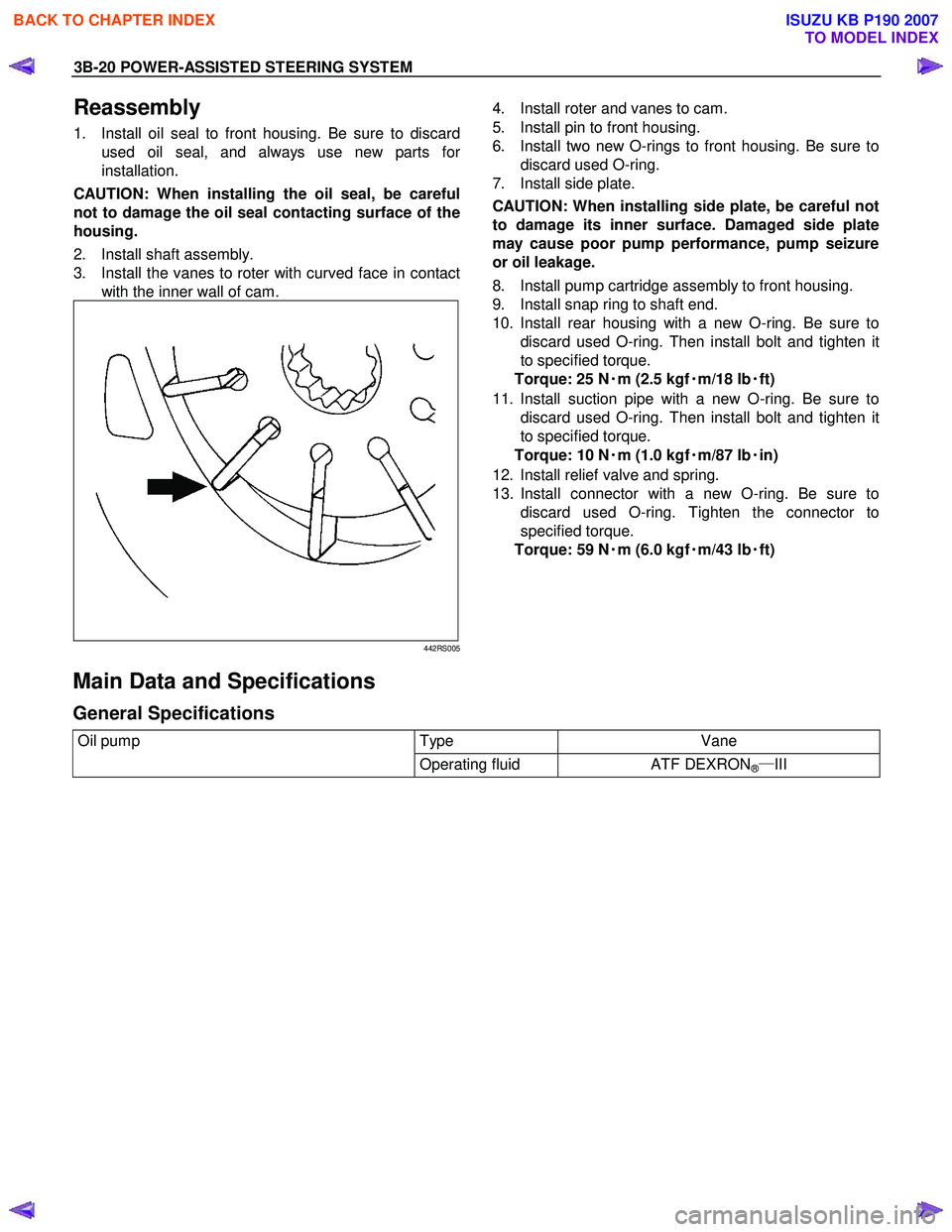

Vane

442RS003

Sliding faces of the vane should be free from wear.

(Particularly the curved face at the tip that contact with

the cam should be free from wear and distortion). W hen

part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Cam

The inner face of the cam should have a uniform

contact pattern without a sign of step wear. W hen part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

Side Plate

The sliding faces of parts must be free from step wear

(more than 0.01 mm (0.0004 in)), which can be felt b

y

the finger nail.

The parts with minor scores may be reused after lapping

the face.

