oil ISUZU TF SERIES 2004 Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 3852 of 4264

7A4–44 UNIT REPAIR (AW30–40LE)

Disassembly

1. Check operation of one-way clutch.

Hold the OD direct clutch drum and turn the input

shaft.

The input shaft should turn freely clockwise and

should lock counterclockwise.

RUW 37A SH00 450 1

2. Remove OD direct clutch assembly from OD

planetary gear assembly.

2 52L10 000 4

3. Then remove thrust bearing with the race from OD

direct clutch drum.4. Check piston stroke of OD direct clutch (C–0).

Place the oil pump onto the torque converter, and

then place the OD direct clutch assembly onto the

oil pump.

25 2L10 0005Use a dial indicator, measure the OD direct clutch

piston stroke applying and releasing the

compressed air (390 – 780 kPa or 57 – 114 psi) as

shown.

Piston stroke: 1.85 – 2.15 mm (0.0728 – 0.0846 in)

25 2L10 0016

Page 3853 of 4264

UNIT REPAIR (AW30–40LE) 7A4–45

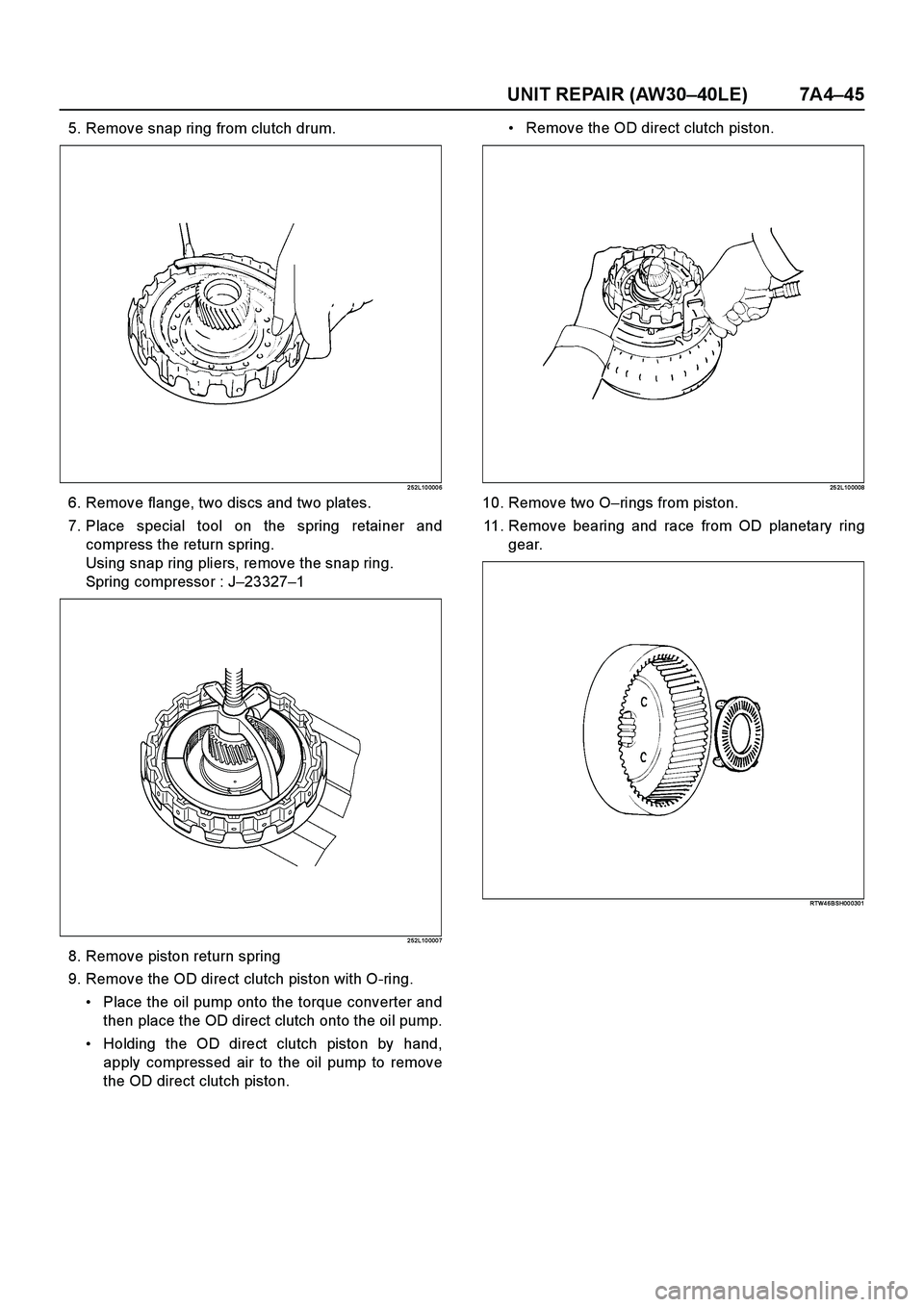

5. Remove snap ring from clutch drum.

2 52L10 000 6

6. Remove flange, two discs and two plates.

7. Place special tool on the spring retainer and

compress the return spring.

Using snap ring pliers, remove the snap ring.

Spring compressor : J–23327–1

2 52L10 000 7

8. Remove piston return spring

9. Remove the OD direct clutch piston with O-ring.

Place the oil pump onto the torque converter and

then place the OD direct clutch onto the oil pump.

Holding the OD direct clutch piston by hand,

apply compressed air to the oil pump to remove

the OD direct clutch piston.Remove the OD direct clutch piston.

25 2L10 0008

10. Remove two O–rings from piston.

11. Remove bearing and race from OD planetary ring

gear.

RTW4 6BSH00 0301

Page 3859 of 4264

UNIT REPAIR (AW30–40LE) 7A4–51

13. Install two plates and two discs then install the

flange, with the flat side facing downward.

2 52L10 001 3

14. Install snap ring.

