fuse ISUZU TF SERIES 2004 User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 85 of 4264

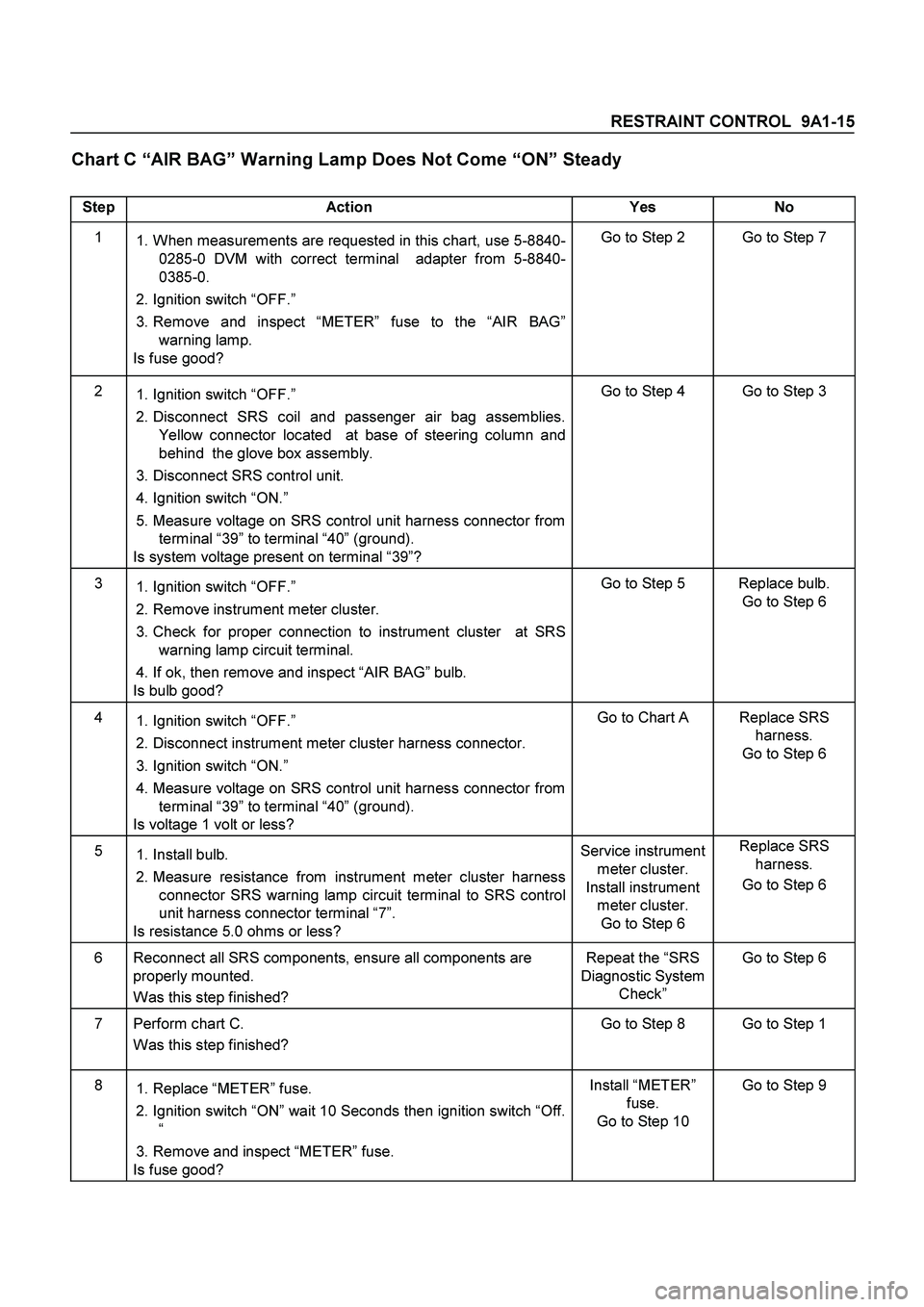

RESTRAINT CONTROL 9A1-15

Chart C “AIR BAG” Warning Lamp Does Not Come “ON” Steady

Step Action Yes No

1

1. When measurements are requested in this chart, use 5-8840-

0285-0 DVM with correct terminal adapter from 5-8840-

0385-0.

2. Ignition switch “OFF.”

3. Remove and inspect “METER” fuse to the “AIR BAG”

warning lamp.

Is fuse good? Go to Step 2 Go to Step 7

2

1. Ignition switch “OFF.”

2. Disconnect SRS coil and passenger air bag assemblies.

Yellow connector located at base of steering column and

behind the glove box assembly.

3. Disconnect SRS control unit.

4. Ignition switch “ON.”

5. Measure voltage on SRS control unit harness connector from

terminal “39” to terminal “40” (ground).

Is system voltage present on terminal “39”? Go to Step 4 Go to Step 3

3

1. Ignition switch “OFF.”

2. Remove instrument meter cluster.

3. Check for proper connection to instrument cluster at SRS

warning lamp circuit terminal.

4. If ok, then remove and inspect “AIR BAG” bulb.

Is bulb good? Go to Step 5 Replace bulb.

