torque ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4402 of 6020

7A2-118 TRANSMISSION CONTROL SYSTEM (JR405E)

J1: Transmission Fluid Leaks from Breather

J2: Transmission Fluid Leaks Between Engine and Converter Housing

J3: Transmission Fluid Leaks Between Converter Housing and Transmission Case

J4: Transmission Fluid Leaks Between Transmission Case and Extension Housing

J3: Transmission Fluid Leaks from Oil Pan

J3: Transmission Fluid Leaks from Manual Shaft Oil Seal

J3: Transmission Fluid Leaks from Oil Cooler Pipe Joint

Z1: Transmission Overheat

Transmission Fluid Checks Inspect the transmission fluid for the following conditions. If the transmission

fluid is extremely blacked, contaminated or smells burnt, slipping of clutch is

suspected.

• Low quantity

• Contamination

• Smell

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Sticking TCC solenoid valve. Perform function check. Refer to On- Vehicle Service section.

• Clogged hydraulic circuit

Sensor Checks Inspect the TFT sensor. Use the Temperature vs. Resistance table to test

the TFT sensor at various temperature levels to evaluate the possibility of a

skewed sensor.

Checks

Action

Checks Action

Definition:

Transmission fluid leaks from breather.

Diagnosis Hints Transmission fluid quantity is excessively high.

Checks Action

Definition:

Transmission fluid leaks between engine and converter housing.

Transmission fluid leaks between converter housing and transmission case.

Transmission fluid leaks between transmission case and extension housing.

Transmission fluid leaks from oil pan.

Transmission fluid leaks from manual shaft oil seal.

Transmission fluid leaks from oil cooler pipe joint.

Diagnosis Hints Faulty oil seal or contact surface is suspected.

Checks Action

Definition:

Smells burnt or smoke from transmission.

Diagnosis Hints • Transmission fluid quantity is excessively high.

• Slipping of the clutch is suspected. Gear ratio error DTC might be set.

• Clogged oil cooler.

• Faulty operation of oil pump.

• Faulty torque converter clutch (TCC) piston.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4406 of 6020

7A2-122 TRANSMISSION CONTROL SYSTEM (JR405E)

Standard Value

Diagnosis 1. If the line pressure is lower than the standard value at idle in all ranges.

• Abraded oil pump.

• Faulty operation of each solenoid valve.

• Sticking of pressure regulator spool valve or pilot spool valve.

• Fatigued pressure regulator spool valve spring or pilot spool valve spring.

• Transmission fluid leaking from the oil strainer, oil pump, pressure regulator spool valve, torque

converter relief spool valve or pressure relief valve.

2. If the line pressure is lower than the standard value at idle in D, 3, 2 and L range.

• Transmission fluid leaking from the low clutch hydraulic circuit.

3. If the line pressure is lower than the standard value at idle in R range.

• Transmission fluid leaking from the reverse clutch hydraulic circuit.

• Transmission fluid leaking from the low & reverse brake hydraulic circuit.

4. If the line pressure is lower that the standard value at idle in L or R range.

• Transmission fluid leaking from the low & reverse brake hydraulic circuit.

5. If the line pressure is higher than the standard value at idle in all ranges.

• Faulty accelerator pedal position signal.

• Faulty transmission fluid temperature (TFT) sensor.

• Faulty operation of low clutch solenoid valve.

• Sticking pilot spool valve.

• Sticking pressure regulator spool valve or plug.

6. If the line pressure is lower than the standard value at stall speed in all ranges.

• Faulty accelerator pedal position signal.

• Faulty operation of pressure control (PC) solenoid valve.

• Faulty operation of low clutch solenoid valve.

• Sticking pilot spool valve.

• Sticking pressure regulator spool valve or plug.

Selector lever position Engine

speed Line pressure (kPa/ psi)

D, 3, 2 or D Idle 350 - 480 / 51 - 70

R Stall 1050 - 1250 / 152 - 182

Idle 450 - 650 / 65 - 95

Stall 1400 - 1630 / 203 - 237

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4407 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-123

Stall Test

Stall Test Procedure1. Fully apply the parking brake and chock all wheels.

