Circuit ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1235 of 6020

Engine Control System (4JH1) 6E-201

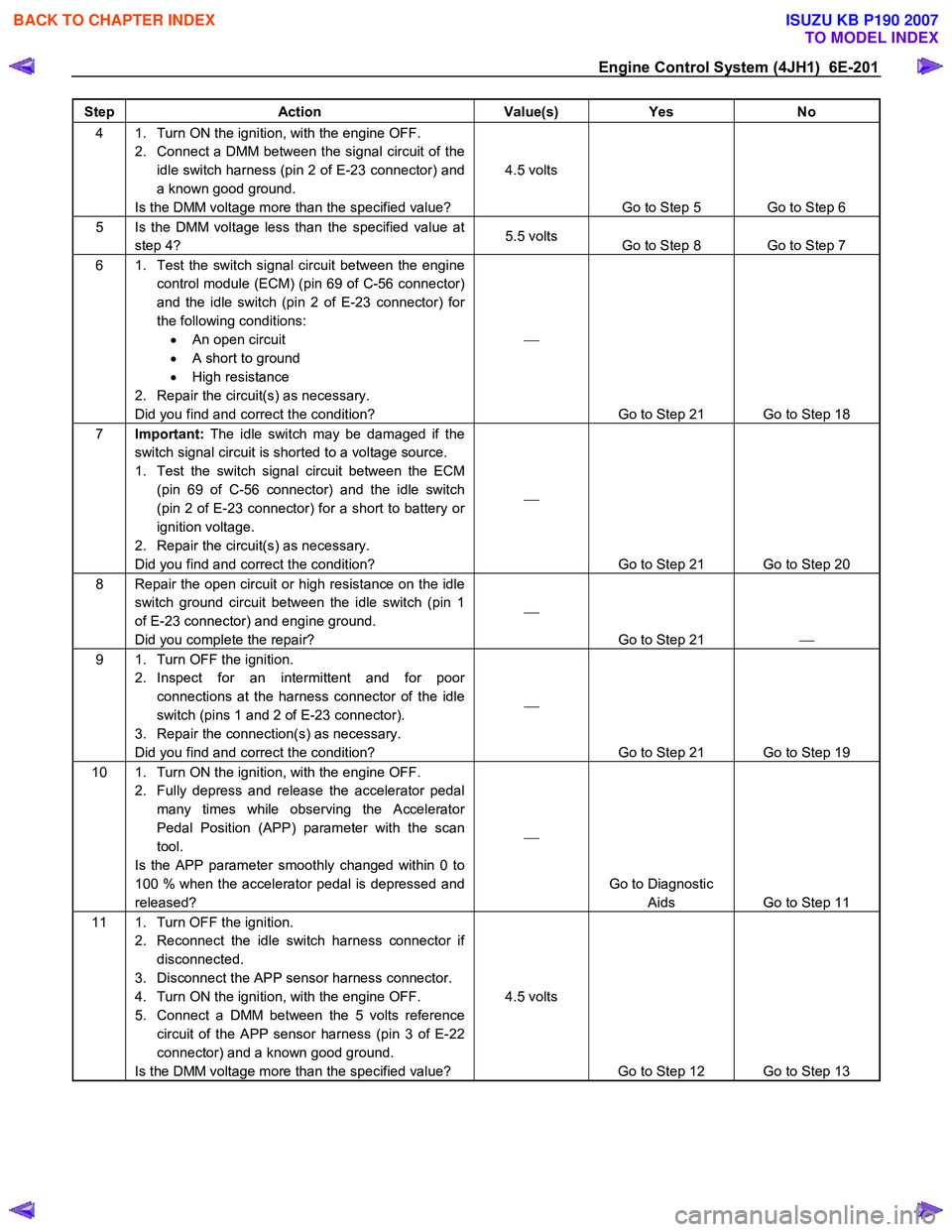

Step Action Value(s) Yes No

4 1. Turn ON the ignition, with the engine OFF.

2. Connect a DMM between the signal circuit of the idle switch harness (pin 2 of E-23 connector) and

a known good ground.

Is the DMM voltage more than the specified value? 4.5 volts

Go to Step 5 Go to Step 6

5 Is the DMM voltage less than the specified value at step 4? 5.5 volts

Go to Step 8 Go to Step 7

6 1. Test the switch signal circuit between the engine

control module (ECM) (pin 69 of C-56 connector)

and the idle switch (pin 2 of E-23 connector) for

the following conditions: • An open circuit

• A short to ground

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 21 Go to Step 18

7 Important: The idle switch may be damaged if the

switch signal circuit is shorted to a voltage source.

