warning lights ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1522 of 6020

6A-162 ENGINE MECHANICAL (4JK1/4JJ1)

Removal

1. Remove the oil pressure SW .

2. Remove the nipple; oil gallery.

3. Remove the nipple; oil pressure warning SW and gasket.

Inspection

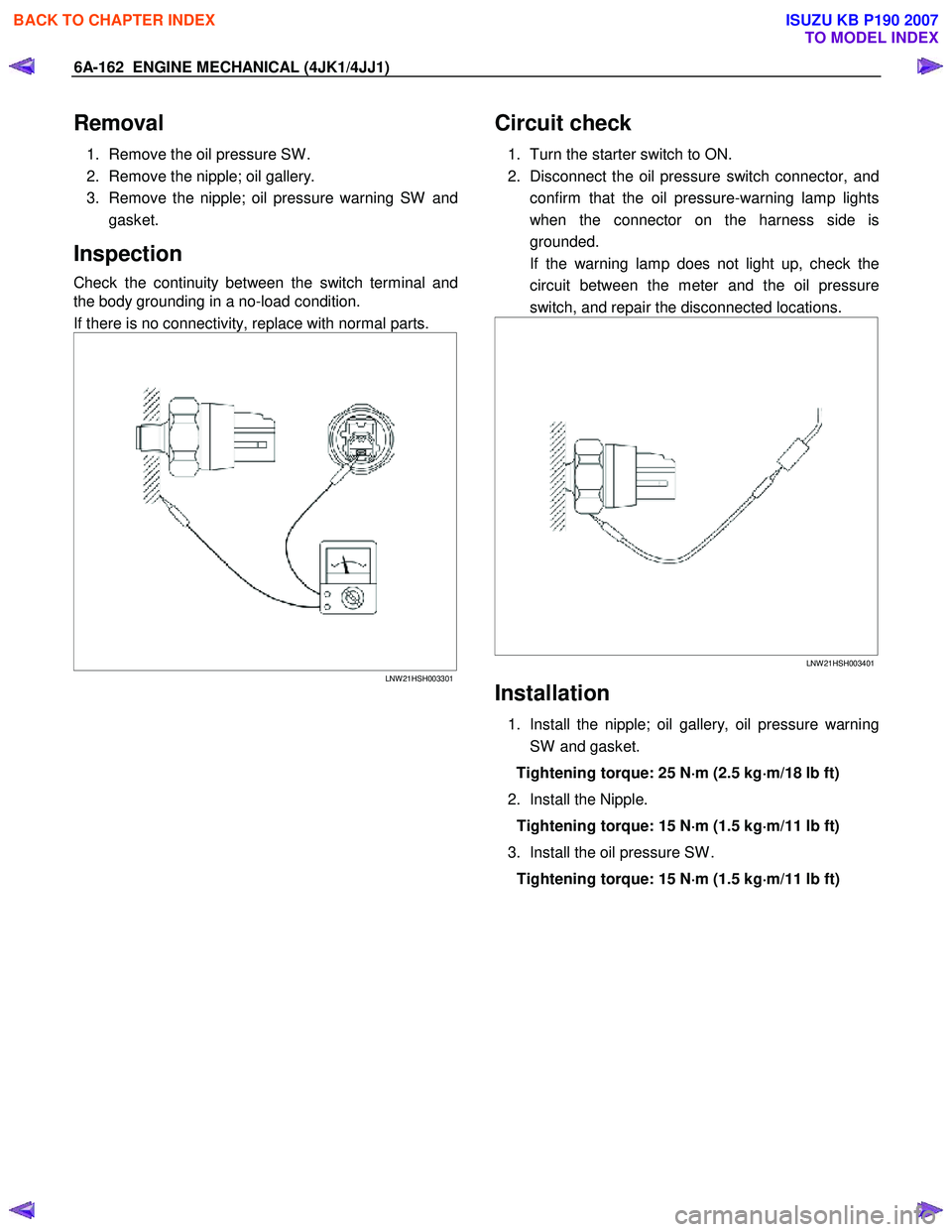

Check the continuity between the switch terminal and

the body grounding in a no-load condition.

If there is no connectivity, replace with normal parts.