2. Check the level of the engine oil, coolant and transmission fluid. Replenish as necessary.

3. Start the engine and warm up (allow engine coolant temperature to reach at least 70 °C

[158 °F]).

Important: Stall test must be finished within 5 seconds.

Prolonged test time may break the transmission.

4. Fully depress the brake pedal with your left foot.

5. Move the selector lever to the D range and fully depress the accelerator pedal. Record the engine

speed as soon as the stall speed.

6. Move the selector lever to the N range and let idle for at least 1 minute.

7. Repeat the stall test (step 4 to 6) in R, 3, 2 and L range.

Standard Value Diagnosis

1. If the stall speed is higher than the standard value in all ranges.

• Low line pressure.

• Abraded oil pump.

• Faulty operation of low clutch.

• Faulty transmission range switch.

• Transmission fluid leaking from the oil pump, valve body or transmission case.

• Sticking of pressure regulator spool valve or pilot spool valve.

2. If the stall speed is higher than the standard value in D, 3, 2 and L ranges.

• Slipping of low clutch

• Slipping of low one-way clutch

3. If the stall speed is higher than the standard value in R range.

• Slipping of low & reverse brake

• Slipping of reverse clutch

4. If the stall speed is lower than the standard value is all ranges.

• Slipping of torque converter one-way clutch

• Problem in engine

Stall speed Pre condition

2050 ± 150 RPM Ambient temperature between 10

and 40 °C [50 and 104 °F]

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4409 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-125

Road Test

Road Test Procedure

*1: Shifting at high vehicle speed, the transmission may

hold the gear position until vehicle speed gets down to

prevent engine overruning.

Notice: Perform this test at the normal transmission

fluid temperature between 50 to 80 °C (122 to 176 °F).

Drive the vehicle on level ground so as not to change to

up slope mode and down slope mode.

1. D range road test in normal and power drive mode. • Select into the D range and hold the accelerator pedal constant at the 50% and 100% accelerator

pedal position.

• 1 to 2, 2 to 3, 3 to 4 upshift and lock up should take place, and shift points should match those shown

in the shift speed chart.

• Also check to see that downshift is made from 4 to 3, 3 to 2 and 2 to 1 point is within the limits shown

in the shift speed chart.

2. 3 range road test in normal and power drive mode. • Select into the 3 range and hold the accelerator pedal constant at the 50% and 100% accelerator

pedal position.

• 1 to 2, 2 to 3 upshift and lock up should take place, and shift points should match those shown in the

shift speed chart.

• While running in the 3 range, does not upshift from 3 to 4.

3. 2 range road test in normal mode. • Select into the 2 range and hold the accelerator

pedal constant at the 50% and 100% accelerator

pedal position.

• 1 to 2 upshift should take place, and shift points should match those shown in the shift speed chart.

• While running in the 2 range, does not upshift from 2 to 3 or 3 to 4, and lock-up does not operate.

4. L range road test in normal mode.

• While running in the L range, does not upshift from 1 to 2, 2 to 3 or 3 to 4, and lock-up does not

operate.

5. R range road test. • Select into the R range and check for slipping.

6. P range road test. • Stop the vehicle on a grade and release the park brake after selecting into the P range. Then check

to see that the parking lock pawl holds the vehicle

in place.

Diagnosis 1. If there is no 1 to 2 upshift.• Faulty operation of 2-4 brake

• Faulty operation of 2-4 brake hydraulic circuits

• Sticking of 2-4 brake solenoid valve

• Refer to symptom diagnosis No. D1: Faulty Gear Shifting or DTC P0731 - P0734 Incorrect Gear

Ratio diagnosis.

2. If there is no 2 to 3 upshift.

• Faulty operation of high clutch

• Faulty operation of high clutch hydraulic circuits

• Sticking of high clutch solenoid valve

• Refer to symptom diagnosis No. D1: Faulty Gear Shifting or DTC P0731 - P0734 Incorrect Gear

Ratio diagnosis.

3. If there is no 3 to 4 upshift.

• Faulty operation of 2-4 brake

• Faulty operation of 2-4 brake hydraulic circuits

• Sticking of 2-4 brake solenoid valve

• Refer to symptom diagnosis No. D1: Faulty Gear Shifting or DTC P0731 - P0734 Incorrect Gear

Ratio diagnosis.