1. Test the switch signal circuit between the ECM (pin 69 of C-56 connector) and the idle switch

(pin 2 of E-23 connector) for a short to battery or

ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 21 Go to Step 20

8 Repair the open circuit or high resistance on the idle switch ground circuit between the idle switch (pin 1

of E-23 connector) and engine ground.

Did you complete the repair?

Go to Step 21

9 1. Turn OFF the ignition.

2. Inspect for an intermittent and for poor connections at the harness connector of the idle

switch (pins 1 and 2 of E-23 connector).

3. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 21 Go to Step 19

10 1. Turn ON the ignition, with the engine OFF. 2. Fully depress and release the accelerator pedal many times while observing the Accelerator

Pedal Position (APP) parameter with the scan

tool.

Is the APP parameter smoothly changed within 0 to

100 % when the accelerator pedal is depressed and

released?

Go to Diagnostic Aids Go to Step 11

11 1. Turn OFF the ignition.

2. Reconnect the idle switch harness connector if disconnected.

3. Disconnect the APP sensor harness connector.

4. Turn ON the ignition, with the engine OFF.

5. Connect a DMM between the 5 volts reference circuit of the APP sensor harness (pin 3 of E-22

connector) and a known good ground.

Is the DMM voltage more than the specified value? 4.5 volts

Go to Step 12 Go to Step 13

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1236 of 6020

6E-202 Engine Control System (4JH1)

Step Action Value(s) Yes No

12 1. Turn OFF the ignition.

2. Connect a 3-amp fused jumper wire across the APP sensor connector between pins 2 and 3 of

the E-22 connector.

3. Turn ON the ignition, with the engine OFF.

Does DTC P1120 (Symptom Code 1) set, but not

P1120 (Symptom Code E)?

Go to Step 15 Go to Step 14

13 1. Test the 5 volts reference circuit between the engine control module (ECM) (pin 57 of C-56

connector) and the APP sensor (pin 3 of E-22

connector) for an open circuit or high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 21 Go to Step 18

14 1. Test the signal circuit between the ECM (pin 38 of C-56 connector) and the APP sensor (pin 2 of

E-22 connector) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 21 Go to Step 18

15 1. Test the signal circuit between the ECM (pin 38 of C-56 connector) and the APP sensor (pin 2 of

E-22 connector) for the following conditions: • A short to ground

• A short to the low reference circuit

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 21 Go to Step 16

16 1. Test the low reference circuit between the ECM (pin 49 of C-56 connector) and the APP sensor

(pin 1 of E-22 connector) for high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 21 Go to Step 17

17 1. Turn OFF the ignition. 2. Inspect for an intermittent and for poor connections or corrosion at the harness

connector of the APP sensor (pin 1, 2 and 3 of E-

22 connector).

3. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 21 Go to Step 19

18 1. Turn OFF the ignition. 2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for poor connections on the APP sensor circuits at the

harness connector of the ECM (pins 38, 49 and

57 of C-56 connector) or the idle switch circuit at

the harness connector of the ECM (pin 69 of C-

56 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 21 Go to Step 20

19 Replace the accelerator pedal position sensor. Refer to Accelerator Pedal Position Sensor Replacement

in this section. (Idle switch is part of APP sensor)

Did you complete the replacement?

Go to Step 21

20 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 21

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1238 of 6020

6E-204 Engine Control System (4JH1)

DTC P1173 (Symptom Code 3) (Flash Code 22)

Circuit Description

The engine coolant temperature (ECT) sensor is

installed to the thermostat housing. The ECT sensor is

a variable resistor. The ECT sensor has a signal circuit

and a low reference circuit. The ECT sensor measures

the temperature of the engine coolant. The engine

control module (ECM) supplies 5 volts to the ECT signal

circuit and a ground for the ECT low reference circuit.

W hen the ECT sensor is cold, the sensor resistance is

high. W hen the engine coolant temperature increases,

the sensor resistance decreases. W ith high senso

r

resistance, the ECM detects a high voltage on the ECT

signal circuit. W ith lower sensor resistance, the ECM

detects a lower voltage on the ECT signal circuit. If the

ECM detects an excessive high coolant temperature,

this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects an excessive high coolant

temperature for longer than 30 seconds.

