service ISUZU TF SERIES 2004 Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 1380 of 4264

6E–8 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

(SYMPTOM CODE B) (FLASH CODE 76) ECM

MAIN RELAY SWITCHED OFF TOO LATE 6E-337

Circuit Description ..................................... 6E-337

Diagnostic Aids .......................................... 6E-337

Diagnostic Trouble Code (DTC) P1625

(Symptom Code A) (Flash Code 76) ECM

Main Relay Switched Off Too Early ......... 6E-338

Diagnostic Trouble Code (DTC) P1625

(Symptom Code B) (Flash Code 76) ECM

Main Relay Switched Off Too Late .......... 6E-339

DIAGNOSTIC TROUBLE CODE (DTC) P1630

(SYMPTOM CODE A) (FLASH CODE 51)

FUEL INJECTION QUANTITY CIRCUIT

MALFUNCTION ....................................... 6E-340

DIAGNOSTIC TROUBLE CODE (DTC) P1630

(SYMPTOM CODE B) (FLASH CODE 51)

FUEL INJECTION QUANTITY CIRCUIT

MALFUNCTION ....................................... 6E-340

Circuit Description ..................................... 6E-340

Diagnostic Aids .......................................... 6E-341

Diagnostic Trouble Code (DTC) P1630

(Symptom Code A) (Flash Code 51) Fuel

Injection Quantity Circuit Malfunction ...... 6E-341

Diagnostic Trouble Code (DTC) P1630

(Symptom Code B) (Flash Code 51) Fuel

Injection Quantity Circuit Malfunction ...... 6E-341

DIAGNOSTIC TROUBLE CODE (DTC) P1650

(SYMPTOM CODE A)

(FLASH CODE 44) CAN DEVICE OFFLINE 6E-342

DIAGNOSTIC TROUBLE CODE (DTC) P1650

(SYMPTOM CODE B) (FLASH CODE 44)

CAN DEVICE HANG-UP ......................... 6E-342

Circuit Description ..................................... 6E-342

Diagnostic Aids .......................................... 6E-342

Diagnostic Trouble Code (DTC) P1650

(Symptom Code A) (Flash Code 44)

CAN Device Offline .................................. 6E-343

Diagnostic Trouble Code (DTC) P1650

(Symptom Code B) (Flash Code 44)

CAN Device Hang-up .............................. 6E-348

DIAGNOSTIC TROUBLE CODE (DTC) P1651

(SYMPTOM CODE A) (FLASH CODE 45)

CAN MALFUNCTION .............................. 6E-349

DIAGNOSTIC TROUBLE CODE (DTC) P1651

(SYMPTOM CODE B) (FLASH CODE 45)

CAN RECEIVES ERROR ........................ 6E-349

Circuit Description ..................................... 6E-349

Diagnostic Aids .......................................... 6E-349

Diagnostic Trouble Code (DTC) P1651

(Symptom Code A) (Flash Code 45)

CAN Malfunction ...................................... 6E-350

Diagnostic Trouble Code (DTC) P1651

(Symptom Code B) (Flash Code 45) CAN Receives Error ................................ 6E-351

DIAGNOSTIC TROUBLE CODE (DTC) P1690

(SYMPTOM CODE 4) (FLASH CODE 77)

CHECK ENGINE LAMP (MIL) CIRCUIT

VOLTAGE LOW ...................................... 6E-356

DIAGNOSTIC TROUBLE CODE (DTC) P1690

(SYMPTOM CODE 8) (FLASH CODE 77)