4. If there is no lock up in 2nd, 3rd and 4th. • Faulty operation of torque converter clutch (TCC) piston

• Faulty operation of lock up hydraulic circuit

• Sticking of TCC solenoid valve

• Refer to symptom diagnosis No. I1: No Lock-up

5. If there is no reverse. • Faulty operation of reverse clutch

• Faulty operation of reverse clutch hydraulic circuits

• Faulty operation of low & reverse brake hydraulic circuits

Selector lever

position GearshiftSelected gear

position

P

R

N

D

3

2

L 1st

2nd 3rd4th1st

2nd 3rd

4th(*1) 1st

2nd

3rd(*1) 4th(*1) 1st

2nd(*1) 3rd(*1)4th(*1)

Reverse

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4410 of 6020

7A2-126 TRANSMISSION CONTROL SYSTEM (JR405E)

• Sticking of low & reverse brake solenoid valve

• Refer to symptom diagnosis No. A2: Vehicle Dose Not Run in R Range

6. If there is no parking. • Faulty parking pawl

• Refer to symptom diagnosis No. G1: Vehicle Moves in P Range or Parking Gear in Not

Disengaged other than P Range.

Notice: The check for the cause of abnormal noise and

vibration must be made with extreme care as it could

also be due to loss of balance in the propeller shaft,

differential, the torque converter, etc. Or insufficient

bending, rigidity, etc. in the powertrain.

Shift Speed Chart 1. All upshifts have a solid green line with:• 1-2 has black filled diamond plot points

• 2-3 has black filled squre plot points

• 2-4 has back filled circular plot posints

2. All donwshift have a sloid blue line with:

• 2-1 has white filled diamonf plot points

• 3-2 has white filled squre plot points

• 4-3 has white filled circular plot points

3. Torque converter clutch apply points have a dashed orange line with:

• 2nd apply has black filled diamond plot points

• 3rd apply has black filled squre plot points

• 4th apply has black filled circulat plot points

4. Torque converter clutch release points have a dashed pink line with:

• 2nd release has white filled diamond plot points

• 3rd release has white filled squre plot points

• 4th release has white filled circulat plot points

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4422 of 6020

7A2-138 TRANSMISSION CONTROL SYSTEM (JR405E)