LNW 21HSH003301

Circuit check

1. Turn the starter switch to ON.

2. Disconnect the oil pressure switch connector, and confirm that the oil pressure-warning lamp lights

when the connector on the harness side is

grounded.

If the warning lamp does not light up, check the circuit between the meter and the oil pressure

switch, and repair the disconnected locations.

LNW 21HSH003401

Installation

1. Install the nipple; oil gallery, oil pressure warning

SW and gasket.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m/18 lb ft)

2. Install the Nipple. Tightening torque: 15 N ⋅

⋅⋅

⋅

m (1.5 kg ⋅

⋅⋅

⋅

m/11 lb ft)

3. Install the oil pressure SW . Tightening torque: 15 N ⋅

⋅⋅

⋅

m (1.5 kg ⋅

⋅⋅

⋅

m/11 lb ft)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1580 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-39

Fuel Sedimenter Switch

Inspection

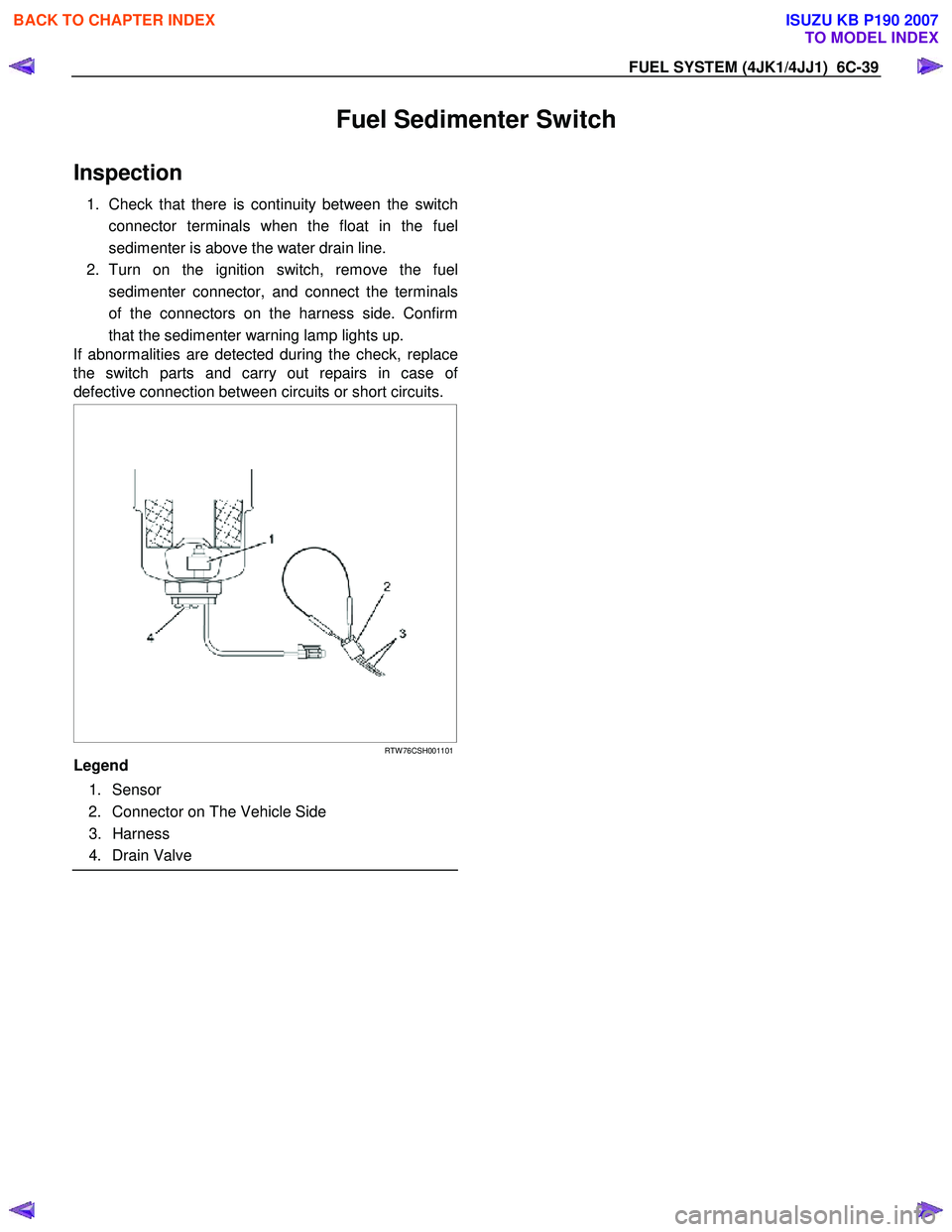

1. Check that there is continuity between the switch

connector terminals when the float in the fuel

sedimenter is above the water drain line.