Go to Step 6

4

1. Ignition switch “OFF.”

2. Disconnect instrument meter cluster harness connector.

3. Ignition switch “ON.”

4. Measure voltage on SRS control unit harness connector from

terminal “39” to terminal “40” (ground).

Is voltage 1 volt or less? Go to Chart A Replace SRS

harness.

Go to Step 6

5

1. Install bulb.

2. Measure resistance from instrument meter cluster harness

connector SRS warning lamp circuit terminal to SRS control

unit harness connector terminal “7”.

Is resistance 5.0 ohms or less? Service instrument

meter cluster.

Install instrument

meter cluster.

Go to Step 6 Replace SRS

harness.

Go to Step 6

6 Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished? Repeat the “SRS

Diagnostic System

Check” Go to Step 6

7 Perform chart C.

Was this step finished? Go to Step 8 Go to Step 1

8

1. Replace “METER” fuse.

2. Ignition switch “ON” wait 10 Seconds then ignition switch “Off.

“

3. Remove and inspect “METER” fuse.

Is fuse good? Install “METER”

fuse.

Go to Step 10 Go to Step 9

Page 86 of 4264

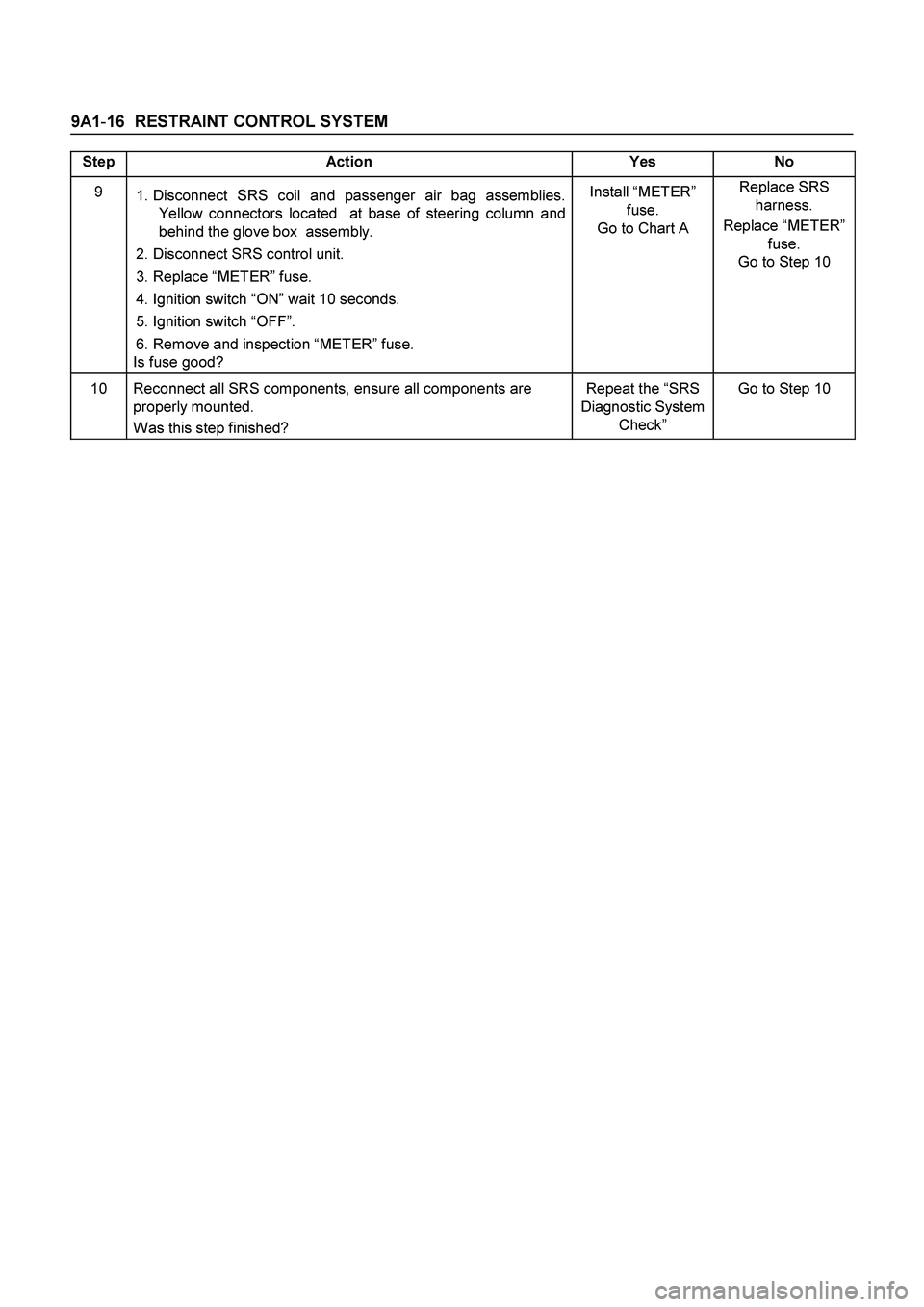

9A1-16 RESTRAINT CONTROL SYSTEM

Step Action Yes No

9

1. Disconnect SRS coil and passenger air bag assemblies.

Yellow connectors located at base of steering column and

behind the glove box assembly.

