ad blue ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 433 of 6020

PROPELLER SHAFT 4A-17

401RS011

Universal Joint Reassembly

1. Set the propeller shafts.

• Be sure to set the propeller shaft yoke by aligning the

setting marks made during disassembly.

2. Spider

• Be sure to install the spider by aligning the setting marks

made during disassembly.

3. Needle Roller Bearing

1) Apply a molybdenum-disulfide grease or a multi-purpose. type grease NLGI No.2 to inside of the bearing cap. Grease Amount g(oz)

Approx. 1.2 (0.042)

401RS012

2) Using either a mallet (or copper hammer) or a press, install

the needle roller bearing into the yoke so that snap ring can

be installed in its groove.

CAUTION: •

••

•

The needle roller bearing cannot be installed smoothly

if it is set at an incorrect angle with the flange.

•

••

•

Excessive hammering will damage the needle rolle

r

bearing.

401R300003

3) Align setting marks and join the yokes.

NOTE:

Assemble the spider and spline yoke so that their grease

fittings are arranged on the same side.(4 ×4)

4. Snap ring

NOTE:

Discard used snap rings and install new ones.

W hen the bearing cap is in position, select and attach a snap

ring of suitable thickness so that the end play of the spider pin

is held within 0.1mm (0.004in).

mm(in)

Snap ring thickness Identification color

1.50 (0.059) Light Blue

1.53 (0.060) W hite

1.56 (0.061) Pink

1.59 (0.063) Yellow

1.62 (0.064) Green

1.65 (0.065) Brown

1.68 (0.066) Not colored

NOTE:

Be sure to use snap rings of the same thickness on both sides.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 443 of 6020

PROPELLER SHAFT 4A-27

401RS012

3. Using either a mallet (or copper hammer) or a press, install

the needle roller bearing into the yoke so that the snap ring

can be installed in its groove.

CAUTION:

The needle roller bearing cannot be installed smoothly if it

is set at an incorrect angle with the flange and excessive

hammering will damage the needle roller bearing.

401RS028

4. Align setting marks (1) and join the yokes.

5. Install snap ring.

NOTE:

Discard used snap rings and install new ones.

W hen the bearing cap is in position, select and attach a snap

ring of suitable thickness so that the end play of the spider pin

is held within 0.1 mm (0.004 in).

Snap ring thickness and Identification color

1.50 mm (0.059 in); Light Blue

1.53 mm (0.060 in); White

1.56 mm (0.061 in); Pink

1.59 mm (0.063 in); Yellow

1.62 mm (0.064 in); Green

1.65 mm (0.065 in); Brown

1.68 mm (0.066 in); Not colored

NOTE:

Be sure to use snap rings of the same thickness

on both sides.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 450 of 6020

4B-6 REAR AXLE

RECOMMENDED LIQUID GASKET

Type Brand Name Manufacture Remarks

RTV* Silicon Base ThreeBond 1207B

ThreeBond 1207C

ThreeBond 1215

Three Bond

Three Bond

Three Bond

For Engine Repairs

For Axle Case

Repairs, T/M

W ater Base ThreeBond 1141E Three Bond For Engine Repairs

Solvent ThreeBond 1104

BelcoBond 4

BelcoBond 401

BelcoBond 402 Three bond

Isuzu

Isuzu

Isuzu

For Engine Repairs

Anaerobic LOCTITE 515

LOCTITE 518 Loctite

Loctite All

* RTV : Room Temperature Vulcanizer

Note :

1. It is very important that the liquid gaskets listed above or their exact equivalent be used on the

vehicle.

2. Be careful to use the specified amount of liquid gasket.

Follow the manufacture's instructions at all times.

3. Be absolutely sure to remove all lubricants and

moisture from the connecting surfaces before

applying the liquid gasket.

The connecting surfaces must be perfectly dry.

4. LOCTITE 515 and LOCTITE 518 harden upon contact with a metal surface.

Do not apply LOCTITE 515 or LOCTITE 518 between two metal surfaces having a clearance

of greater than 0.25 mm (0.01 in). Poo

r

adhesion will result.

RECOMMENDED THREAD LOCKING AGENTS

LOCTITE Type LOCTITE Color Application Steps

LOCTITE 242

Blue 1. Completely remove all lubricant and moisture from the bolts and

the female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

LOCTITE 262

Red 2. Apply LOCTITE to the bolts.