Action Taken When the DTC Sets • The ECM does not illuminate the malfunction

indicator lamp (MIL) when the diagnostic runs and

fails.

Condition for Clearing the DTC

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

•

After starting the engine, the ECT should rise

steadily to about 80°C – 85°C (176°F – 185°F)

then stabilize when the thermostat opens.

• Use the Temperature vs. Resistance table to test

the ECT sensor at various temperature levels to

evaluate the possibility of a skewed sensor.

A

skewed sensor could result in poor driveabilit

y

concerns.

Notice: • This DTC is caused by an engine overheat

condition (i.e. low engine coolant level). Since this

DTC does not illuminate any lamps, clear the DTC

and ensure there are no signs of engine damage.

Excessive engine overheat may damage internal

engine components.

DTC P1173 (Symptom Code 3) (Flash Code 22)

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and wait until engine is fully warms upped.

4. Observe the Engine Coolant Temperature (ECT) parameter with the scan tool.

Is the ECT parameter more than the specified

value? 100°C (212°F)

Go to Step 4 Go to Step 3

3 Ask the driver if overheat is caused by low engine coolant level, etc.

If engine overheat has experienced, the engine must

be inspected and repaired as necessary.

Did you complete the action?

Go to Step 6

4 1. Test the ECT sensor at various temperature

levels to evaluate the possibility if a skewed

sensor.

2. Replace the ECT sensor as necessary.

Did you find and correct the condition?

Go to Step 6 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1240 of 6020

6E-206 Engine Control System (4JH1)

DTC P1173 (Symptom Code 7, A) (Flash Code 22)

Circuit Description

The fuel temperature (FT) sensor is internal to the fuel

injection pump control unit (PCU). It detects fuel

temperature in the fuel injection pump. If the PCU

detects an excessively high or low fuel temperature, this

DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects an excessive high FT for longe

r

than 30 seconds. (Symptom Code 7)

• The ECM detects an excessive low FT for longe

r

than 30 seconds. (Symptom Code A)

Action Taken When the DTC Sets • The ECM does not illuminate the malfunction

indicator lamp (MIL) when the diagnostic runs and

fails.

• The PCU limits fuel injection quantity. (Symptom

Code 7)

Condition for Clearing the DTC

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice:

• FT sensor is internal to the PCU and it is part o

f

the fuel injection pump assembly.

DTC P1173 (Symptom Code 7, A) (Flash Code 22)

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Step 4

3 Important: The fuel injection pump must be timed to

the engine.

Replace the fuel injection pump. Refer to Fuel

Injection Pump Replacement in engine mechanical

section. (Fuel temperature [FT] sensor is internal to

the fuel injection pump control unit [PCU] and it is

part of the fuel injection pump assembly.)

Did you complete the replacement?

Go to Step 4

4 1. Clear the DTCs with the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 3 Go to Step 5

5 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1241 of 6020

Engine Control System (4JH1) 6E-207

DTC P1335 (Symptom Code A) (Flash Code 43)

Circuit Description

The crankshaft position (CKP) sensor is located on top

of the flywheel housing. There are 4 slits spaced 90 °

on the flywheel circumference. The CKP sensor is a

magnetic coil type sensor, which generates an AC

signal voltage based on the crankshaft rotational speed.

The engine control module (ECM) monitors both the

CKP sensor and injection pump camshaft position

(CMP) sensor signals to ensure they correlate with each

other. If the fuel injection pump control unit (PCU)

receives faulty CKP sensor signal pulses, this DTC will

set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC • The PCU detects CKP sensor signal from the

ECM is faulty.

Action Taken When the DTC Sets • The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice: • PCU is part of the fuel injection pump assembly.

DTC P1335 (Symptom Code A) (Flash Code 43)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine (Note a slight start delay may be noticed).

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Is DTC P0335 (Symptom Code B or D) set?

Go to Applicable DTC Go to Step 3

3 1. Turn OFF the ignition. 2. Disconnect the engine control module (ECM) C-57 harness connector. Keep the C-56 harness

connector with connected.

3. Connect a DMM between the crankshaft position (CKP) sensor signal output circuit (pin 91 of C-57

connector) and a known good ground.

