ISUZU TF SERIES 2004 Workshop Manual

TF SERIES 2004

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57180/w960_57180-0.png

ISUZU TF SERIES 2004 Workshop Manual

Trending: section 7, stop start, wiring, jump cable, checking oil, towing, fog light bulb

Page 3821 of 4264

UNIT REPAIR (AW30–40LE) 7A4–13

24 0RY 0 002 9

24 0RY 0 001 0

8. Install new check valve and spring.

24 0RY 0 001 6

9. Install the valve body.

Align the groove of the manual valve to the pin of

the lever.

24 0RY 0 0017

Install the twenty bolts.

NOTE: Each bolt length (mm) is indicated in the figure.

Torque: 10 N·m (87lbin)

2 44R20 0078

Page 3822 of 4264

7A4–14 UNIT REPAIR (AW30–40LE)

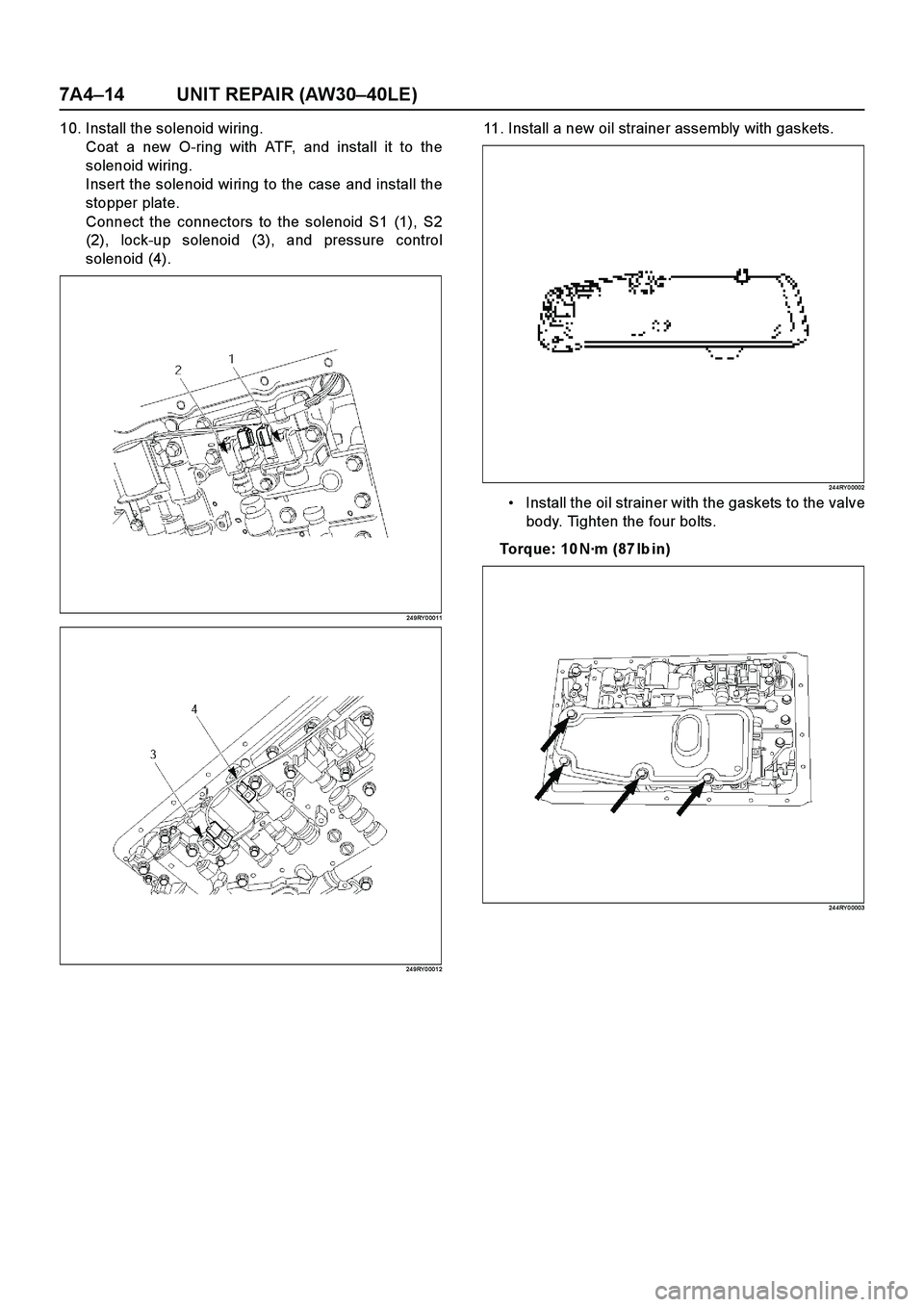

10. Install the solenoid wiring.

Coat a new O-ring with ATF, and install it to the

solenoid wiring.

Insert the solenoid wiring to the case and install the

stopper plate.

Connect the connectors to the solenoid S1 (1), S2

(2), lock-up solenoid (3), and pressure control

solenoid (4).

24 9RY 0 0011

24 9RY 0 001 2

11. Install a new oil strainer assembly with gaskets.

24 4RY 0 0002

Install the oil strainer with the gaskets to the valve

body. Tighten the four bolts.

