torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4554 of 6020

UNIT REPAIR (JR405E) 7A4-77

30ASSY067

•

Apply ATF to the O-ring at the outside of the oil pump.

• Install the oil pump assembly to the transmission case.

•

Apply sealing agent (TB1215) to the threaded surfaces

of the 8 fixing bolts and tighten to the specified torque.

Torque: 58 N ⋅

⋅⋅

⋅

m (5.9 kgf ⋅

⋅⋅

⋅

m/43 Ib ⋅

⋅⋅

⋅

ft)

31ASSY068

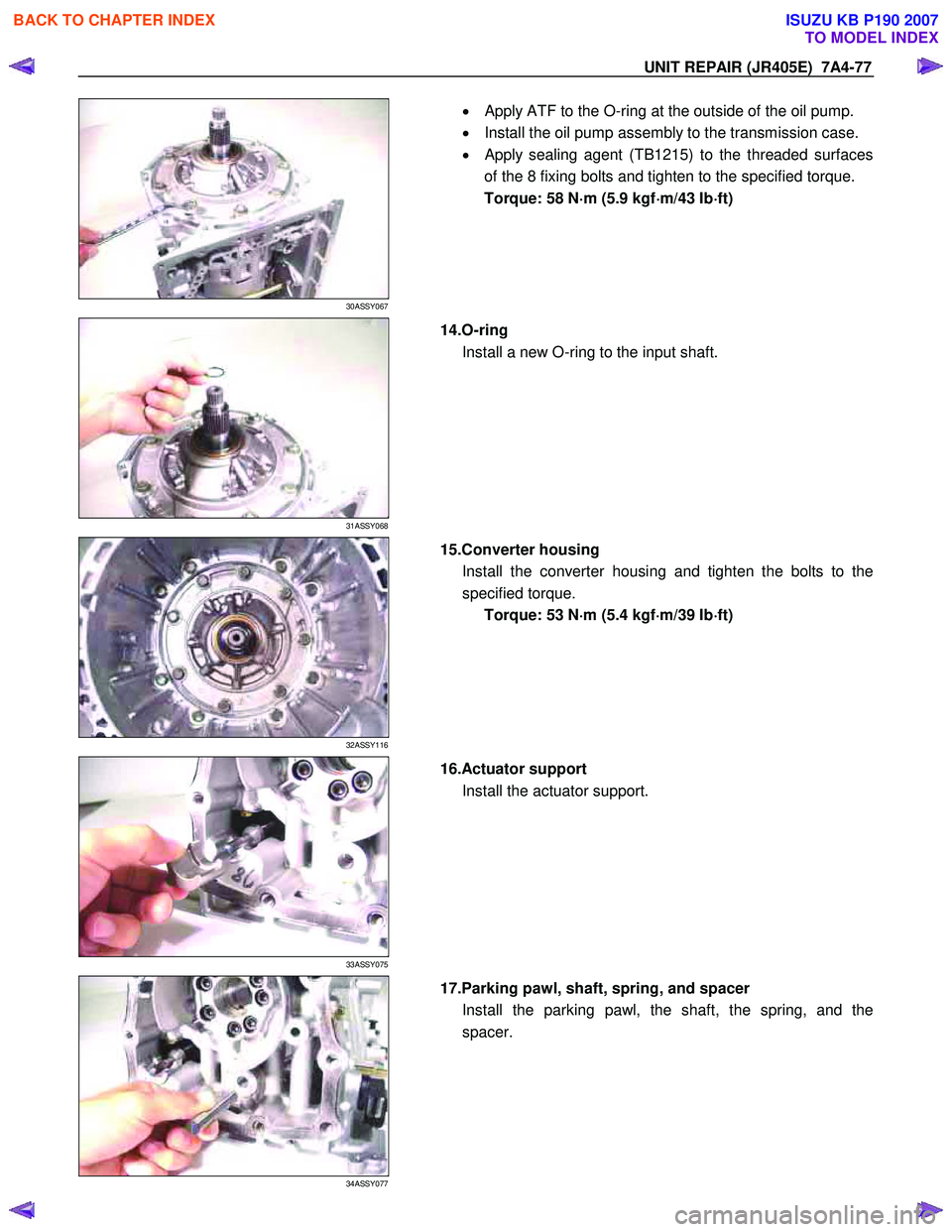

14.O-ring

Install a new O-ring to the input shaft.

32ASSY116

15.Converter housing

Install the converter housing and tighten the bolts to the

specified torque. Torque: 53 N ⋅

⋅⋅

⋅

m (5.4 kgf ⋅

⋅⋅

⋅

m/39 Ib ⋅

⋅⋅

⋅

ft)

33ASSY075

16.Actuator support

Install the actuator support.

34ASSY077

17.Parking pawl, shaft, spring, and spacer

Install the parking pawl, the shaft, the spring, and the

spacer.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4556 of 6020

UNIT REPAIR (JR405E) 7A4-79

40ASSY091

•

Push the output shaft into place.