4. Turn ON the ignition, with the engine OFF.

Does the DMM voltage more than the specified

value? 10 volts

Go to Step 5 Go to Step 4

4 1. Test the CKP sensor signal output circuit between the ECM (pin 91 of C-57 connector) and

the fuel injection pump (pin 8 of E-6 connector)

for the following conditions: • An open circuit

• A short to ground

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 10 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1242 of 6020

6E-208 Engine Control System (4JH1)

Step Action Value(s) Yes No

5 1. Test the CKP sensor signal output circuit

between the ECM (pin 91 of C-57 connector) and

the fuel injection pump control unit (PCU) (pin 8

of E-6 connector) for a short to battery or ignition

voltage.

Notice:

Perform this by connecting a test lamp between the

ECM harness connector (pin 91 of C-57 connector)

and a known good ground. If the test lamp

illuminate, circuit is short to battery or ignition

voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 10 Go to Step 7

6 1. Turn OFF the ignition. 2. Disconnect the PCU harness connector.

3. Inspect for an intermittent and for a poor connection on the CKP sensor signal circuit at

the harness connector of the PCU (pin 8 of E-6

connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 10 Go to Step 8

7 1. Turn OFF the ignition. 2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection on the CKP sensor signal output

circuit at the harness connector of the ECM (pin

92 of C-57 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 10 Go to Step 9

8 Important: The fuel injection pump must be timed to

the engine.

Replace the fuel injection pump. Refer to Fuel

Injection Pump Replacement in engine mechanical

section.

Did you complete the replacement?

Go to Step 10

9 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 10

10 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 2 Go to Step 11

11 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1243 of 6020

Engine Control System (4JH1) 6E-209

DTC P1345 (Symptom Code A) (Flash Code 41)

Circuit Description

The engine control module (ECM) calculates the

desired fuel injection quantity and timing using data sent

from various sensors. These desired data are sent to

the fuel injection pump control unit (PCU) via a

controller area network (CAN) communication bus. The

PCU also receives signals from the internal inputs:

pump camshaft position (CMP) sensor that is located

inside the fuel injection pump to determine the cam ring

rotation angle and the fuel injection pump speed. The

fuel temperature (FT) sensor is internal the PCU. These

values are used to compare the desired values sent

from the ECM then PCU determines the injection time

r

piston position and fuel injection quantity, and actuates

timing control valve (TCV) & fuel injection solenoid

valve based on control maps in the PCU. The PCU also

compares the engine speed signal sent from the ECM

and the fuel injection pump speed. If the PCU received

faulty fuel injection pump CMP sensor signal, this DTC

will set.

Condition for Setting the DTC • The PCU received faulty fuel injection pump CMP

sensor signal for 1 second.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

Condition for Clearing the MIL/DTC • The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice:

• Fuel injection pump CMP sensor is internal to the

fuel injection pump assembly.

• PCU is part of the fuel injection pump assembly.

DTC P1345 (Symptom Code A) (Flash Code 41)

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Step 4

3 Important: The fuel injection pump must be timed to

the engine.

Replace the fuel injection pump. Refer to Fuel

Injection Pump Replacement in engine mechanical

section.

Did you complete the replacement?

Go to Step 4

4 1. Clear the DTCs with the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Step 5

5 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1244 of 6020

6E-210 Engine Control System (4JH1)

DTC P1520 (Symptom Code A) (Flash Code 47)

Circuit Description

(Manual Transmission)

The neutral switch is installed on the transmission gea

r

control box. W hen the gear position is neutral, the

switch is closed and the switch signal is provided to the

engine control module (ECM). If the ECM detects the

neutral switch signal is not changed from neutral during

the predetermined engine speed and vehicle speed

range, this DTC will set.

(Automatic Transmission)

The inhibitor switch is installed to the transmission case.

W hen the selector position is P or N range, the switch is

closed and the switch signal is provided to the Emir the

ECM detects the neutral switch signal is not changed

from P or N during the predetermined engine speed and

vehicle speed range, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

• The engine speed is higher than 1500 RPM.

• The vehicle speed is higher than 63 km/h (39

MPH) (M/T) or 78 km/h (49 MPH) (A/T).

• The clutch pedal is released. (M/T).

Condition for Setting the DTC

• The ECM detects that the neutral switch signal is

continuously ON (neutral or P/N range) during

three consecutive driving cycles.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

Condition for Clearing the MIL/DTC

Important: • Following conditions must be met two consecutive

driving cycles. (One driving cycle: Ignition switch

ON > Engine run > Vehicle run > Ignition switch

OFF for 10 seconds)

- The engine speed is higher than 1500 RPM

- The vehicle speed is higher than 63 km/h (39 MPH) (M/T) or 78 km/h (49 MPH) (A/T)

- The clutch pedal is released (M/T)

- Other than neutral or P/N range

- After the above procedure is done, a history

DTC clears after 40 consecutive driving cycles

without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P1520 (Symptom Code A) (Flash Code 47)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Chart for M/T

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn ON the ignition, with the engine OFF.

