ISUZU TF SERIES 2004 Workshop Manual

Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 1211 of 4264

ENGINE MECHANICAL 6A – 71

Cylinder Liner Grade Selection

Subtract the average cylinder body bore from the average

cylinder liner outside diameter to obtain the fitting interference.

Fitting Interference mm (in)

Standard

-0.0010*-0.019 (-0.00004*-0.0007)

* A minus (-) value indicates that the cylinder body bore is

smaller than the liner outside diameter.

Cylinder Body Bore Measurement

1. Take measurements at measuring point (1) across

positions 1-1 and 2-2.

Measuring Point (1):

4JA1T(L), 4JA1TC : 13,48,83,118,153 mm

(0.51,1.89,3.27,4.65,6.02 in)

4JH1TC : 18,53,88,123,158 mm (0.71,2.09,3.46,4.84,6.22

in)

Cylinder Liner Grade Selection and Standard

Fitting Interference

Accurately measured fitting interference and proper cylinder

liner grade selection are extremely important.

If the cylinder liner fitting interference is too small, engine

cooling efficiency will be adversely affected.

If the cylinder liner fitting interference is too large, it will be

difficult to insert the cylinder liner into the cylinder body.

012RY00013

012RY00014

012R300001

Page 1212 of 4264

6A – 72 ENGINE MECHANICAL

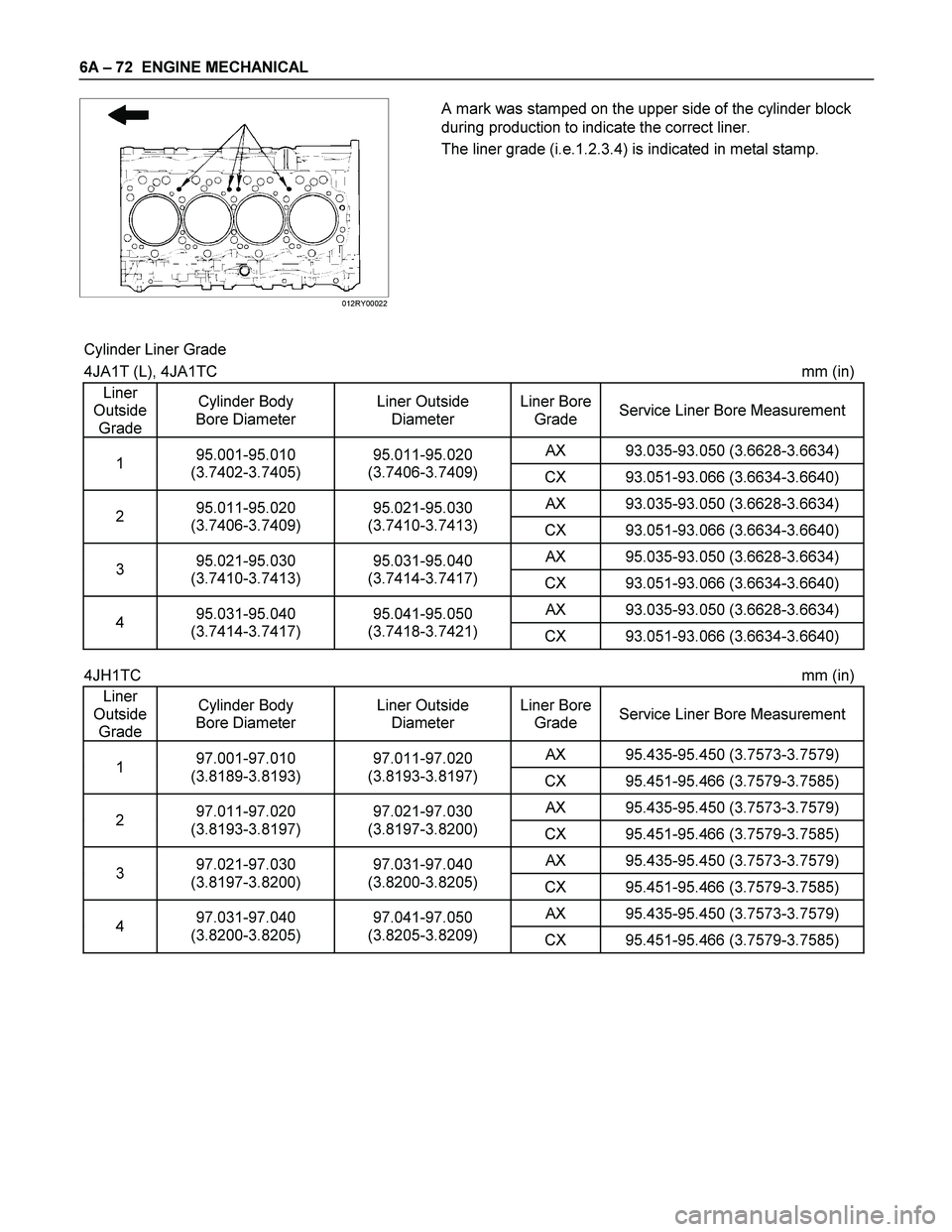

012RY00022

A mark was stamped on the upper side of the cylinder block

during production to indicate the correct liner.