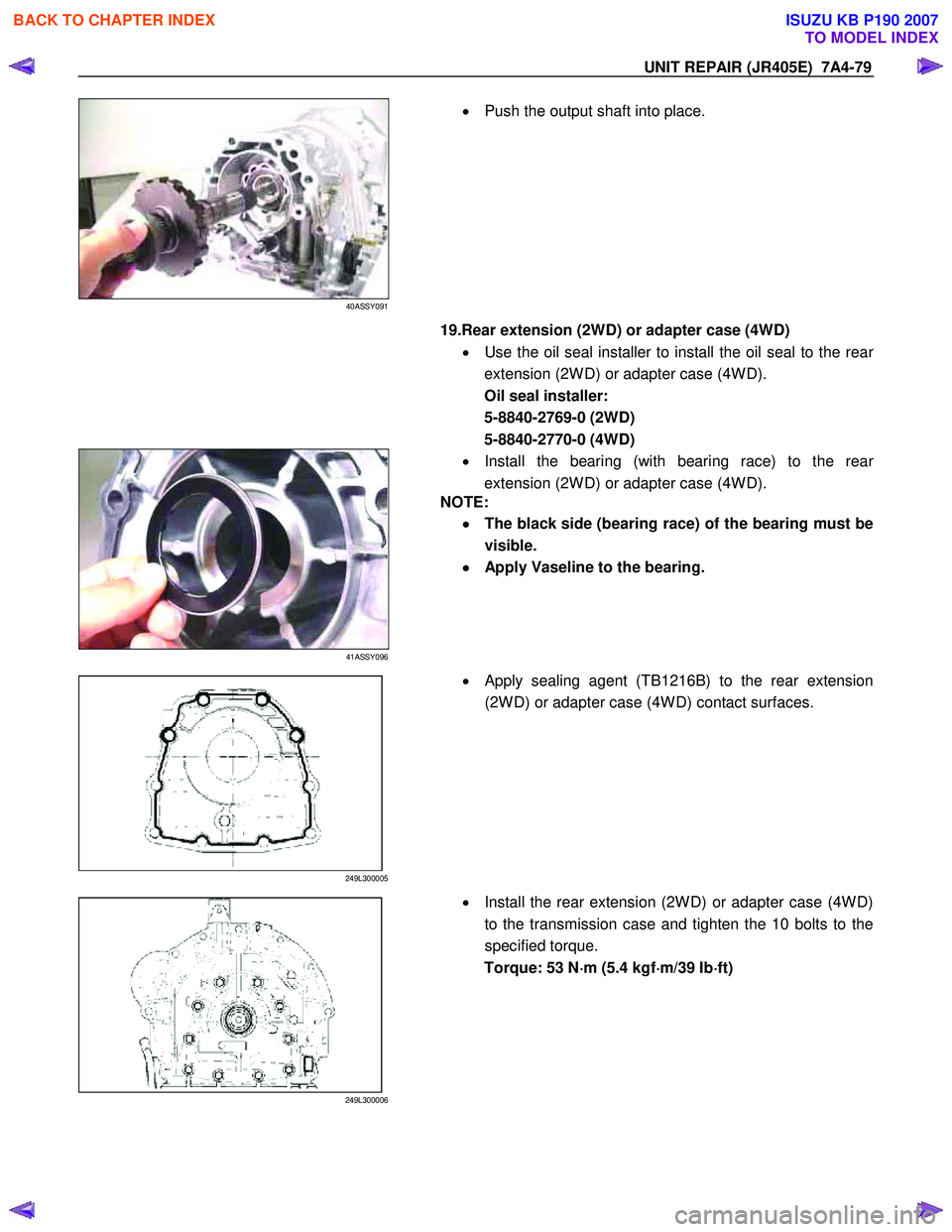

19.Rear extension (2WD) or adapter case (4WD)

• Use the oil seal installer to install the oil seal to the rea

r

extension (2W D) or adapter case (4W D).

Oil seal installer:

5-8840-2769-0 (2WD)

5-8840-2770-0 (4WD)

41ASSY096

•

Install the bearing (with bearing race) to the rear

extension (2W D) or adapter case (4W D).

NOTE:

•

••

•

The black side (bearing race) of the bearing must be

visible.

•

••

•

Apply Vaseline to the bearing.

249L300005

•

Apply sealing agent (TB1216B) to the rear extension

(2W D) or adapter case (4W D) contact surfaces.

249L300006

• Install the rear extension (2W D) or adapter case (4W D)

to the transmission case and tighten the 10 bolts to the

specified torque.