2. Turn on the ignition switch, remove the fuel sedimenter connector, and connect the terminals

of the connectors on the harness side. Confirm

that the sedimenter warning lamp lights up.

If abnormalities are detected during the check, replace

the switch parts and carry out repairs in case o

f

defective connection between circuits or short circuits.

RTW 76CSH001101

Legend

1. Sensor

2. Connector on The Vehicle Side

3. Harness

4. Drain Valve

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2142 of 6020

ENGINE ELECTRICAL 6D1-5

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly rinse

the affected area with clean tap water.

Never allow metal tools or jumper cables to come in contact

with the positive battery terminal, or any other metal surface of

the vahicle. This will protect against a short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake and place the shift lever in the

"NEUTRAL" position.

Turn "OFF" the ignition.

Turn "OFF" all lights and any other accessory requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer is completel

y

clear, do not try to jump start.

3.

Attach the end of one jumper cable to the positive terminal

of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will cause a ground connection, effectively neutralizing the

charging procedure.

Be sure that the booster battery has a 12 volt rating.

4.

Attach one end of the remaining cable to the negative

terminal of the booster battery.

Attach the other end of the same cable to a solid engine ground (such as the air conditioning compressor bracket o

r

the generator mounting bracket) of the vehicle with the

discharged battery.

The ground connection must be at least 450 mm (18 in.) from the battery of the vehicle whose battery is being

charged.

WARNING: NEVER ATTACH THE END OF THE JUMPER

CABLE DIRECTLY TO THE NEGATIVE TERMINAL OF THE

DEAD BATTERY.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical accessories have been turned "OFF".

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above directions in reverse order.

Be sure to first disconnect the negative cable from the vehicle with the discharged battery.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2161 of 6020

STARTING AND CHARGING SYSTEM 6D3-13

5. During current output tests please make sure that the

ammeter is securely connceted into the charge circuit.

6. Some battery powered timing lights can produce high transient voltages when connected or disconnected. Onl

y

disconnect or connect timing lights when the engine is

switched off.

7. Make sure the warning lamp circuit is functioning normall

y

before commencing tests.

8. Battery isolation switches must only be operated when the engine is stopped.

9. To protect the charging system when using 240 volt chargers it is recommeneded that the battery is

disconnected whilst charging.

10. Due to the very low resistance value of the stator winding it may not be possible to obtain accurate readings without

special equipment.

11. 12 volts must never be connected to the "L" terminal of the regulator as this will damage the lamp driver circuit.

12. No loads apart from the warning lamp can be connected to the "L" termainal. The "W " terminal is provided for this

purpose.

Disassembly

1. Mark the relative positions of the end housings in relation to the stator assembly to aid reassembly. Use a permanent

marking pen do not use centre punched as this can cause

misalignmnet of the housings.

2. Remove the EP regulator from the slipring end housing b

y

removing the two screws. Tilt the regulator slightly from the

plug connection until the regulator clears the housing, then

lift clear.

3. Remove the four through bolts.

4. Carefully remove the stator assembly along with the slipring end housing taking care not to put strain on the stator wires.

5. To disconnect the stator from the rectifier assembly, grasp the stator wires close to the wire loop with a pair of long

nosed pliers, heat the joint with a soldering iron, when the

point becomes plastic apply a slight twisting motion to the

wires, then pull upwards to release the wires. Remove the

stator.

This procedure opens the wire loop to release the stato

r

connections easily.

6. To remove the rectifier remove the three retaining scre

w

and the B+ terminal nut and washers.

Note: the B+ bolt and the positive heatsink retaining screw are

fitted with mica insulating washers.