CHECK ENGINE LAMP (MIL) CIRCUIT

VOLTAGE HIGH ...................................... 6E-356

Circuit Description ...................................... 6E-356

Diagnostic Aids .......................................... 6E-356

Diagnostic Trouble Code (DTC) P1690

(Symptom Code 4) (Flash Code 77) Check

Engine Lamp (MIL) Circuit Voltage Low .. 6E-357

Diagnostic Trouble Code (DTC) P1690

(Symptom Code 8) (Flash Code 77) Check

Engine Lamp (MIL) Circuit Voltage High . 6E-360

SYMPTOM DIAGNOSIS ............................ 6E-361

PRELIMINARY CHECKS .......................... 6E-361

VISUAL/PHYSICAL CHECK ...................... 6E-361

INTERMITTENT ........................................ 6E-361

ENGINE CRANKS BUT WILL NOT RUN .. 6E-362

HARD START SYMPTOM ......................... 6E-366

ROUGH, UNSTABLE, OR INCORRECT

IDLE, STALLING SYMPTOM .................. 6E-370

SURGES AND/OR CHUGS SYMPTOM ... 6E-377

HESITATION, SAG, STUMBLE SYMPTOM 6E-383

CUTS OUT, MISSES SYMPTOM .............. 6E-389

LACK OF POWER, SLUGGISH OR

SPONGY SYMPTOM .............................. 6E-396

POOR FUEL ECONOMY SYMPTOM ....... 6E-402

EXCESSIVE WHITE SMOKE .................... 6E-407

EXCESSIVE BLACK SMOKE .................... 6E-413

ON-VEHICLE SERVICE PROCEDURE .... 6E-418

ENGINE CONTROL MODULE (ECM) ... 6E-418

CRANKSHAFT POSITION (CKP) SENSOR 6E-419

ENGINE COOLANT TEMPERATURE

(ECT) SENSOR ....................................... 6E-419

MASS AIR FLOW (MAF) & INTAKE AIR

TEMPERATURE (IAT) SENSOR ............ 6E-420

THROTTLE POSITION SENSOR (TPS) ... 6E-420

EGR EVRV

(Electrical Vacuum Regulating Valve) ..... 6E-421

Page 1448 of 4264

6E–76 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

ISUZU Strategy Based Diagnostics

Overview

As a retail service technician, you are part of the ISUZU

service team. The team goal is FIX IT RIGHT THE

FIRST TIME for the satisfaction of every customer. You

are a very important member of the team as you

diagnose and repair customer vehicles.You have max imum efficiency in diagnosis when you

have an effective, organized plan for your work.

Strategy Based Diagnostics (refer to Figure 1) provides

you with guidance as you create and follow a plan of

action for each specific diagnostic situation.

STRATEGY BASED DIAGNOSTICS CHART

Page 1449 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–77

Diagnostic Thought Process

As you follow a diagnostic plan, every box on the

Strategy Based Diagnostics chart requires you to use

the diagnostic thought process. This method of thinking

optimizes your diagnosis in the following ways:

Improves your understanding and definition of the

customer complaint

Saves time by avoiding testing and/or replacing good

parts

Allows you to look at the problem from different

perspectives

Guides you to determine what level of understanding

about system operation is needed:

–Owner’s manual level

–Service manual level

–In-depth (engineering) level

–Owner’s manual level

–Service manual level

–In-depth (engineering) level

1. Verify the Complaint

What you should do

To verify the customer complaint, you need to know the

correct (normal) operating behavior of the system and

verify that the customer complaint is a valid failure of the

system.

The following information will help you verify the

complaint:

WHAT the vehicle model/options are

WHAT aftermarket and dealer-installed accessories

exist

WHAT related system(s) operate properly

WHEN the problem occurs

WHERE the problem occurs

HOW the problem occurs

HOW LONG the condition has ex isted (and if the

system ever worked correctly)

HOW OFTEN the problem occurs

Whether the severity of the problem has increased,

decreased or stayed the same

What resources you should use

Whenever possible, you should use the following

resources to assist you in verifying the complaint:

Service manual Theory or Circuit Description

sections

Service manual “System Performance Check”

Owner manual operational description

Technician ex perience

Identical vehicle for comparisonCircuit testing tools

Vehicle road tests

Complaint check sheet

Contact with the customer

2. Perform Preliminary Checks

NOTE: An estimated 10 percent of successful vehicle

repairs are diagnosed with this step!