Relief Valve

The sliding face of the valve must be free from burrs

and damage. The parts with minor scores may be

reused after smoothing with emery cloth (#800 or finer).

Shaft

Oil seal sliding faces must be free from a step wear

which can be felt by the finger nail. Bushing fitting face

must be free from damage and wear.

O-ring, Oil Seal, Snap Ring

Be sure to discard used parts, and always use new

parts for installation. Prior to installation, lubricate all

seals and rings with power steering fluid.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 281 of 6020

3B-20 POWER-ASSISTED STEERING SYSTEM

Reassembly

1. Install oil seal to front housing. Be sure to discard

used oil seal, and always use new parts fo

r

installation.

CAUTION: When installing the oil seal, be careful

not to damage the oil seal contacting surface of the

housing.

2. Install shaft assembly.

3. Install the vanes to roter with curved face in contact with the inner wall of cam.

442RS005

4. Install roter and vanes to cam.

5. Install pin to front housing.

6. Install two new O-rings to front housing. Be sure to discard used O-ring.

7. Install side plate.

CAUTION: When installing side plate, be careful not

to damage its inner surface. Damaged side plate

may cause poor pump performance, pump seizure

or oil leakage.

8. Install pump cartridge assembly to front housing.

9. Install snap ring to shaft end.

10. Install rear housing with a new O-ring. Be sure to discard used O-ring. Then install bolt and tighten it

to specified torque.

Torque: 25 N ・

・・

・

m (2.5 kgf ・

・・

・

m/18 lb ・

・・

・

ft)

11. Install suction pipe with a new O-ring. Be sure to discard used O-ring. Then install bolt and tighten it

to specified torque.

Torque: 10 N ・

・・

・

m (1.0 kgf ・

・・

・

m/87 lb ・

・・

・

in)

12. Install relief valve and spring.

13. Install connector with a new O-ring. Be sure to discard used O-ring. Tighten the connector to

specified torque.

Torque: 59 N ・

・・

・

m (6.0 kgf ・

・・

・

m/43 lb ・

・・

・

ft)