The liner grade (i.e.1.2.3.4) is indicated in metal stamp.

Cylinder Liner Grade

4JA1T (L), 4JA1TC mm (in)

Liner

Outside

Grade Cylinder Body

Bore Diameter Liner Outside

Diameter Liner Bore

Grade Service Liner Bore Measurement

AX 93.035-93.050 (3.6628-3.6634) 1 95.001-95.010

(3.7402-3.7405) 95.011-95.020

(3.7406-3.7409)

CX 93.051-93.066 (3.6634-3.6640)

AX 93.035-93.050 (3.6628-3.6634) 2 95.011-95.020

(3.7406-3.7409) 95.021-95.030

(3.7410-3.7413)

CX 93.051-93.066 (3.6634-3.6640)

AX 95.035-93.050 (3.6628-3.6634) 3 95.021-95.030

(3.7410-3.7413) 95.031-95.040

(3.7414-3.7417)

CX 93.051-93.066 (3.6634-3.6640)

AX 93.035-93.050 (3.6628-3.6634) 4 95.031-95.040

(3.7414-3.7417) 95.041-95.050

(3.7418-3.7421)

CX 93.051-93.066 (3.6634-3.6640)

4JH1TC mm (in)

Liner

Outside

Grade Cylinder Body

Bore Diameter Liner Outside

Diameter Liner Bore

Grade Service Liner Bore Measurement

AX 95.435-95.450 (3.7573-3.7579) 1 97.001-97.010

(3.8189-3.8193) 97.011-97.020

(3.8193-3.8197)

CX 95.451-95.466 (3.7579-3.7585)

AX 95.435-95.450 (3.7573-3.7579) 2 97.011-97.020

(3.8193-3.8197) 97.021-97.030

(3.8197-3.8200)

CX 95.451-95.466 (3.7579-3.7585)

AX 95.435-95.450 (3.7573-3.7579) 3 97.021-97.030

(3.8197-3.8200) 97.031-97.040

(3.8200-3.8205)

CX 95.451-95.466 (3.7579-3.7585)

AX 95.435-95.450 (3.7573-3.7579) 4 97.031-97.040

(3.8200-3.8205) 97.041-97.050

(3.8205-3.8209)

CX 95.451-95.466 (3.7579-3.7585)

