fuel ISUZU TF SERIES 2004 Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 1380 of 4264

6E–8 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

(SYMPTOM CODE B) (FLASH CODE 76) ECM

MAIN RELAY SWITCHED OFF TOO LATE 6E-337

Circuit Description ..................................... 6E-337

Diagnostic Aids .......................................... 6E-337

Diagnostic Trouble Code (DTC) P1625

(Symptom Code A) (Flash Code 76) ECM

Main Relay Switched Off Too Early ......... 6E-338

Diagnostic Trouble Code (DTC) P1625

(Symptom Code B) (Flash Code 76) ECM

Main Relay Switched Off Too Late .......... 6E-339

DIAGNOSTIC TROUBLE CODE (DTC) P1630

(SYMPTOM CODE A) (FLASH CODE 51)

FUEL INJECTION QUANTITY CIRCUIT

MALFUNCTION ....................................... 6E-340

DIAGNOSTIC TROUBLE CODE (DTC) P1630

(SYMPTOM CODE B) (FLASH CODE 51)

FUEL INJECTION QUANTITY CIRCUIT

MALFUNCTION ....................................... 6E-340

Circuit Description ..................................... 6E-340

Diagnostic Aids .......................................... 6E-341

Diagnostic Trouble Code (DTC) P1630

(Symptom Code A) (Flash Code 51) Fuel

Injection Quantity Circuit Malfunction ...... 6E-341

Diagnostic Trouble Code (DTC) P1630

(Symptom Code B) (Flash Code 51) Fuel

Injection Quantity Circuit Malfunction ...... 6E-341

DIAGNOSTIC TROUBLE CODE (DTC) P1650

(SYMPTOM CODE A)

(FLASH CODE 44) CAN DEVICE OFFLINE 6E-342

DIAGNOSTIC TROUBLE CODE (DTC) P1650

(SYMPTOM CODE B) (FLASH CODE 44)

CAN DEVICE HANG-UP ......................... 6E-342

Circuit Description ..................................... 6E-342

Diagnostic Aids .......................................... 6E-342

Diagnostic Trouble Code (DTC) P1650

(Symptom Code A) (Flash Code 44)

CAN Device Offline .................................. 6E-343

Diagnostic Trouble Code (DTC) P1650

(Symptom Code B) (Flash Code 44)

CAN Device Hang-up .............................. 6E-348

DIAGNOSTIC TROUBLE CODE (DTC) P1651

(SYMPTOM CODE A) (FLASH CODE 45)

CAN MALFUNCTION .............................. 6E-349

DIAGNOSTIC TROUBLE CODE (DTC) P1651

(SYMPTOM CODE B) (FLASH CODE 45)

CAN RECEIVES ERROR ........................ 6E-349

Circuit Description ..................................... 6E-349

Diagnostic Aids .......................................... 6E-349

Diagnostic Trouble Code (DTC) P1651

(Symptom Code A) (Flash Code 45)

CAN Malfunction ...................................... 6E-350

Diagnostic Trouble Code (DTC) P1651

(Symptom Code B) (Flash Code 45) CAN Receives Error ................................ 6E-351

DIAGNOSTIC TROUBLE CODE (DTC) P1690

(SYMPTOM CODE 4) (FLASH CODE 77)

CHECK ENGINE LAMP (MIL) CIRCUIT

VOLTAGE LOW ...................................... 6E-356

DIAGNOSTIC TROUBLE CODE (DTC) P1690

(SYMPTOM CODE 8) (FLASH CODE 77)

CHECK ENGINE LAMP (MIL) CIRCUIT

VOLTAGE HIGH ...................................... 6E-356

Circuit Description ...................................... 6E-356

Diagnostic Aids .......................................... 6E-356

Diagnostic Trouble Code (DTC) P1690

(Symptom Code 4) (Flash Code 77) Check

Engine Lamp (MIL) Circuit Voltage Low .. 6E-357

Diagnostic Trouble Code (DTC) P1690

(Symptom Code 8) (Flash Code 77) Check

Engine Lamp (MIL) Circuit Voltage High . 6E-360

SYMPTOM DIAGNOSIS ............................ 6E-361

PRELIMINARY CHECKS .......................... 6E-361

VISUAL/PHYSICAL CHECK ...................... 6E-361

INTERMITTENT ........................................ 6E-361

ENGINE CRANKS BUT WILL NOT RUN .. 6E-362

HARD START SYMPTOM ......................... 6E-366

ROUGH, UNSTABLE, OR INCORRECT

IDLE, STALLING SYMPTOM .................. 6E-370

SURGES AND/OR CHUGS SYMPTOM ... 6E-377

HESITATION, SAG, STUMBLE SYMPTOM 6E-383

CUTS OUT, MISSES SYMPTOM .............. 6E-389

LACK OF POWER, SLUGGISH OR

SPONGY SYMPTOM .............................. 6E-396

POOR FUEL ECONOMY SYMPTOM ....... 6E-402

EXCESSIVE WHITE SMOKE .................... 6E-407

EXCESSIVE BLACK SMOKE .................... 6E-413

ON-VEHICLE SERVICE PROCEDURE .... 6E-418

ENGINE CONTROL MODULE (ECM) ... 6E-418

CRANKSHAFT POSITION (CKP) SENSOR 6E-419

ENGINE COOLANT TEMPERATURE

(ECT) SENSOR ....................................... 6E-419

MASS AIR FLOW (MAF) & INTAKE AIR

TEMPERATURE (IAT) SENSOR ............ 6E-420

THROTTLE POSITION SENSOR (TPS) ... 6E-420

EGR EVRV

(Electrical Vacuum Regulating Valve) ..... 6E-421

Page 1384 of 4264

6E–12 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

324

1

(1) Throttle Position Sensor (TPS)