LOCTITE 270

Green

LOCTITE 271

Red

3. Tighten the bolts to the specified torque.

4. W ait at least one hour before continuing the installation procedure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 476 of 6020

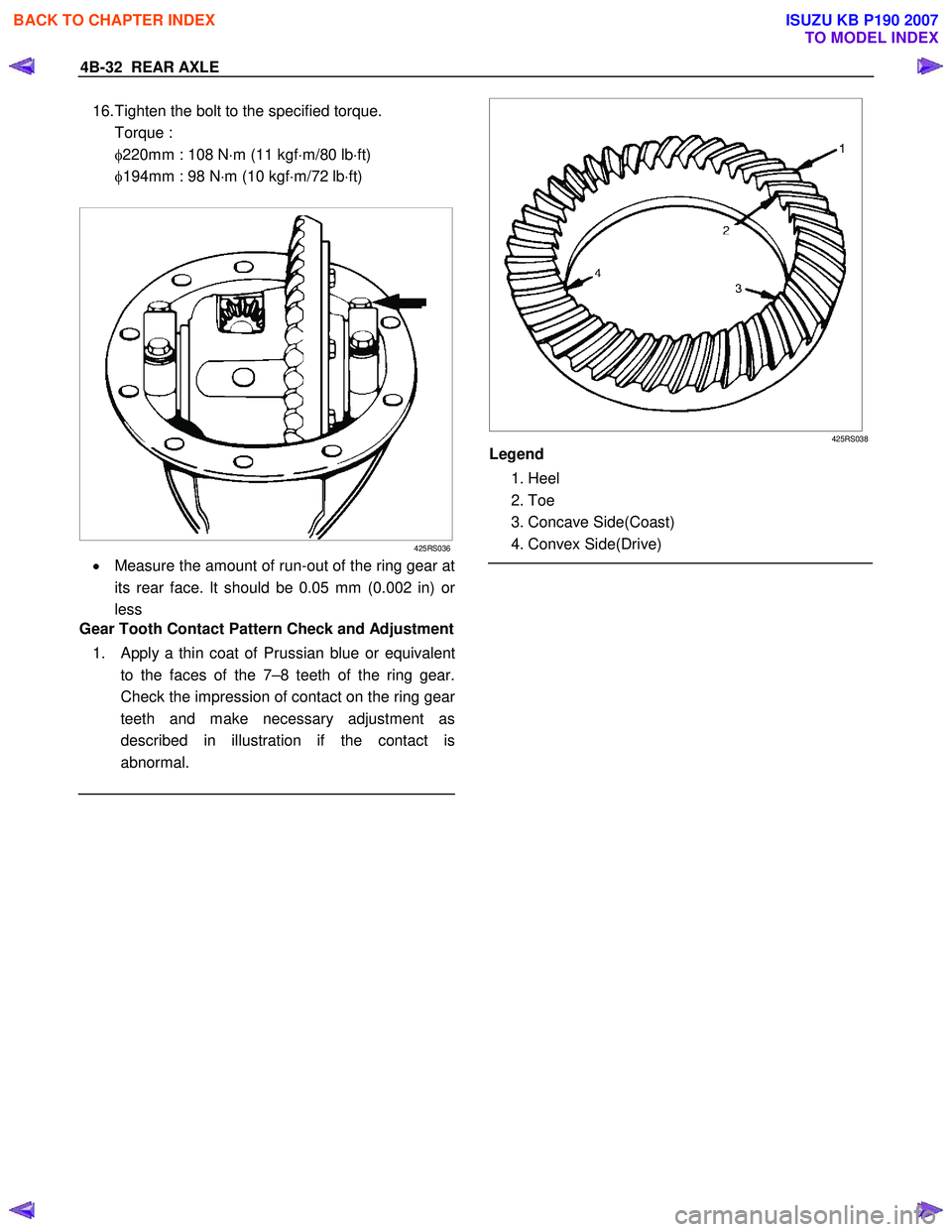

4B-32 REAR AXLE

16. Tighten the bolt to the specified torque.

Torque :

φ220mm : 108 N ⋅m (11 kgf ⋅m/80 lb ⋅ft)

φ194mm : 98 N ⋅m (10 kgf ⋅m/72 lb ⋅ft)

425RS036

• Measure the amount of run-out of the ring gear at

its rear face. It should be 0.05 mm (0.002 in) o

r

less

Gear Tooth Contact Pattern Check and Adjustment

1.

Apply a thin coat of Prussian blue or equivalent

to the faces of the 7–8 teeth of the ring gear.

Check the impression of contact on the ring gea

r

teeth and make necessary adjustment as

described in illustration if the contact is

abnormal.