Page 1213 of 4264

ENGINE MECHANICAL 6A – 73

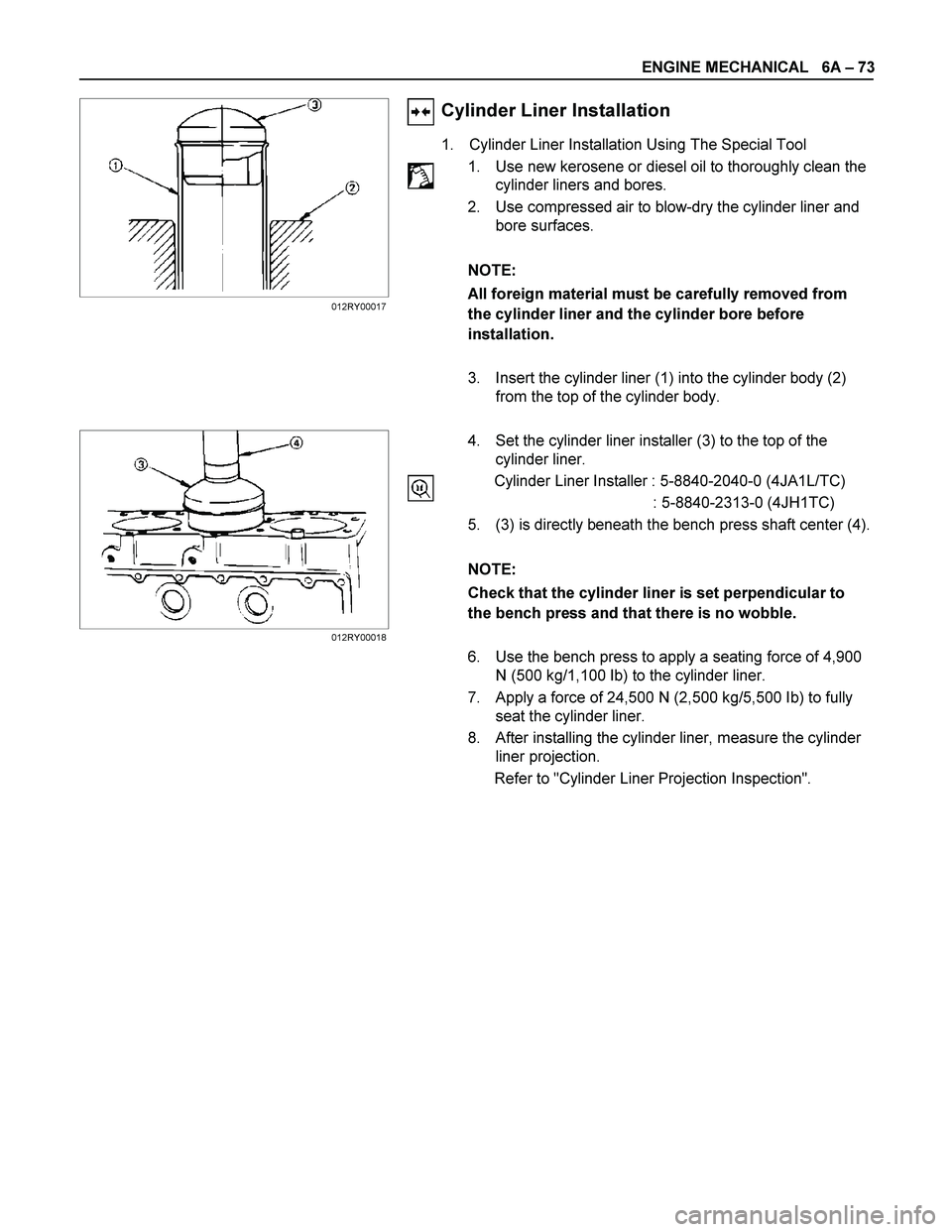

Cylinder Liner Installation

1. Cylinder Liner Installation Using The Special Tool

1. Use new kerosene or diesel oil to thoroughly clean the

cylinder liners and bores.

2. Use compressed air to blow-dry the cylinder liner and

bore surfaces.

NOTE:

All foreign material must be carefully removed from

the cylinder liner and the cylinder bore before

installation.

3. Insert the cylinder liner (1) into the cylinder body (2)

from the top of the cylinder body.

4. Set the cylinder liner installer (3) to the top of the

cylinder liner.

Cylinder Liner Installer : 5-8840-2040-0 (4JA1L/TC)

: 5-8840-2313-0 (4JH1TC)

5. (3) is directly beneath the bench press shaft center (4).

NOTE:

Check that the cylinder liner is set perpendicular to

the bench press and that there is no wobble.

6. Use the bench press to apply a seating force of 4,900

N (500 kg/1,100 Ib) to the cylinder liner.

7. Apply a force of 24,500 N (2,500 kg/5,500 Ib) to fully

seat the cylinder liner.

8. After installing the cylinder liner, measure the cylinder

liner projection.

Refer to "Cylinder Liner Projection Inspection".