2. Disconnect SRS control unit.

3. Replace “METER” fuse.

4. Ignition switch “ON” wait 10 seconds.

5. Ignition switch “OFF”.

6. Remove and inspection “METER” fuse.

Is fuse good? Install “METER”

fuse.

Go to Chart A Replace SRS

harness.

Replace “METER”

fuse.

Go to Step 10

10 Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished? Repeat the “SRS

Diagnostic System

Check” Go to Step 10

Page 330 of 4264

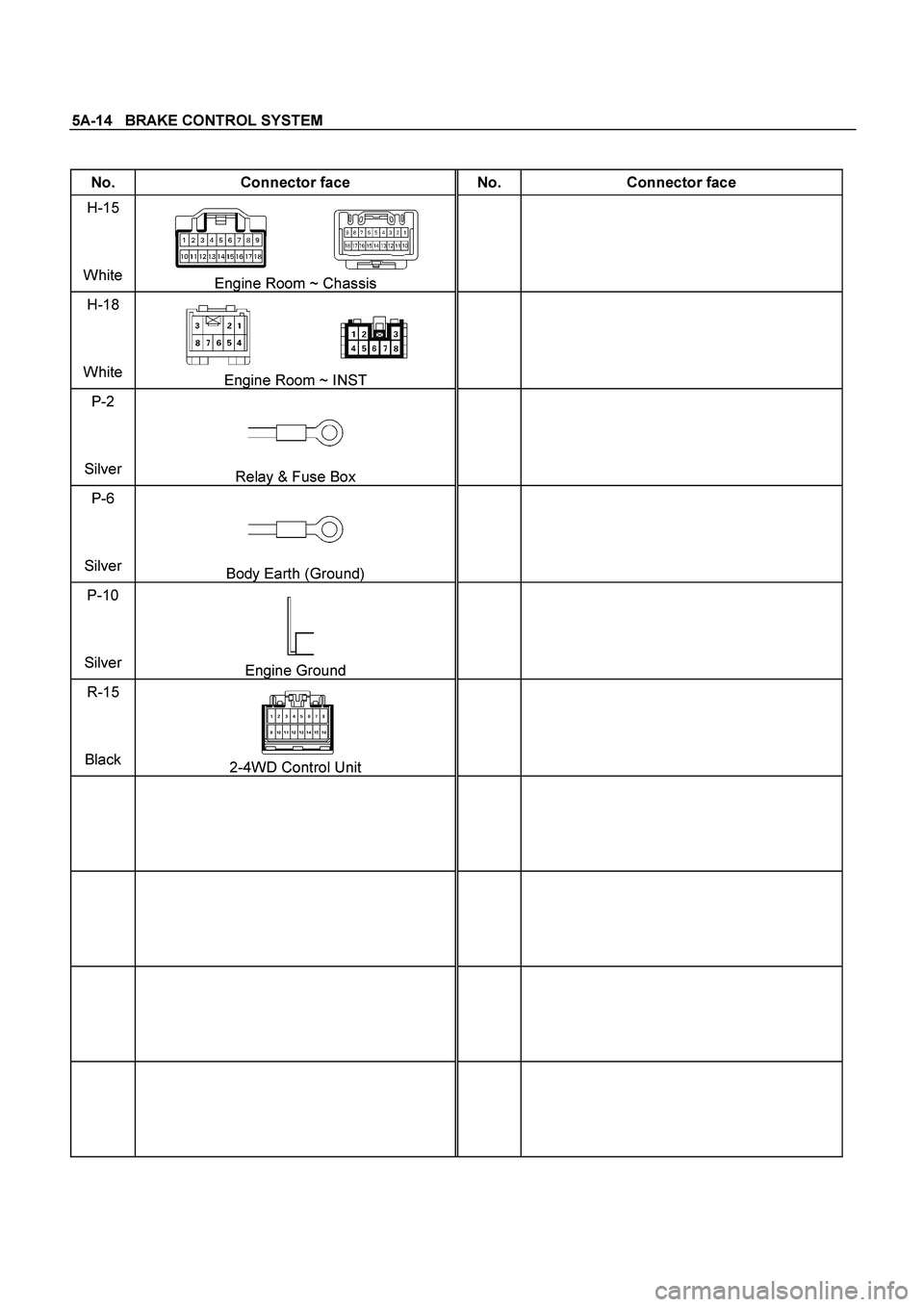

5A-14 BRAKE CONTROL SYSTEM

No. Connector face No. Connector face

H-15

White

Engine Room ~ Chassis

H-18

White

Engine Room ~ INST

P-2

Silver

Relay & Fuse Box

P-6

Silver

Body Earth (Ground)

P-10

Silver

Engine Ground

R-15

Black

2-4WD Control Unit

Page 337 of 4264

BRAKE CONTROL SYSTEM 5A-21

Computer System Service Precautions

The Anti-lock Brake System and Electronic Brake-force

Distribution interfaces directly with the Electronic

Hydraulic Control Unit (EHCU) which is a control

computer that is similar in some regards to the Engine

Control Module. These modules are designed to

withstand normal current draws associated with vehicle

operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for

opens or shorts, do not ground or apply voltage to any

of the circuits unless instructed to do so by the

appropriate diagnostic procedure. These circuits should

only be tested with a high impedance multimeter

5-8840-0366-0 or special tools as described in this

section. Power should never be removed or applied to

any control module with the ignition in the “ON”

position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure to

observe these precautions may result in Anti-lock Brake

System and Electronic Brake-force Distribution

damage.