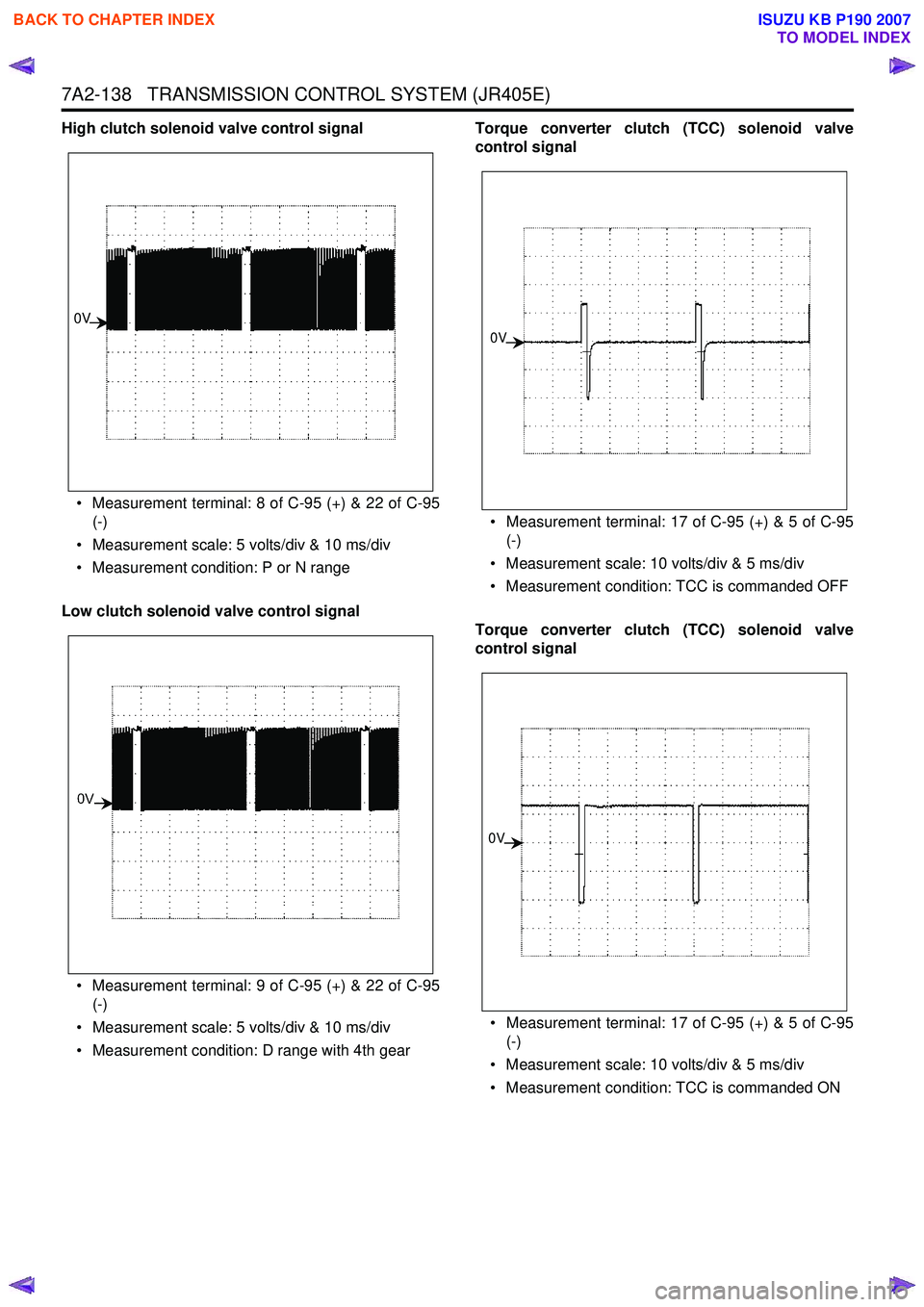

High clutch solenoid valve control signal• Measurement terminal: 8 of C-95 (+) & 22 of C-95 (-)

• Measurement scale: 5 volts/div & 10 ms/div

• Measurement condition: P or N range

Low clutch solenoid valve control signal

• Measurement terminal: 9 of C-95 (+) & 22 of C-95 (-)

• Measurement scale: 5 volts/div & 10 ms/div

• Measurement condition: D range with 4th gear Torque converter clutch (TCC) solenoid valve

control signal

• Measurement terminal: 17 of C-95 (+) & 5 of C-95 (-)

• Measurement scale: 10 volts/div & 5 ms/div

• Measurement condition: TCC is commanded OFF

Torque converter clutch (TCC) solenoid valve

control signal

• Measurement terminal: 17 of C-95 (+) & 5 of C-95 (-)

• Measurement scale: 10 volts/div & 5 ms/div

• Measurement condition: TCC is commanded ON

0V

0V

0V

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4427 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-143