What you should do

You perform preliminary checks for several reasons:

To detect if the cause of the complaint is VISUALLY

OBVIOUS

To identify parts of the system that work correctly

To accumulate enough data to correctly and

accurately search for a ISUZU Service Bulletin on

ISUZU Web site.

The initial checks may vary depending on the

complex ity of the system and may include the following

actions:

Operate the suspect system

Make a visual inspection of harness routing and

accessible/visible power and ground circuits

Check for blown fuses

Make a visual inspection for separated connectors

Make a visual inspection of connectors (includes

checking terminals for damage and tightness)

Check for any DTCs stored by the on-board

computers

Sense unusual noises, smells, vibrations or

mov ements

Investigate the vehicle service history (call other

dealerships, if appropriate)

What resources you should use

Whenever appropriate, you should use the following

resources for assistance in performing preliminary

checks:

Tech II or other technical equipment for viewing DTCs

Service manual information:

–Component locations

–Harness routing

–Wiring schematics

–Procedures for viewing DTCs

Dealership service history file

Vehicle road test

Identical vehicle or system for comparison

Page 1450 of 4264

6E–78 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

3. Check Bulletins and

Troubleshooting Hints

NOTE: As estimated 30 percent of successful vehicle

repairs are diagnosed with this step!

What you should do

You should have enough information gained from

preliminary checks to accurately search for a bulletin

and other related service information. Some service

manual sections provide troubleshooting hints that

match symptoms with specific complaints.

What resources you should use

You should use the following resources for assistance in

checking for bulletins and troubleshooting hints:

Printed bulletins

Access ISUZU Bulletin Web site.

Videotapes

Service manual

4. Perform Service Manual

Diagnostic Checks

What you should do

The “System Checks” in most service manual sections

and in most cells of section 8A (electrical) provide you

with:

A systematic approach to narrowing down the

possible causes of a system fault

Direction to specific diagnostic procedures in the

service manual

Assistance to identify what systems work correctly

What resources you should use

Whenever possible, you should use the following

resources to perform service manual checks:

Service manual

Technical equipment (for viewing DTCs and

analyzing data)

Digital multimeter and circuit testing tools

Other tools as needed

5a and 5b. Perform Service Manual

Diagnostic Procedures

NOTE: An estimated 40 percent of successful vehicle

repairs are diagnosed with these steps!

What you should do

When directed by service manual diagnostic checks,

you must then carefully and accurately perform the

steps of diagnostic procedures to locate the fault relatedto the customer complaint.

What resources you should use

Whenever appropriate, you should use the following

resources to perform service manual diagnostic

procedures:

Service manual

Technical equipment (for analyzing diagnostic data)

Digital multimeter and circuit testing tools

Essential and special tools

5c. Technician Self Diagnoses

When there is no DTC stored and no matching

symptom for the condition identified in the service

manual, you must begin with a thorough understanding

of how the system(s) operates. Efficient use of the

service manual combined with you ex perience and a

good process of elimination will result in accurate

diagnosis of the condition.

What you should do

Step 1: Identify and understand the suspect

circuit(s)

Having completed steps 1 through 4 of the Strategy

Based Diagnostics chart, you should have enough

information to identify the system(s) or sub-system(s)

involved. Using the service manual, you should

determine and investigate the following circuit

characteristics:

Electrical:

–How is the circuit powered (power distribution

charts and/or fuse block details)?

–How is the circuit grounded (ground distribution

charts)?

–How is the circuit controlled or sensed (theory of

operation):

–If it is a switched circuit, is it normally open or

normally closed?

–Is the power switched or is the ground

switched?

–Is it a variable resistance circuit (ECT sensor

or TP sensor, for ex ample)?

–Is it a signal generating device (MAF sensor of

VSS, for example)?

–Does it rely on some mechanical/vacuum

device to operate?

Physical:

–Where are the circuit components (component

locators and wire harness routing diagrams):

–Are there areas where wires could be chafed

or pinched (brackets or frames)?