Main Data and Specifications

General Specifications

Oil pump Type Vane

Operating fluid

ATF DEXRON®―III

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 283 of 6020

3B-22 POWER-ASSISTED STEERING SYSTEM

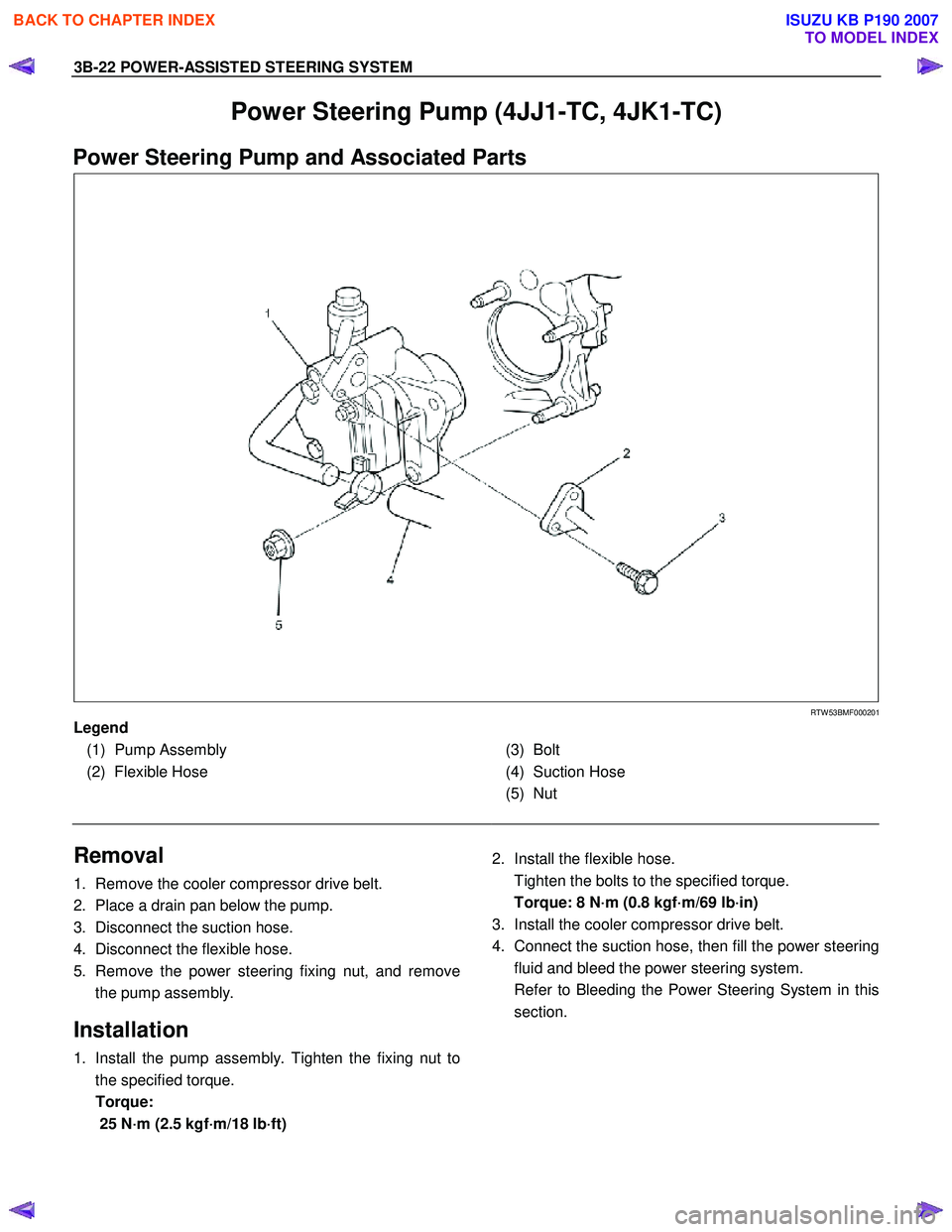

Power Steering Pump (4JJ1-TC, 4JK1-TC)

Power Steering Pump and Associated Parts

RTW 53BMF000201

Legend

(1) Pump Assembly

(2) Flexible Hose

(3) Bolt

(4) Suction Hose

(5) Nut

Removal

1. Remove the cooler compressor drive belt.

2. Place a drain pan below the pump.

3. Disconnect the suction hose.

4. Disconnect the flexible hose.

5. Remove the power steering fixing nut, and remove the pump assembly.

Installation

1. Install the pump assembly. Tighten the fixing nut to

the specified torque.

Torque: 25 N·m (2.5 kgf·m/18 lb·ft)

2. Install the flexible hose.

Tighten the bolts to the specified torque.

Torque: 8 N·m (0.8 kgf·m/69 lb·in)

3. Install the cooler compressor drive belt.

4. Connect the suction hose, then fill the power steering fluid and bleed the power steering system.

Refer to Bleeding the Power Steering System in this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 285 of 6020

3B-24 POWER-ASSISTED STEERING SYSTEM

Disassembly

1. Clean the oil pump with solvent (plug the discharge

and suction ports to prevent the entry of solvent).

Be careful not to expose the oil seal of the shaft assembly to solvent.

2. Remove the bolt, suction pipe and O-ring.

3. Remove the nut and bracket.

4. Remove the nut, washer and joint.

5. Remove the connector, O-ring, relief valve and spring.

6. Remove the bolt, rear housing and O-ring.

7. Remove the pump cartridge assembly and the side plate from the shaft. Remove two O-rings.

Inspection and Repair

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspection.