Torque: 53 N ⋅

⋅⋅

⋅

m (5.4 kgf ⋅

⋅⋅

⋅

m/39 Ib ⋅

⋅⋅

⋅

ft)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4557 of 6020

7A4-80 UNIT REPAIR (JR405E)

43ASSY119

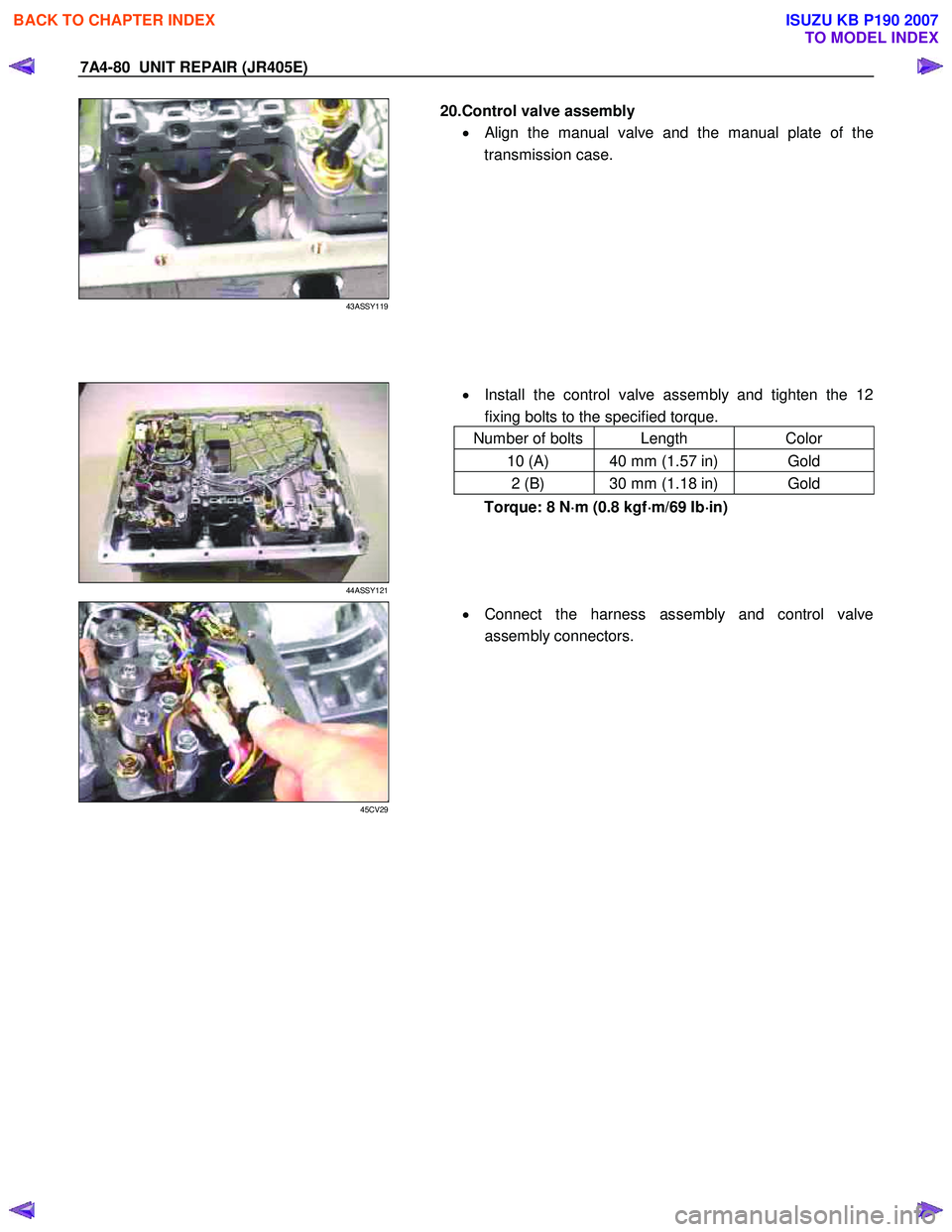

20.Control valve assembly

•

Align the manual valve and the manual plate of the

transmission case.

• Install the control valve assembly and tighten the 12

fixing bolts to the specified torque.

Number of bolts Length Color

10 (A) 40 mm (1.57 in) Gold

2 (B) 30 mm (1.18 in) Gold

44ASSY121

Torque: 8 N ⋅

⋅⋅

⋅

m (0.8 kgf ⋅

⋅⋅

⋅

m/69 Ib ⋅

⋅⋅

⋅

in)

45CV29

•

Connect the harness assembly and control valve

assembly connectors.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4558 of 6020