If welding work is to be performed on the vehicle

using an electric arc welder, the EHCU and valve

block connectors should be disconnected before

the welding operation begins.

The EHCU and valve block connectors should

never be connected or disconnected with the

ignition “ON”.

Note:

If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS and Brake” warning lamp

will illuminate. But actually no trouble exists. When

the DTC is not detected and the ABS and BRAKE

warning lamp is on, “How to erase code” is

performed and a ABS and BRAKE warning lamp

are off.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS) and

Electronic Brake-force Distribution (EBD) System

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS and EBD

to a non-operative state by removing the fuse for the

ABS. After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning Lamp does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case

duplicating the system malfunction during a test drive or

a good description of vehicle behavior from the

customer may be helpful in locating a “most likely”

failed component or circuit. The symptom diagnosis

chart may also be useful in isolating the failure. Most

intermittent problems are caused by faulty electrical

connections or wiring. When an intermittent failure is

encountered, check suspect circuits for:

Suspected harness damage.

Poor mating of connector halves or terminals not

fully seated in the connector body (backed out).

Improperly formed or damaged terminals.

Test Driving ABS Complaint Vehicles

In case that there has been an abnormality in the

lighting pattern of “ABS” warning lamp, the fault can be

located in accordance with the “DIAGNOSIS BY “ABS”

WARNING LAMP ILLUMINATION PATTERN”. In case

of such trouble as can be detected by the driver as a

vehicle symptom, however, it is necessary to give a test

drive following the test procedure mentioned below,

thereby reproducing the symptom for trouble diagnosis

on a symptom basis:

1.

Start the engine and make sure that the “ABS” W/L

goes OFF. If the W/L remains ON, it means that

the Diagnostic Trouble Code (DTC) is stored.

Therefore, read the code and locate the fault.

Note: The DTC cannot be cleared if the vehicle speed

does not exceed about 6km/h (4mph) at DTC, even

though the repair operation is completed.

2. Start the vehicle and accelerate to about 30 km/h

(19 mph) or more.

3. Slowly brake and stop the vehicle completely.

4. Then restart the vehicle and accelerate to about 40

km/h (25 mph) or more.

5. Brake at a time so as to actuate the ABS and stop

the vehicle.

6. Be cautious of abnormality during the test. If the

W/L is actuated while driving, read the DTC and

locate the fault.

7. If the abnormality is not reproduced by the test,

make best efforts to reproduce the situation

reported by the customer.

8. If the abnormality has been detected, repair in

accordance with the “SYMPTOM DIAGNOSIS” .

Note:

Be sure to give a test drive on a wide, even road

with a small traffic.

If an abnormality is detected, be sure to suspend

the test and start trouble diagnosis at once.