Description and Operation

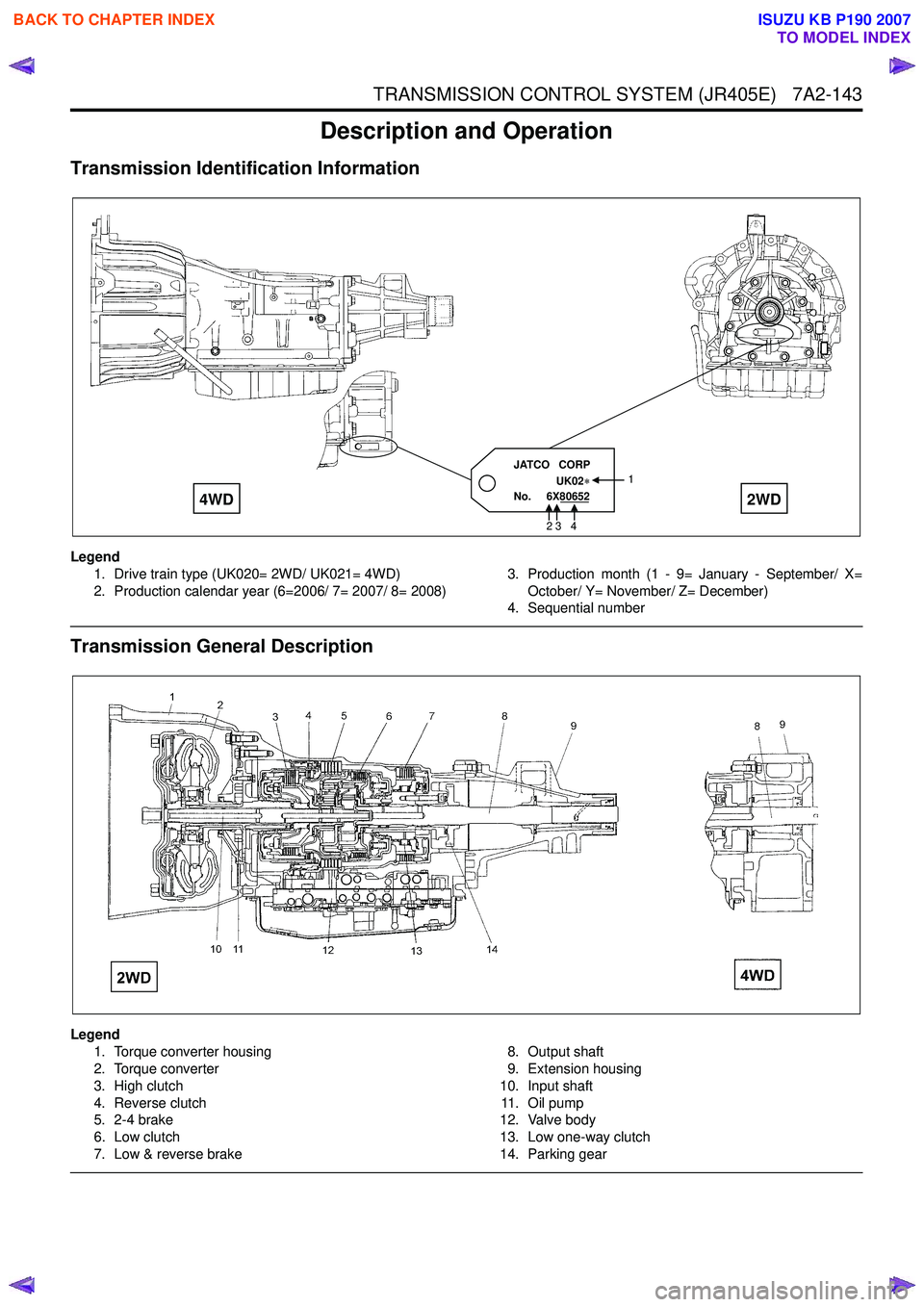

Transmission Identification Information

Legend1. Drive train type (UK020= 2WD/ UK021= 4WD)

2. Production calendar year (6=2006/ 7= 2007/ 8= 2008) 3. Production month (1 - 9= January - September/ X=

October/ Y= November/ Z= December)

4. Sequential number

Transmission General Description

Legend

1. Torque converter housing

2. Torque converter

3. High clutch

4. Reverse clutch

5. 2-4 brake

6. Low clutch

7. Low & reverse brake 8. Output shaft

9. Extension housing

10. Input shaft 11 . O i l p u m p

12. Valve body

13. Low one-way clutch

14. Parking gear

JATCO CORP

UK02

No. 6X80652 1

2 3 4

4WD

2WD

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4428 of 6020

7A2-144 TRANSMISSION CONTROL SYSTEM (JR405E)

The JR405E automatic transmission is electrically

controlled by a transmission control module (TCM).

There are four forward speeds and one reverse speed.