UNIT REPAIR (JR405E) 7A4-81

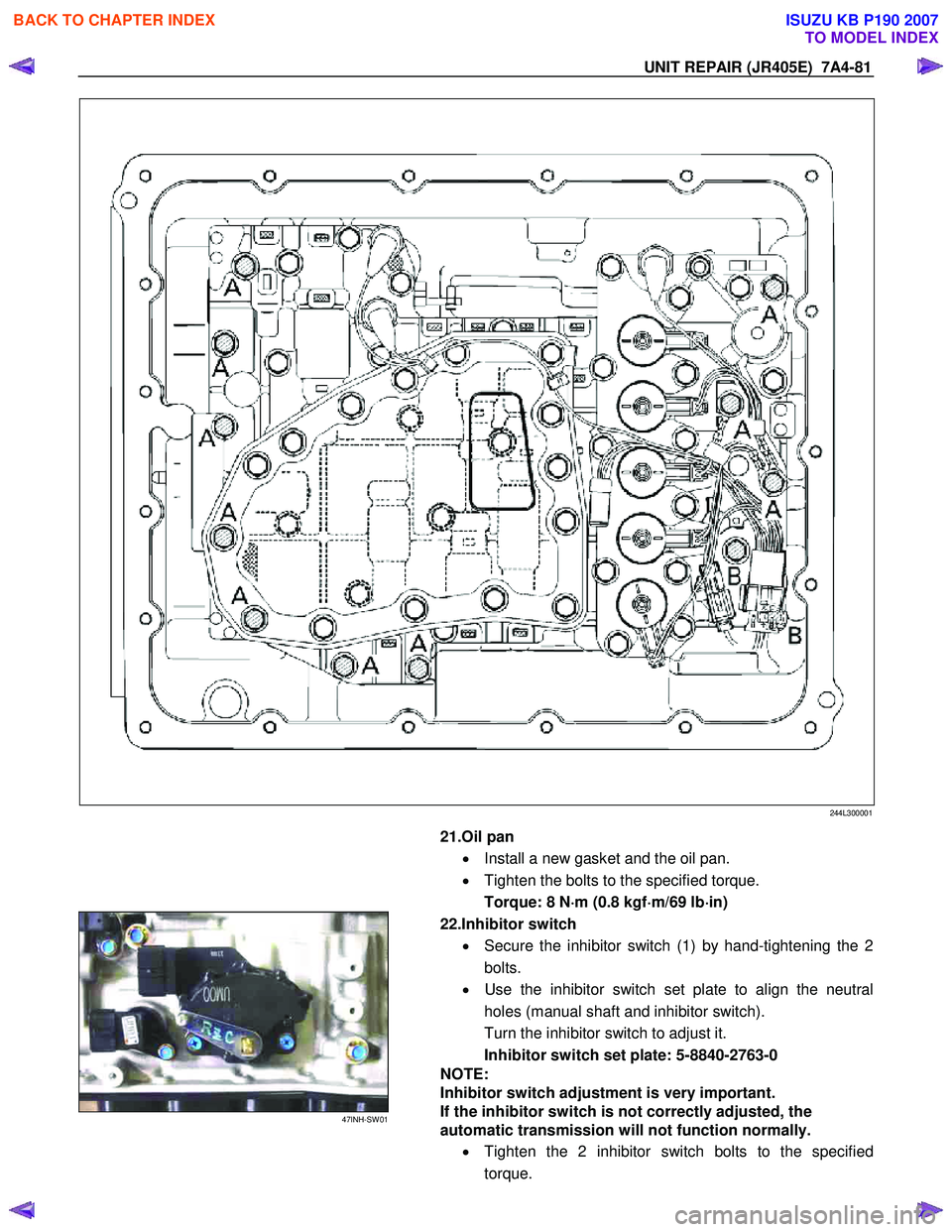

244L300001

21.Oil pan

• Install a new gasket and the oil pan.

• Tighten the bolts to the specified torque.

Torque: 8 N ⋅

⋅⋅

⋅

m (0.8 kgf ⋅

⋅⋅

⋅

m/69 lb ⋅

⋅⋅

⋅

in)

47INH-SW 01

22.Inhibitor switch

• Secure the inhibitor switch (1) by hand-tightening the 2

bolts.

• Use the inhibitor switch set plate to align the neutral

holes (manual shaft and inhibitor switch).

Turn the inhibitor switch to adjust it.

Inhibitor switch set plate: 5-8840-2763-0

NOTE:

Inhibitor switch adjustment is very important.

If the inhibitor switch is not correctly adjusted, the

automatic transmission will not function normally.

• Tighten the 2 inhibitor switch bolts to the specified

torque.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4559 of 6020

7A4-82 UNIT REPAIR (JR405E)

Torque: 6 N⋅

⋅⋅

⋅

m (0.6 kgf ⋅

⋅⋅

⋅

m/52 lb ⋅

⋅⋅

⋅

in)

• Remove the holding fixture from the transmission case.

RTW 47ASH001001

23.Speed sensor and turbine sensor

• Apply ATF to the new O-rings and install them in the

speed sensor (2) and the turbine sensor (3).

• Install the speed sensor and the turbine sensor. Tighten

the bolt to the specified torque.

Torque: 6 N ⋅

⋅⋅

⋅

m (0.6 kgf ⋅

⋅⋅

⋅

m/52 Ib ⋅

⋅⋅

⋅

in)

24.Torque converter • Pour the new ATF into the torque converter.

• Shake the torque converter to thoroughly clean the

inside.

• Drain the ATF from the torque converter.

• Pour the new ATF into the torque converter.

NOTE:

If significant amounts of foreign material (clutch facing,

metallic fragments, etc.) are found in the automatic

transmission at time of disassembly, the existing torque

converter must be replaced with a new one.

RTW 47ASH000901

•

Install the torque converter.

• Measure the torque converter end play (A).

If the measured value is greater than the specified

minimum, the torque converter is correctly installed.