425RS038

Legend

1. Heel

2. Toe

3. Concave Side(Coast)

4. Convex Side(Drive)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 510 of 6020

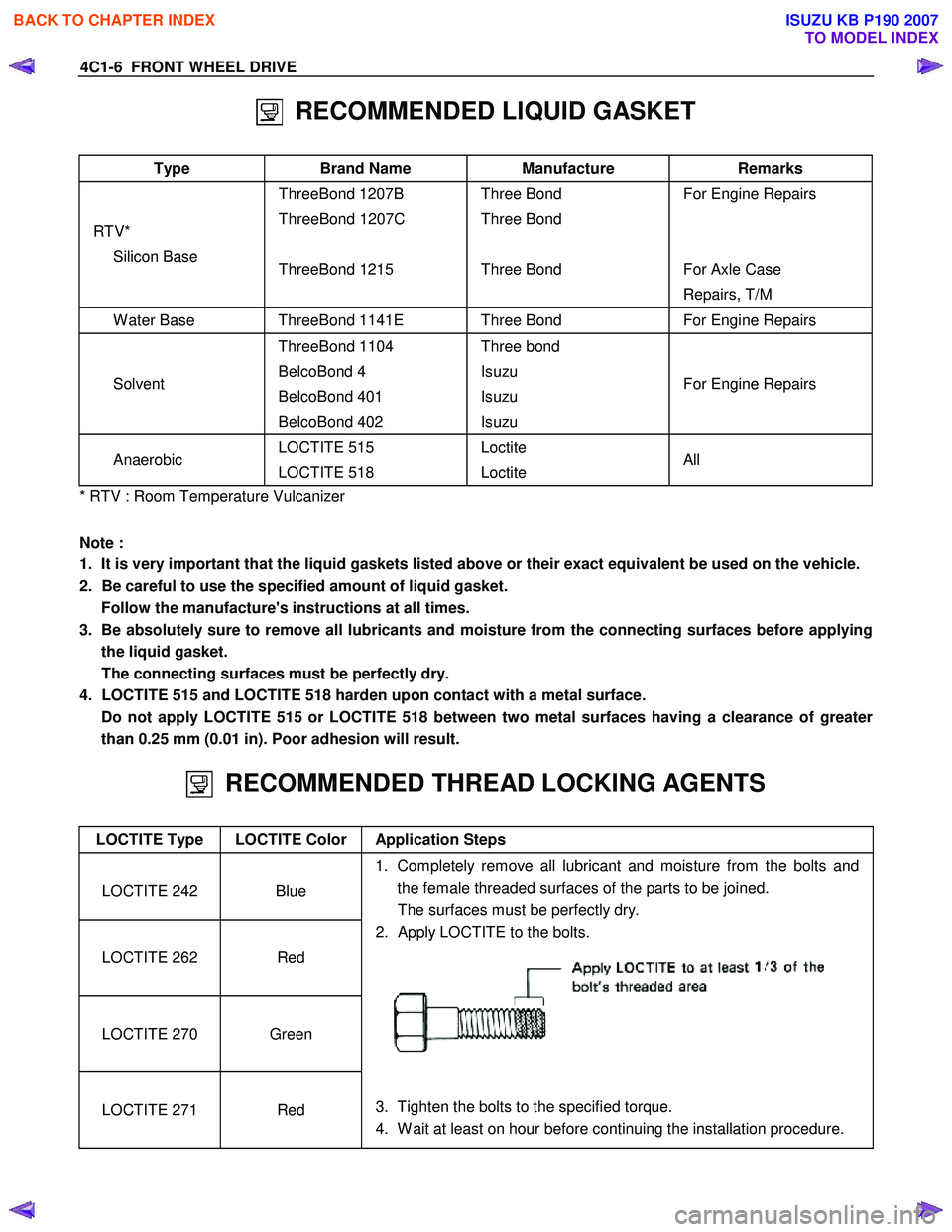

4C1-6 FRONT WHEEL DRIVE

RECOMMENDED LIQUID GASKET

Type Brand Name Manufacture Remarks

RTV* Silicon Base ThreeBond 1207B

ThreeBond 1207C

ThreeBond 1215

Three Bond

Three Bond

Three Bond

For Engine Repairs

For Axle Case

Repairs, T/M

W ater Base ThreeBond 1141E Three Bond For Engine Repairs

Solvent ThreeBond 1104

BelcoBond 4

BelcoBond 401

BelcoBond 402 Three bond

Isuzu

Isuzu

Isuzu

For Engine Repairs

Anaerobic LOCTITE 515

LOCTITE 518 Loctite

Loctite All

* RTV : Room Temperature Vulcanizer

Note :

1. It is very important that the liquid gaskets listed above or their exact equivalent be used on the vehicle.

2. Be careful to use the specified amount of liquid gasket. Follow the manufacture's instructions at all times.

3. Be absolutely sure to remove all lubricants and moisture from the connecting surfaces before applying the liquid gasket.

The connecting surfaces must be perfectly dry.

4. LOCTITE 515 and LOCTITE 518 harden upon contact with a metal surface.

Do not apply LOCTITE 515 or LOCTITE 518 between two metal surfaces having a clearance of greater than 0.25 mm (0.01 in). Poor adhesion will result.