These must be discarded and replaced with new washers and

heatsink compound.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4256 of 6020

CONSTRUCTION AND FUNCTION 7A1-17

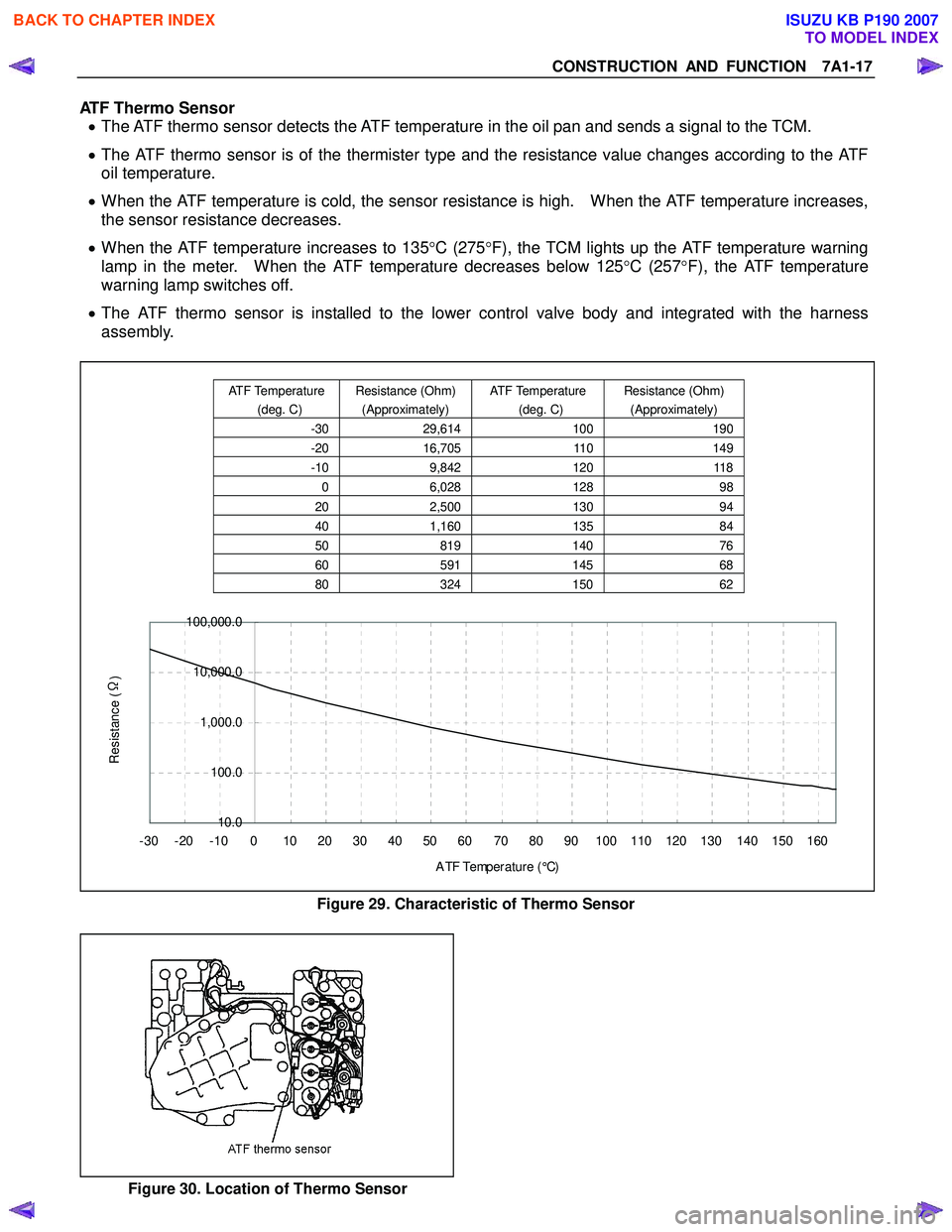

ATF Thermo Sensor • The ATF thermo sensor detects the ATF temperature in the oil pan and sends a signal to the TCM.

• The ATF thermo sensor is of the thermister type and the resistance value changes according to the ATF

oil temperature.

• When the ATF temperature is cold, the sensor resistance is high. When the ATF temperature increases,

the sensor resistance decreases.

• When the ATF temperature increases to 135 °C (275 °F), the TCM lights up the ATF temperature warning

lamp in the meter. When the ATF temperature decreases below 125 °C (257 °F), the ATF temperature

warning lamp switches off.