Torque converter end pay (Minimum): 67 mm (2.64

in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4561 of 6020

7A4-84 UNIT REPAIR (JR405E)

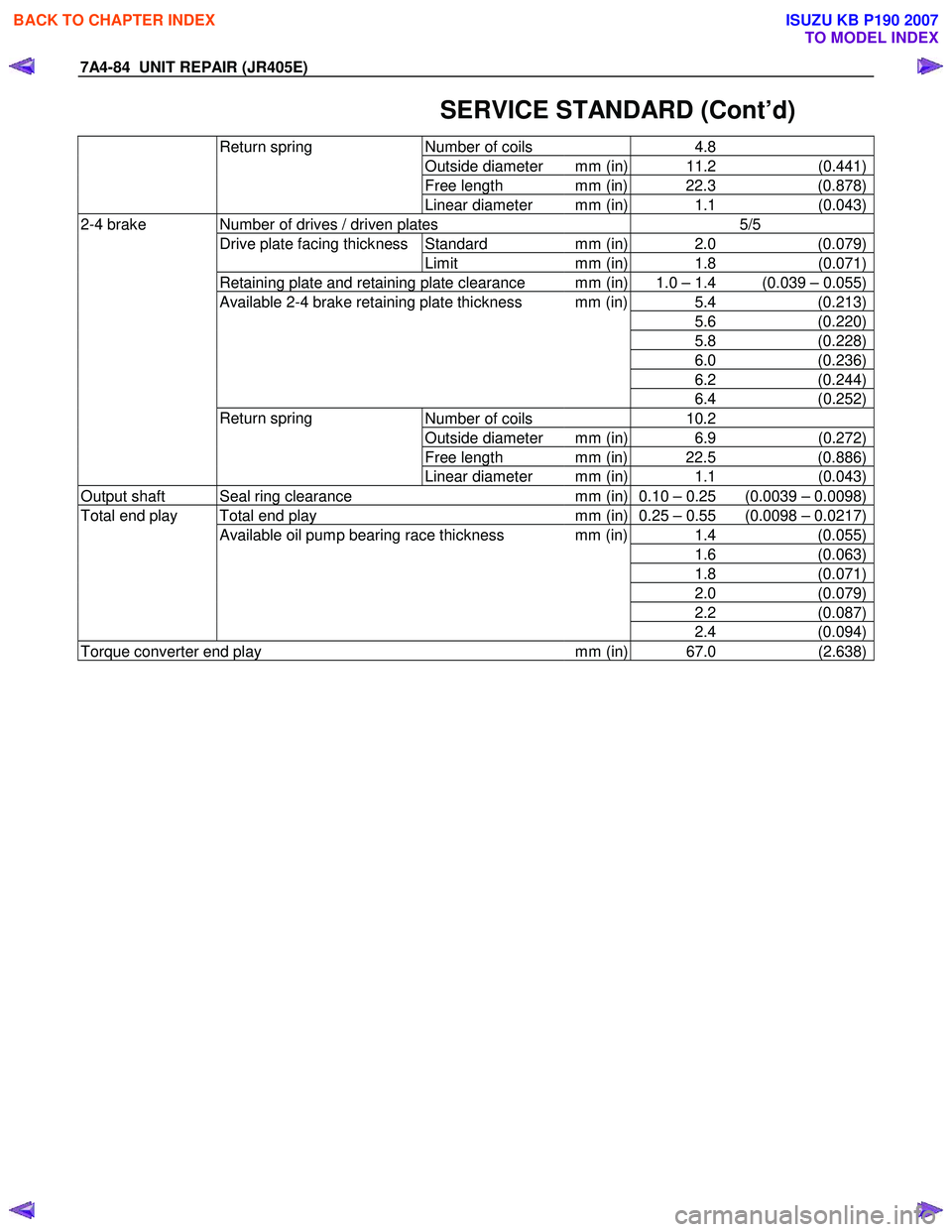

SERVICE STANDARD (Cont’d)

Number of coils 4.8

Outside diameter mm (in) 11.2 (0.441)

Free length mm (in) 22.3 (0.878)

Return spring

Linear diameter mm (in) 1.1 (0.043)

Number of drives / driven plates 5/5

Standard mm (in) 2.0 (0.079)Drive plate facing thickness

Limit mm (in) 1.8 (0.071)

Retaining plate and retaining plate clearance mm (in) 1.0 – 1.4 (0.039 – 0.055)

5.4 (0.213)

5.6 (0.220)

5.8 (0.228)

6.0 (0.236)

6.2 (0.244)

Available 2-4 brake retaining plate thickness mm (in)

6.4 (0.252)

Number of coils 10.2

Outside diameter mm (in) 6.9 (0.272)

Free length mm (in) 22.5 (0.886)

2-4 brake

Return spring Linear diameter mm (in) 1.1 (0.043)

Output shaft Seal ring clearance mm (in) 0.10 – 0.25 (0.0039 – 0.0098)

Total end play mm (in) 0.25 – 0.55 (0.0098 – 0.0217)

1.4 (0.055)

1.6 (0.063)

1.8 (0.071)

2.0 (0.079)

2.2 (0.087)

Total end play

Available oil pump bearing race thickness mm (in)

2.4 (0.094)

Torque converter end play mm (in) 67.0 (2.638)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4565 of 6020

MSG MODEL 7B-1

SECTION 7B

MANUAL TRANSMISSION (MSG)

