Fuel sensor ISUZU TF SERIES 2004 Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 1492 of 4264

6E–120 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

67 P0381 4 ON Glow Plug Indicator Circuit

Voltage LowGlow plug indicator circuit

open or short to ground

circuit.No fail-safe function. Glow plug indicator circuit is

correct condition.1. Glow plug indicator

circuit open or short to

g r o u n d c i r c u i t .

2. Glow plug indicator lamp

m a l f u n c t i o n .

3. ECM malfunction.43 —

8 ON Glow Plug Indicator Circuit

Voltage HighGlow plug indicator circuit

short to voltage circuit.ECM malfunction.

——

32 P0400 3 ON Exhaust Gas Recirculation

Flow Excessive Detected1. Intake air temperature is

between 15 deg. C and

1 0 0 d e g . C .

2. Engine coolant

temperature is between

55 deg. C and 100 deg.

C (4JA1-TC) or 35 deg. C

and 100 deg. C (4JH1-

T C ) .

3. Barometric pressure is

between 850hpa and

1 1 0 0 h p a .

4. Small amount of mass air

flow. (Desired mass air

flow - mass air flow is

more than 150mg/strk)Fuel injection quantity is

reduced. 1. Engine speed is between

1500rpm and 3100rpm

(4JA1-TC) or 1500rpm

and 3200rpm (4JH1-TC).

2. Injection quantity is

below 32mg/strk (4JA1-

TC) or 40mg/stk (4JH1-

T C ) .

3. Correct amount of mass

air flow.1. EGR valve is stuck at

o p e n p o s i t i o n .

2. EGR EVRV malfunction.

3 . A i r i n t a k e i s o b s t r u c t e d .

4. Air intake is leaking.

5. MAF sensor malfunction.

6. ECM malfunction.

8 8 /

97—

4 ON Exhaust Gas Recirculation

Circuit Short to Ground or

Open CircuitEGR EVRV circuit open or

short to ground circuit.Fuel injection quantity is

reduced and EGR EVRV

10% conditions as substitute.EGR EVRV circuit is correct

condition.1. EGR EVRV circuit open

or short to ground circuit.

2. EGR EVRV malfunction.

3. ECM malfunction.97 —

5 ON Exhaust Gas Recirculation

Flow Insufficient Detected1. Intake air temperature is

between 15 deg. C and

100 deg. C.

2. Engine coolant

temperature is between

55 deg. C and 100 deg.

C (4JA1-TC) or 35 deg. C

and 100 deg. C (4JH1-

T C ) .

3. Barometric pressure is

between 850hpa and

1 1 0 0 h p a .

4. Large mount of mass air

flow. (Desired mass air

flow - mass air flow is

below -150 mg/strk)Fuel injection quantity is

reduced. 1. Engine speed is between

1500rpm and 3100rpm

(4JA1-TC) or 1500rpm

and 3200rpm (4JH1-TC).

2. Injection quantity is

below 32mg/strk (4JA1-

TC) or 40mg/stk (4JH1-

T C ) .

3. Correct amount of mass

air flow.1. EGR valve is stuck at

c l o s e p o s i t i o n .

2. EGR valve operating

vacuum hose is clogged

or disconnected.

3. EGR EVRV malfunction.

4. MAF sensor signal circuit

short to voltage circuit.

5. MAF sensor malfunction.

6. ECM malfunction.8 8 /

97—

8 ON Exhaust Gas Recirculation

Circuit Short to BatteryEGR EVRV circuit short to

voltage circuit.Fuel injection quantity is

reduced & EGR EVRV 10%

conditions as substitute.EGR EVRV circuit is correct

condition.1. EGR EVRV circuit short

t o v o l t a g e c i r c u i t .