–Are there areas subjected to ex treme

temperatures?

Page 1451 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–79

–Are there areas subjected to vibration or

movement (engine, transmission or

suspension)?

–Are there areas ex posed to moisture, road salt

or other corrosives (battery acid, oil or other

fluids)?

–Are there common mounting areas with other

systems/components?

–Have previous repairs been performed to wiring,

connectors, components or mounting areas

(causing pinched wires between panels and

drivetrain or suspension components without

causing and immediate problem)?

–Does the vehicle have aftermarket or dealer-

installed equipment (radios, telephone, etc.)

Step 2: Isolate the problem

At this point, you should have a good idea of what could

cause the present condition, as well as could not cause

the condition. Actions to take include the following:

Divide (and separate, where possible) the system or

circuit into smaller sections

Confine the problem to a smaller area of the vehicle

(start with main harness connections while removing

panels and trim as necessary in order to eliminate

large vehicle sections from further investigation)

For two or more circuits that do not share a common

power or ground, concentrate on areas where

harnesses are routed together or connectors are

shared (refer to the following hints)

Hints

Though the symptoms may vary, basic electrical failures

are generally caused by:

Loose connections:

–Open/high resistance in terminals, splices,

connectors or grounds

Incorrect connector/harness routing (usually in new

vehicles or after a repair has been made):

–Open/high resistance in terminals, splices,

connectors of grounds

Corrosion and wire damage:

–Open/high resistance in terminals, splices,

connectors of grounds

Component failure:

–Opens/short and high resistance in relays,

modules, switches or loads

Aftermarket equipment affecting normal operation of

other systems

You may isolate circuits by:

Unplugging connectors or removing a fuse to

separate one part of the circuit from another part

Operating shared circuits and eliminating those that

function normally from the suspect circuit

If only one component fails to operate, begin testingat the component

If a number of components do no operate, begin tests

at the area of commonality (such as power sources,

ground circuits, switches or major connectors)

What resources you should use

Whenever appropriate, you should use the following

resources to assist in the diagnostic process:

Service manual

Technical equipment (for data analysis)

Ex perience

Technical Assistance

Circuit testing tools

5d. Intermittent Diagnosis

By definition, an intermittent problem is one that does

not occur continuously and will occur when certain

conditions are met. All these conditions, however, may

not be obvious or currently known. Generally,

intermittents are caused by:

Faulty electrical connections and wiring

Malfunctioning components (such as sticking relays,

solenoids, etc.)

EMI/RFI (Electromagnetic/radio frequency

interference)

Aftermarket equipment

Intermittent diagnosis requires careful analysis of

suspected systems to help prevent replacing good

parts. This may involve using creativity and ingenuity to

interpret customer complaints and simulating all

ex ternal and internal system conditions to duplicate the

problem.

What you should do

Step 1: A cquire information

A thorough and comprehensive customer check sheet

is critical to intermittent problem diagnosis. You should

require this, since it will dictate the diagnostic starting

point. The vehicle service history file is another

source for accumulating information about the

complaint.

Step 2: A nalyze the intermittent problem

Analyze the customer check sheet and service history

file to determine conditions relevant to the suspect

system(s).

Using service manual information, you must identify,

trace and locate all electrical circuits related to the

malfunctioning system(s). If there is more than one

system failure, you should identify, trace and locate

areas of commonality shared by the suspect circuits.

Page 1452 of 4264

6E–80 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

Step 3: Simulate the symptom and isolate the

problem

Simulate the symptom and isolate the system by

reproducing all possible conditions suggested in Step 1

while monitoring suspected circuits/components/

systems to isolate the problem symptom. Begin with the

most logical circuit/component.

Isolate the circuit by dividing the suspect system into

simpler circuits. Nex t, confine the problem into a smaller

area of the system. Begin at the most logical point (or

point of easiest access) and thoroughly check the

isolated circuit for the fault, using basic circuit tests.