TABLE OF CONTENTS

PAGE

Main Data and Specifications ..................................................................................... 7B - 2

General Description .................................................................................................... 7B - 3

Torque Specification ................................................................................................... 7B - 4

Repair Kit .................................................................................................................... 7B - 6

Removal and Installation ........................................................................................... 7B - 7

Disassembly ................................................................................................................ 7B - 15

Inspection and Repair ................................................................................................ 7B - 25

Reassembly ................................................................................................................. 7B - 29

Special Service Tool ................................................................................................... 7B - 42

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4568 of 6020

7B-4 MSG MODEL

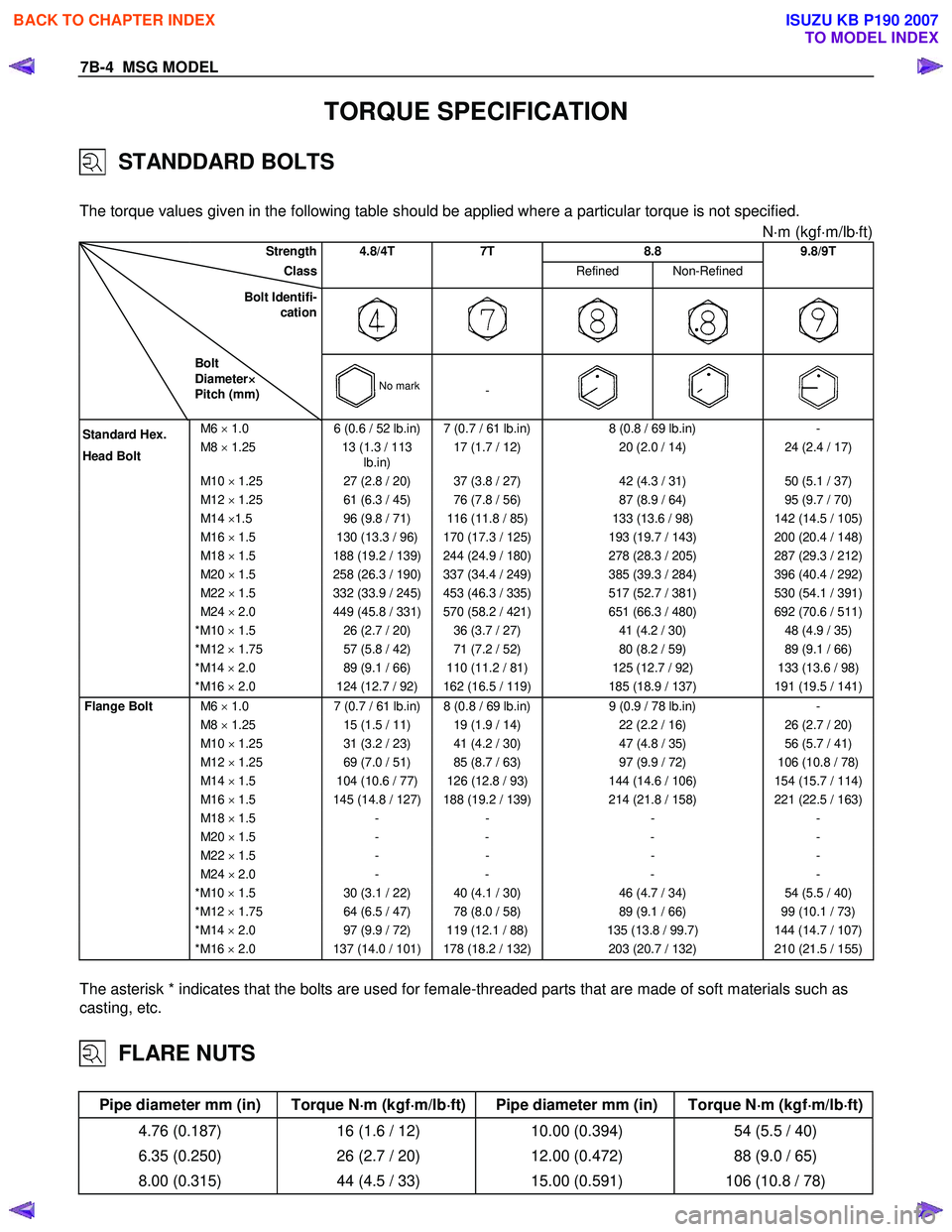

TORQUE SPECIFICATION

STANDDARD BOLTS

The torque values given in the following table should be applied where a particular torque is not specified.