(2) Pump Control Unit (PSG)(3) Injection Pump Assembly

(4) Fuel Filter (Ex cept Euro 3)

213

(1) Mass Air Flow (MAF) & Intake Air Temperature

(IAT) Sensor Assembly

(2) EGR EVRV(3) Air Cleaner Case

Page 1436 of 4264

6E–64 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

GENERAL DESCRIPTION FOR ECM AND

SENSORS

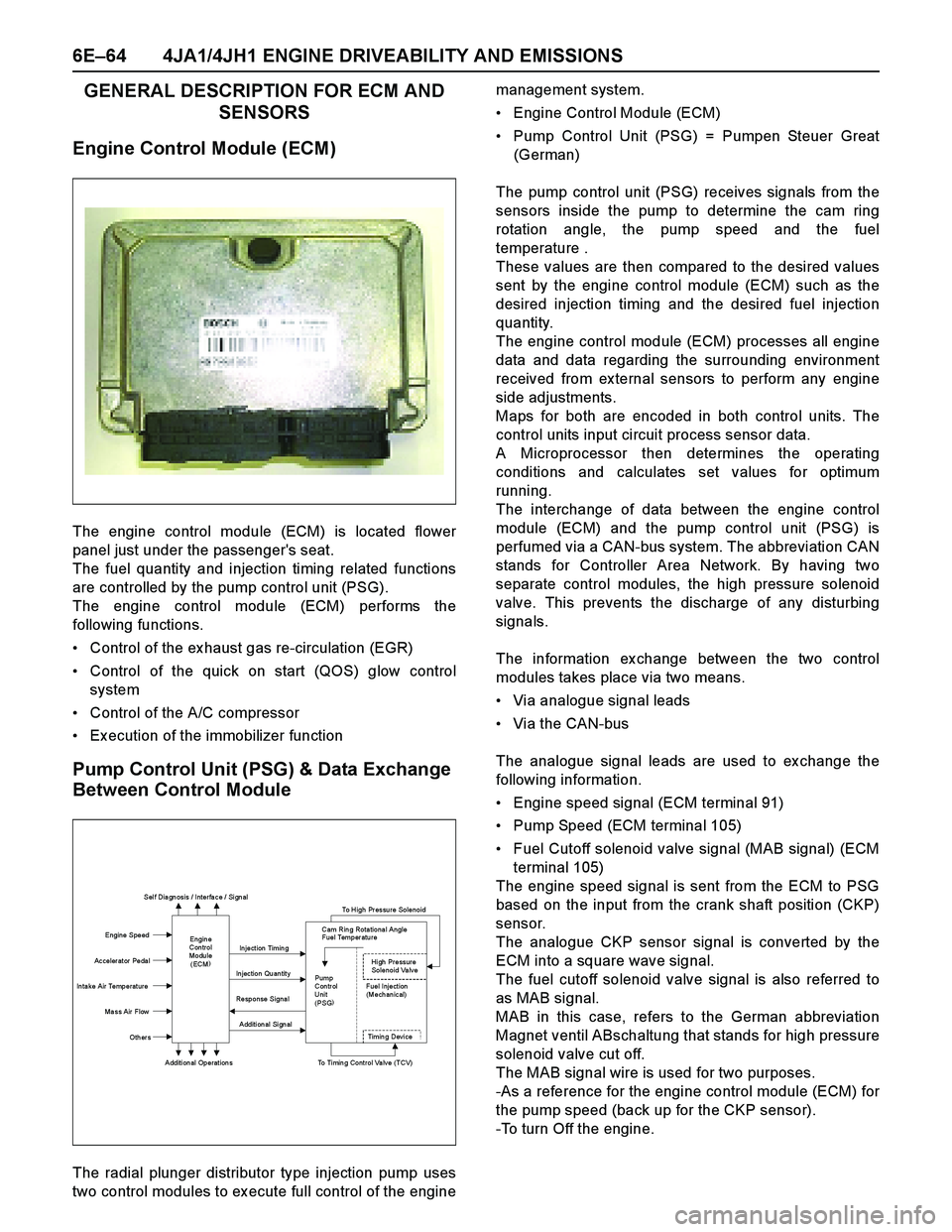

Engine Control Module (ECM)

The engine control module (ECM) is located flower

panel just under the passenger's seat.

The fuel quantity and injection timing related functions

are controlled by the pump control unit (PSG).

The engine control module (ECM) performs the

following functions.

Control of the ex haust gas re-circulation (EGR)

Control of the quick on start (QOS) glow control

system

Control of the A/C compressor

Ex ecution of the immobilizer function

Pump Control Unit (PSG) & Data Exchange

Between Control Module

The radial plunger distributor type injection pump uses

two control modules to ex ecute full control of the enginemanagement system.

Engine Control Module (ECM)

Pump Control Unit (PSG) = Pumpen Steuer Great

(German)

The pump control unit (PSG) receives signals from the

sensors inside the pump to determine the cam ring

rotation angle, the pump speed and the fuel

temperature .

These values are then compared to the desired values

sent by the engine control module (ECM) such as the

desired injection timing and the desired fuel injection

quantity.

The engine control module (ECM) processes all engine

data and data regarding the surrounding environment

received from ex ternal sensors to perform any engine

side adjustments.

Maps for both are encoded in both control units. The

control units input circuit process sensor data.

A Microprocessor then determines the operating

conditions and calculates set values for optimum

running.