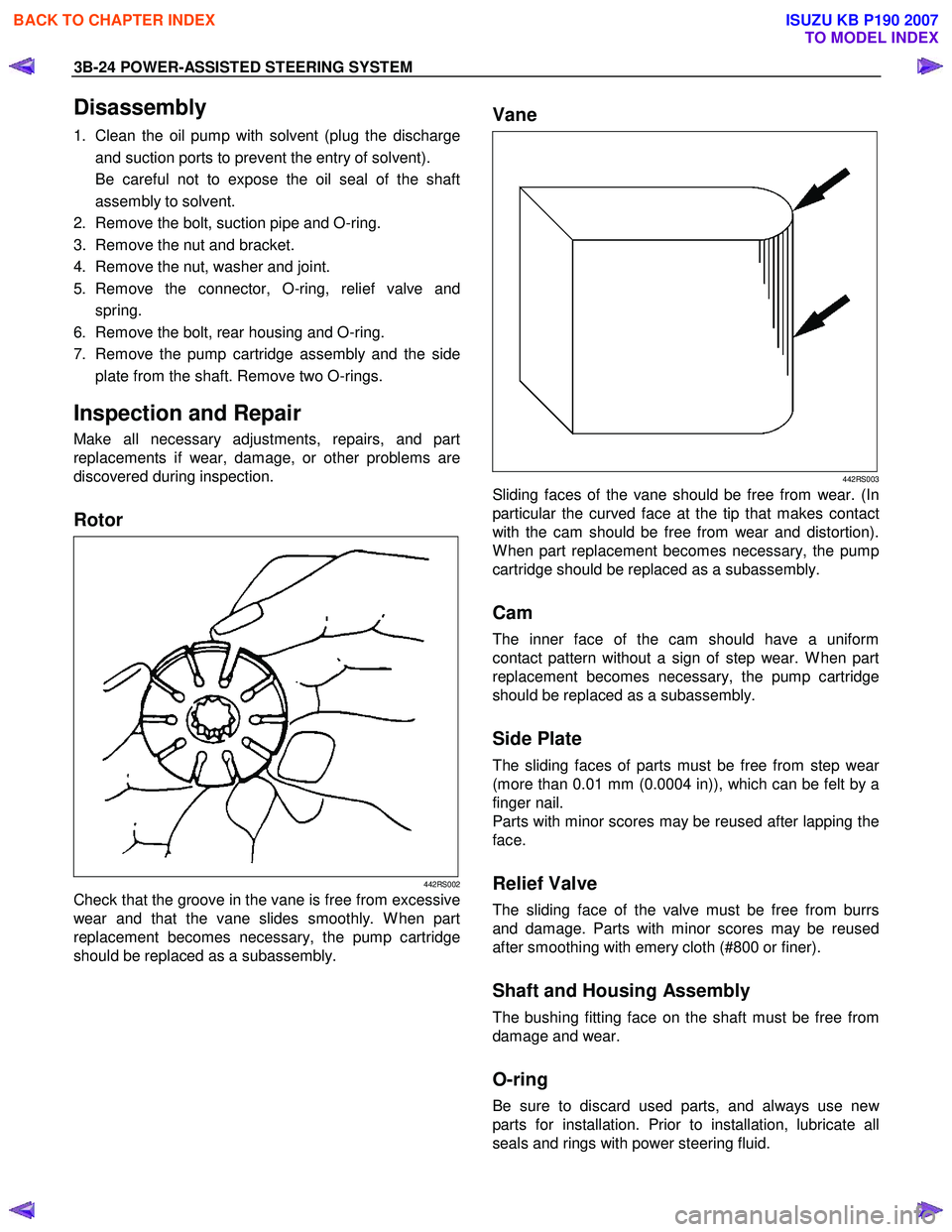

Rotor

442RS002

Check that the groove in the vane is free from excessive

wear and that the vane slides smoothly. W hen part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

Vane

442RS003

Sliding faces of the vane should be free from wear. (In

particular the curved face at the tip that makes contact

with the cam should be free from wear and distortion).

W hen part replacement becomes necessary, the pump

cartridge should be replaced as a subassembly.

Cam

The inner face of the cam should have a uniform

contact pattern without a sign of step wear. W hen part

replacement becomes necessary, the pump cartridge

should be replaced as a subassembly.

Side Plate

The sliding faces of parts must be free from step wear

(more than 0.01 mm (0.0004 in)), which can be felt by a

finger nail.

Parts with minor scores may be reused after lapping the

face.

Relief Valve

The sliding face of the valve must be free from burrs

and damage. Parts with minor scores may be reused

after smoothing with emery cloth (#800 or finer).

Shaft and Housing Assembly

The bushing fitting face on the shaft must be free from

damage and wear.

O-ring

Be sure to discard used parts, and always use new

parts for installation. Prior to installation, lubricate all

seals and rings with power steering fluid.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 286 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-25

Reassembly

1. Install two new O-rings on shaft and housing

assembly. Be sure to discard used O-ring.