Hints

You can isolate a circuit by:

Unplugging connectors or removing a fuse to

separate one part of the circuit from another

If only component fails to operate, begin testing the

component

If a number of components do not operate, begin test

at areas of commonality (such as power sources,

ground circuits, switches, main connectors or major

components)

Substitute a known good part from the parts

department or the vehicle system

Try the suspect part in a known good vehicle

See Symptom Simulation Tests on the nex t page for

problem simulation procedures. Refer to service manual

sections 6E and 8A for information about intermittent

diagnosis. Follow procedures for basic circuit testing in

service manual section 8A.

What resources you should use

Whenever appropriate, you should use the following

resources to assist in the diagnostic process:

Service manual

Bulletins

Digital multimeter (with a MIN/MAX feature)

Tech II and Tech II upload function

Circuit testing tools (including connector kits/

harnesses and jumper wires)

Ex perience

Intermittent problem solving simulation methods

Customer complaint check sheet

Symptom Simulation Tests

1. Vibration

This method is useful when the customer complaint

analysis indicates that the problem occurs when the

vehicle/system undergoes some form of vibration.

For connectors and wire harness, slightly shake

vertically and horizontally. Inspect the connector joint

and body for damage. Also, tapping lightly along a

suspected circuit may be helpful.For parts and sensors, apply slight vibration to the part

with a light tap of the finger while monitoring the system

for a malfunction.

2. Heat

This method is important when the complaint suggests

that the problem occurs in a heated environment. Apply

moderate heat to the component with a hair drier or

similar tool while monitoring the system for a

malfunction.

CA UTION: Care must be take to avoid overheating

the component.

3. Water and Moisture

This method may be used when the complaint suggests

that the malfunction occurs on a rainy day or under

conditions of high humidity. In this case, apply water in a

light spray on the vehicle to duplicate the problem.

CA UTION: Care must be take to avoid directly

exposing electrical connections to water.

4. Electrical loads

This method involves turning systems ON (such as the

blower, lights or rear window defogger) to create a load

on the vehicle electrical system at the same time you

are monitoring the suspect circuit/component.

5e. Vehicle Operates as Designed

This condition refers to instances where a system

operating as designed is perceived to be unsatisfactory

or undesirable. In general, this is due to:

A lack of understanding by the customer

A conflict between customer ex pectations and

vehicle design intent

A system performance that is unacceptable to the

customer

What you should do

You can verify that a system is operating as designed

by:

Reviewing service manual functional/diagnostic

checks

Ex amining bulletins and other service information for

supplementary information

Compare system operation to an identical vehicle

If the condition is due to a customer misunderstanding

or a conflict between customer ex pectation and system

operation, you should ex plain the system operation to

the customer.

If the complaint is due to a case of unsatisfactory

system performance, you should contact Technical

Assistance for the latest information.

What resources you should use

Whenever possible, you should use the following

resources to facilitate the diagnostic process:

Page 1453 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–81

Vehicle service information (service manual, etc.)

ISUZU field support

Ex perience

Identical vehicle or system for comparison

6. Re-examine the complaint

When you do not successfully find/isolate the problem

after ex ecuting a diagnostic path, you should re-

ex amine the complaint.

What you should do

In this case, you will need to backtrack and review

information accumulated from step 1 through 4 of

Strategy Based Diagnostics. You also should repeat any

procedures that require additional attention.

A previous path may be eliminated from consideration

only if you are certain that all steps were ex ecuted as

directed. You must then select another diagnostic path

(step 5a, 5b, 5c or 5d). If all possible options have been

ex plored, you may call or seek ISUZU field support.

What resources you should use

Whenever possible, you should use the following

resources to facilitate the diagnostic process:

Service manual

Accumulated information form a previous diagnostic

path

Service information and publications

ISUZU field support

7. Repair and Verify Fix

What you should do

After you have located the cause of the problem, you

must ex ecute a repair by following recommended

service manual procedures.

When the repair is completed, you should verify the fix

by performing the system checks under the conditions

listed in the customer complaint.