2 52L10 001 4

15. Check piston stroke of OD direct clutch (C–0)

Place the oil pump onto the torque converter, and

then place the OD direct clutch assembly onto the

oil pump.

25 2L10 0005Using a dial indicator, measure the OD direct clutch

piston stroke by applying and releasing the

compressed air (390 – 780 kPa or 57 – 114 psi) as

shown.

Piston stroke: 1.85 – 2.15 mm (0.0729 – 0.0847 in)

If the piston stroke is not within specification,

replace the disc and recheck the piston stroke.

If the piston stroke is nonstandard, select another

flange.

Flange sizes

25 2L10 0016

Flange thickness Flange thickness

3.8 mm (0.150 in) 3.4 mm (0.134 in)

3.7 mm (0.146 in) 3.3 mm (0.130 in)

3.6 mm (0.142 in) 3.2 mm (0.126 in)

3.5 mm (0.138 in) 3.1 mm (0.122 in)

Page 3861 of 4264

UNIT REPAIR (AW30–40LE) 7A4–53

OD Support Assembly

Disassembled View

2 52R20 0003

E nd O FCallo ut

Disassembly

1. Check OD brake piston movement.

Place the OD support assembly onto the direct

clutch assembly.

25 2RY 0 0042

Legend

(1) Thrust bearing

(2) Race

(3) Thrust washer (plastic)

(4) Snap ring(5) Piston return spring

(6) OD brake piston

(7) O-ring

(8) Oil seal ring

(9) OD support

Page 3862 of 4264

7A4–54 UNIT REPAIR (AW30–40LE)

Apply compressed air into the oil passage as

shown, and be sure that the OD brake piston moves

smoothly.

25 2RY 0 004 3

2. Remove the thrust bearing.

3. Remove the race.

4. Remove the thrust washer (plastic).

5. Place special tool on the spring retainer, and

compress the return spring with a shop press.

Spring compressor : J–37233

Remove the snap ring with a screwdriver.

RUW 37A SH00 310 1

6. Romove the piston return spring.7. Place the OD support onto the direct clutch

assembly.

Hold the OD brake piston so it is not slanted and

apply compressed air into the passage to remove

the OD brake piston.

Remove the OD brake piston.