012RY00017

012RY00018

Page 1214 of 4264

6A – 74 ENGINE MECHANICAL

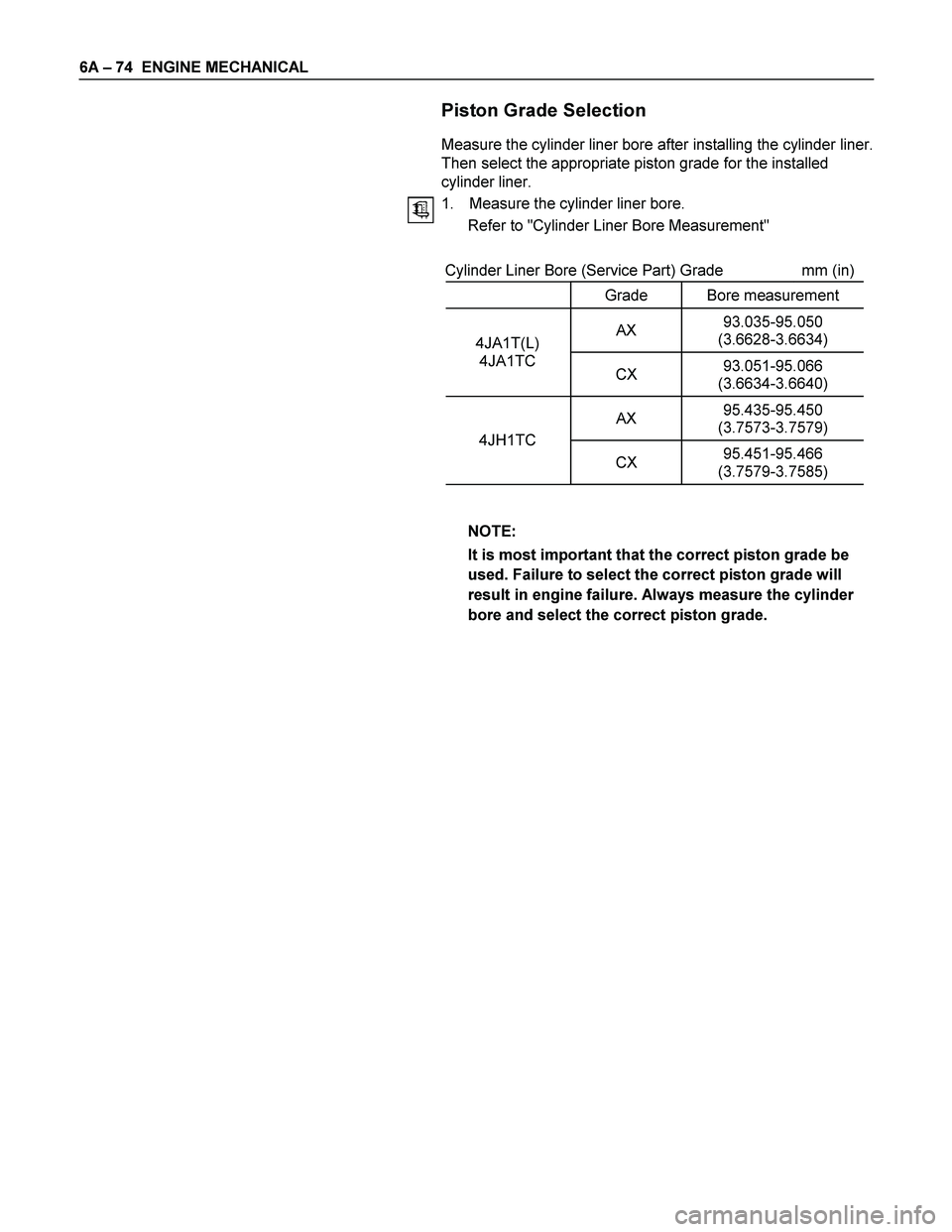

Piston Grade Selection

Measure the cylinder liner bore after installing the cylinder liner.

Then select the appropriate piston grade for the installed

cylinder liner.

1. Measure the cylinder liner bore.

Refer to "Cylinder Liner Bore Measurement"

Cylinder Liner Bore (Service Part) Grade mm (in)

Grade Bore measurement

AX 93.035-95.050

(3.6628-3.6634) 4JA1T(L)

4JA1TC

CX 93.051-95.066

(3.6634-3.6640)

AX 95.435-95.450

(3.7573-3.7579)

4JH1TC

CX 95.451-95.466

(3.7579-3.7585)

NOTE:

It is most important that the correct piston grade be

used. Failure to select the correct piston grade will

result in engine failure. Always measure the cylinder

bore and select the correct piston grade.

Page 1215 of 4264

ENGINE MECHANICAL 6A – 75

2. Measure the piston diameter.

Piston Measuring Point mm (in)

4JA1T(L)

4JA1TC 78 (3.07)

4JH1TC 70 (2.76)

Piston Grade (Service Part) mm (in)

AX 92.949 - 92.964

(3.6549 - 3.6600)

4JA1T(L)

4JA1TC

CX 92.965 - 92.980

(3.6600 - 3.6606)

AX 95.359 - 95.374

(3.7542 - 3.7548)

4JH1TC

CX 95.375 - 95.390

(3.7548 - 3.7555)

Cylinder Liner and Piston Clearance mm (in)

4JA1T(L)

4JA1TC 0.041-0.071 (0.0016-0.0027)

4JH1TC 0.047-0.065 (0.0019-0.0026)

NOTE:

Cylinder liner kit clearances are preset. However, the

cylinder liner installation procedure may result in

slight decreases in cylinder liner clearances. Always

measure the cylinder liner clearance after installation

to be sure that it is correct.