This JR405E automatic transmission employs a clutch

pressure direct control system (Direct Electronic Shift

Control: DESC) using duty cycle type solenoid valves,

which ensure high shift quality. This transmission also

has a learning function and constantly checks the time

of each clutch and brake required for the shift in order

to match this time with the target value for the optimum

shift. The TCM will automatically select the most

appropriate shift points and lock-up points depending

on the accelerator pedal opening, the vehicle speed

and the vehicle load. If any trouble arises in the speed

sensor, solenoid valve, etc., the fail-safe control

function is activated to keep the running performance.

The JR405E automatic transmission consists of the

torque converter, oil pump, input shaft, out put shaft,

planetary gears and valve body. The gear train consists

of two planetary gear sets and three multiple plate

clutches in combination with two multiple plate brakes

and a one-way clutch.

Transmission Component Description

Torque Converter

Legend

1. Pump impeller

2. Turbine runner

3. Stator

4. Converter front cover

5. One-way clutch

6. Torque converter clutch (TCC) piston

7. Torsion damper

The torque converter is a device for transmitting the

engine torque to the transmission. It transmits power by

means of oil when the lock up clutch is disengaged,

and by means of a lock up clutch when it is engaged. The torque converter is of the symmetrical, three-

element, single-stage, two-phase type. As shown in the

picture, the symmetrical three-elements refer to three

elements (components) consisting of impeller (1),

turbine (2) and stator (3) that are arranged

symmetrically. Single-stage means that there is only

one turbine as an output element; two-phase means

that the pump impeller acts as a torque converter when

the turbine speed is comparatively low, and as a fluid

coupling when the speed is high. Lock up refers to a

fixed state of the lock up clutch (=torque converter

clutch (TCC) inside the torque converter and thus

connects the engine directly to the transmission.

Oil Pump

Legend 1. Torque converter

2. Oil pump

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4429 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-145