2. EGR EVRV malfunction.

3. ECM malfunction.97 — Flash

CodeCodeSymptom

CodeMILDTC Name DTC Setting Condition Fail-Safe (Back Up) Recovery Condition Related Failure PartsRelated

ECM Pin

No.Related

Multiple

DTC4JA1-TC

(MT)4JH1-TC

(MT)4JH1-TC

(AT)

Page 1493 of 4264

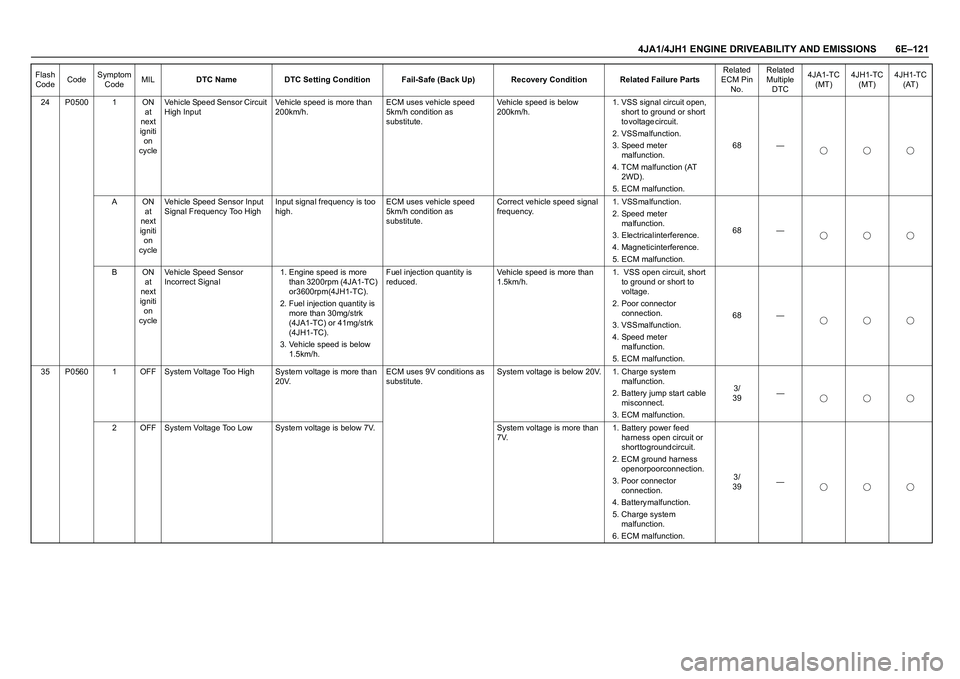

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–121

24 P0500 1 ON

at

next

igniti

on

cycleVehicle Speed Sensor Circuit

High InputVehicle speed is more than

200km/h.ECM uses vehicle speed

5km/h condition as

substitute.Vehicle speed is below

200km/h.1. VSS signal circuit open,

short to ground or short

t o v o l t a g e c i r c u i t .

2. VSS malfunction.

3. Speed meter

m a l f u n c t i o n .

4. TCM malfunction (AT

2 W D ) .

5. ECM malfunction.68 —

A O N

at

next

igniti

on

cycleVehicle Speed Sensor Input

Signal Frequency Too HighInput signal frequency is too

high.ECM uses vehicle speed

5km/h condition as

substitute.Correct vehicle speed signal

frequency. 1. VSS malfunction.

2. Speed meter

m a l f u n c t i o n .

3. Electrical interference.

4. Magnetic interference.

5. ECM malfunction.68 —

B O N

at

next

igniti

on

cycleVehicle Speed Sensor

Incorrect Signal1. Engine speed is more

than 3200rpm (4JA1-TC)

or 3600rpm (4JH1-TC).

2. Fuel injection quantity is

more than 30mg/strk

(4JA1-TC) or 41mg/strk

( 4 J H 1 - T C ) .

3. Vehicle speed is below

1.5km/h.Fuel injection quantity is

reduced.Vehicle speed is more than

1.5km/h.1. VSS open circuit, short

to ground or short to

voltage.

2. Poor connector

c o n n e c t i o n .

3. VSS malfunction.

4. Speed meter

m a l f u n c t i o n .

5. ECM malfunction.68 —

35 P0560 1 OFF System Voltage Too High System voltage is more than

20V.ECM uses 9V conditions as

substitute.System voltage is below 20V. 1. Charge system

m a l f u n c t i o n .