The interchange of data between the engine control

module (ECM) and the pump control unit (PSG) is

perfumed via a CAN-bus system. The abbreviation CAN

stands for Controller Area Network. By having two

separate control modules, the high pressure solenoid

valve. This prevents the discharge of any disturbing

signals.

The information ex change between the two control

modules takes place via two means.

Via analogue signal leads

Via the CAN-bus

The analogue signal leads are used to ex change the

following information.

Engine speed signal (ECM terminal 91)

Pump Speed (ECM terminal 105)

Fuel Cutoff solenoid valve signal (MAB signal) (ECM

terminal 105)

The engine speed signal is sent from the ECM to PSG

based on the input from the crank shaft position (CKP)

sensor.

The analogue CKP sensor signal is converted by the

ECM into a square wave signal.

The fuel cutoff solenoid valve signal is also referred to

as MAB signal.

MAB in this case, refers to the German abbreviation

Magnet ventil ABschaltung that stands for high pressure

solenoid v alv e cut off.

The MAB signal wire is used for two purposes.

-As a reference for the engine control module (ECM) for

the pump speed (back up for the CKP sensor).

-To turn Off the engine.

Sel f Dia gn osis / Interfa ce / Si gn al

To High Pressure Solenoid

Engine Speed

Injection Timing

Accelerator Pedal

Injection Quantity

In ta ke Air Temperat ure

Response Signal

Ma ss Air Flow

Additional Signal

Others

Additional Operations To Timing Control Valve (TCV)

Engin e

Con trol

Modu le

(ECM) Cam Rin g Rota tiona l Angle

Fuel Temper atu re

High Pressure

Solenoid Valve

Pump

Con tr ol Fuel Inject ion

Unit (Mechanical)

(PSG)

Ti m i n

g Devi ce

Page 1437 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–65

The following signals are ex changed via the CAN-bus:

From ECM to PSG

Desired injection quantity

Desired injection timing

Engine speed

From PSG to ECM

Fuel temperature

Pump speed

Cylinder identifier

Control pulse (actual injection quantity + actual

injection timing)

PSG status

Mass Air Flow (MAF) Sensor & Intake Air

Temperature (IAT) Sensor

The mass air flow (MAF) sensor is part of the intake air

system.

It is fitted between the air cleaner and turbocharger and

measure the mass air flowing into the engine.

The mass air flow (MAF) sensor uses a hot film element

to determine the amount of air flowing into the engine.

The mass air flow (MAF) sensor assembly consist of a

mass air flow (MAF) sensor element and an intake air

temperature sensor that are both ex posed to the air flow

to be measured.

The mass air flow (MAF) sensor element measures the

partial air mass through a measurement duct on the

sensor housing.

Using calibration, there is an ex trapolation to the entire

mass air flow to the engine.The IAT sensor is a thermistor. A temperature changes

the resistance value. And it changes voltage. In other

words it measures a temperature value. Low air

temperature produces a high resistance.

The ECM supplies 5 volts signal to the IAT sensor

through resisters in the ECM and measures the voltage.

The signal voltage will be high when the air temperature

is cold, and it will be low when the air temperature is

hot.

(1) Air Cleaner Case

(2) Mass Air Flow (MAF) & Intake Air Temperature

(IAT) Sensor

1 2

Characteristic of IAT Sensor -Reference-

10 100 1000 10000 100000

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110

Intake Air Temp. (deg. C) (Tech2 Reading)

Resistance (ohm) (Solid Line)