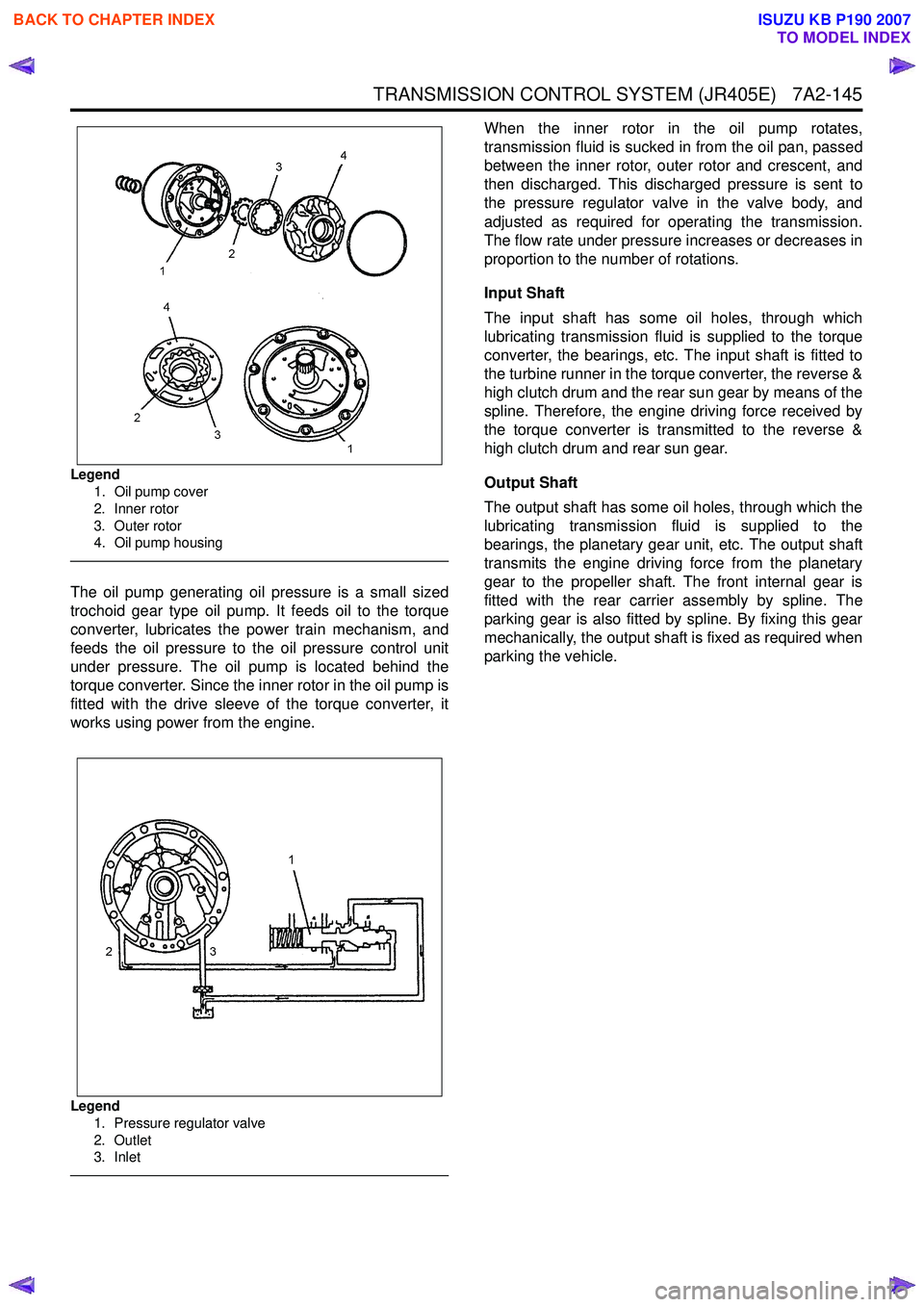

Legend1. Oil pump cover

2. Inner rotor

3. Outer rotor

4. Oil pump housing

The oil pump generating oil pressure is a small sized

trochoid gear type oil pump. It feeds oil to the torque

converter, lubricates the power train mechanism, and

feeds the oil pressure to the oil pressure control unit

under pressure. The oil pump is located behind the

torque converter. Since the inner rotor in the oil pump is

fitted with the drive sleeve of the torque converter, it

works using power from the engine.

Legend

1. Pressure regulator valve

2. Outlet

3. Inlet

When the inner rotor in the oil pump rotates,

transmission fluid is sucked in from the oil pan, passed

between the inner rotor, outer rotor and crescent, and

then discharged. This discharged pressure is sent to

the pressure regulator valve in the valve body, and

adjusted as required for operating the transmission.

The flow rate under pressure increases or decreases in

proportion to the number of rotations.

Input Shaft

The input shaft has some oil holes, through which

lubricating transmission fluid is supplied to the torque

converter, the bearings, etc. The input shaft is fitted to

the turbine runner in the torque converter, the reverse &

high clutch drum and the rear sun gear by means of the

spline. Therefore, the engine driving force received by

the torque converter is transmitted to the reverse &

high clutch drum and rear sun gear.

Output Shaft

The output shaft has some oil holes, through which the

lubricating transmission fluid is supplied to the

bearings, the planetary gear unit, etc. The output shaft

transmits the engine driving force from the planetary

gear to the propeller shaft. The front internal gear is

fitted with the rear carrier assembly by spline. The

parking gear is also fitted by spline. By fixing this gear

mechanically, the output shaft is fixed as required when

parking the vehicle.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4432 of 6020

7A2-148 TRANSMISSION CONTROL SYSTEM (JR405E)