• The ATF thermo sensor is installed to the lower control valve body and integrated with the harness

assembly.

10.0

100.0

1,000.0

10,000.0

100,000.0

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 A TF Temp er a t ur e ( °C)

Resistance (Ω

)

Figure 29. Characteristic of Thermo Sensor

Figure 30. Location of Thermo Sensor

ATF Temperature

(deg. C) Resistance (Ohm)

(Approximately) ATF Temperature

(deg. C) Resistance (Ohm)

(Approximately)

-30 29,614 100190

-20 16,705 110149

-10 9,842 120118

0 6,028 128 98

20 2,500 130 94

40 1,160 135 84

50 819 140 76

60 591 14568

80 324 15062

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5307 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-369

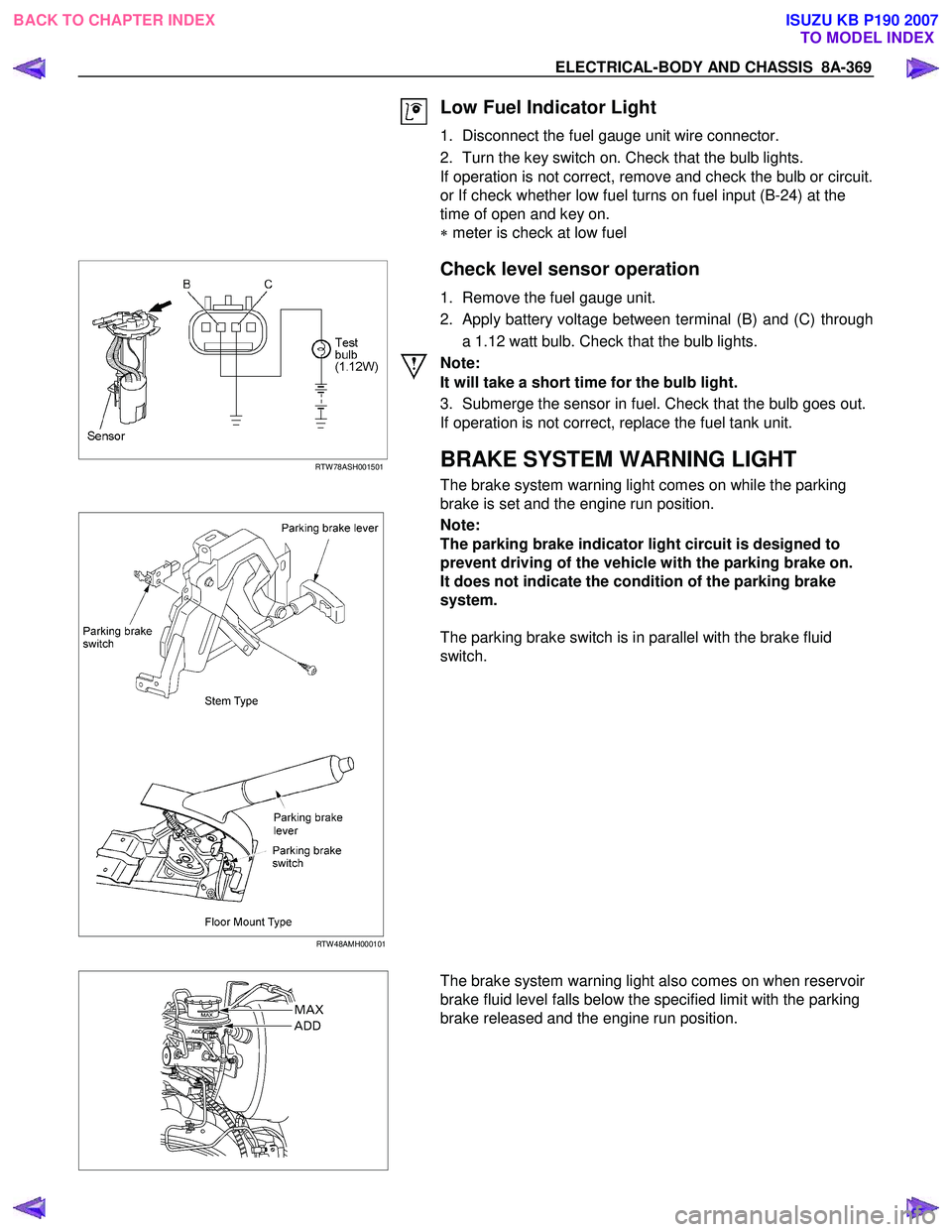

Low Fuel Indicator Light

1. Disconnect the fuel gauge unit wire connector.

2. Turn the key switch on. Check that the bulb lights.

If operation is not correct, remove and check the bulb or circuit.

or If check whether low fuel turns on fuel input (B-24) at the

time of open and key on.