Page 357 of 4264

BRAKE CONTROL SYSTEM 5A-41

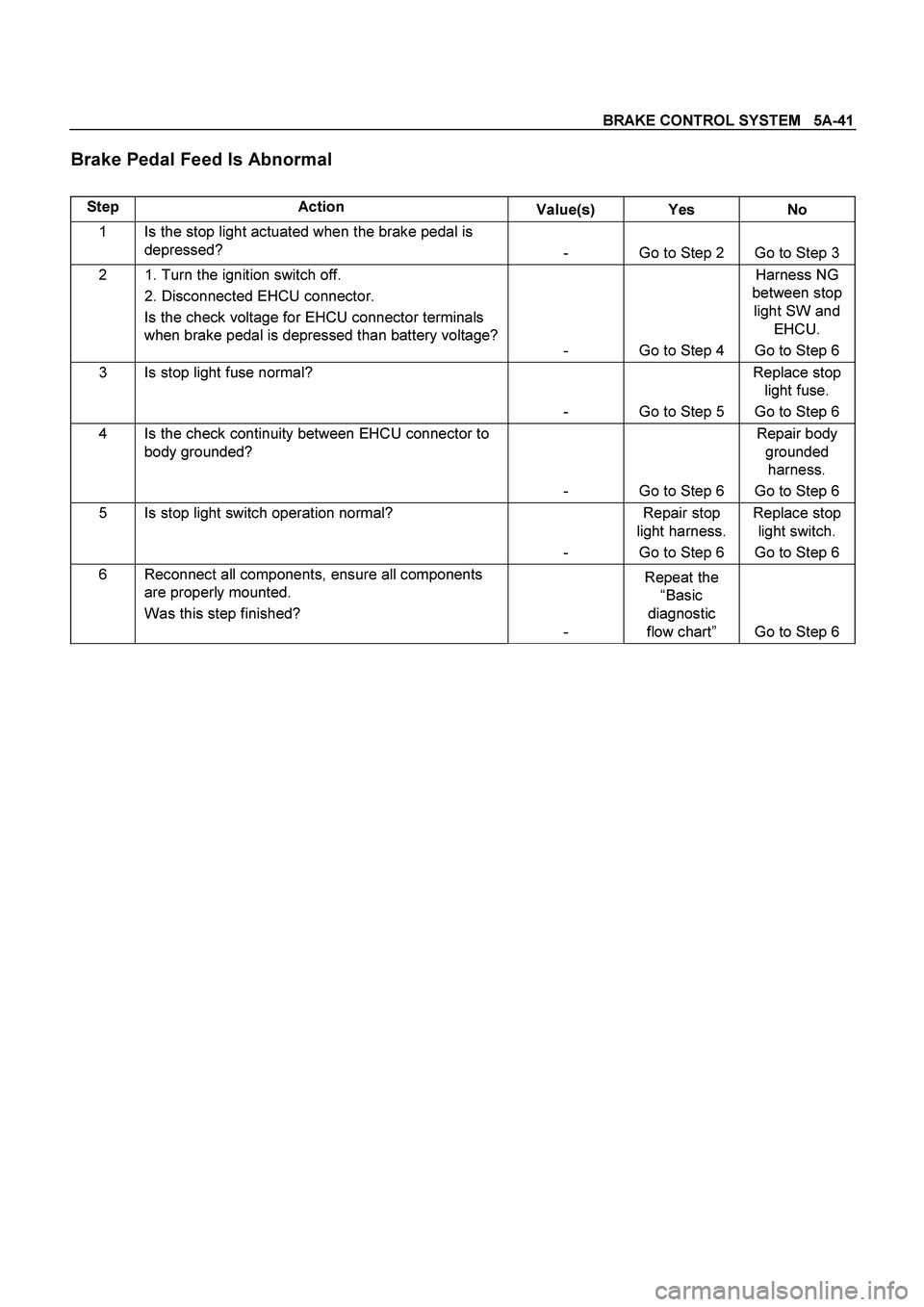

Brake Pedal Feed Is Abnormal

Step Action

Value(s) Yes No

1 Is the stop light actuated when the brake pedal is

depressed?

- Go to Step 2 Go to Step 3

2 1. Turn the ignition switch off.

2. Disconnected EHCU connector.

Is the check voltage for EHCU connector terminals

when brake pedal is depressed than battery voltage?

- Go to Step 4 Harness NG

between stop

light SW and

EHCU.

Go to Step 6

3 Is stop light fuse normal?

- Go to Step 5 Replace stop

light fuse.

Go to Step 6

4 Is the check continuity between EHCU connector to

body grounded?

- Go to Step 6 Repair body

grounded

harness.

Go to Step 6

5 Is stop light switch operation normal?

- Repair stop

light harness.

Go to Step 6 Replace stop

light switch.

Go to Step 6

6 Reconnect all components, ensure all components

are properly mounted.

Was this step finished?

- Repeat the

“Basic

diagnostic

flow chart” Go to Step 6

Page 359 of 4264

BRAKE CONTROL SYSTEM 5A-43

No ABS Warning Lamp

Step Action

Value(s) Yes No

1 Check the meter fuse for the instrument cluster

ignition feed circuit.

Is the fuse OK? - Go to Step 3 Go to Step 2

2 Replace the fuse.

Is the action complete? - Verify repair

Go to Step 3 -

3 1. Ignition “OFF,” disconnect the EHCU.

2. Ignition “ON,”engine “OFF.”

3. Observe the ABS warning lamp.

Is the ABS warning lamp “ON”?

- Go to Step 5 Go to Step 4

4 Repair or replace the meter circuit or meter.

Is the action complete? - Verify repair -

5 1. Check the EHCU circuit for an open, short to

ground, or short to voltage. Also, check the EHCU

ignition feed circuit for an open or short to ground

and the EHCU ground circuit for an open.

2. If a problem is found, repair as necessary.

Was a problem found?

- Verify repair Go to Step 6

6 1. Ignition “OFF,” reconnect the EHCU.

2. Ignition “ON,”engine “OFF.”

3. Observe the ABS warning lamp.

Is the ABS warning lamp “ON”?

- Verify repair Go to Step 7

7 Replace EHCU.

Note : Check the EHCU type for specification, the

EHCU is replaced.

(Specification; 2WD or 4WD Model)