N⋅m (kgf ⋅m/lb ⋅ft)

Strength 4.8/4T 7T 8.8 9.8/9T

Class Refined Non-Refined

Bolt Identifi-

cation

Bolt

Diameter ×

××

×

Pitch (mm)

No mark-

M6 × 1.0 6 (0.6 / 52 lb.in) 7 (0.7 / 61 lb.in) 8 (0.8 / 69 lb.in) -

M8 × 1.25 13 (1.3 / 113

lb.in) 17 (1.7 / 12)

20 (2.0 / 14) 24 (2.4 / 17)

M10 × 1.25 27 (2.8 / 20) 37 (3.8 / 27) 42 (4.3 / 31) 50 (5.1 / 37)

M12 × 1.25 61 (6.3 / 45) 76 (7.8 / 56) 87 (8.9 / 64) 95 (9.7 / 70)

M14 ×1.5 96 (9.8 / 71) 116 (11.8 / 85) 133 (13.6 / 98) 142 (14.5 / 105)

M16 × 1.5 130 (13.3 / 96) 170 (17.3 / 125) 193 (19.7 / 143) 200 (20.4 / 148)

M18 × 1.5 188 (19.2 / 139) 244 (24.9 / 180) 278 (28.3 / 205) 287 (29.3 / 212)

M20 × 1.5 258 (26.3 / 190) 337 (34.4 / 249) 385 (39.3 / 284) 396 (40.4 / 292)

M22 × 1.5 332 (33.9 / 245) 453 (46.3 / 335) 517 (52.7 / 381) 530 (54.1 / 391)

M24 × 2.0 449 (45.8 / 331) 570 (58.2 / 421) 651 (66.3 / 480) 692 (70.6 / 511)

* M10 × 1.5 26 (2.7 / 20) 36 (3.7 / 27) 41 (4.2 / 30) 48 (4.9 / 35)

* M12 × 1.75 57 (5.8 / 42) 71 (7.2 / 52) 80 (8.2 / 59) 89 (9.1 / 66)

* M14 × 2.0 89 (9.1 / 66) 110 (11.2 / 81) 125 (12.7 / 92) 133 (13.6 / 98)

* M16 × 2.0 124 (12.7 / 92) 162 (16.5 / 119) 185 (18.9 / 137) 191 (19.5 / 141)

Flange Bolt M6 × 1.0 7 (0.7 / 61 lb.in) 8 (0.8 / 69 lb.in) 9 (0.9 / 78 lb.in) -

M8 × 1.25 15 (1.5 / 11) 19 (1.9 / 14) 22 (2.2 / 16) 26 (2.7 / 20)

M10 × 1.25 31 (3.2 / 23) 41 (4.2 / 30) 47 (4.8 / 35) 56 (5.7 / 41)

M12 × 1.25 69 (7.0 / 51) 85 (8.7 / 63) 97 (9.9 / 72) 106 (10.8 / 78)

M14 × 1.5 104 (10.6 / 77) 126 (12.8 / 93) 144 (14.6 / 106) 154 (15.7 / 114)

M16 × 1.5 145 (14.8 / 127) 188 (19.2 / 139) 214 (21.8 / 158) 221 (22.5 / 163)

M18 × 1.5 - - - -

M20 × 1.5 - - - -

M22 × 1.5 - - - -

M24 × 2.0 - - - -

* M10 × 1.5 30 (3.1 / 22) 40 (4.1 / 30) 46 (4.7 / 34) 54 (5.5 / 40)

* M12 × 1.75 64 (6.5 / 47) 78 (8.0 / 58) 89 (9.1 / 66) 99 (10.1 / 73)

* M14 × 2.0 97 (9.9 / 72) 119 (12.1 / 88) 135 (13.8 / 99.7) 144 (14.7 / 107)

* M16 × 2.0 137 (14.0 / 101) 178 (18.2 / 132) 203 (20.7 / 132) 210 (21.5 / 155)

The asterisk * indicates that the bolts are used for female-threaded parts that are made of soft materials such as

casting, etc.

FLARE NUTS

Pipe diameter mm (in) Torque N ⋅

⋅⋅

⋅

m (kgf ⋅

⋅⋅

⋅

m/lb ⋅

⋅⋅

⋅

ft) Pipe diameter mm (in) Torque N ⋅

⋅⋅

⋅

m (kgf ⋅

⋅⋅

⋅

m/lb ⋅

⋅⋅

⋅

ft)

4.76 (0.187) 16 (1.6 / 12) 10.00 (0.394) 54 (5.5 / 40)

6.35 (0.250) 26 (2.7 / 20) 12.00 (0.472) 88 (9.0 / 65)

8.00 (0.315) 44 (4.5 / 33) 15.00 (0.591) 106 (10.8 / 78)

Standard Hex.