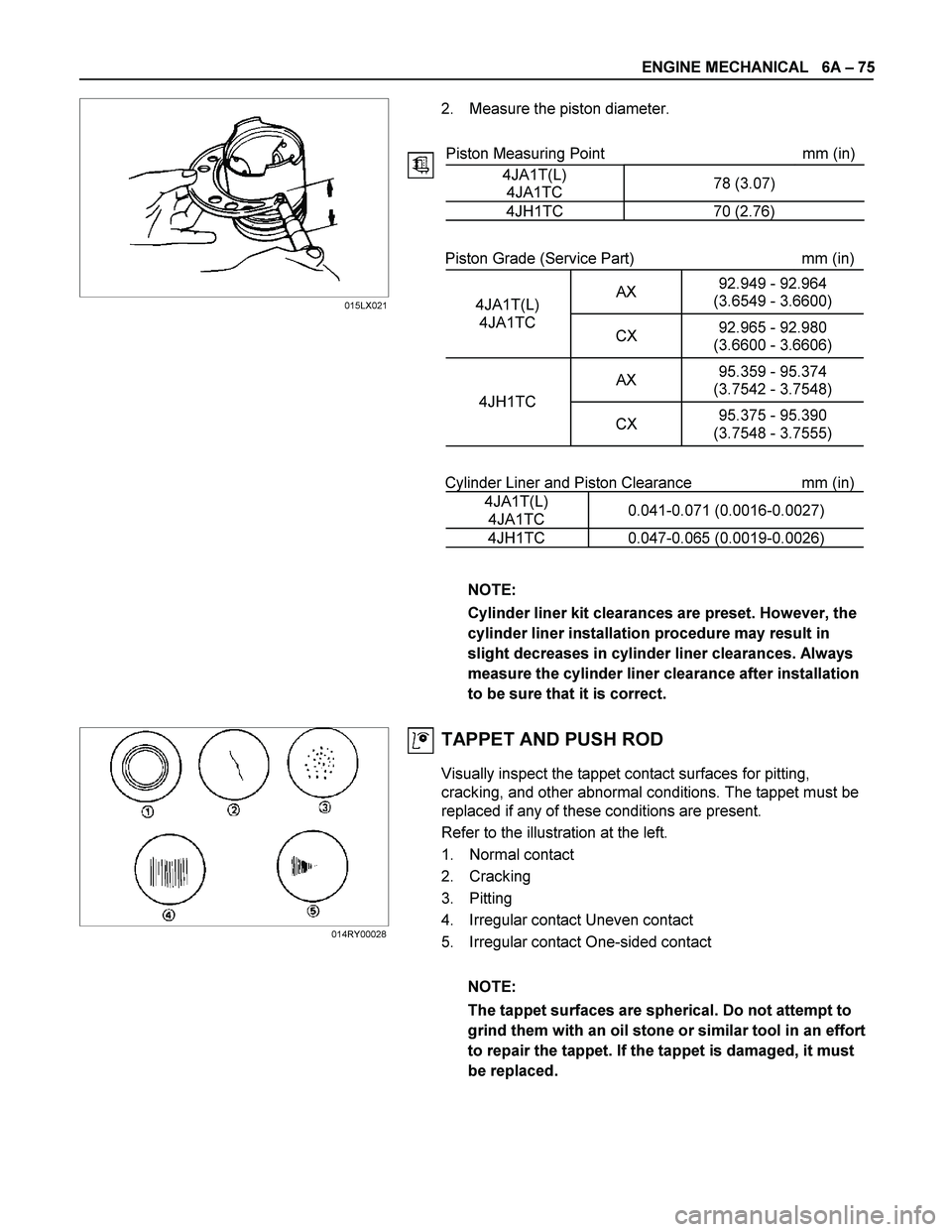

TAPPET AND PUSH ROD

Visually inspect the tappet contact surfaces for pitting,

cracking, and other abnormal conditions. The tappet must be

replaced if any of these conditions are present.

Refer to the illustration at the left.

1. Normal contact

2. Cracking

3. Pitting

4. Irregular contact Uneven contact

5. Irregular contact One-sided contact

NOTE:

The tappet surfaces are spherical. Do not attempt to

grind them with an oil stone or similar tool in an effort

to repair the tappet. If the tappet is damaged, it must

be replaced.

015LX021

014RY00028

Page 1216 of 4264

6A – 76 ENGINE MECHANICAL

Tappet Outside Diameter

Measure the tappet outside diameter with a micrometer.

If the measured value is less than the specified limit, the tappet

must be replaced.

Tappet Outside Diameter mm (in)

Standard Limit

12.97 - 12.99

(0.510 - 0.511) 12.95 (0.510)

Tappet and Cylinder Body Clearance mm (in)

Standard Limit

0.01 - 0.046

(0.0004 - 0.0018) 0.10 (0.004)

Push Rod Curvature

1. Lay the push rod on a surface plate.

2. Roll the push rod along the surface plate and measure the

push rod curvature with a thickness gauge.

If the measured value exceeds the specified limit, the push

rod must be replaced.

Pushrod Curvature mm (in)

Limit

0.3 (0.012)

3. Visually inspect both ends of the push rod for excessive

wear and damage. The push rod must be replaced if these

conditions are discovered during inspection.