Page 1438 of 4264

6E–66 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

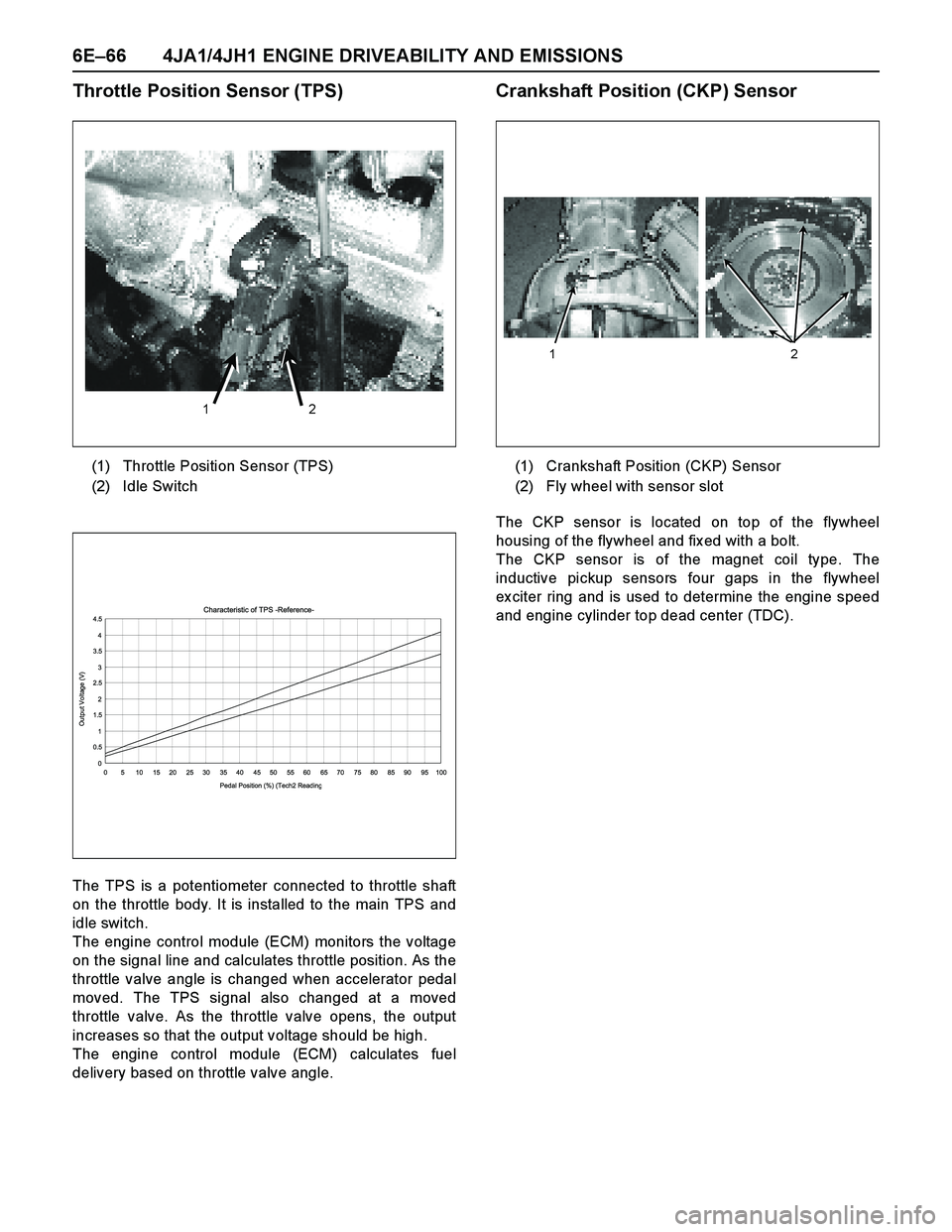

Throttle Position Sensor (TPS)

The TPS is a potentiometer connected to throttle shaft

on the throttle body. It is installed to the main TPS and

idle switch.

The engine control module (ECM) monitors the voltage

on the signal line and calculates throttle position. As the

throttle valve angle is changed when accelerator pedal

moved. The TPS signal also changed at a moved

throttle valve. As the throttle valve opens, the output

increases so that the output voltage should be high.

The engine control module (ECM) calculates fuel

delivery based on throttle valve angle.

Crankshaft Position (CKP) Sensor

The CKP sensor is located on top of the flywheel

housing of the flywheel and fix ed with a bolt.

The CKP sensor is of the magnet coil type. The

inductive pickup sensors four gaps in the flywheel

ex citer ring and is used to determine the engine speed

and engine cylinder top dead center (TDC). (1) Throttle Position Sensor (TPS)

(2) Idle Switch

1 2

Characteristic of TPS -Reference-

0 0.51 1.52 2.53 3.54 4.5

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Pedal Position (%) (Tech2 Readin

g

Output Voltage (V)