RECOMMENDED THREAD LOCKING AGENTS

LOCTITE Type LOCTITE Color Application Steps

LOCTITE 242

Blue 1. Completely remove all lubricant and moisture from the bolts and

the female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

LOCTITE 262

Red 2. Apply LOCTITE to the bolts.

LOCTITE 270

Green

LOCTITE 271

Red

3. Tighten the bolts to the specified torque.

4. W ait at least on hour before continuing the installation procedure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 540 of 6020

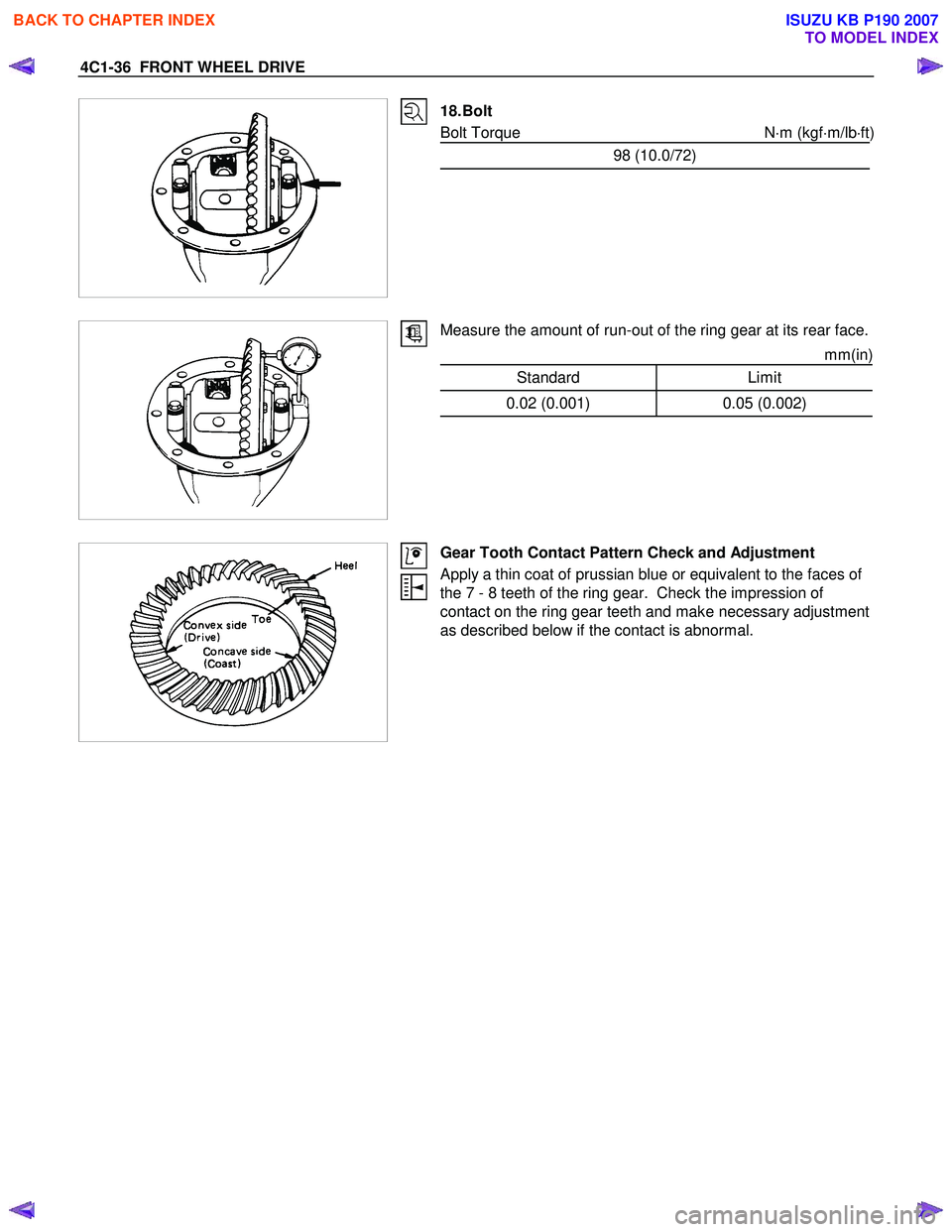

4C1-36 FRONT WHEEL DRIVE

18. Bolt

Bolt Torque N⋅m (kgf ⋅m/lb ⋅ft)

98 (10.0/72)

Measure the amount of run-out of the ring gear at its rear face.

mm(in)

Standard Limit

0.02 (0.001) 0.05 (0.002)

Gear Tooth Contact Pattern Check and Adjustment

Apply a thin coat of prussian blue or equivalent to the faces of

the 7 - 8 teeth of the ring gear. Check the impression of

contact on the ring gear teeth and make necessary adjustment

as described below if the contact is abnormal.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 828 of 6020