25 2RY 0 0045

8. Remove the O-ring and oil seal rings from OD

support.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage or any abnormal conditions are found through

inspection.

1. Check piston return spring

Using calipers, measure the free length of the return

spring.

Standard length: 17.2 mm (0.677 in)

25 2RY 0 0046

Page 3863 of 4264

UNIT REPAIR (AW30–40LE) 7A4–55

Reassembly

1. Coat the two oil seal rings with ATF.

Contract the oil seals as shown, and install them

onto the OD support.

NOTE: Do not spread the ring ends more than

necessary.

25 2RY 0 004 7

2. Coat two new O-rings with ATF and install them on

the OD brake piston.

3. Being careful not to damage the O-rings, press the

brake piston into the OD support, using both hands.

25 2RY 0 004 8

4. Install piston return spring.

25 2RY 0 0049

5. Place special tool on the spring retainer, and

compress the return spring with a shop press.

Spring compressor : J–37233

Install the snap ring with a screwdriver.

Be sure the end gap of the snap ring is not aligned

with cutout portion of the OD support.

RUW3 7A SH00 3201

Page 3865 of 4264

UNIT REPAIR (AW30–40LE) 7A4–57

Apply compressed air into the oil passage as

shown, and be sure that the OD brake piston moves

smoothly.

25 2RY 0 004 3

Page 3872 of 4264

7A4–64 UNIT REPAIR (AW30–40LE)

Forward Clutch Asseembly (C-1)

Disassembled View

2 48R20 0003

E nd O FCallo ut

Legend

(1) Thrust bearing

(2) Race

(3) Snap ring

(4) Flange

(5) Disc and plate

Six discs and six plates

(6) Cushion plate(7) Snap ring

(8) Piston return spring

(9) Piston

(10) O-ring

(11) O-ring

(12 Oil seal ring

(13) Thrust bearing

(14) Forward clutch drum

Page 3874 of 4264

7A4–66 UNIT REPAIR (AW30–40LE)

5. Place special tool on the spring retainer and

compress the return spring.

Using snap ring pliers, remove the snap ring.

Spring compressor : J–25048

24 8RY 0 000 3

6. Remove the piston return spring.

7. Place the forward clutch drum onto the OD support.

Holding the forward clutch piston by hand, apply

compressed air to the OD support to remove the

forward clutch piston.

24 8RY 0 004 2

8. Remove the O-rings from piston.

9. Remove the O-ring from forward clutch drum.

10. Remove the oil seal rings and thrust bearing from

forward clutch drum.

Inspection and Repair

1. Check forward clutch piston

Check that check ball is free by shaking the piston.

Check that the valve does not leak by applying

low-pressure compressed air.

24 8RY 0 0031

2. Check forward clutch drum bushing.

Using a dial indicator, measure the inside diameter

of the forward clutch drum bushing.

Maximum inside diameter: 24.08 mm (0.948 in)

If the inside diameter is greater then the maximum,

replace the forward clutch drum.

24 8RY 0 0043

3. Check disc, plate and flange.

Check to see if the sliding surface of the disc, plate

and flange are worn or burnt. If necessary, replace

them.

If the lining of the disc is peeling off or discolored,

or even if parts of the printed numbers are

defaced, replace all discs.

Page 3875 of 4264

UNIT REPAIR (AW30–40LE) 7A4–67

Before assembling new discs, soak them in ATF

for at least fifteen minutes.

24 8RY 0 004 5

4. Check piston return spring.

Using calipers, measure the free length of the return

spring.

Standard length: 19.47 mm (0.7665 in)

24 7RY 0 003 4

Reassembly

1. Coat the assembled thrust bearing and race with

petroleum jelly and install it onto the forward clutch

drum, with the race side facing downward.

Bearing and race (Reference)

24 8RY 0 0044

2. Coat the three oil rings with ATF.

Contract the oil seal rings as shown, and install

three oil seal rings onto the forward clutch drum.

NOTE: Do not spread the ring ends more than

necessary.

24 8RY 0 0046

Inside diameter 33.7 mm (1.327 in)

Outside diameter 47.8 mm (1.882 in)