Torque: 10 N·m (87lbin)

24 4RY 0 0003

Page 3823 of 4264

UNIT REPAIR (AW30–40LE) 7A4–15

12. Install the oil pan.

Install two magnets in oil pan.

Remove any gasket material and be careful not to

drop oil on the contacting surfaces of the

transmission case and oil pan.

Apply liquid gasket (TB1281 or its equivalent) to the

oil pan as shown in the figure.

NOTE: Install the oil pan as soon as the seal gasket is

applied.

24 0RY 0 001 9

Install and tighten the nineteen bolts.

24 0RY 0 002 0

Torque: 7.4 N·m (65lb in)

Page 3824 of 4264

7A4–16 UNIT REPAIR (AW30–40LE)

Major Components (3)

Major Components (3) and Associated Parts

24 8L10 0001

E nd O FCallo ut

Legend

(1) Oil pump

(2) Race

(3) OD planetary gear and OD direct clutch

(4) Race

(5) OD planetary ring gear

(6) Snap ring

(7) Flange, plate and disc (B–0)

(8) Bearing and race

(9) Snap ring

(10) OD support

(11) Race

(12) Snap ring

(13) Second coast brake piston assembly

(14) Direct clutch and forward clutch(15) E-ring and pin

(16) Second coast brake band

(17) Front planetary ring gear

(18) Bearing and race

(19) Race

(20) Snap ring

(21) Front planetary gear

(22) Drum and one-way clutch

(23) Snap ring

(24) Flange, plate and disc (B–2)

(25) Snap ring

(26) Rear planetary gear, second brake drum and

output shaft

(27) Bearing

Page 3825 of 4264

UNIT REPAIR (AW30–40LE) 7A4–17

Disassembly

1. Remove seven bolts fix ing the oil pump to the

transmission case.

Remove the oil pump.

24 1RY 0 000 3

2. Remove race from oil pump.

24 1RY 0 000 2

3. Remove the overdrive planetary gear and overdrive

direct clutch with thrust needle bearing from the

transmission case.

25 2L10 0001

4. Remove the race from OD planetary gear.

25 2L10 0017

Page 3826 of 4264

7A4–18 UNIT REPAIR (AW30–40LE)

5. Remove the overdrive planetary ring gear from the

transmission case.

25 2RY 0 000 2

6. Check piston stroke of overdrive brake

Place a dial indicator onto the overdrive brake

piston as shown in the figure.

25 2RY 0 000 3Measure the stroke applying and releasing the

compressed air (390 – 780 kPa or 57 – 114 psi) as

shown in the figure.

Piston stroke: 1.40 – 1.70 mm (0.0551 – 0.0669 in)

If the values are nonstandard, select another flange.Available flange sizes

24 4RY 0 0001

7. Remove the snap ring.

24 6RY 0 0001

3.3 mm (0.130 in) 3.8 mm (0.150 in)

3.5 mm (0.138 in) 3.9 mm (0.154 in)

3.6 mm (0.142 in) 4.0 mm (0.158 in)

3.7 mm (0.146 in)

Page 3827 of 4264

UNIT REPAIR (AW30–40LE) 7A4–19

8. Remove one flange, four plates and four discs (B–

0).

24 6RY 0 002 6

9. Remove the thrust bearing and two races.

24 7RY 0 000 3

10. Using snap ring pliers, remove the snap ring.

24 6RY 0 0002

11. Remove the OD support.

Remove two bolts fix ing the overdrive support

assembly to the transmission case.

25 2RY 0 0004

Page 3828 of 4264

7A4–20 UNIT REPAIR (AW30–40LE)

Install two removed bolts to the OD support, and

pull out the OD support assembly.

25 2RY 0 000 5

12. Remove the race from OD support.

25 2RY 0 000 6

13. Check piston stroke of second coast brake (B–1)

Place a mark on the second coast brake piston rod

as shown in the figure.

Using feeler gauge, measure the stroke applying

the compressed air (390 – 780 kPa or 57 – 114 psi)

as shown in the figure.

Piston stroke: 1.5 – 3.0 mm (0.059 – 0.118 in)

If the values are nonstandard, replace piston rod

and recheck piston stroke.

If piston stroke is nonstandard, replace brake band.There are two piston rods.

24 8RY 0 0004

24 8RY 0 0005

Rod length 78.4 mm (3.09 in)

79.9 mm (3.15 in)

Page 3829 of 4264

UNIT REPAIR (AW30–40LE) 7A4–21

14. Using snap ring pliers, remove the snap ring.

24 8RY 0 000 6

15. Applying compressed air to the oil hole, remove the

second coast brake piston assembly.

24 8RY 0 000 7

16. Remove the direct clutch and forward clutch from

the transmission case.

24 8RY 0 0008

17. Remove the E-ring from the pin.

Remove the pin from the brake band.

24 8RY 0 0009

Page 3830 of 4264

7A4–22 UNIT REPAIR (AW30–40LE)

18. Remove the second coast brake band from the

transmission case.

24 8RY 0 001 0

19. Remove the front planetary ring gear from the

transmission case.

24 7RY 0 000 4

20. Remove the bearing and race.

24 7RY 0 0005

21. Remove the race.

24 7RY 0 0006

22. Using snap ring pliers, remove the snap ring.

24 8RY 0 0011

Trending: steering wheel adjustment, drain bolt, roof, engine, height, injector, maintenance reset