014RY00029

012LX014

014RY00031

Page 1217 of 4264

ENGINE MECHANICAL 6A – 77

CAMSHAFT

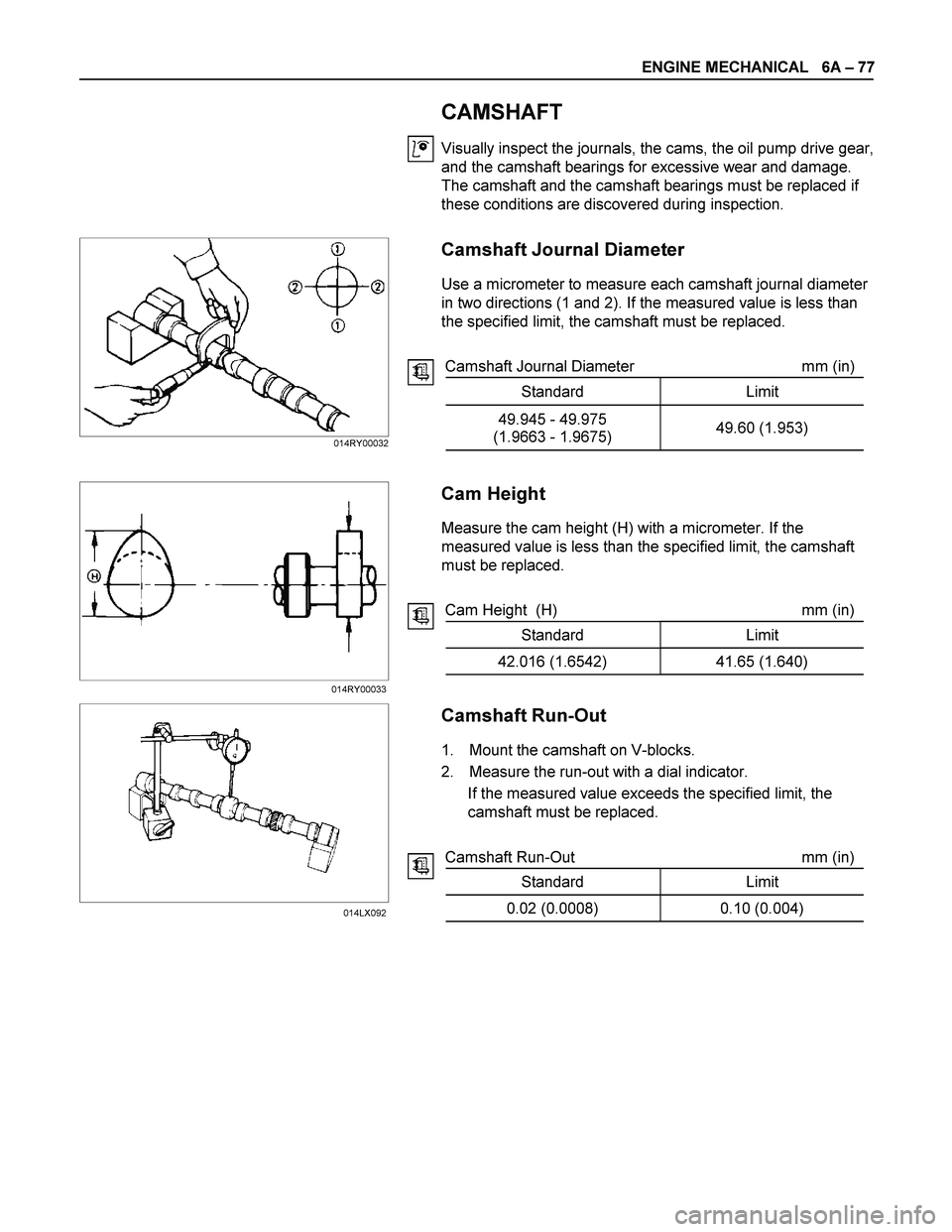

Visually inspect the journals, the cams, the oil pump drive gear,

and the camshaft bearings for excessive wear and damage.

The camshaft and the camshaft bearings must be replaced if

these conditions are discovered during inspection.

Camshaft Journal Diameter

Use a micrometer to measure each camshaft journal diameter

in two directions (1 and 2). If the measured value is less than

the specified limit, the camshaft must be replaced.

Camshaft Journal Diameter mm (in)

Standard Limit

49.945 - 49.975

(1.9663 - 1.9675) 49.60 (1.953)

Cam Height

Measure the cam height (H) with a micrometer. If the

measured value is less than the specified limit, the camshaft

must be replaced.

Cam Height (H) mm (in)

Standard Limit

42.016 (1.6542) 41.65 (1.640)