2. Battery jump start cable

misconnect.

3. ECM malfunction.3 /

39—

2 OFF System Voltage Too Low System voltage is below 7V. System voltage is more than

7V.1. Battery power feed

harness open circuit or

short to ground circuit.

2. ECM ground harness

open or poor connection.

3. Poor connector

c o n n e c t i o n .

4 . B a t t e r y m a l f u n c t i o n .

5. Charge system

m a l f u n c t i o n .

6. ECM malfunction.3 /

39— Flash

CodeCodeSymptom

CodeMILDTC Name DTC Setting Condition Fail-Safe (Back Up) Recovery Condition Related Failure PartsRelated

ECM Pin

No.Related

Multiple

DTC4JA1-TC

(MT)4JH1-TC

(MT)4JH1-TC

(AT)

Page 1496 of 4264

6E–124 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

21 P1120 1 ON Pedal/Throttle Position

Sensor Circuit High InputThrottle position sensor

output voltage is more than

4.5V.ECM increases idle speed up

to 1400rpm.Throttle position sensor

output voltage is below 4.5V.1. Sensor power supply

circuit short to voltage

c i r c u i t .

2. Sensor signal circuit

short to voltage circuit.

3. Sensor ground circuit

open or short to voltage

c i r c u i t .

4. Poor connector

c o n n e c t i o n .

5 . T P S m a l f u n c t i o n .

6. ECM malfunction.3 8 /

4 9 /

57—

7 ON Pedal/Throttle Position

Sensor Voltage Supply

Circuit High InputThrottle position sensor

power supply voltage is more

than 5.2V.Throttle position sensor

power supply voltage is

below 5.2V.1. Sensor power supply

circuit short to battery

voltage circuit.

2 . T P S m a l f u n c t i o n .

3. ECM malfunction.57 —

9 ON Pedal/Throttle Position

Sensor Voltage Supply

Circuit Low InputThrottle position sensor

power supply voltage is

below 4.6V.Throttle position sensor

power supply voltage is more

than 4.6V.1. Sensor power supply

circuit short to ground

c i r c u i t .

2 . T P S m a l f u n c t i o n .

3. ECM malfunction.57 —

D ON Pedal/Throttle Position

Sensor Brake Switch Error1. Engine speed is more

t h a n 1 7 0 0 r p m .

2. Vehicle speed is more

t h a n 1 . 5 k m / h .

3. When brake pedal is

depressed during

accelerator pedal is

d e p r e s s i n g . Throttle position is more than

20% or brake pedal is

released (switch is inactive). 1 . T h r o t t l e s t i c k i n g .

2. TPS incorrect adjusting.

3 . T P S m a l f u n c t i o n .

4. Brake switch

m a l f u n c t i o n .

5. ECM malfunction.3 0 /

3 8 /

65—

E ON Pedal/Throttle Position

Sensor Idle Position Switch

Error1. When idle switch is

turned off, throttle

position sensor was

b e l o w 0 . 3 5 % .

o r

2. When idle switch is tuned

on, throttle position

sensor was more than

7.8%.1. When throttle position

sensor is 100%, idle

s w i t c h t u r n s o f f .

2. When throttle position

sensor is 0%, idle switch

turns on.1 . T P S m a l f u n c t i o n .

2. Idle switch malfunction.

3. ECM malfunction.

3 8 /

69—

22 P1173 3 OFF Fuel Reduction Caused By

High Coolant TemperatureExcessive high engine

coolant temperature is

detected.No fail-safe function. Engine coolant temperature

is normal range.1 . E n g i n e o v e r h e a t .

2. ECT sensor malfunction.

3. ECM malfunction.89 —

7 OFF Fuel Reduction Caused By

High Fuel TemperatureFuel temperature is more

than 100 deg. C.PSG (pump control unit)

controls fuel injection

quantity based on engine

speed and fuel temperature.Fuel temperature is below

100 deg. C.1 . E C M m a l f u n c t i o n .

2. PSG (pump control unit)

malfunction.——

A OFF Fuel Reduction Caused By

Low Fuel TemperatureExcessive low fuel

temperature is detected.No fail-safe function. Fuel temperature is normal

range.1 . E C M m a l f u n c t i o n .