∗ meter is check at low fuel

RTW 78ASH001501

Check level sensor operation

1. Remove the fuel gauge unit.

2. Apply battery voltage between terminal (B) and (C) through a 1.12 watt bulb. Check that the bulb lights.

Note:

It will take a short time for the bulb light.

3. Submerge the sensor in fuel. Check that the bulb goes out.

If operation is not correct, replace the fuel tank unit.

BRAKE SYSTEM WARNING LIGHT

The brake system warning light comes on while the parking

brake is set and the engine run position.

RTW 48AMH000101

Note:

The parking brake indicator light circuit is designed to

prevent driving of the vehicle with the parking brake on.

It does not indicate the condition of the parking brake

system.

The parking brake switch is in parallel with the brake fluid

switch.

The brake system warning light also comes on when reservoir

brake fluid level falls below the specified limit with the parking

brake released and the engine run position.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5956 of 6020

11B-2 ANTITHEFT SYSTEM

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or

other corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

General Description

The Antitheft system consists of the four major

components which are Antitheft Control Unit (ACU),

Antitheft horn, key (remote key), and scan tool (Tech-2).

This system can be activated by a correctly

programmed key (remote key) and starter switch is set

to OFF.

This system can be deactivated by a correctly

programmed key (remote key) connected with a

correctly programmed ACU and a correctly

programmed lCU.

W hen the vehicle doors, and engine hood are locked,

the antitheft alarm system is designed to protect your

vehicle and valuables from theft.

Any attempt to forcibly open any door, the engine hood

without using the vehicle key (or remote control) will

cause the hazard lights to flash on and off and the horn

to sound intermittently. This will continue for 30 seconds

(Hazard lamp flash; For 5 minutes) before the system

automatically shuts itself off.

Please operate the door either the key lock or remote

key after closing all doors to arm the alarm system.

Miss waning will be detected when the passenger door

is opened with locked condition and then this door is

closed.

During the first 10 seconds:

• LED lights up; Test, switch - on delay

• LED rapidly flashes (2Hz); Door, bonnet, open or

system fault

After approx. 10 seconds:

• LED slowly flashes; System on (0.5Hz)

RTU7Z0SH019101

Activating the anti-theft system

1. W hen the key switch is turned to the ACC position or

removed from the starter switch.

2. Closing and locking all the doors by the keylock o

r

remote key, and the engine hood will cause the

indicator light to come on.

3. Approximately 10 seconds later, the indicator light will slow flash. The anti-theft system is now in

operation.

Antitheft system alarm operating

conditions

W hen the antitheft system is engaged, the alarm will

operate under the following condition;

1. W henever some forcibly attempts to open a door, the engine hood without using the key.

2. W henever someone unlocks a door with door lock knob.

3. W henever the engine hood release handle is operated.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5957 of 6020