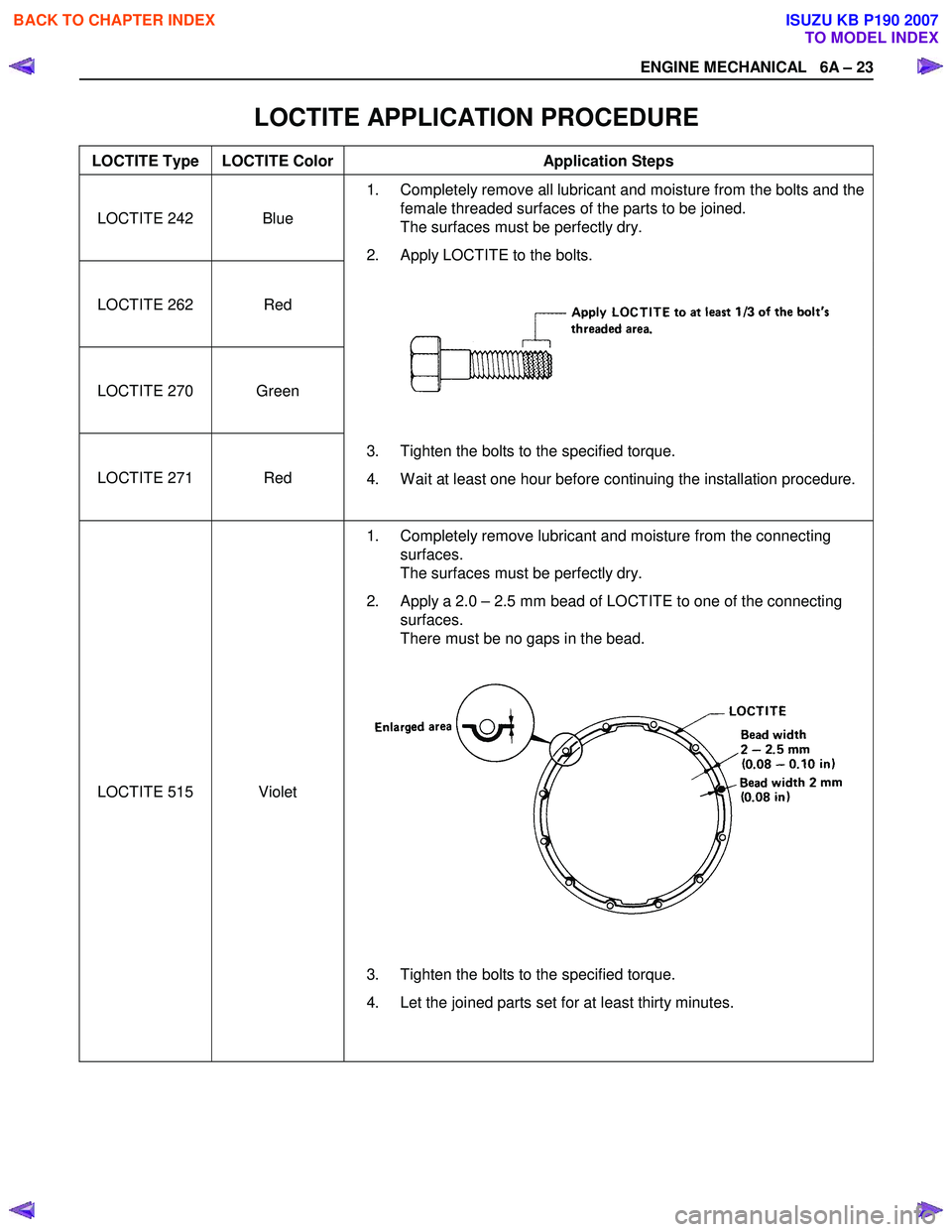

ENGINE MECHANICAL 6A – 23

LOCTITE APPLICATION PROCEDURE

LOCTITE Type LOCTITE Color Application Steps

LOCTITE 242 Blue

LOCTITE 262 Red

LOCTITE 270 Green

LOCTITE 271 Red 1. Completely remove all lubricant and moisture from the bolts and the

female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

2. Apply LOCTITE to the bolts.

3. Tighten the bolts to the specified torque.

4. W ait at least one hour before continuing the installation procedure.

LOCTITE 515 Violet 1. Completely remove lubricant and moisture from the connecting

surfaces.

The surfaces must be perfectly dry.

2. Apply a 2.0 – 2.5 mm bead of LOCTITE to one of the connecting surfaces.

There must be no gaps in the bead.