If applicable, you should carry out preventive measures

to avoid a repeat complaint.

What resources you should use

Whenever possible, you should use the following

resources to facilitate the repair process:

Electrical repair procedures

Service manual information and publications

Page 1454 of 4264

6E–82 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

GENERAL SERVICE INFORMATION

Serviceability Issues

Non-OEM Parts

All of the OBD diagnostics have been calibrated to run

with OEM parts. Accordingly, if commercially sold

sensor or switch is installed, it makes a wrong diagnosis

and turns on the check engine lamp.

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into the

control system if they are improperly installed. This may

cause a false sensor reading and turn on the check

engine lamp.

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the check

engine lamp to turn on if the vehicle is not maintained

properly. Restricted oil filters, fuel filters, and crankcase

deposits due to lack of oil changes or improper oil

viscosity can trigger actual vehicle faults that were not

previously monitored prior to OBD. Poor vehicle

maintenance can not be classified as a “non-vehicle

fault”, but with the sensitivity of OBD diagnostics,

vehicle maintenance schedules must be more closely

followed.

Related System Faults

Many of the OBD system diagnostics will not run if the

ECM detects a fault on a related system or component.

Visual/Physical Engine Compartment

Inspection

Perform a careful visual and physical engine

compartment inspection when performing any

diagnostic procedure or diagnosing the cause of an

emission test failure. This can often lead to repairing a

problem without further steps. Use the following

guidelines when performing a visual/physical

inspection:

Inspect all vacuum hoses for punches, cuts,

disconnects, and correct routing.

Inspect hoses that are difficult to see behind other

components.

Inspect all wires in the engine compartment for

proper connections, burned or chafed spots, pinched

wires, contact with sharp edges or contact with hot

exhaust manifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain

when performing diagnostic procedures could result in

an incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to

effectively use this section of the Service Manual.

ON-BOARD DIAGNOSTIC (OBD)

On-Board Diagnostic (Self Diagnosis

System) Tests

A diagnostic test is a series of steps, the result of which

is a pass or fail reported to the diagnostic ex ecutive.

When a diagnostic test reports a pass result, the

diagnostic ex ecutive records the following data:

The diagnostic test has been completed since the

last ignition cycle.

The diagnostic test has passed during the current

ignition cycle.

The fault identified by the diagnostic test is not

currently active.

When a diagnostic test reports a fail result, the

diagnostic ex ecutive records the following data:

The diagnostic test has been completed since the

last ignition cycle.

The fault identified by the diagnostic test is currently

active.

The fault has been active during this ignition cycle.

The operating conditions at the time of the failure.

The Diagnostic Executive

The Diagnostic Executive is a unique segment of

software which is designed to coordinate and prioritize

the diagnostic procedures as well as define the protocol

for recording and displaying their results. The main

responsibilities of the Diagnostic Ex ecutive are listed as

follow s:

Commanding the check engine lamp on and off

DTC logging and clearing

Current status information on each diagnostic

Diagnostic Information

The diagnostic charts and functional checks are

designed to locate a faulty circuit or component through

a process of logical decisions. The charts are prepared

with the requirement that the vehicle functioned

correctly at the time of assembly and that there are not

multiple faults present.

There is a continuous self-diagnosis on certain control

functions. This diagnostic capability is complemented

by the diagnostic procedures contained in this manual.

The language of communicating the source of the

malfunction is a system of diagnostic trouble codes.

When a malfunction is detected by the control module, a

diagnostic trouble code is set and the check engine

lamp is illuminated.

Check Engine Lamp

The check engine lamp looks the same as the check

engine lamp you are already familiar with, the “Check

Engine” lamp.

Basically, the check engine lamp is turned on when the

Page 1455 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–83

ECM detects a DTC that will impact the vehicle

emissions.

When the check engine lamp remains “ON” while the

engine is running, or when a malfunction is

suspected due to a driveability or emissions problem,

a Powertrain On-Board Diagnostic (OBD) System

Check must be performed. The procedures for these

checks are given in On-Board Diagnostic (OBD)

System Check. These checks will ex pose faults

which may not be detected if other diagnostics are

performed first.

