mileage ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1671 of 6020

6E-54 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Cruise Cancel Switch

This parameter displays the input state of the cruise

cancel switch to the ECM. When the Cruise Cancel

switch is applied, the scan tool displays Off.

Cruise Resume Switch

This parameter displays the input state of the cruise

resume/accel. switch to the ECM. When the Cruise

Resume/Accel. switch is applied, the scan tool displays

On.

Cruise Set Switch

This parameter displays the input state of the cruise

set/coast switch to the ECM. When the Cruise Set/

Coast switch is pushed, the scan tool displays On.

MIL Command (Malfunction Indicator Lamp)

This parameter displays the commanded state of the

malfunction indicator lamp (MIL) control circuit. The

MIL should be On when the scan tool indicates

command On. The MIL should be Off when the scan

tool indicates command Off.

SVS Lamp Command (Service Vehicle Soon)

This parameter displays the commanded state of the

service vehicle soon (SVS) lamp control circuit. The

SVS lamp should be On when the scan tool indicates

command On. The SVS lamp should be Off when the

scan tool indicates command Off.

Limp Home Mode

This parameter indicates the state of the limp-home

mode. None indicates limp-home mode is not applied.

1, 2, 3 and 4 indicates fuel injection quantity reduction

is applied. 2 or higher number inhibits pilot injection. If 4

is indicated, engine running will be stopped when the

vehicle speed is less than 5 km/h (3 MPH) for 5

seconds.

Distance While MIL is Activated

This parameter displays the mileage since the

malfunction indicator lamp (MIL) is turned ON.

Engine Runtime With MIL Active

This parameter displays the engine run time elapsed

since the malfunction indicator lamp (MIL) is turned

ON. The scan tool will display the time in minutes.

Total Engine Overspeed Event

This parameter indicates counter of engine overspeed

event. Counter will be zero if any DTC is cleared.

Total Engine Coolant Overtemperature Event

This parameter indicates counter of engine overheat

event. The counter is active if engine coolant is over

11 0 °C (230 °F). Counter will be zero if any DTC is

cleared. Total Fuel Temperature Overtemperature Event

This parameter indicates counter of fuel temperature

excessively high condition. The counter is active if fuel

temperature is over 95 °C (203 °F). Counter will be zero

if any DTC is cleared.

Total Intake Air Temperature Overtemperature

Event

This parameter indicates counter of intake air

temperature excessively high condition. The counter is

active if intake air temperature is over 55 °C (131 °F).

Counter will be zero if any DTC is cleared.

Immobilizer Function Programmed

This parameter displays the state of the immobilizer

function programming in the ECM. The scan tool will

display Yes or No. Yes indicates the immobilizer

security information is correctly programmed in the

ECM. No indicates the ECM is not programmed or

ECM is reset.

Wrong Immobilizer Signal

This parameter displays the input state of the received

response signal to the ECM. When the ECM received

wrong response signal from the immobilizer control unit

(ICU), the scan tool displays Yes.

Immobilizer Signal

This parameter displays the input state of the response

signal to the ECM. When the ECM received any

response signal from the immobilizer control unit (ICU),

the scan tool displays Yes.

Security Wait Time

This parameter displays the security wait time length in

the ECM. Inactive indicates not in security wait time.

Time indicates under security wait time. This wait time

stage will prevent any further attempts to enter the

security code until the wait time has elapsed. The wait

time will increase each time an incorrect security code

is entered. Note that this parameter is not count

downed. It keeps displaying the same time until that

wait time has elapsed. The ignition switch must be kept

at ON position during the wait time period.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2035 of 6020