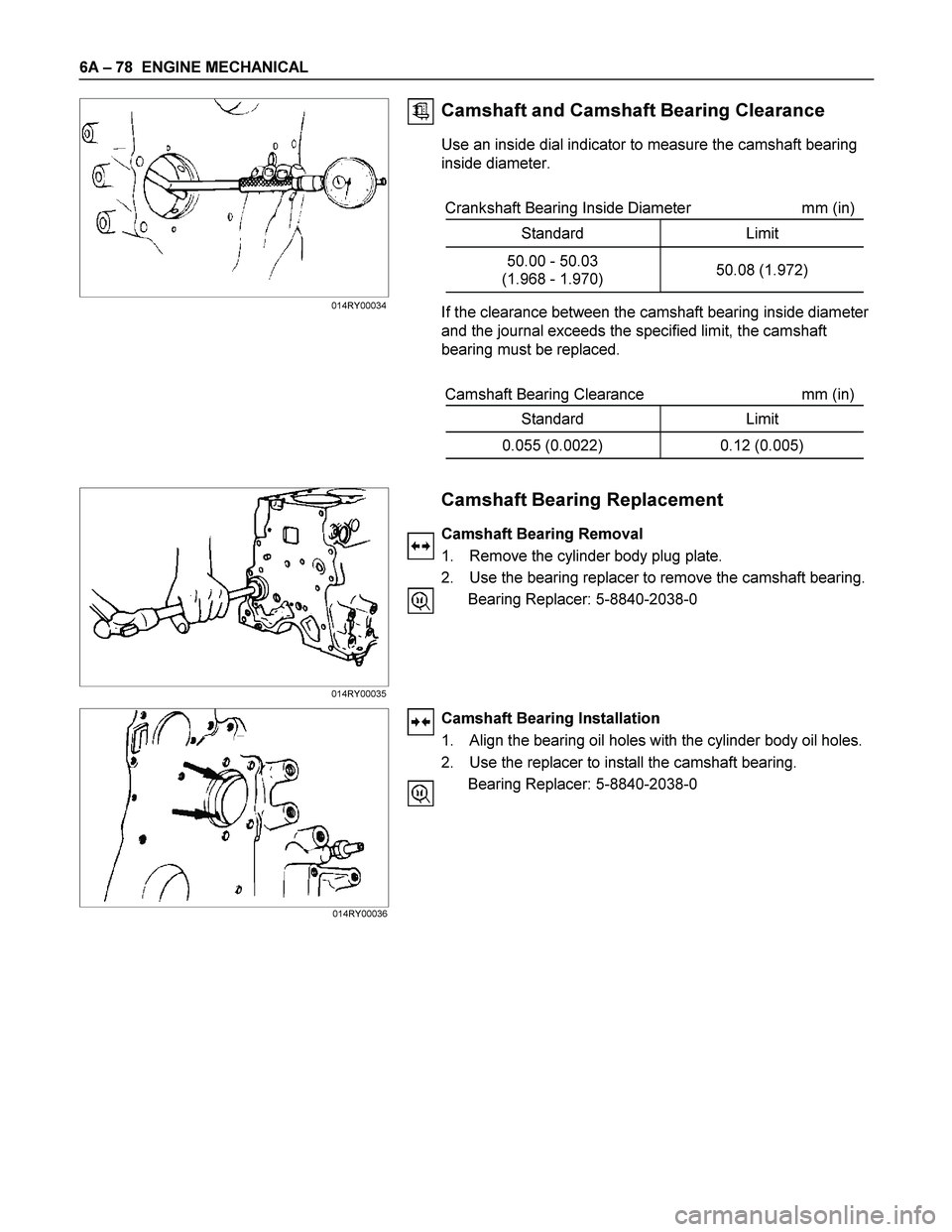

Camshaft Run-Out

1. Mount the camshaft on V-blocks.

2. Measure the run-out with a dial indicator.

If the measured value exceeds the specified limit, the

camshaft must be replaced.

Camshaft Run-Out mm (in)

Standard Limit

0.02 (0.0008) 0.10 (0.004)