(1) Crankshaft Position (CKP) Sensor

(2) Fly wheel with sensor slot

1 2

Page 1442 of 4264

6E–70 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

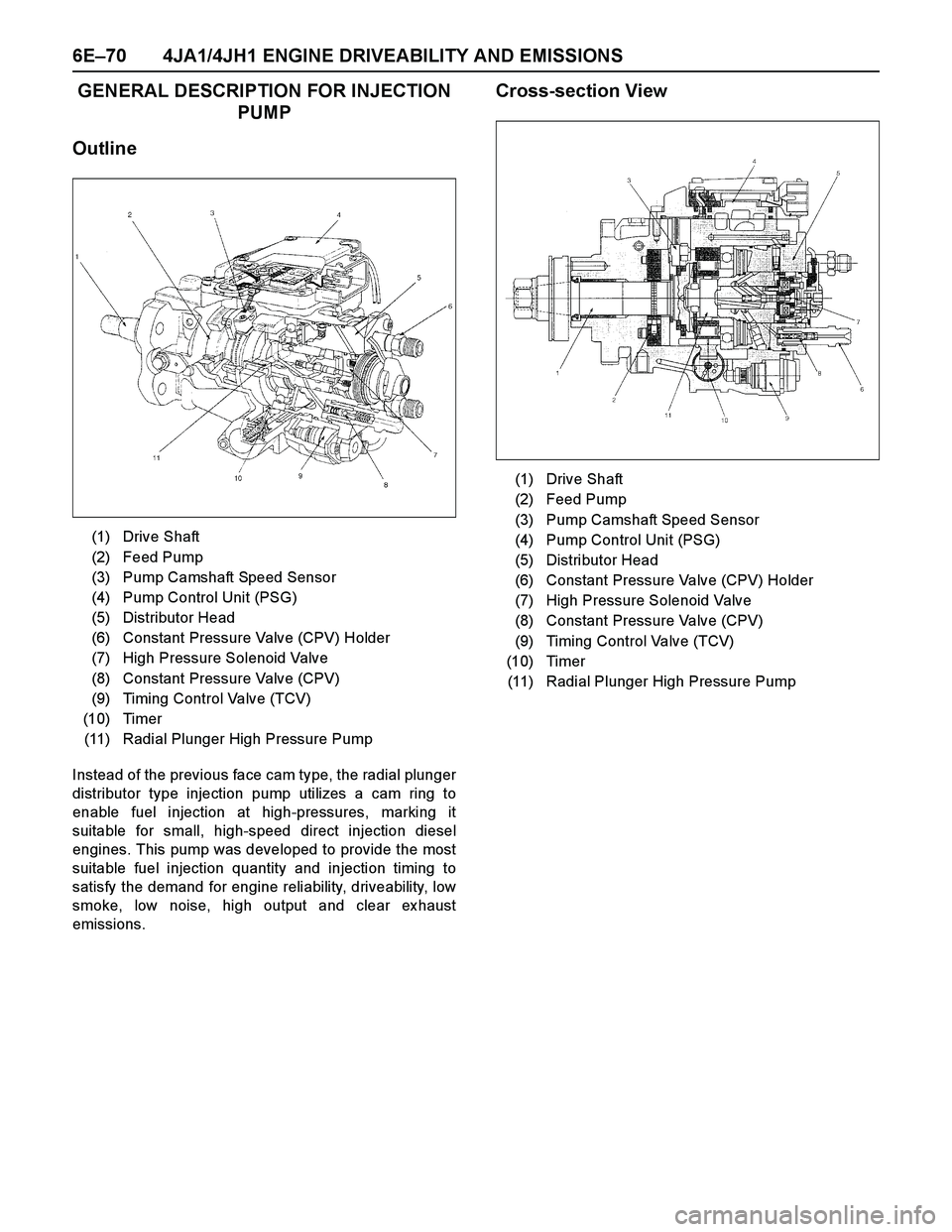

GENERAL DESCRIPTION FOR INJECTION

PUMP

Outline

Instead of the previous face cam type, the radial plunger

distributor type injection pump utilizes a cam ring to

enable fuel injection at high-pressures, marking it

suitable for small, high-speed direct injection diesel

engines. This pump was developed to provide the most

suitable fuel injection quantity and injection timing to

satisfy the demand for engine reliability, driveability, low

smoke, low noise, high output and clear ex haust

emissions.

Cross-section View

(1) Drive Shaft

(2) Feed Pump

(3) Pump Camshaft Speed Sensor

(4) Pump Control Unit (PSG)

(5) Distributor Head

(6) Constant Pressure Valve (CPV) Holder

(7) High Pressure Solenoid Valve

(8) Constant Pressure Valve (CPV)

(9) Timing Control Valve (TCV)

(10) Timer

(11) Radial Plunger High Pressure Pump

(1) Drive Shaft

(2) Feed Pump

(3) Pump Camshaft Speed Sensor

(4) Pump Control Unit (PSG)

(5) Distributor Head

(6) Constant Pressure Valve (CPV) Holder

(7) High Pressure Solenoid Valve

(8) Constant Pressure Valve (CPV)

(9) Timing Control Valve (TCV)