3. Tighten the bolts to the specified torque.

4. Let the joined parts set for at least thirty minutes.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 889 of 6020

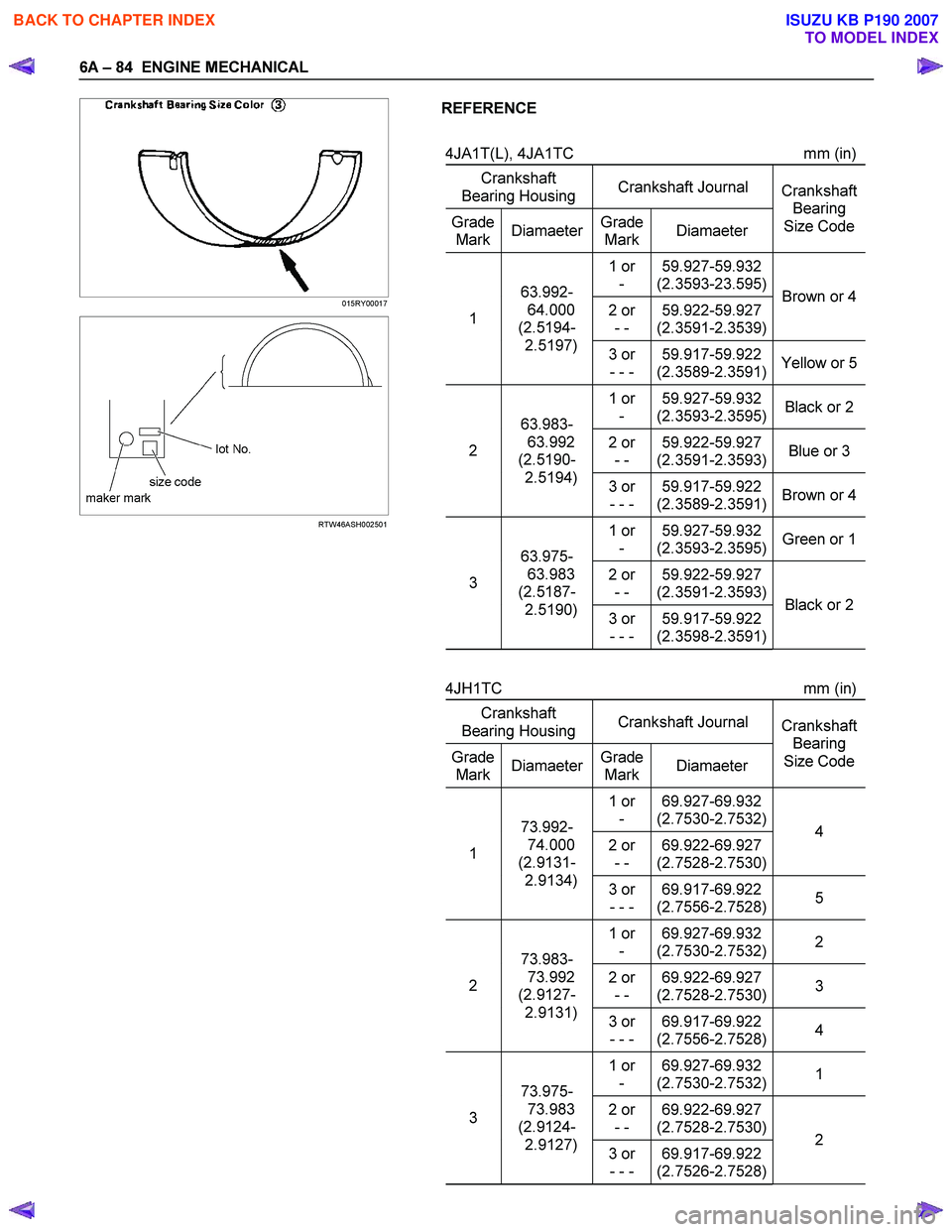

6A – 84 ENGINE MECHANICAL

015RY00017

RTW46ASH002501

REFERENCE

4JA1T(L), 4JA1TC mm (in)

Crankshaft

Bearing Housing Crankshaft Journal

Grade

Mark Diamaeter

Grade

Mark Diamaeter Crankshaft

Bearing

Size Code

1 or - 59.927-59.932

(2.3593-23.595)

2 or - - 59.922-59.927

(2.3591-2.3539) Brown or 41

63.992-

64.000

(2.5194-

2.5197) 3 or

- - - 59.917-59.922

(2.3589-2.3591) Yellow or 5

1 or

- 59.927-59.932

(2.3593-2.3595) Black or 2

2 or

- - 59.922-59.927

(2.3591-2.3593) Blue or 3 2 63.983-

63.992

(2.5190-

2.5194) 3 or

- - - 59.917-59.922

(2.3589-2.3591) Brown or 4

1 or

- 59.927-59.932

(2.3593-2.3595) Green or 1

2 or

- - 59.922-59.927

(2.3591-2.3593)3 63.975-

63.983

(2.5187-

2.5190) 3 or

- - - 59.917-59.922

(2.3598-2.3591) Black or 2

4JH1TC mm (in)