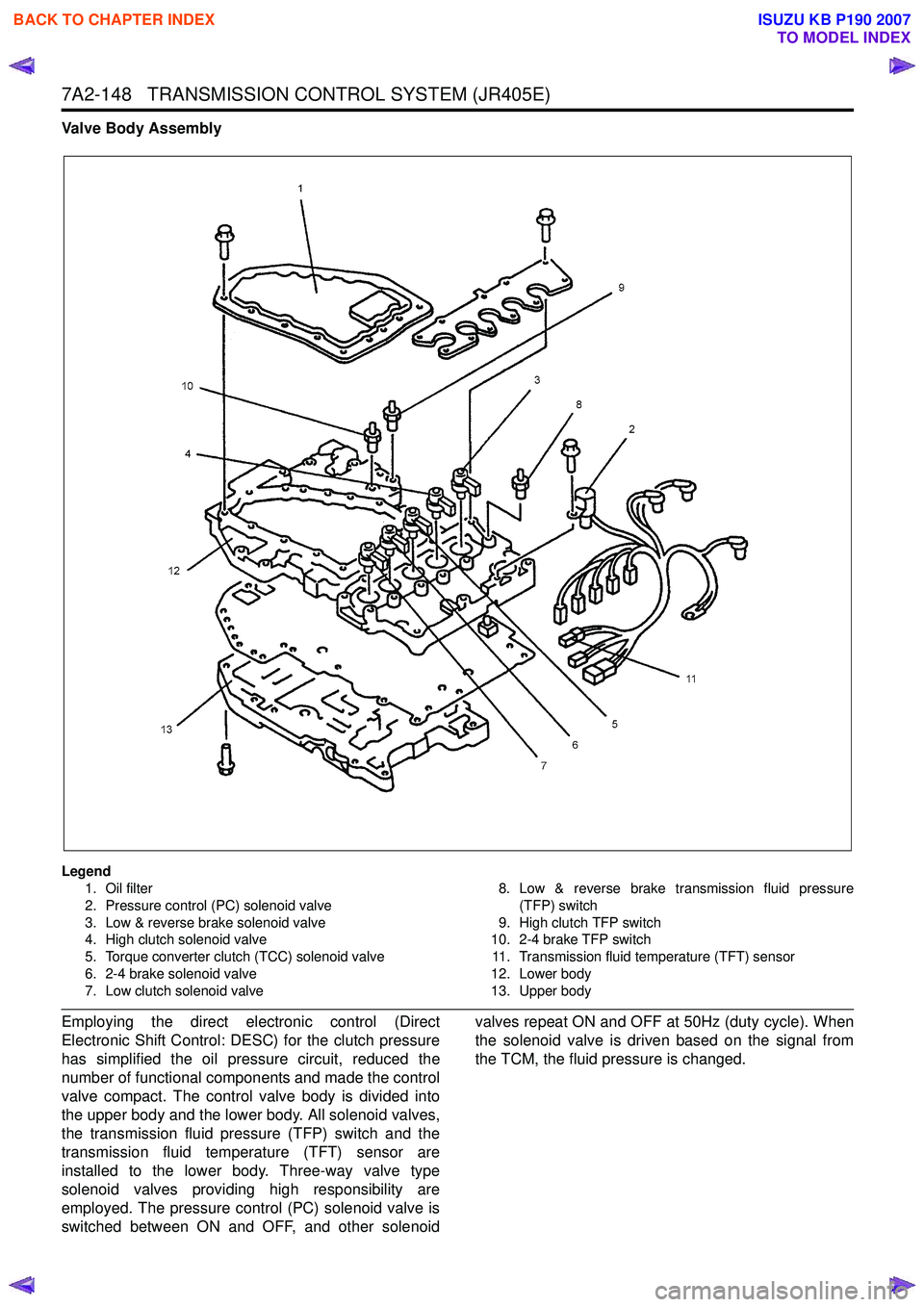

Valve Body Assembly

Legend1. Oil filter

2. Pressure control (PC) solenoid valve

3. Low & reverse brake solenoid valve

4. High clutch solenoid valve

5. Torque converter clutch (TCC) solenoid valve

6. 2-4 brake solenoid valve

7. Low clutch solenoid valve 8. Low & reverse brake transmission fluid pressure

(TFP) switch

9. High clutch TFP switch

10. 2-4 brake TFP switch

11. Transmission fluid temperature (TFT) sensor

12. Lower body

13. Upper body

Employing the direct electronic control (Direct

Electronic Shift Control: DESC) for the clutch pressure

has simplified the oil pressure circuit, reduced the

number of functional components and made the control

valve compact. The control valve body is divided into

the upper body and the lower body. All solenoid valves,

the transmission fluid pressure (TFP) switch and the

transmission fluid temperature (TFT) sensor are

installed to the lower body. Three-way valve type

solenoid valves providing high responsibility are

employed. The pressure control (PC) solenoid valve is

switched between ON and OFF, and other solenoid valves repeat ON and OFF at 50Hz (duty cycle). When

the solenoid valve is driven based on the signal from

the TCM, the fluid pressure is changed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007