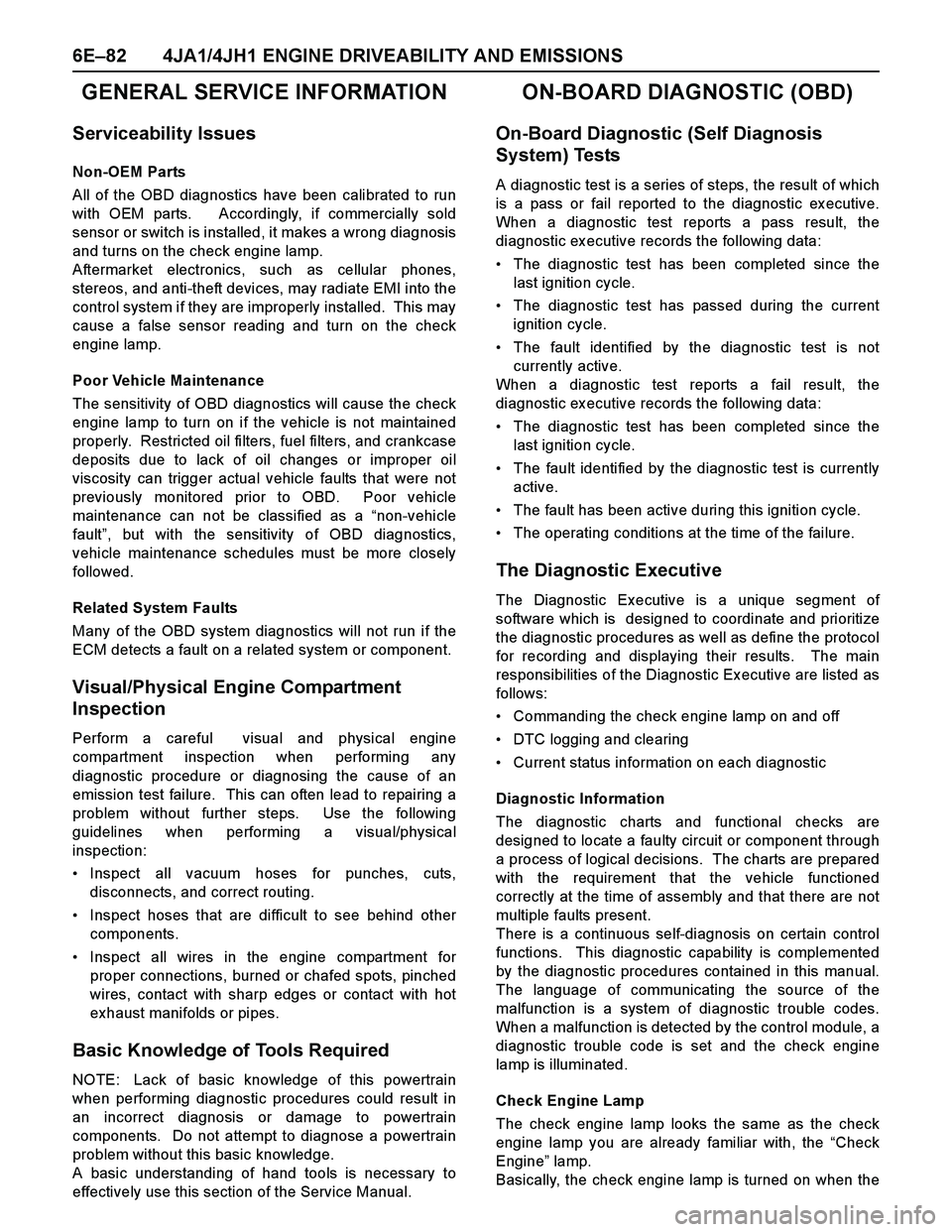

Data Link Connector (DLC)

The provision for communication with the contorl

module is the Data Link Connector (DLC). It is located

behind the lower front instrument panel. The DLC is

used to connect to a Tech 2. Some common uses of the

Tech 2 are listed below:

Identifying stored Diagnostic Trouble Codes (DTCs).