2. Install side plate.

CAUTION: When installing side plate, be careful not

to damage its inner surface. A damaged side plate

may cause poor pump performance, pump seizure

or oil leakage.

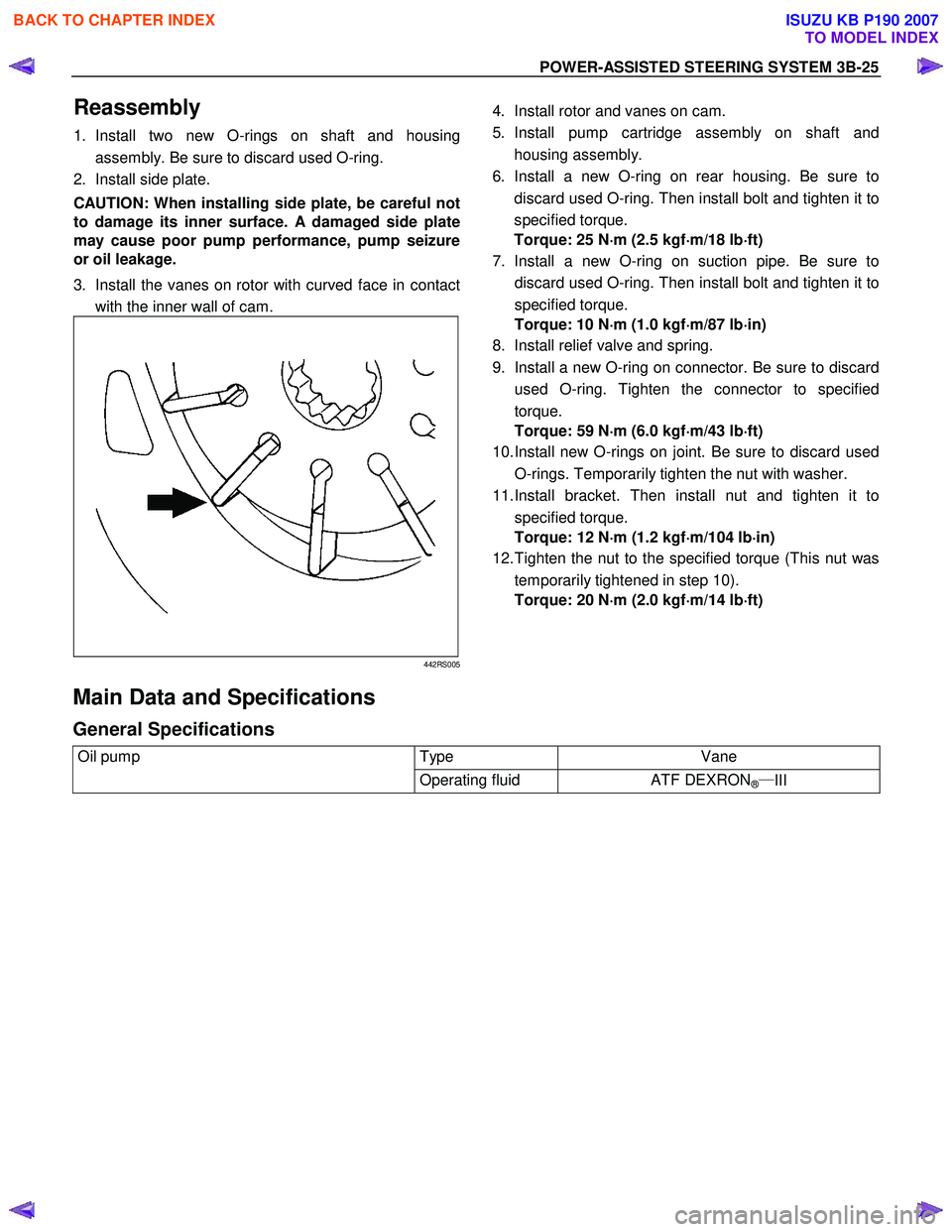

3. Install the vanes on rotor with curved face in contact with the inner wall of cam.

442RS005

4. Install rotor and vanes on cam.

5. Install pump cartridge assembly on shaft and housing assembly.

6. Install a new O-ring on rear housing. Be sure to discard used O-ring. Then install bolt and tighten it to

specified torque.

Torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kgf ⋅

⋅⋅

⋅

m/18 lb ⋅

⋅⋅

⋅

ft)

7. Install a new O-ring on suction pipe. Be sure to

discard used O-ring. Then install bolt and tighten it to

specified torque.

Torque: 10 N ⋅

⋅⋅

⋅

m (1.0 kgf ⋅

⋅⋅

⋅

m/87 lb ⋅

⋅⋅

⋅

in)

8. Install relief valve and spring.

9. Install a new O-ring on connector. Be sure to discard used O-ring. Tighten the connector to specified

torque.

Torque: 59 N ⋅

⋅⋅

⋅

m (6.0 kgf ⋅

⋅⋅

⋅

m/43 lb ⋅

⋅⋅

⋅

ft)

10. Install new O-rings on joint. Be sure to discard used

O-rings. Temporarily tighten the nut with washer.

11. Install bracket. Then install nut and tighten it to specified torque.

Torque: 12 N ⋅

⋅⋅

⋅

m (1.2 kgf ⋅

⋅⋅

⋅

m/104 lb ⋅

⋅⋅

⋅

in)

12. Tighten the nut to the specified torque (This nut was

temporarily tightened in step 10).

Torque: 20 N ⋅

⋅⋅

⋅

m (2.0 kgf ⋅

⋅⋅

⋅

m/14 lb ⋅

⋅⋅

⋅

ft)

Main Data and Specifications

General Specifications

Oil pump Type Vane

Operating fluid

ATF DEXRON®―III

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2438 of 6020

6E–268 ENGINE DRIVEABILITY AND EMISSIONS

KNOCK SENSOR

Location

Right-hand side of the cylinder block.

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect the knock sensor connector.

3. Loosen a bolt and remove knock sensor from the cylinder block.

Installation Procedure 1. Tighten the knock sensor by a bolt with specified tightening torque.

Tightening Torque

• Bolt: 20N·m (2.0kgf·m) 2. Connect a knock sensor connector to the knock sensor.

3. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

POWER STEERING PRESSURE (PSP)

SWITCH

Location

Installed on the power steering pump assembly.

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect the power steering pressure switch connector.

3. Loosen and remove the power steering pressure switch from the power steering pump.

Installation Procedure 1. Install the power steering pressure switch to the power steering pump.

2. Tighten the power steering pressure switch.

3. Connect a connector to the power steering pressure switch.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify no power steering fluid leaking from the sensor

threads after replacement.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2519 of 6020

Engine Mechanical – V6 Page 6A1–40

Cause Correction

W orn valve guides and or valve stems. Inspect and repair valves and valve guides as required,

refer to 3.22 Cylinder Head Assembly.

W orn or damaged valve stem oil seal. Replace valve stem oil seals as required, refer to 3.22

Cylinder Head Assembly.

Piston rings broken, worn or not seated correctly. Allowing adequate time for the piston rings to seat correctly,

replace piston rings as required, refer to 4.5 Pistons, Pins,

Rings, Connecting Rods and Big-end Bearings.

Piston rings incorrectly installed or not matched to cylinder

bore oversize. Replace piston rings as required, refer to 4.5 Pistons, Pins,

Rings, Connecting Rods and Big-end Bearings.

2.18 Engine Oil Leak Diagnosis

Introduction

It is important to correctly identify the source of an engine oil leak. For example, a power steering fluid leak or spillage

during servicing can travel across the valley area of the engine and run-out the weep hole, which is located at the back of

the cylinder block. Failure to correctly identify the source of an engine oil leak can lead to unnecessary replacement of

engine components.

Most fluid leaks can be repaired by repairing or replacing the faulty component or resealing the gasket surface. However,

once a leak is identified it is important to determine and repair the cause as well as the leak itself.

Locating and Identifying the Leak

Inspect the leaking fluid and determine whether it is engine oil, transmission fluid, power steering fluid, brake fluid or

some other fluid. If unsure of the source of the leaking lubricant, a quick check of fluid levels should indicate where the

fluid is coming from, as one or more fluid level should be low.

Visual Inspection

Once the type of leaking fluid has been determined, a visual inspection of the affected system should be performed.