014RY00032

014RY00033

014LX092

Page 1218 of 4264

6A – 78 ENGINE MECHANICAL

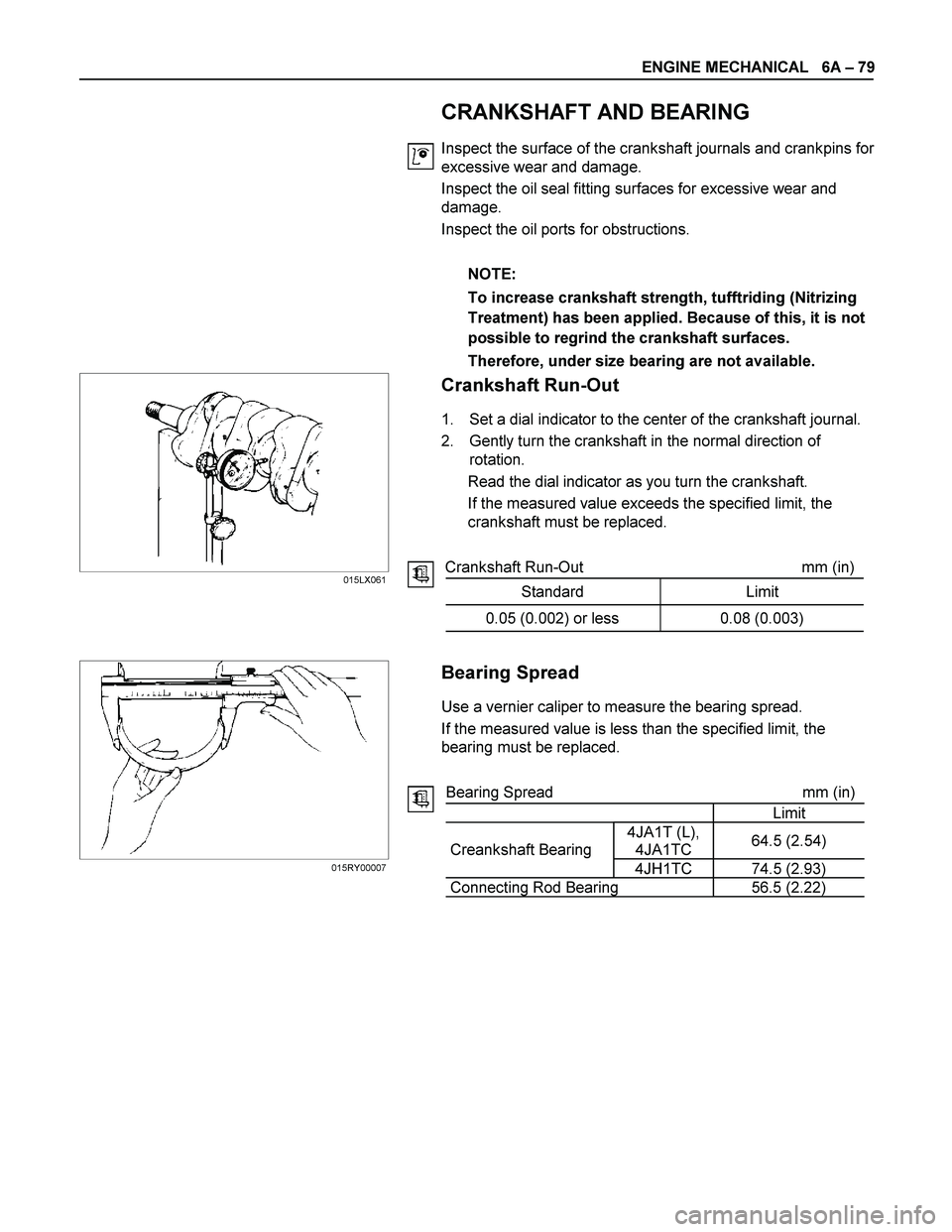

Camshaft and Camshaft Bearing Clearance

Use an inside dial indicator to measure the camshaft bearing

inside diameter.

Crankshaft Bearing Inside Diameter mm (in)

Standard Limit

50.00 - 50.03

(1.968 - 1.970) 50.08 (1.972)

If the clearance between the camshaft bearing inside diameter

and the journal exceeds the specified limit, the camshaft

bearing must be replaced.

Camshaft Bearing Clearance mm (in)

Standard Limit

0.055 (0.0022) 0.12 (0.005)

Camshaft Bearing Replacement

Camshaft Bearing Removal

1. Remove the cylinder body plug plate.

2. Use the bearing replacer to remove the camshaft bearing.

Bearing Replacer: 5-8840-2038-0

Camshaft Bearing Installation

1. Align the bearing oil holes with the cylinder body oil holes.

2. Use the replacer to install the camshaft bearing.

Bearing Replacer: 5-8840-2038-0

014RY00034

014RY00035

014RY00036

Page 1219 of 4264

ENGINE MECHANICAL 6A – 79

CRANKSHAFT AND BEARING

Inspect the surface of the crankshaft journals and crankpins for

excessive wear and damage.

Inspect the oil seal fitting surfaces for excessive wear and

damage.

Inspect the oil ports for obstructions.

NOTE:

To increase crankshaft strength, tufftriding (Nitrizing

Treatment) has been applied. Because of this, it is not

possible to regrind the crankshaft surfaces.

Therefore, under size bearing are not available.

Crankshaft Run-Out

1. Set a dial indicator to the center of the crankshaft journal.

2. Gently turn the crankshaft in the normal direction of

rotation.

Read the dial indicator as you turn the crankshaft.

If the measured value exceeds the specified limit, the

crankshaft must be replaced.

Crankshaft Run-Out mm (in)

Standard Limit

0.05 (0.002) or less 0.08 (0.003)

Bearing Spread

Use a vernier caliper to measure the bearing spread.

If the measured value is less than the specified limit, the

bearing must be replaced.

Bearing Spread mm (in)

Limit

4JA1T (L),

4JA1TC 64.5 (2.54)

Creankshaft Bearing

4JH1TC 74.5 (2.93)

Connecting Rod Bearing 56.5 (2.22)

015LX061

015RY00007

Page 1220 of 4264

6A – 80 ENGINE MECHANICAL

Crankshaft Journal and Crankpin Diameter

1. Use a micrometer to measure the crankshaft journal

diameter across points 1 - 1 and 2 - 2.

2. Use the micrometer to measure the crankshaft journal

diameter at the two points (3 and 4).

3. Repeat Steps 1 and 2 to measure the crankpin diameter.

If the measured values are less than the specified limit, the

crankshaft must be replaced.

Crankshaft Journal and Diameter mm (in)

Standard Limit

4JA1T (L),

4JA1TC 59.921-59.928

(2.3591-2.3594) 59.91 (2.3586)

4JH1TC 69.917-69.932

(2.7526-2.7532) 69.91(2.7524)

Crankpin Diameter mm (in)

Standard Limit

52.915 - 52.930

(2.0833 - 2.0839) 52.90 (2.083)

Crankshaft Journal and Crankpin Uneven Wear mm (in)

Standard Limit

0.05 (0.002) or less 0.08 (0.003)

Crankshaft Journal and Crankpin Diameter

If the clearance between the measured bearing inside diameter

and the crankshaft journal diameter exceeds the specified limit,

the bearing and/or the crankshaft must be replaced.

Crankshaft Journal and Bearing Clearance mm (in)

Standard Limit

0.032 - 0.077

(0.0013 - 0.0030) 0.110 (0.0043)

015RY00008

015RY00009