ANTITHEFT SYSTEM 11B-3

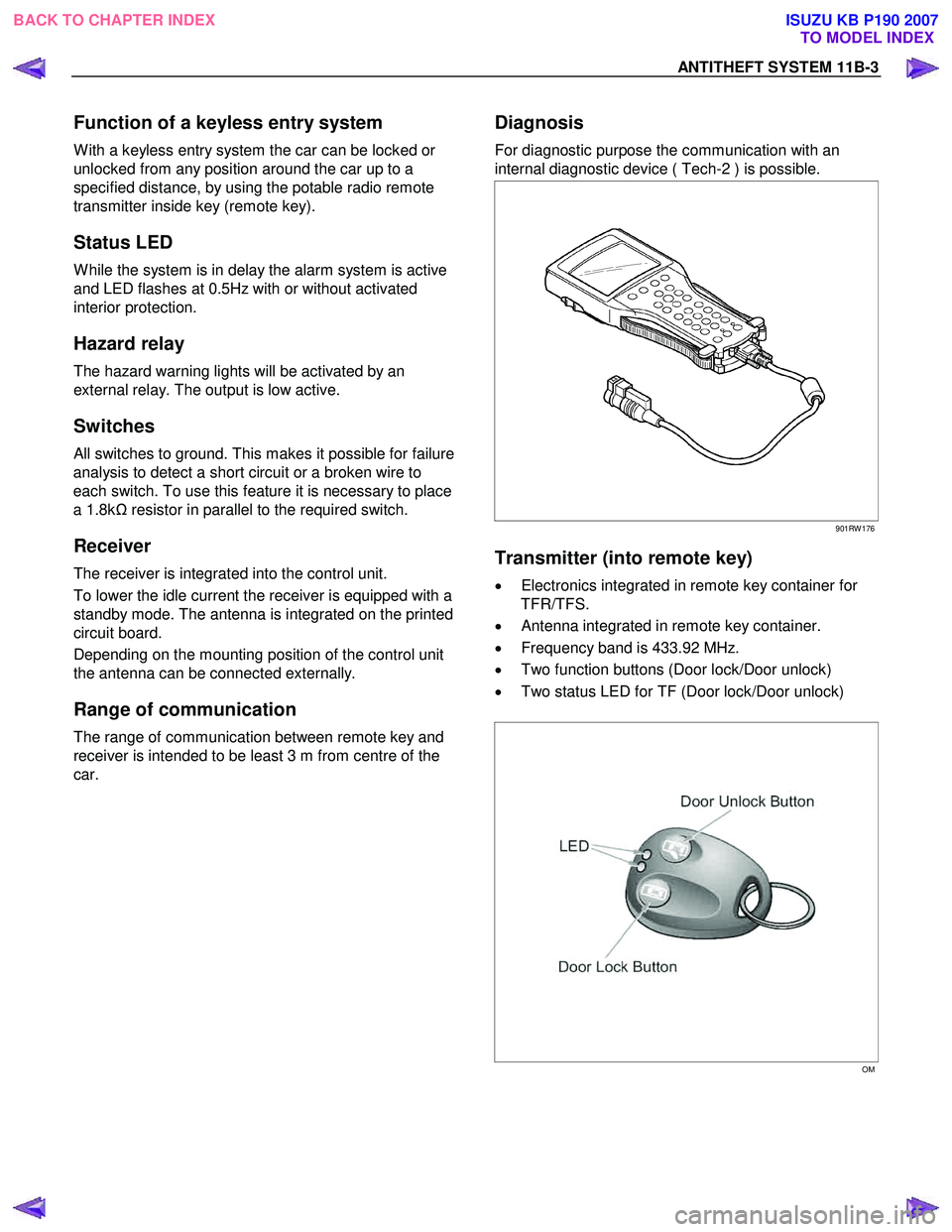

Function of a keyless entry system

W ith a keyless entry system the car can be locked or

unlocked from any position around the car up to a

specified distance, by using the potable radio remote

transmitter inside key (remote key).

Status LED

W hile the system is in delay the alarm system is active

and LED flashes at 0.5Hz with or without activated

interior protection.

Hazard relay

The hazard warning lights will be activated by an

external relay. The output is low active.

Switches

All switches to ground. This makes it possible for failure

analysis to detect a short circuit or a broken wire to

each switch. To use this feature it is necessary to place

a 1.8k Ω resistor in parallel to the required switch.

Receiver

The receiver is integrated into the control unit.

To lower the idle current the receiver is equipped with a

standby mode. The antenna is integrated on the printed

circuit board.

Depending on the mounting position of the control unit

the antenna can be connected externally.

Range of communication

The range of communication between remote key and

receiver is intended to be least 3 m from centre of the

car.

Diagnosis

For diagnostic purpose the communication with an

internal diagnostic device ( Tech-2 ) is possible.

901RW 176

Transmitter (into remote key)

• Electronics integrated in remote key container for

TFR/TFS.

• Antenna integrated in remote key container.

• Frequency band is 433.92 MHz.

• Two function buttons (Door lock/Door unlock)

• Two status LED for TF (Door lock/Door unlock)

OM

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007