3. Observe the Neutral Switch parameter with the scan tool while shift to neutral and other

positions.

Does the scan tool indicate ON when the position is

neutral and OFF when other than the neutral?

Go to Diagnostic Aids Go to Step 3

3 1. Turn OFF the ignition. 2. Disconnect the neutral switch harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Observe the Neutral Switch parameter with the scan tool.

Does the scan tool indicate ON?

Go to Step 4 Go to Step 5

4 1. Test the neutral switch input signal circuit between the engine control module (ECM) (pin

87 of C-57 connector) and the neutral switch (pin

1 of E-11 connector) for a short to battery or

ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1246 of 6020

6E-212 Engine Control System (4JH1)

Step Action Value(s) Yes No

4 1. Check to ensure the inhibitor switch is adjusted

correctly.

2. Adjust the inhibitor switch as necessary. Refer to Inhibitor Switch Adjustment in Automatic

Transmission Section.

Did you find and correct the condition?

Go to Step 7 Go to Step 5

5 1. Test the P & N position switch signal circuit between the engine control module (ECM) (pin

87 of C-57 connector) and the diode (pin 2 of X-

16 connector) for a short to battery or ignition

voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 6

6 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 7

7 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

Important: Following conditions must be met two

consecutive driving cycles before clear with the scan

tool. (One driving cycle: Ignition switch ON > Engine

run > Vehicle run > Ignition switch OFF for 10

seconds) • The engine speed is higher than 1500 RPM

• The vehicle speed is higher than 78 km/h

(49 MPH)

• Other than P/N range

3. Turn ON the ignition, with the engine OFF.

4. Observe the Neutral Switch parameter with the scan tool while shift to P or N and other

positions.

Does the scan tool indicate ON when the position is

P or N and OFF when other than the P or N?

Go to Step 8 Go to Step 2

8 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1247 of 6020

Engine Control System (4JH1) 6E-213

DTC P1520 (Symptom Code B) (Flash Code 47)

Circuit Description

The neutral switch is installed on the transmission gea

r

control box. W hen the gear position is neutral, the

switch is closed and the switch signal is provided to the

engine control module (ECM). If the ECM detects the

neutral switch signal is not changed from other than

neutral during the predetermined engine speed and

vehicle speed range, this DTC will set. This DTC runs

only manual transmission.

Condition for Running the DTC

• The ignition switch is ON.

• The engine speed is higher than 665 RPM

• The vehicle speed is lower than 2 km/h (1.2 MPH).

• The clutch pedal is released after once depressed.

Condition for Setting the DTC • The ECM detects that the neutral switch signal is

continuously OFF (other than neutral) during three

consecutive driving cycles.

Action Taken When the DTC Sets • The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

Condition for Clearing the MIL/DTC

Important: • Following conditions must be met two consecutive

driving cycles. (One driving cycle: Ignition switch

ON > Engine run > Ignition switch OFF for 10

seconds)

- The engine speed is higher than 665 RPM

- The vehicle speed is lower than 2 km/h (1.2 MPH)

- The clutch pedal is released after once depressed

- Neutral position

- After the above procedure is done, a history

DTC clears after 40 consecutive driving cycles

without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P1520 (Symptom Code B) (Flash Code 47)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn ON the ignition, with the engine OFF.

3. Observe the Neutral Switch parameter with the scan tool while shift to neutral and other

positions.

Does the scan tool indicate ON when the position is

neutral and OFF when other than the neutral?

Go to Diagnostic Aids Go to Step 3

3 1. Turn OFF the ignition. 2. Inspect the ECM (10A) fuse (EB-4) in the engine room fuse block.

Is the ECM (10A) fuse (EB-4) open?

Go to Step 4 Go to Step 5

4 Replace the ECM (10A) fuse (EB-4). If the fuse continues to open, repair the short to ground on one

of the circuits that is fed by the ECM (10A) fuse (EB-

4) or replace the shorted attached component fed by

the ECM (10A) fuse (EB-4).

Did you complete the repair?

Go to Step 13

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007