Head Bolt

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4576 of 6020

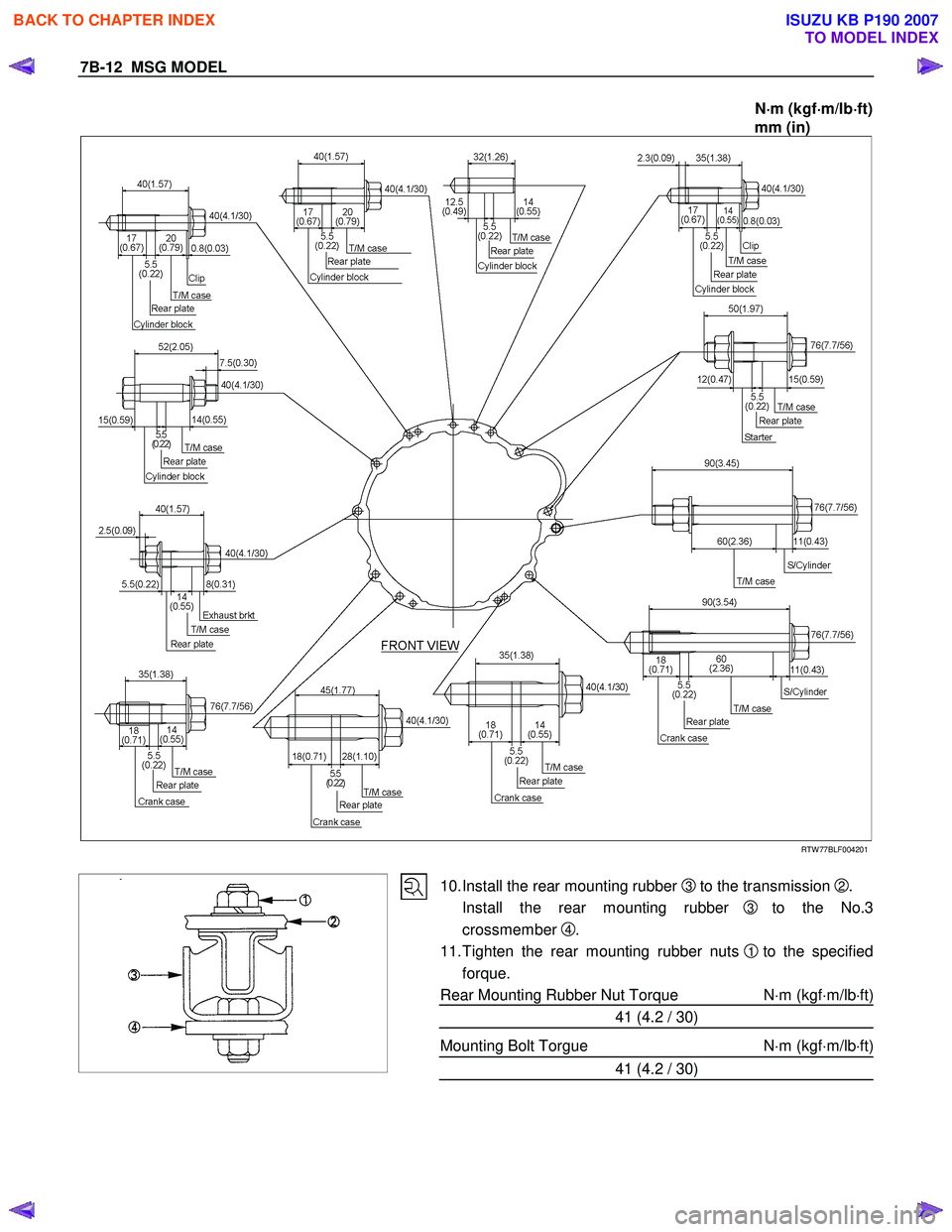

7B-12 MSG MODEL

N⋅

⋅⋅

⋅

m (kgf ⋅

⋅⋅

⋅

m/lb ⋅

⋅⋅

⋅

ft)

mm (in)

RTW 77BLF004201

10. Install the rear mounting rubber 3 to the transmission 2.

Install the rear mounting rubber

3 to the No.3

crossmember

4.

11. Tighten the rear mounting rubber nuts

1 to the specified

forque.

Rear Mounting Rubber Nut Torque N⋅m (kgf ⋅m/lb ⋅ft)

41 (4.2 / 30)

Mounting Bolt Torgue N⋅m (kgf ⋅m/lb ⋅ft)

41 (4.2 / 30)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4577 of 6020

MSG MODEL 7B-13

Starter Motor

1. Install the starter motor to the engine rear plate.

2. Tighten the starter motor bolts to the specified torque.

Starter Motor Torque N⋅m (kgf ⋅m/lb ⋅ft)

78 (8.0 / 58)

Slave Cylinder

Install the slave cylinder to the transmission case.

Slave Cylinder Bolt Torque N ⋅m (kgf ⋅m/lb ⋅ft

)

78 (8.0 / 58)

Harness Connector

Connect the back up light switch connector and speedometer

sensor connector.

Rear Propeller Shaft (Dual Shaft Type)

1. Place the center bearing and retainer 1 together with the

1st propeller shaft

2 and 2nd propeller shaft 7on the No.4

crossmember

3.

2. Insert the splined yoke

4 into the transmission main shaft

spline

5.

3. Tighten the center bearing retainer bolts

6 to the specified

torque.

Center Bearing Retainer Bolt Torque N ⋅m (kgf ⋅m/lb ⋅ft)

61 (6.2 / 45)

4. Connect the 2nd propeller shaft

7 and drive pinion side 8.

Be sure to align the setting marks applied at disassembly.

5. Tighten the coupling bolts to the specified torque.

Propeller Shaft Flange Yoke Bolt

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

M8 : 35 (3.6 / 26)

M10 : 63 (6.4 / 46)

Exhaust Pipe

1. Install the exhaust pipe to the exhaust manifold and the 2nd

exhaust pipe.

2. Install the exhaust pipe bracket to the transmission case.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007