(10) Timer

(11) Radial Plunger High Pressure Pump

Page 1443 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–71

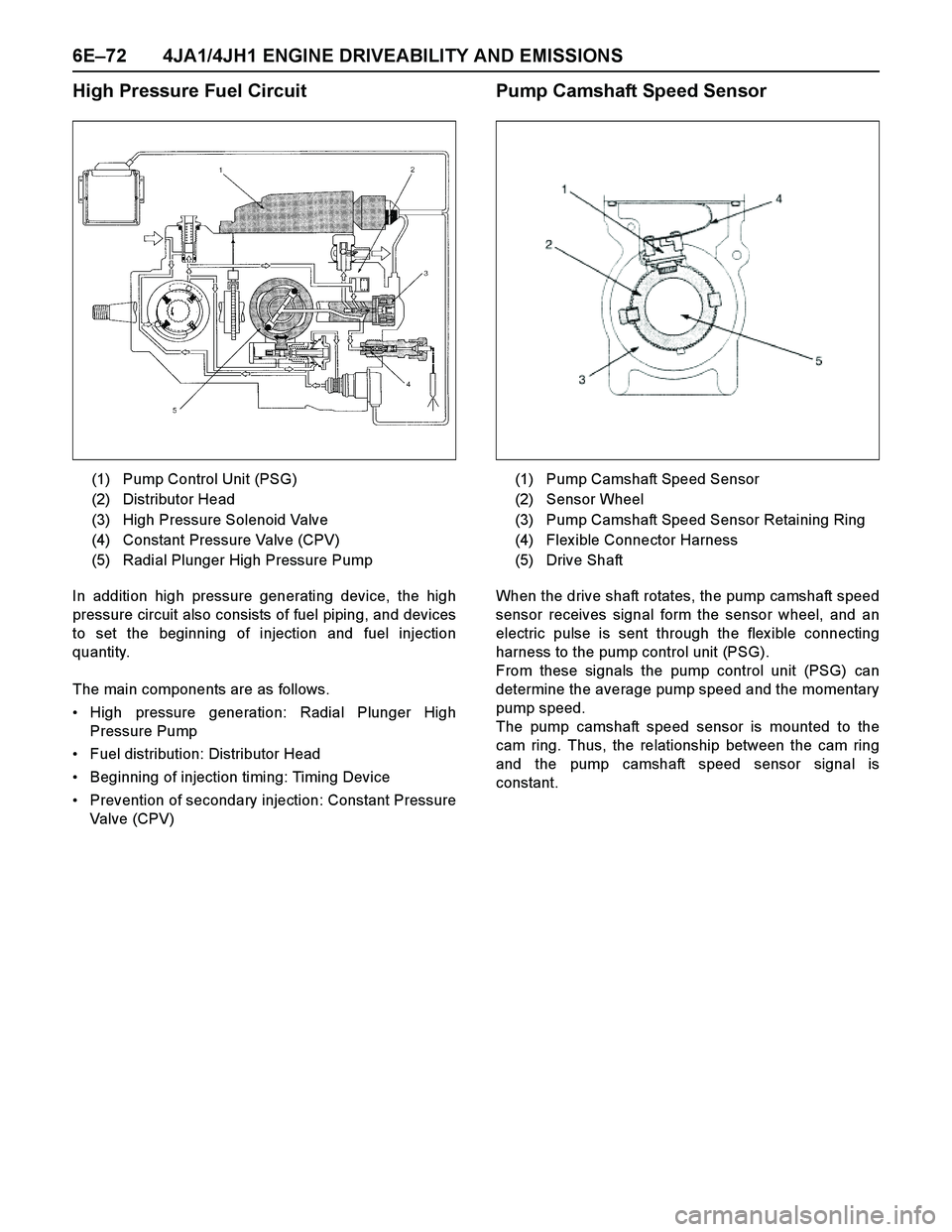

Low Pressure Fuel Circuit

The low pressure fuel circuit must supply sufficient fuel

to the high pressure fuel circuit. The main components

are the feed pump, the regulating valve and the

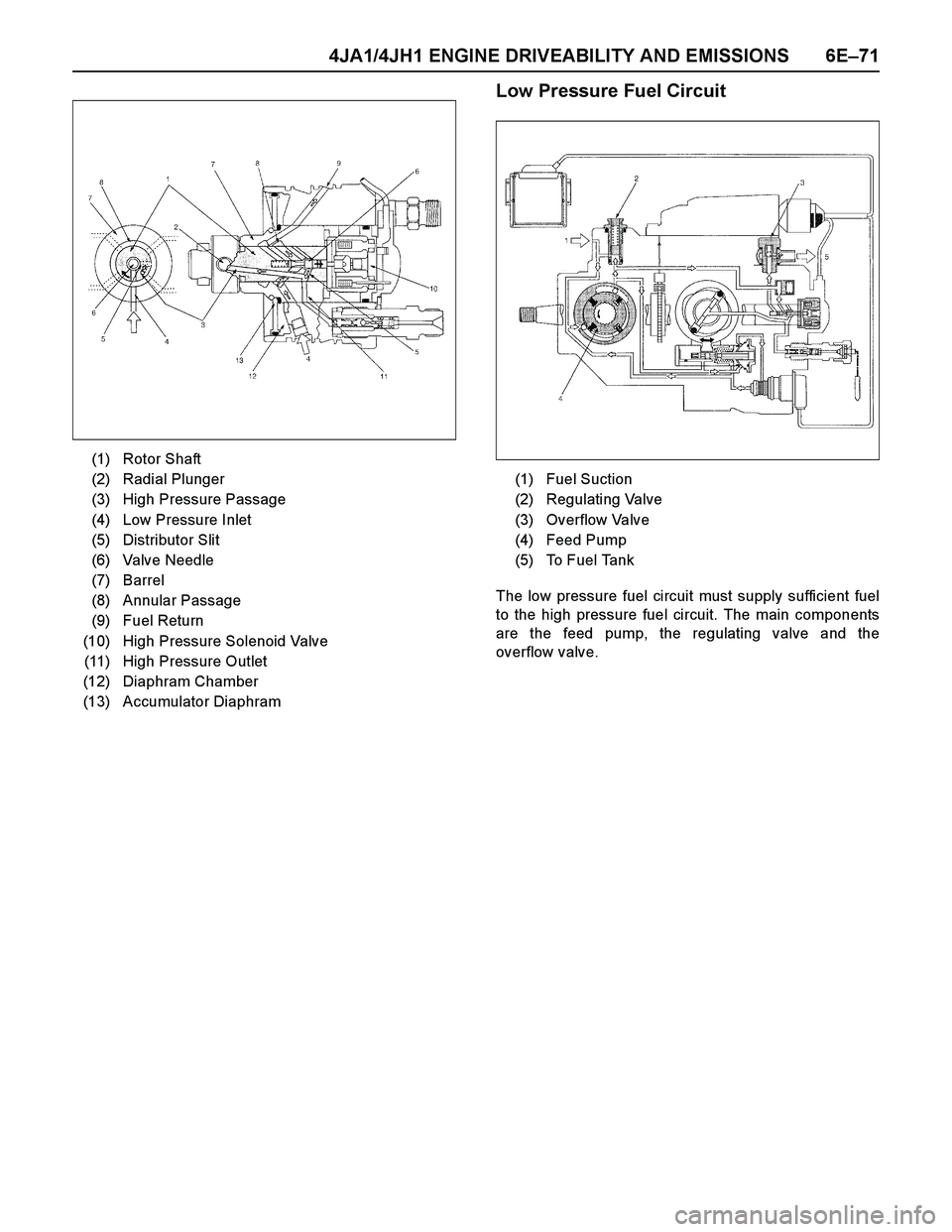

overflow valve. (1) Rotor Shaft

(2) Radial Plunger

(3) High Pressure Passage

(4) Low Pressure Inlet

(5) Distributor Slit

(6) Valve Needle

(7) Barrel

(8) Annular Passage

(9) Fuel Return

(10) High Pressure Solenoid Valve

(11) High Pressure Outlet

(12) Diaphram Chamber

(13) Accumulator Diaphram

(1) Fuel Suction

(2) Regulating Valve

(3) Overflow Valve

(4) Feed Pump

(5) To Fuel Tank

Page 1444 of 4264

6E–72 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

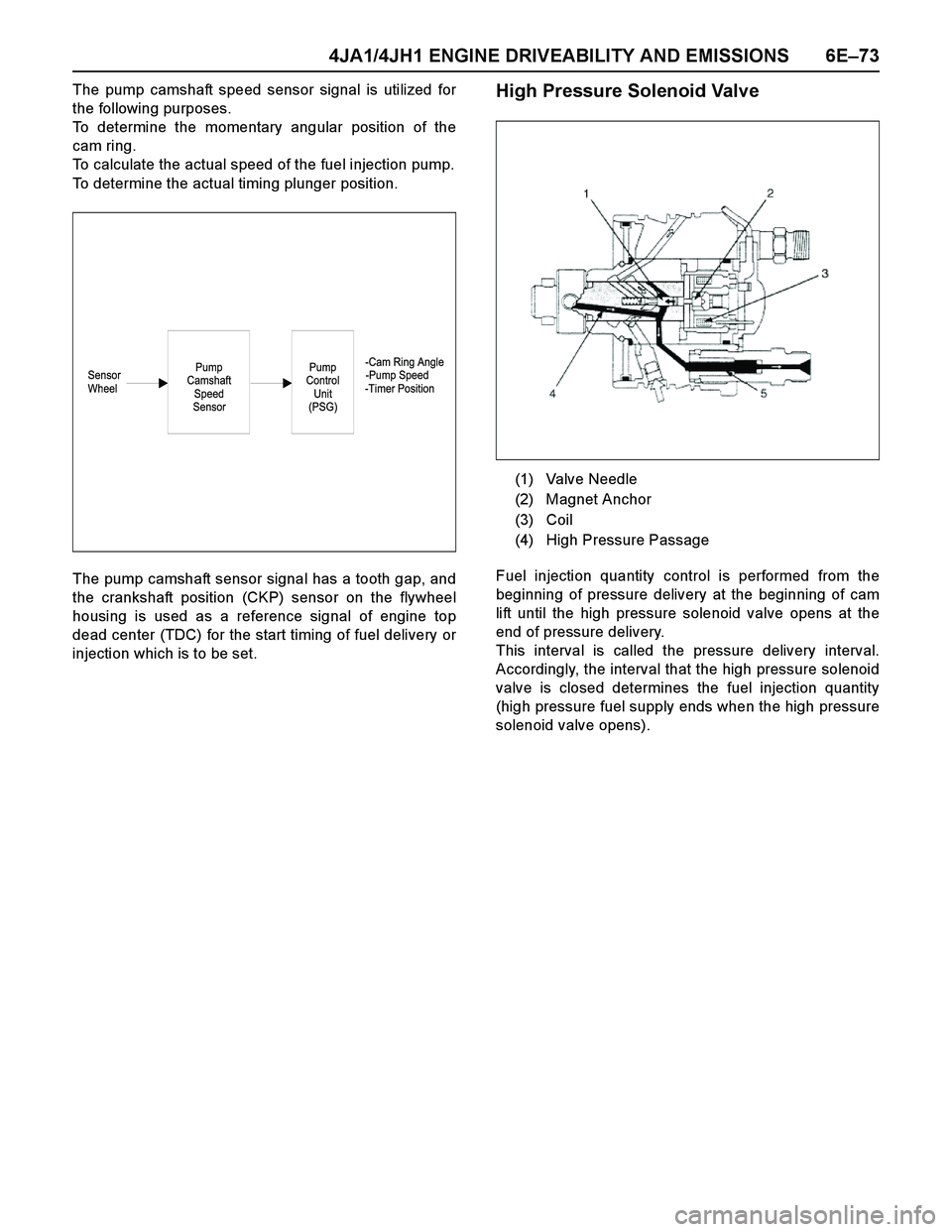

High Pressure Fuel Circuit

In addition high pressure generating device, the high

pressure circuit also consists of fuel piping, and devices

to set the beginning of injection and fuel injection

quantity.

The main components are as follows.

High pressure generation: Radial Plunger High

Pressure Pump

Fuel distribution: Distributor Head

Beginning of injection timing: Timing Device

Prevention of secondary injection: Constant Pressure

Valve (CPV)

Pump Camshaft Speed Sensor

When the drive shaft rotates, the pump camshaft speed

sensor receives signal form the sensor wheel, and an

electric pulse is sent through the flex ible connecting

harness to the pump control unit (PSG).

From these signals the pump control unit (PSG) can

determine the average pump speed and the momentary

pump speed.

The pump camshaft speed sensor is mounted to the

cam ring. Thus, the relationship between the cam ring

and the pump camshaft speed sensor signal is

constant. (1) Pump Control Unit (PSG)

(2) Distributor Head

(3) High Pressure Solenoid Valve

(4) Constant Pressure Valve (CPV)

(5) Radial Plunger High Pressure Pump

(1) Pump Camshaft Speed Sensor

(2) Sensor Wheel

(3) Pump Camshaft Speed Sensor Retaining Ring

(4) Flex ible Connector Harness

(5) Drive Shaft

Page 1445 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–73

The pump camshaft speed sensor signal is utilized for

the following purposes.

To determine the momentary angular position of the

cam ring.

To calculate the actual speed of the fuel injection pump.

To determine the actual timing plunger position.