Crankshaft

Bearing Housing Crankshaft Journal

Grade

Mark Diamaeter

Grade

Mark Diamaeter Crankshaft

Bearing

Size Code

1 or - 69.927-69.932

(2.7530-2.7532)

2 or - - 69.922-69.927

(2.7528-2.7530) 4 1

73.992-

74.000

(2.9131-

2.9134) 3 or

- - - 69.917-69.922

(2.7556-2.7528) 5

1 or

- 69.927-69.932

(2.7530-2.7532) 2

2 or

- - 69.922-69.927

(2.7528-2.7530) 3 2 73.983-

73.992

(2.9127-

2.9131) 3 or

- - - 69.917-69.922

(2.7556-2.7528) 4

1 or

- 69.927-69.932

(2.7530-2.7532) 1

2 or

- - 69.922-69.927

(2.7528-2.7530)3 73.975-

73.983

(2.9124-

2.9127) 3 or

- - - 69.917-69.922

(2.7526-2.7528) 2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1039 of 6020

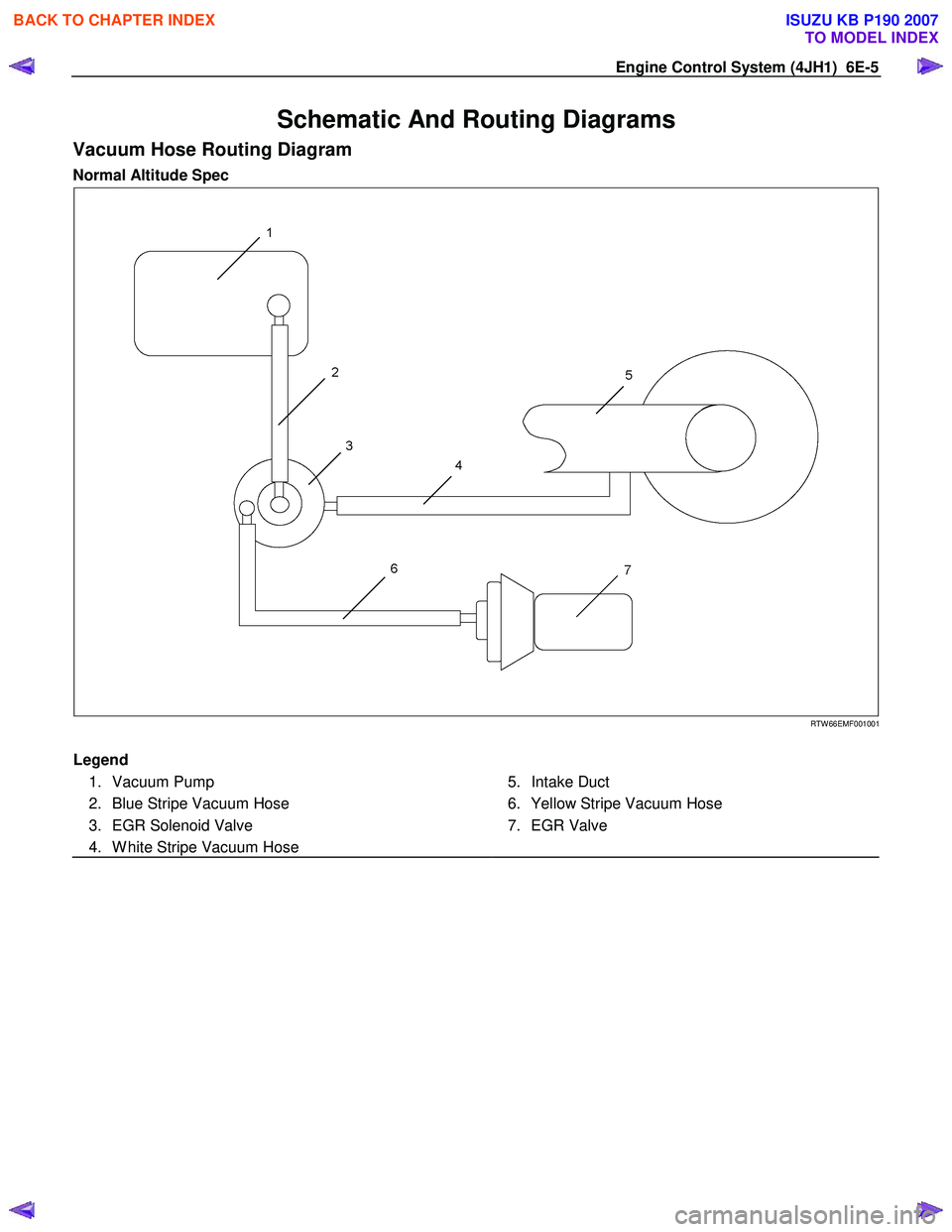

Engine Control System (4JH1) 6E-5

Schematic And Routing Diagrams