W hen performing the visual inspection:

1 Bring the vehicle to the normal operating temperature.

2 Park the vehicle over a large sheet of paper or other clean surface.

3 Leave the vehicle idling for 2-3 minutes, then check for dripping fluid.

4 If required, identify the type of fluid leaking and the approximate location of the leak.

5 Visually inspect the suspected area. A small mirror may assist viewing areas that are difficult to see normally.

6 Check for leaks at all sealing surfaces and fittings.

7 Check for any cracked or damaged components.

8 If the leak cannot be located, completely clean the entire engine and surrounding components, drive the vehicle at normal operating temperature for several kilometres and then repeat Steps 3 to 8.

9 If the leak still cannot be located, proceed with either the Powder Method or Black Light and Dye Method as outlined below.

Powder Method

1 Completely clean the entire engine and surrounding components.

2 Apply an aerosol type powder (e.g. foot powder) to the suspected area.

3 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

4 Identify the source of the leak from the discoloration of the powder around the suspect components.

5 If required, use a small mirror to assist in viewing areas that are difficult to see normally.

6 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

Black Light and Dye Method

A black light and die kit Tool No. J28428-E or a commercially available equivalent is available to technicians to aid in

engine oil leak diagnosis. W hen using a black light and die kit for the first time, it is recommended the technician read the

manufacturers instructions prior to using the kit.

1 Add the specified amount of dye, as per manufacturers instructions, into the engine or suspected source of the oil leak.

2 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2566 of 6020

Engine Mechanical – V6 Page 6A1–87

3.14 Crankshaft Front Seal

Replace

1 Remove the crankshaft balancer assembly, refer to 3.13 Crankshaft Balancer Assembly.

2 Using a flat bladed tool (2) or seal remover, Tool No. E-308, carefully remove the crankshaft front seal (1)

from the front cover.

Figure 6A1 – 81

3 Using crankshaft front seal installer, Tool No. J-29184 (2) and a suitable hammer, install a new crankshaft

front seal (1) until fully seated against the front cover

housing.

4 Install the crankshaft balancer assembly, refer to 3.13 Crankshaft Balancer Assembly.

CAUTION

Do not lubricate the crankshaft front oil seal

or crankshaft balancer sealing surfaces. The

crankshaft balancer is installed into a dry

seal.

Figure 6A1 – 82

3.15 Front Cover Assembly

Remove

1 Drain the engine coolant, refer to 6B1_Engine Cooling.

2 Remove the water outlet pipe and coolant pump assembly, refer to 6B1_ Engine Cooling:

3 Remove the camshaft covers, refer to 3.12 Camshaft Cover.

4 Remove the crankshaft balancer assembly, refer to 3.13 Crankshaft Balancer Assembly.

5 Disconnect the purge vent hose from the water outlet pipe.

NOTE

Do not disconnect the power steering pipes or

drain the power steering fluid.

6 Remove the power steering pump reservoir mounting bracket, refer to 3.8 Power Steering Pump Bracket.

7 Remove the camshaft position sensor, refer to 6C1-3 Engine Management – V6 – Service Operations.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2677 of 6020

Engine Mechanical – V6 Page 6A1–198

k Timing chains, tensioners, shoes, guides & sprockets, refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides.

l Cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

m Oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly.

n Piston and connecting rod assemblies, refer to 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings.

o Crankshaft assembly, refer to 4.6 Crankshaft and Main Bearings.

p Piston oil nozzles, refer 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings.

Reassemble

Reassembly of the engine assembly is the reverse of the disassembly procedure.

Reinstall

Reinstallation of the engine assembly is the reverse to the removal procedure, noting the following:

NOTE

Refer to 6 Torque Wrench Specifications

for the correct torque specifications.

1 Tighten the fasteners to the correct torque specification.

Engine ground connector bolt

torque specification ............................................10.0 Nm

Power steering high pressure line

attaching bolt torque specification .............8.0 – 12.0 Nm

Power steering high pressure line

flare nut torque specification ...................25.0 – 35.0 Nm

Engine mount to frame attaching bolt

torque specification .................................44.0 – 60.0 Nm

Knock Sensor Attaching Nut

torque specification ............................................23.0 Nm

2 Use only the specified engine lubricant type and quantity. It is recommended that a fluorescent oil dye, such as that contained in J 28481-B, be added to assist in any future oil leak diagnosis.