Clearing DTCs.

Reading serial data.

Verifying Vehicle Repair

Verification of vehicle repair will be more

comprehensive for vehicles with OBD system

diagnostic. Following a repair, the technician should

perform the following steps:

1. Review and record the Fail Records for the DTC

which has been diagnosed.

2. Clear DTC(s).

3. Operate the vehicle within conditions noted in the

Fail Records.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.

Following these steps is very important in verifying

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

Reading Flash Diagnostic Trouble Codes

The provision for communicating with the Engine

Control Module (ECM) is the Data Link Connector

(DLC). The DLC is located in the front console box . It is

used in the assembly plant to receive information in

checking that the engine is operating properly before it

leaves the plant.

The diagnostic trouble code(s) (DTCs) stored in the

ECM’s memory can be read either through a hand-held

diagnostic scanner plugged into the DLC or by counting

the number of flashes of the check engine lamp when

the diagnostic test terminal of the DLC is grounded. The

DLC terminal “6” (diagnostic request) is pulled “Low”

(grounded) by jumping to DLC terminal “4 or 5”, which is

a ground wire.

This will signal the ECM that you want to “flash” DTC(s),

if any are present. Once terminals “4 or 5” and “6” have

been connected, the ignition switch must be moved to

the “ON” position, with the engine not running.

The check engine lamp will indicate a DTC three times if

a DTC is present. If more than one DTC has been

stored in the ECM’s memory, the DTC(s) will be output

from the lowest to the highest, with each DTC being

displayed three times.

The DTC display will continue as long as the DLC is

shorted.

Reading Diagnostic Trouble Codes Using a

Tech 2

The procedure for reading diagnostic trouble code(s) is

to used a diagnostic Tech 2. When reading DTC(s),

follow instructions supplied by Tech 2 manufacturer.

For the 1998 model year, Isuzu dealer service

departments will continue to use Tech 2.

Clearing Diagnostic Trouble Codes

To clear Diagnostic Trouble Codes (DTCs), use the

Te c h 2 “clear DTCs” or “clear information” function.

When clearing DTCs follow instructions supplied by the

Tech 2 manufacturer.

History DTC

History DTC can be candeled after 40 cycle driving with

no defect. Or history code can be deleted by Tech 2

“Clear DTCs” function.

Page 1471 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–99

SERVICE PROGRAMMING SYSTEM (SPS)

The procedure to program the control unit by using the

Service Programming System (SPS) software contained

in TIS2000 is ex plained below.

NOTE:

If the Engine Control Module (ECM) was

programmed, the Immobilizer System must be

linked to the ECM: Refer to section 11

“Immobilizer System-ECM replacement” for the

ECM/Immobilizer linking procedure.

Should Tech2 display "SPS Procedure was not

successful", engine will not start, but no DTCs

are present, low battery voltage or poor electrical

connections should be the primary suspects.

Perform the SPS procedure again after rectifying

the fault/s.IMPORTANT:

Perform the following checks before attempting to

program the control unit:

The Tech2 PCMCIA card is programmed with The

latest software release.

The latest release of TIS2000 is loaded on the PC.

The vehicle battery is fully charged.

The control unit to be programmed is connected

to the vehicle.

1. Preparations of TIS 2000

1. Connect Tech 2 to P/C.

2. Check to see if Hardware Key is plugged into Port.

3. Activate TIS 2000 by P/C.

4. On the activating screen of TIS2000, choose

“Service Programming System”

5. On the screen of “Diagnostic Tester and Processing

Program Selection”, choose the one that will comply

with the following.

Tech-2 in use

New programming by the ex isting module or new

programming by the replaced/new module.

Fix ing position of the control unit.6. Upon completion of the selection, push the button of

“Nex t”.