2. PSG (pump control unit)

malfunction.——— Flash

CodeCodeSymptom

CodeMILDTC Name DTC Setting Condition Fail-Safe (Back Up) Recovery Condition Related Failure PartsRelated

ECM Pin

No.Related

Multiple

DTC4JA1-TC

(MT)4JH1-TC

(MT)4JH1-TC

(AT)

Page 1497 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–125

43 P1335 A ON Engine Speed Output Circuit

MalfunctionThe PSG (pump control unit)

is recognized defective

engine speed signal form the

ECM.Fuel injection quantity is

reduced.Correct engine speed signal. 1. CKP sensor harness

open circuit, short to

ground or short to

voltage.

2. CKP sensor output

harness open circuit,

short to ground or short

t o v o l t a g e .

3. Poor connector

c o n n e c t i o n .

4. CKP sensor malfunction.

5. Pulse sensing gap

i n c o r r e c t .

6 . P u l s e r m a l f u n c t i o n .

7. Electrical interference.

8. Magnetic interference.

9. ECM malfunction.

10. PSG (pump control unit)

malfunction.9 0 /

9 1 /

9 8 /

101P0335(B)/

P0335(D)

45 P1345 A ON Camshaft Speed Malfunction The PSG (pump control unit)

is recognized incorrect

camshaft speed signal.No fail-safe function. Correct camshaft speed. 1. Pump camshaft speed

s e n s o r m a l f u n c t i o n .

2. Pulse sensing gap

i n c o r r e c t .

3 . P u l s e r m a l f u n c t i o n .

4. Electrical interference.

5. Magnetic interference.

6. ECM malfunction.

7. PSG (pump control unit)

malfunction.——

47 P1520 A ON Neutral Switch ON Error Neutral switch signal is

inputted "On" three times

consecutively under driving

conditions.No fail-safe function. Correct neutral switch signal

is inputted two times

consecutively under driving

conditions.1. Neutral switch circuit

short to voltage circuit.

2. Neutral switch

m a l f u n c t i o n .

3. ECM malfunction.87 —

B ON Neutral Switch OFF Error Neutral switch signal is

inputted "Off" three times

consecutively under driving

conditions.1. Neutral switch circuit

open, short to ground

c i r c u i t .

2. Poor connector

c o n n e c t i o n .

3. Neutral switch

m a l f u n c t i o n .

4. ECM malfunction.87 — —

55 P1605 C ON Seed and Key File Destroyed Seed or key file in EEPROM

is destroyed.No fail-safe function. No recovery. ECM malfunction.

——

D ON EEPROM Defect Write and read from the

EEPROM are failed during

initialization of the ECM.ECM uses default values

from the EPROM.Write and read from the

EEPROM are correct during

initialization of the ECM.ECM malfunction.

—— Flash

CodeCodeSymptom

CodeMILDTC Name DTC Setting Condition Fail-Safe (Back Up) Recovery Condition Related Failure PartsRelated

ECM Pin

No.Related

Multiple

DTC4JA1-TC

(MT)4JH1-TC

(MT)4JH1-TC

(AT)

Page 1513 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–141

Condition for setting the DTC and action taken when the DTC sets

Circuit description

The ECM monitors altitude from the barometric

pressure sensor. To apply specified vacuum pressure to

the turbocharger wastegate valve, ECM sends control

signal to the wastegate control solenoid depending on

altitude.

Then, apply vacuum pressure to the turbocharger

wastegate valve is monitored by the ECM form the

vacuum pressure sensor output signal. The ECM

controls wastegate control solenoid based on signal

from vacuum pressure sensor output.

The output voltage ex cessively high or low, DTC P0105

(Symptom Code 1) or P0105 (Symptom Code 2) will be

stored.

The supply voltage is out of range, DTC P0105

(Symptom Code 7) or P0105 (Symptom Code 9) will be

stored.

Diagnostic Aids

An intermittent may be caused by the following:

Poor connections.

Misrouted harness.

Rubbed through wire insulation.