Is the action complete? - Verify repair -

Page 659 of 4264

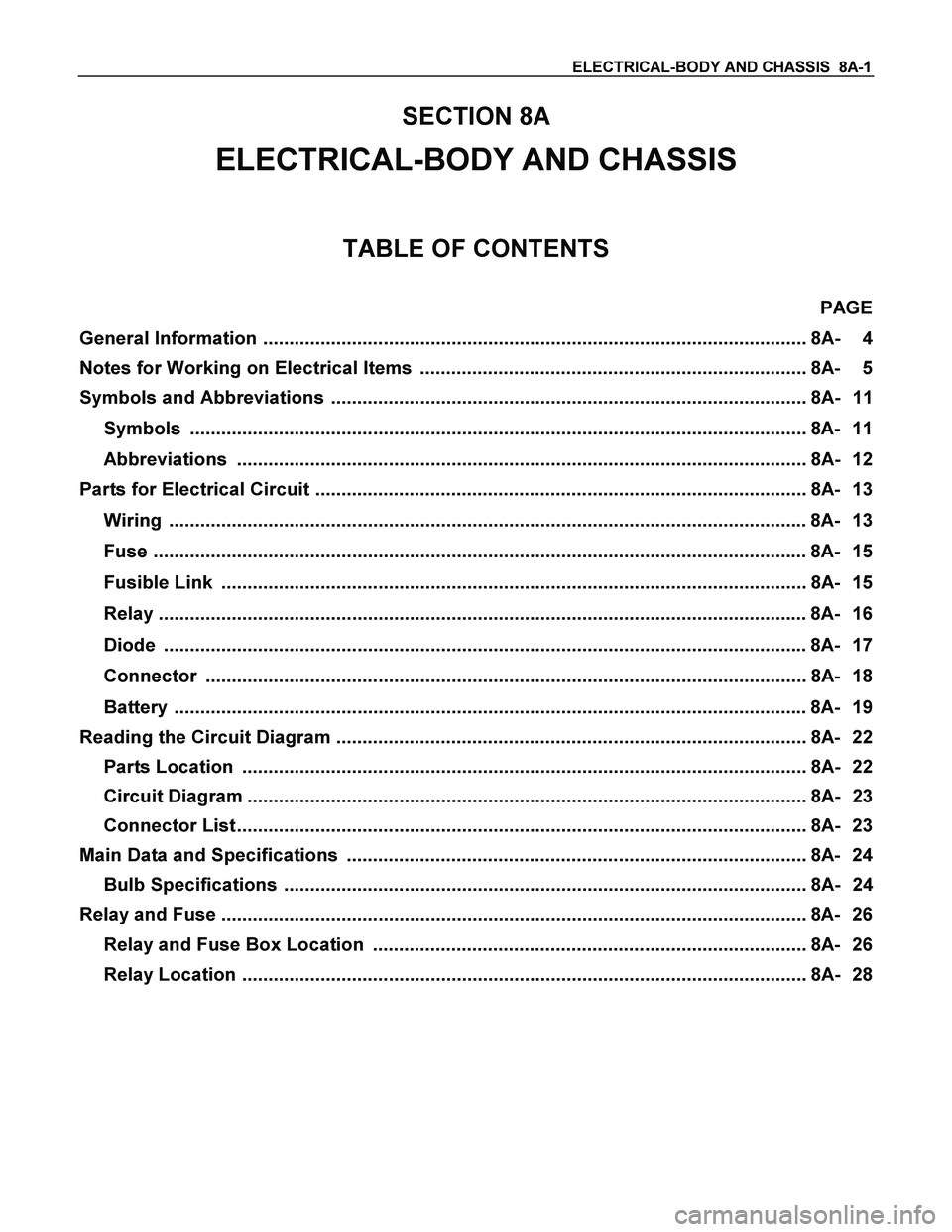

ELECTRICAL-BODY AND CHASSIS 8A-1

SECTION 8A

ELECTRICAL-BODY AND CHASSIS

TABLE OF CONTENTS

PAGE

General Information ........................................................................................................ 8A- 4

Notes for Working on Electrical Items .......................................................................... 8A- 5

Symbols and Abbreviations ........................................................................................... 8A- 11

Symbols ...................................................................................................................... 8A- 11

Abbreviations ............................................................................................................. 8A- 12

Parts for Electrical Circuit .............................................................................................. 8A- 13

Wiring .......................................................................................................................... 8A- 13

Fuse ............................................................................................................................. 8A- 15

Fusible Link ................................................................................................................ 8A- 15

Relay ............................................................................................................................ 8A- 16

Diode ........................................................................................................................... 8A- 17

Connector ................................................................................................................... 8A- 18

Battery ......................................................................................................................... 8A- 19

Reading the Circuit Diagram .......................................................................................... 8A- 22

Parts Location ............................................................................................................ 8A- 22

Circuit Diagram ........................................................................................................... 8A- 23

Connector List ............................................................................................................. 8A- 23

Main Data and Specifications ........................................................................................ 8A- 24

Bulb Specifications .................................................................................................... 8A- 24

Relay and Fuse ................................................................................................................ 8A- 26

Relay and Fuse Box Location ................................................................................... 8A- 26

Relay Location ............................................................................................................ 8A- 28