Vacuum Hose Routing Diagram

Normal Altitude Spec

RTW 66EMF001001

Legend

1. Vacuum Pump

2. Blue Stripe Vacuum Hose

3. EGR Solenoid Valve

4. W hite Stripe Vacuum Hose

5. Intake Duct

6. Yellow Stripe Vacuum Hose

7. EGR Valve

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

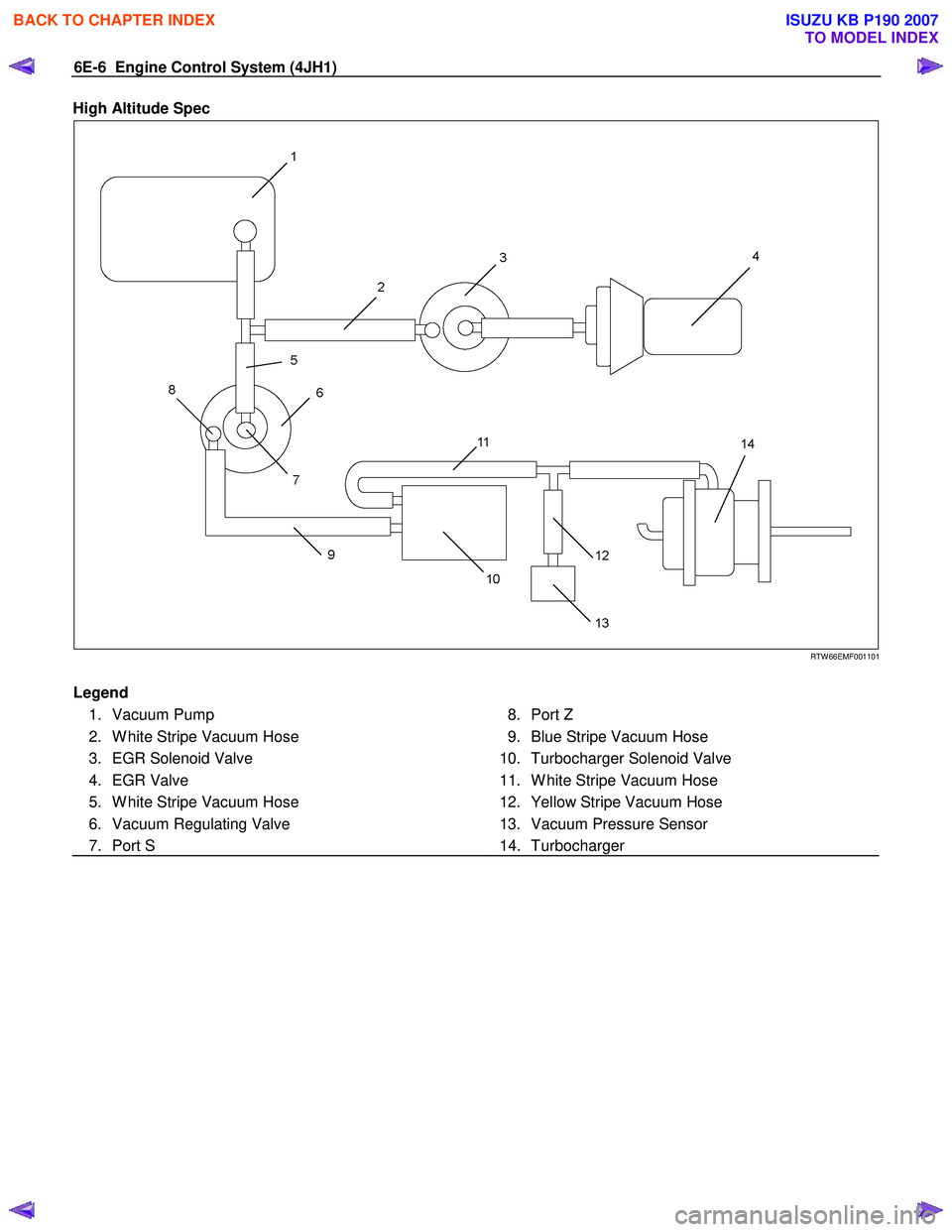

Page 1040 of 6020

6E-6 Engine Control System (4JH1)

High Altitude Spec

RTW 66EMF001101

Legend

1. Vacuum Pump

2. W hite Stripe Vacuum Hose

3. EGR Solenoid Valve

4. EGR Valve

5. W hite Stripe Vacuum Hose

6. Vacuum Regulating Valve

7. Port S

8. Port Z

9. Blue Stripe Vacuum Hose

10. Turbocharger Solenoid Valve

11. W hite Stripe Vacuum Hose

12. Yellow Stripe Vacuum Hose

13. Vacuum Pressure Sensor

14. Turbocharger

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007