The pump camshaft sensor signal has a tooth gap, and

the crankshaft position (CKP) sensor on the flywheel

housing is used as a reference signal of engine top

dead center (TDC) for the start timing of fuel delivery or

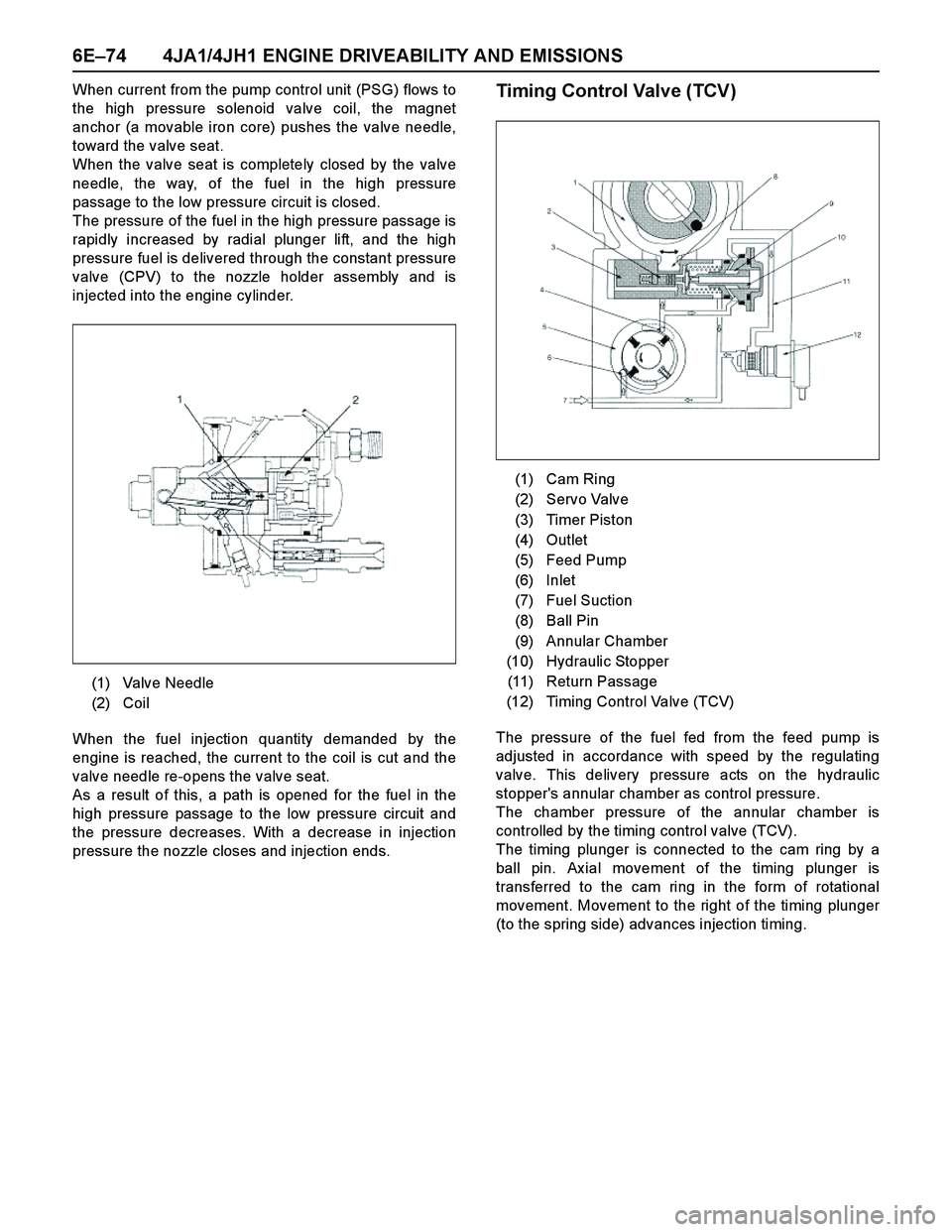

injection which is to be set.High Pressure Solenoid Valve

Fuel injection quantity control is performed from the

beginning of pressure delivery at the beginning of cam

lift until the high pressure solenoid valve opens at the

end of pressure delivery.

This interval is called the pressure delivery interval.

Accordingly, the interval that the high pressure solenoid

valve is closed determines the fuel injection quantity

(high pressure fuel supply ends when the high pressure

solenoid valve opens).

-Cam Ring Angle

Sensor -Pump Speed

Wheel -Timer PositionPump

Control

Unit

(PSG)Pump

Camshaft

Speed

Sensor

(1) Valve Needle

(2) Magnet Anchor

(3) Coil

(4) High Pressure Passage

Page 1446 of 4264

6E–74 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

When current from the pump control unit (PSG) flows to

the high pressure solenoid valve coil, the magnet

anchor (a movable iron core) pushes the valve needle,

toward the valve seat.

When the valve seat is completely closed by the valve

needle, the way, of the fuel in the high pressure

passage to the low pressure circuit is closed.

The pressure of the fuel in the high pressure passage is

rapidly increased by radial plunger lift, and the high

pressure fuel is delivered through the constant pressure

valve (CPV) to the nozzle holder assembly and is

injected into the engine cylinder.

When the fuel injection quantity demanded by the

engine is reached, the current to the coil is cut and the

valve needle re-opens the valve seat.

As a result of this, a path is opened for the fuel in the

high pressure passage to the low pressure circuit and

the pressure decreases. With a decrease in injection

pressure the nozzle closes and injection ends.Timing Control Valve (TCV)

The pressure of the fuel fed from the feed pump is

adjusted in accordance with speed by the regulating

valve. This delivery pressure acts on the hydraulic

stopper's annular chamber as control pressure.

The chamber pressure of the annular chamber is

controlled by the timing control valve (TCV).

The timing plunger is connected to the cam ring by a

ball pin. Ax ial movement of the timing plunger is

transferred to the cam ring in the form of rotational

movement. Movement to the right of the timing plunger

(to the spring side) advances injection timing. (1) Valve Needle

(2) Coil

(1) Cam Ring

(2) Servo Valve

(3) Timer Piston

(4) Outlet

(5) Feed Pump

(6) Inlet

(7) Fuel Suction

(8) Ball Pin

(9) Annular Chamber

(10) Hydraulic Stopper

(11) Return Passage

(12) Timing Control Valve (TCV)