Broken wire inside insulation.

Check for the following conditions:

Poor connection at ECM-Inspect harness connectors

for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal to wire connection.

Damaged harness-Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the DTC P0105 display on the Tech 2 while moving

connectors and wiring harnesses. A change in the

display will indicate the location of the fault.

Flash

CodeCode Symptom

CodeMIL DTC Name DTC Setting Condition Fail-Safe (Back Up)

34 P0105 1 ON Vacuum Pressure Sensor

Circuit High InputVacuum sensor output

voltage is more than 4.4V.1. Fuel injection quantity is

r e d u c e d .

2. ECM use 615hpa

conditio ns for

turbo cha rge r wa ste gate

contro l. 2 ON Vacuum Pressure Sensor

Circuit Low InputVacuum sensor output

voltage is below 0.5V.

7 ON Vacuum Pressure Sensor

Volta ge Supply Circuit High

InputVacuum senso r po wer supply

voltage is more than 5.2V.1. Fuel injection quantity is

r e d u c e d .

2. ECM use vacuum sensor

output voltage 5.0V

condition as substitute. 9 ON Vacuum Pressure Sensor

Volta ge Supply Circuit Lo w

InputVacuum senso r po wer supply

voltage is below 4.5V.

Page 1540 of 4264

6E–168 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

DIAGNOSTIC TROUBLE CODE (DTC) P0180 (SYMPTOM CODE B)

(FLASH CODE 15) FUEL TEMPERATURE SENSOR CIRCUIT RANGE/

PERFORMANCE

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The fuel temperature sensor is assembled inside of the

pump control unit (PSG). The signal of fuel temperature

is sent via the CAN-bus from the PSG to ECM.

If the fuel temperature is ex cessively high or low

condition, DTC P0180 will be stored.

Diagnostic Aids

An intermittent may be caused by the following:

Poor connections.Misrouted harness.

Rubbed through wire insulation.

Broken wire inside the insulation.

Check for the following conditions:

Poor connection at ECM and PSG-Inspect harness

connectors for backed out terminals, improper

mating, broken locks, improperly formed or damaged

terminals, and poor terminal to wire connection.

Damaged harness-Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the “Fuel Temperature” display on the Tech2 while

Flash

CodeCode Symptom

CodeMIL DTC Name DTC Setting Condition Fail-Safe (Back Up)

15 P0180 B ON Fuel Temperature Sensor Cir-

cuit Range/PerformanceFT sensor output is high tem-

pe ra ture (mo re tha n

150deg.C) or low temperature

(below -40deg.C).The ECM use 75de g.C condi-

tions as substitute.

Page 1541 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–169

moving connectors and wiring harness related to the

sensor.

Diagnostic Trouble Code (DTC) P0180 (Sy mptom Code B) (Flash Code 15) Fuel

Temperature Sensor Circuit Range/Performance

Step Action Value(s) Yes No

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2Go to On Board

Diagnostic

(OBD) System

Check

2 1. Connect the Tech 2.

2. Review and record the failure information.

3. Select “F0: Read DTC Infor As Stored By ECU” in

“F0: Diagnostic Trouble Codes”.

Is the DTC P0180 (Symptom Code B) stored as

“Present Failure”?—Go to Step 3Refer to

Diagnostic Aids

and Go to Step

3

3 1. Using the Tech 2, ignition “On” and engine “Off”.

2. Select “F1: Clear DTC Information” in “F0:

Diagnostic Trouble Codes” with the Tech 2 and

clear the DTC information.

3. Operate the vehicle and monitor the “F0: Read

DTC Infor As Stored By ECU” in the “F0:

Diagnostic Trouble Codes”.

Was the DTC P0180 (Symptom Code B) stored in this

ignition cycle?—Go to Step 4Refer to

Diagnostic Aids

4 Is the ECM programmed with the latest software

release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved?—Verify repair Go to Step 5

5 Substitute a known good ECM and recheck.

Was the problem solved?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure. —Go to Step 6Go to Step 7

6 Replace the ECM.

Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure.—Verify repair—

7 Replace the injection pump assembly.

Is the action complete?—Verify repair—

Page 1551 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–179

Circuit Description

The ECM is calculates an injection quantity and an

injection timing using the various sensors (crankshaft

position sensor, camshaft position sensor, engine

coolant temperature sensor, etc.). The timing control

valve (TCV) operation performs an injection timing

decision.