Page 660 of 4264

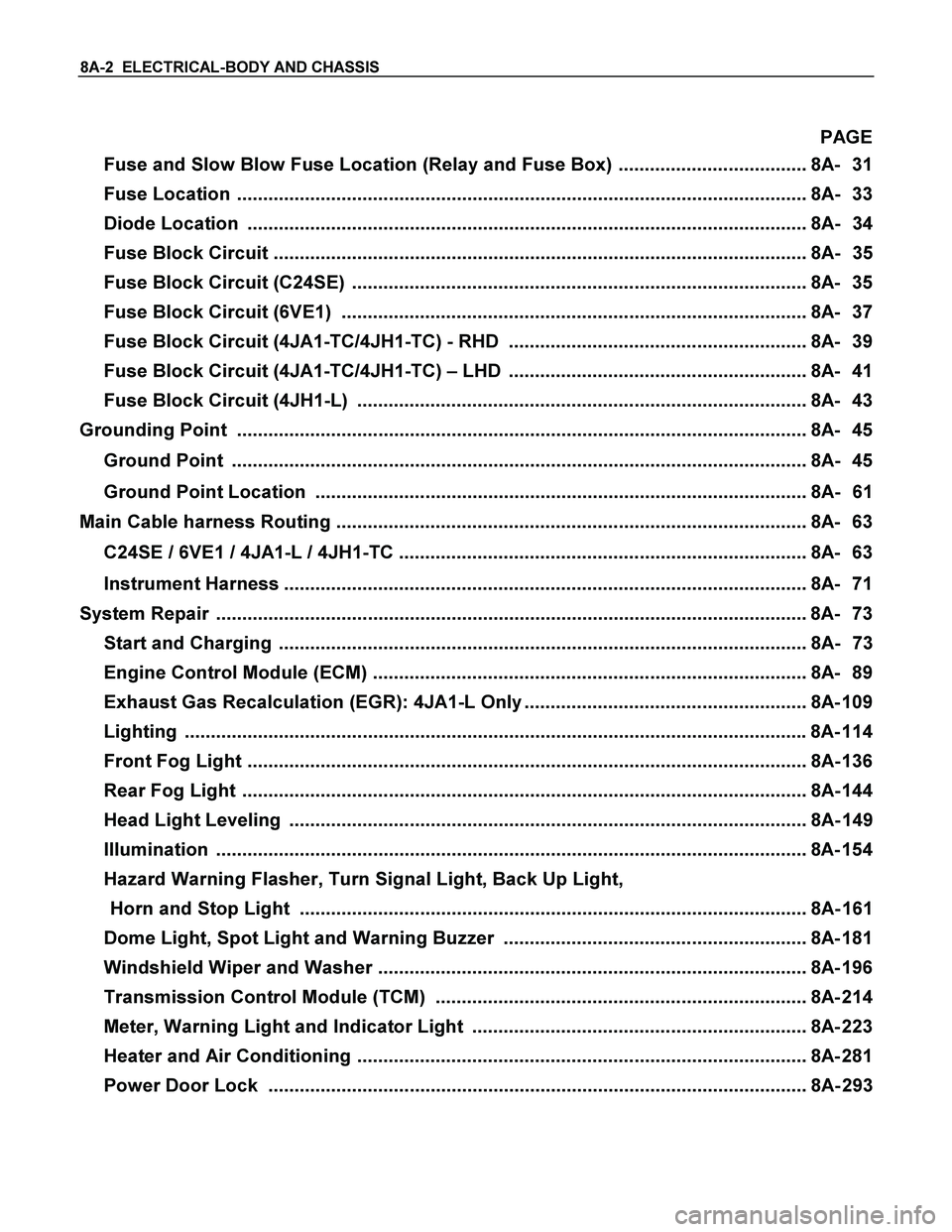

8A-2 ELECTRICAL-BODY AND CHASSIS

PAGE

Fuse and Slow Blow Fuse Location (Relay and Fuse Box) .................................... 8A- 31

Fuse Location ............................................................................................................. 8A- 33

Diode Location ........................................................................................................... 8A- 34

Fuse Block Circuit ...................................................................................................... 8A- 35

Fuse Block Circuit (C24SE) ....................................................................................... 8A- 35

Fuse Block Circuit (6VE1) ......................................................................................... 8A- 37

Fuse Block Circuit (4JA1-TC/4JH1-TC) - RHD ......................................................... 8A- 39

Fuse Block Circuit (4JA1-TC/4JH1-TC) – LHD ......................................................... 8A- 41

Fuse Block Circuit (4JH1-L) ...................................................................................... 8A- 43

Grounding Point ............................................................................................................. 8A- 45

Ground Point .............................................................................................................. 8A- 45

Ground Point Location .............................................................................................. 8A- 61

Main Cable harness Routing .......................................................................................... 8A- 63

C24SE / 6VE1 / 4JA1-L / 4JH1-TC .............................................................................. 8A- 63

Instrument Harness .................................................................................................... 8A- 71

System Repair .................................................................................................................8A- 73

Start and Charging ..................................................................................................... 8A- 73

Engine Control Module (ECM) ................................................................................... 8A- 89

Exhaust Gas Recalculation (EGR): 4JA1-L Only ...................................................... 8A- 109

Lighting ....................................................................................................................... 8A- 114

Front Fog Light ........................................................................................................... 8A- 136

Rear Fog Light ............................................................................................................ 8A- 144

Head Light Leveling ................................................................................................... 8A- 149

Illumination ................................................................................................................. 8A- 154

Hazard Warning Flasher, Turn Signal Light, Back Up Light,

Horn and Stop Light ................................................................................................. 8A- 161

Dome Light, Spot Light and Warning Buzzer .......................................................... 8A- 181

Windshield Wiper and Washer .................................................................................. 8A- 196

Transmission Control Module (TCM) ....................................................................... 8A- 214

Meter, Warning Light and Indicator Light ................................................................ 8A- 223

Heater and Air Conditioning ...................................................................................... 8A- 281

Power Door Lock ....................................................................................................... 8A- 293

Page 662 of 4264

8A-4 ELECTRICAL-BODY AND CHASSIS

GENERAL INFORMATION

The body and chassis electrical system operates on a twelve volt power supply with negative ground polarity.

The main harness consists of the engine harness, the instrument harness, the body harness, and the chassis

harness.

The harnesses use a split corrugated tube to protect the wires from the elements.

Wire size is determined by current flow, circuit length, and voltage drop.

All wires have color-coded insulation.

Wire color-codes are shown in the circuit diagrams.

This makes it easier to trace circuits and to make the proper connections.