ENGINE MECHANICAL (C24SE) 6A-21

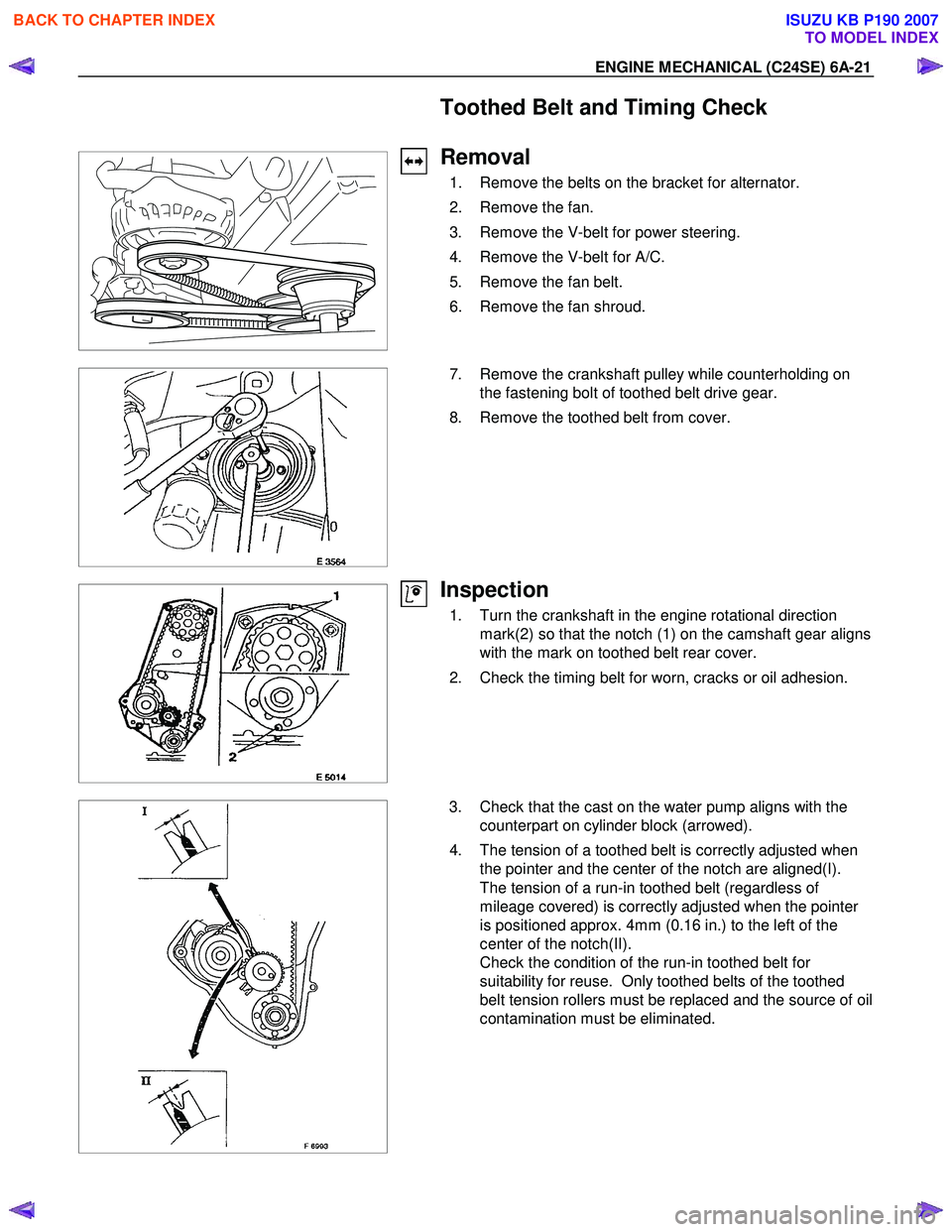

Toothed Belt and Timing Check

Removal

1. Remove the belts on the bracket for alternator.

2. Remove the fan.

3. Remove the V-belt for power steering.

4. Remove the V-belt for A/C.

5. Remove the fan belt.

6. Remove the fan shroud.

7. Remove the crankshaft pulley while counterholding on

the fastening bolt of toothed belt drive gear.

8. Remove the toothed belt from cover.

Inspection

1. Turn the crankshaft in the engine rotational direction mark(2) so that the notch (1) on the camshaft gear aligns

with the mark on toothed belt rear cover.

2. Check the timing belt for worn, cracks or oil adhesion.

3. Check that the cast on the water pump aligns with the counterpart on cylinder block (arrowed).

4. The tension of a toothed belt is correctly adjusted when the pointer and the center of the notch are aligned(I).

The tension of a run-in toothed belt (regardless of

mileage covered) is correctly adjusted when the pointer

is positioned approx. 4mm (0.16 in.) to the left of the

center of the notch(II).

Check the condition of the run-in toothed belt for

suitability for reuse. Only toothed belts of the toothed

belt tension rollers must be replaced and the source of oil

contamination must be eliminated.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5990 of 6020

11B-36 ANTITHEFT SYSTEM

Diagnosis

Diagnostic procedure

• Once the cause of DTC is repaired or gone,

engine can be operated normally, and present

DTC becomes history code.

• History code is canceled by no repeat failure on 25

consequence ignition key on afterward.

• History code cannot be canceled by batter

y

connector disconnected.

Clearing Diagnostic Trouble Codes

IMPORTANT: Do not clear DTCs unless directed to do

so by the service information provided for each

diagnostic procedure. W hen DTCs are cleared, the

Failure Record data which may help diagnose an

intermittent fault will also be erased from memory.

Verifying Vehicle Repair

Verification of vehicle repair will be more

comprehensive for vehicles with immobilizer system

diagnostic. Following a repair, the technician should

perform the following steps:

1. Review and record the Fail Records for the DTC which has been diagnosed.

2. Clear DTC (s).

3. Operate the vehicle within conditions noted in the Fail Records.

4. Monitor the DTC status information for the DTC which has been diagnosed until the diagnostic test

associated with that DTC runs.

Following these steps are very important in verifying

repairs on immobilizer systems. Failure to follow these

steps could result in unnecessary repairs.

Diagnostic Aids

An intermittent may be caused by the following:

• Poor connections.

• Miss routed harness.

• Rubbed through wire insulation.

• Broken wire inside the insulation.

Check for the following conditions:

• Poor connection at ACU-Inspect harness

connectors for backed out terminals, imprope

r

mating, broken locks, improperly formed or

damaged terminals, and poor terminal to wire

connection.

• Damaged harness-Inspect the wiring harness fo

r

damage.

If the harness appears to be OK, observe the data

display on the Tech2 while moving connectors and

wiring harnesses related to the switch or actuator.

A change in the display will indicate the location of

the fault.

If DTC cannot be duplicated, the information included in the Failure Records data can be useful

in determined vehicle mileage since the DTC was

last set.

If it is determined that the DTC occurs intermittently, performing the DTC Diagnostic

Chart may isolate the cause of the fault.

NOTE: Breakage of antitheft fuse does not operate

antitheft system. Check LED lamp flashes at this time.

Check the Electro-Magnetic Interference (EMI)

• Location of vehicle check

Move the vehicle to a new location and perform

the check again.

• Non-OEM Parts.

Switch is “OFF” or remove the Non-OEM parts and

perform the check again.

• Other

Remove the accessory and another key from key.

Check the other items.

• Battery voltage is low.

• Antitheft programming functions.

Must be programmed antitheft system.

• Registration for security code, antitheft control unit

parts number.

• Key switch operation.

Antitheft system may detect a history DTC by the

timing of ON-OFF of a key switch.

• Active the antitheft system.

• Keyless entry system is malfunction.

• Immobilizer system is malfunction.

Check the operation

Check the operation "Lock / unlock" by using transmitter

(key) on the vehicle.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007