The TCV performs as a variable throttle, using the rapid

opening and closing cycle of the valve needle in the

TCV.

The TCV is assembled in the injection pump. The signal

of desired injection timing and actual injection timing are

ex changed via the CAN-bus between the PSG and

ECM.

If the timer position is out of tolerance (deviation or

fluctuation), DTC P0216 will be stored.

Diagnostic Aids

An intermittent may be caused by the following:

Poor connections.

Misrouted harness.

Rubbed through wire insulation.

Broken wire inside the insulation.

Insufficient air bleeding of fuel line.

Low fuel quantity in the fuel tank.

Check for the following conditions:

Insufficient air bleeding of fuel line inside, clogged

fuel filter or pinched fuel pipe/hose may cause the

DTC store or improper engine performance.Air bleeding procedure:

1.Operate the priming pump until strong resistance is

felt.

2.Wait 1 minute, and operate the priming pump until

strong resistance is felt.

3.Wait 1 minute, and operate the priming pump until

strong resistance is felt.

4.Turn the ignition switch to the "ON" position. Wait

until the glow indicator lamp turns off.

5.Turn the ignition switch to the "START" position and

crank the engine until it starts.

6.If the engine does not start, repeat Step 3 - 5.

7.Allow the engine to idle for 3 minutes to bleed air

completely form the fuel system and check for fuel

leakage.

Poor connection at ECM and PSG-Inspect harness

connectors for backed out terminals, improper

mating, broken locks, improperly formed or damaged

terminals, and poor terminal to wire connection.

Damaged harness-Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the "Actual Injection Start" display on the Tech2 while

moving connectors and wiring harness related to the

sensor.

Page 1556 of 4264

6E–184 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

Condition for setting the DTC and action taken when the DTC sets

Circuit description

The ECM monitors altitude from the barometric

pressure sensor. To apply specified vacuum pressure to

the turbocharger wastegate valve, ECM sends control

signal to the wastegate control solenoid depending on

altitude.

Then, apply vacuum pressure to the turbocharger

wastegate valve is monitored by the ECM form the

vacuum pressure sensor output signal. The ECM

controls wastegate control solenoid based on signal

from vacuum pressure sensor output.

If the vacuum pressure sensor detected vacuum

pressure is excessively low or high due to faulty vacuum

line, vacuum pump or turbocharger wastegate valve,

DTC P0243 (Symptom Code 3), P0243 (Symptom Code

5) or P0243 (Symptom Code 6) will be stored.

If the wastegate control solenoid circuit is open or short

to ground circuit, DTC P0243 (Symptom Code 4) will be

stored.

If the wastegate control solenoid circuit is short to

voltage circuit, DTC P0243 (Symptom Code 8) will be

stored.

Diagnostic Aids

An intermittent may be caused by the following:

Poor connections.

Misrouted harness.

Rubbed through wire insulation.

Broken wire inside insulation.

Turbocharger wastegate valve sticking or broken.

Misrouted vacuum hose.

Faulty vacuum pump or regulating valve.

Check for the following conditions:

Poor connection at ECM-Inspect harness connectors

for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal to wire connection.

Damaged harness-Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the DTC P0243 display on the Tech 2 while moving

connectors and wiring harnesses. A change in the

display will indicate the location of the fault.

Flash

CodeCode Symptom

CodeMIL DTC Name DTC Setting Condition Fail-Safe (Back Up)

64 P0243 3 ON Turbocharger Wastegate

So le no id "A" Ra nge/

Pe rfo rma nce1. Intake air temperature is

between -50 deg. C and

2 0 0 d e g . C .

2. Engine coolant

temperature is between -

50 deg. C and 150 deg.

C. 1. Fuel injection quantity is

r e d u c e d .

2. EGR EVRV becomes 10%

co nditio n.