Each circuit consists of the following:

1. Power source - The battery and the alternator

2. Wires - To carry electrical current through the circuit

3. Fuses - To protect the circuit against current overload

4. Relays - To protect voltage drop between the battery and the circuit parts and to protect the switch points against

burning

5. Switches - To open and close the circuit

6. Load - Any device, such as a light or motor, which converts the electrical current into useful work

7. Ground - To allow the current to flow back to the power source

Page 665 of 4264

ELECTRICAL-BODY AND CHASSIS 8A-7

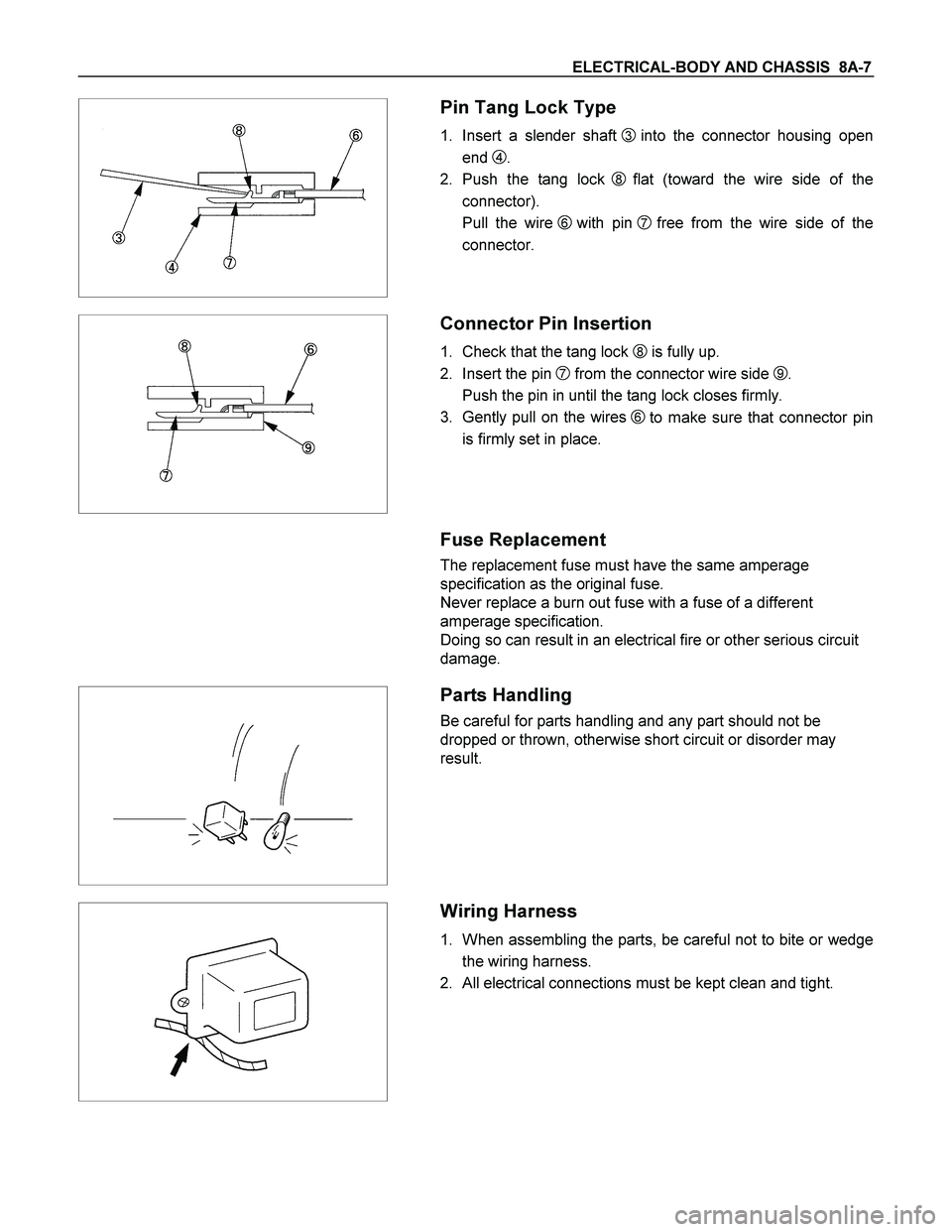

Pin Tang Lock Type

1. Insert a slender shaft 3 into the connector housing open

end

4.

2. Push the tang lock

8flat (toward the wire side of the

connector).

Pull the wire

6 with pin 7free from the wire side of the

connector.

Connector Pin Insertion

1. Check that the tang lock 8 is fully up.

2. Insert the pin

7 from the connector wire side 9.

Push the pin in until the tang lock closes firmly.

3. Gently pull on the wires

6to make sure that connector pin

is firmly set in place.

Fuse Replacement

The replacement fuse must have the same amperage

specification as the original fuse.

Never replace a burn out fuse with a fuse of a different

amperage specification.

Doing so can result in an electrical fire or other serious circuit

damage.

Parts Handling

Be careful for parts handling and any part should not be

dropped or thrown, otherwise short circuit or disorder may

result.

Wiring Harness

1. When assembling the parts, be careful not to bite or wedge

the wiring harness.

2. All electrical connections must be kept clean and tight.