3 Fill the cooling system with the correct quantity and grade of coolant, refer to 6B1 Engine Cooling – V6.

4 Check transmission fluid level, replenishing as required, using the specified lubricant for the transmission fitted, refer to 7C1 Automatic – 4L60E – General Information.

5 Disable the ignition system, refer to 6C1-3 Engine Management – V6 – Service Operations.

6 Crank the engine several times. Listen for any unusual noises or evidence that parts are binding.

7 Enable the ignition system. Start the engine and listen for any unusual noises.

8 Check the vehicle oil pressure gauge or warning indicator and confirm the engine has acceptable oil pressure. If required, install an oil pressure gauge and measure the engine oil pressure, refer to 2.19 Engine Oil Pressure

Diagnosis.

9 Run the engine at about 1,000 r.p.m. until the engine has reached normal operating temperature.

10 Listen for any unusual noises.

11 Check for oil, fuel, coolant and exhaust leaks while the engine is running, correcting as required.

12 Perform a final inspection for correct engine oil and coolant levels.

4.2 Oil Pan and Oil Pump Suction Pipe Assembly

Remove

1 Remove the engine assembly from the vehicle, refer to 4.1 Engine .

2 Separate the engine and transmission assemblies, refer to 7C1 Automatic – 4L60E – General Information.

3 Mount the engine assembly on a suitable engine stand.

4 Remove the engine front cover, refer to 3.15 Front Cover Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2825 of 6020

Engine Mechanical – V6 Page 6A1–48

Page 6A1–48

2.18 Engine Oil Leak Diagnosis

Introduction

It is important to correctly identify the source of an engine oil leak. For example, a power steering fluid leak or spillage

during servicing can travel across the va lley area of the engine and run-out the weep hole, which is located at the back of

the cylinder block. Failure to correctly identify the source of an engine oil leak can lead to unnecessary replacement of

engine components.

Most fluid leaks can be repaired by repairi ng or replacing the faulty component or resealing the gasket surface. However,

once a leak is identified it is im portant to determine and repair the c ause as well as the leak itself.

Locating and Identifying the Leak

Inspect the leaking fluid and determine whet her it is engine oil, transmission fluid, power steering fluid, brake fluid or

some other fluid. If unsure of the source of the leaking lubricant, a quick check of fluid levels should indicate where the

fluid is coming from, as one or more fluid level should be low.

Visual Inspection

Once the type of leaking fluid has been determined, a visual inspection of the affected system should be performed.

When performing the visual inspection:

1 Bring the vehicle to the normal operating temperature.

2 Park the vehicle over a large s heet of paper or other clean surface.

3 Leave the vehicle idling for 2-3 minut es, then check for dripping fluid.

4 If required, identify the type of fluid leak ing and the approximate location of the leak.

5 Visually inspect the suspected area. A small mirror may assist viewing areas that are difficult to see normally.

6 Check for leaks at all sealing surfaces and fittings.

7 Check for any cracked or damaged components.

8 If the leak cannot be located, completely clean the entire engine and surrounding components, drive the vehicle at

normal operating temperature for several k ilometres and then repeat Steps 3 to 8.

9 If the leak still cannot be located, proceed with either the Powder Method or Black Light and Dye Method as

outlined below.

Powder Method

1 Completely clean the entir e engine and surrounding components.

2 Apply an aerosol type powder (e.g. f oot powder) to the suspected area.

3 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

4 Identify the source of the leak from the discoloration of the powder around the suspect components.

5 If required, use a small mirror to assist in vi ewing areas that are difficult to see normally.

6 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

Black Light and Dye Method

A black light and die kit Tool No. J28428-E or a commercially av ailable equivalent is available to technicians to aid in

engine oil leak diagnosis. When using a black light and die kit fo r the first time, it is recommended the technician read the

manufacturers instructions prior to using the kit.

1 Add the specified amount of dye, as per manufacturers instructions, into the engine or suspected source of the oil

leak.

2 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

3 With the vehicle parked on a flat leve l surface, aim the black light at the suspected component/s. The dyed fluid will

appear as a yellow path leading to the oil leak source

4 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007