4 ON Turbocharger Wastegate

So le no id "A" Lo w Wastegate control EVRV

circuit open or short to ground

circuit.1. Fuel injection quantity is

r e d u c e d .

2. EGR EVRV becomes 10%

c o n d i t i o n .

3. Wastegate control EVRV

be co mes 32% conditio n.

5 ON Turbocharger Wastegate

So le no id "A" Ra nge/

Pe rfo rma nce1. Intake air temperature is

between -50 deg. C and

2 0 0 d e g . C .

2. Engine coolant

temperature is between -

50 deg. C and 150 deg.

C. 1. Fuel injection quantity is

r e d u c e d .

2. EGR EVRV becomes 10%

co nditio n.

6 ON Turbocharger Wastegate

So le no id "A" Malfunctio n1. Engine coolant

temperature is between -

50 deg. C and 150 deg.

C .

2. EGR contro l EVRV 0%

co nditio n.

8 ON Turbocharger Wastegate

So le no id "A" HighWastegate control EVRV

circuit short to voltage circuit.1. Fuel injection quantity is

r e d u c e d .

2. EGR EVRV becomes 10%

c o n d i t i o n .

3. Wastegate control EVRV

be co mes 32% conditio n.

Page 1569 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–197

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The ECM is calculates an injection quantity and an

injection timing using the various sensors. And the PSG

controls the high pressure solenoid valve depending on

programmed pump map data.

The signal of desired injection quantity and actual injec-

tion quantify are ex changed via the CAN-bus between

the PSG and ECM.

If the relation of engine speed signal and doubled pump

camshaft speed signal ex cessively large, DTC P0251

(Symptom Code 7) will be stored.

If the CAN high or low circuit is defected, DTC P0251

(Symptom Code E) will be stored.

Diagnostic Aids

An intermittent may be caused by the following:

Poor connections.

Misrouted harness.

Rubbed through wire insulation.

Broken wire inside the insulation.

Check for the following conditions:

Poor connection at ECM and PSG-Inspect harness

connectors for backed out terminals, improper

mating, broken locks, improperly formed or damaged

terminals, and poor terminal to wire connection.

Damaged harness-Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the “Injection Quantity” display on the Tech2 while

moving connectors and wiring harness related to the

sensor.

Diagnostic Trouble Code (DTC) P0251 (Symptom Code 6) (Flash Code 53)

Injection Pump Malfunction

Flash

CodeCode Symptom

CodeMIL DTC Name DTC Setting Condition Fail-Safe (Back Up)

53 P0251 6 ON Injection Pump Malfunction 1. No pump camshaft speed

se nsor erro r.

2. High pressure solenoid

v a lv e co ntro l pulse w idth

doe s no t ma tch with

desired fuel injection quan-

tity. 1. MAB (fuel cutoff solenoid

valve) is operated.

2. Desired injection quantity

becomes 0mg/strk.

7 ON Injection Pump Malfunction 1. No pump camshaft speed

se nsor erro r.

2. No CKP senso r e rror.

3. Difference of engine speed

and doubled pump cam-

shaft speed is more than

720rpm (4JA1-TC) or 690

rpm (4JH1-TC).

9 ON Injection Pump Malfunction No pump map programmed in

the PSG (pump co ntrol unit)

or PSG malfunction.

A ON Injection Pump Malfunction EEPROM or A/D converter

malfunctio n in the PSG (pump

control unit).Fuel inje ctio n qua ntity is

reduced.

B ON Injection Pump Malfunction PSG (pump control unit) rec-

ognized high pressure sole -

noid valve drive circuit error.No fa il-sa fe fun ctio n.

D ON Injection Pump Malfunction PSG (pump control unit) could

no t me asure the high pres-

sure solenoid valve drive volt-

age.

E ON Injection Pump Malfunction ECM could not accept PSG

(pump co ntrol unit) messa ge.1. MAB (fuel cutoff solenoid

valve) is operated.

2. Desired injection quantity

becomes 0mg/strk.

Step Action Value(s) Yes No

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2Go to On Board

Diagnostic

(OBD) System

Check