ISUZU TFS SERIES 1997 Owner's Manual

TFS SERIES 1997

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57182/w960_57182-0.png

ISUZU TFS SERIES 1997 Owner's Manual

Page 76 of 1600

FRONT WHEEL DRIVE 4C1-13

Important Operations - Removal

1. Assembly of hub and disc, back plate, knuckle, knuckle

arm, and lower end.

Before removal, jack up the front of vehicle and support the

frame with jack stands.

2. Propeller Shaft

Apply the setting marks.

5. Front Drive Axle Assembly

(1) Put the lifting jack under the center part of the front.

(2) Remove four bolts fixing axle case mounting brackets to the

frame.

Note :

Be careful not to damage birfield joints or double off-set

joints when supporting axle shaft assembly.

(3) Lower the front axle assembly and roll it out toward the front

of the vehicle.

Take care not to damage the birfield joints or the double off-

set joints.

Page 77 of 1600

4C1-14 FRONT WHEEL DRIVE

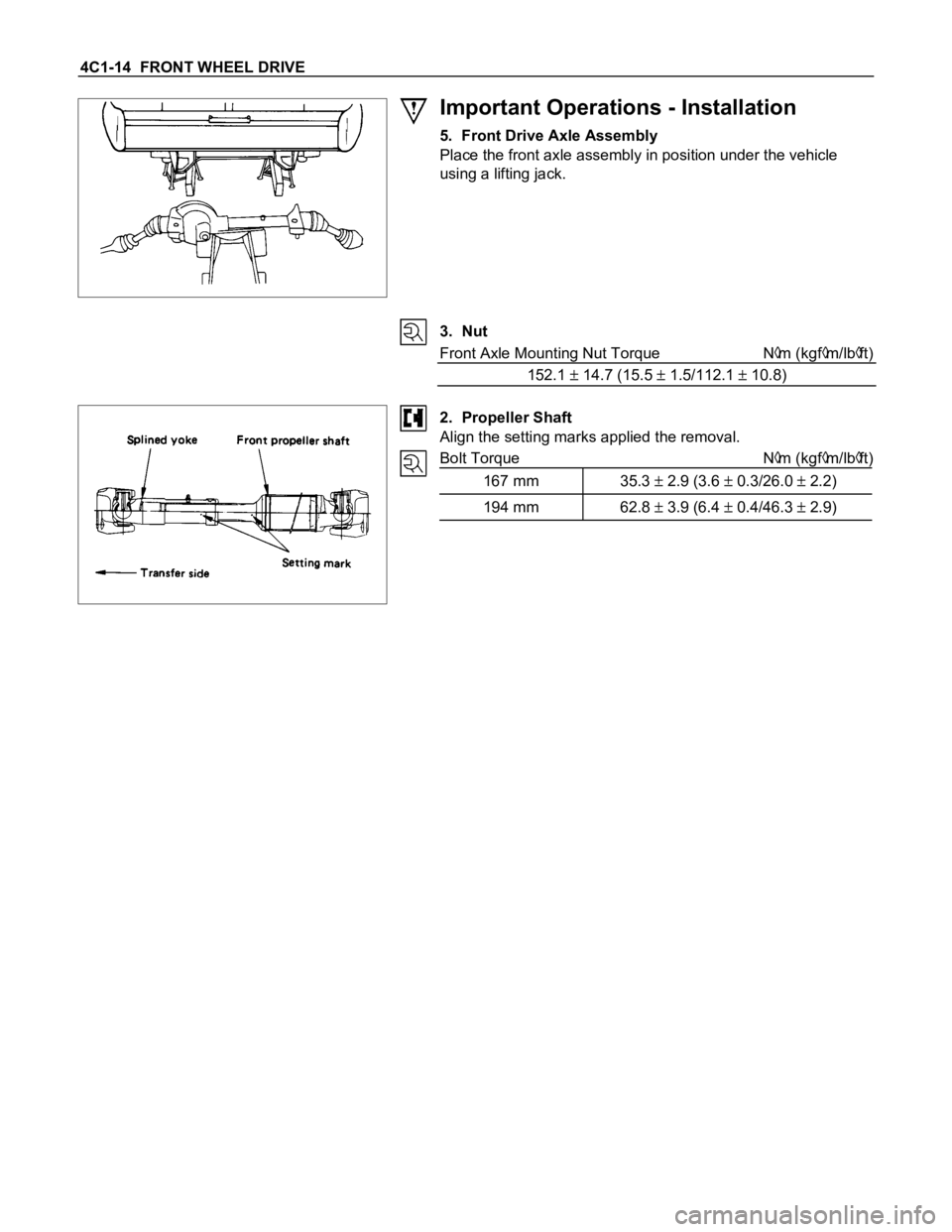

Important Operations - Installation

5. Front Drive Axle Assembly

Place the front axle assembly in position under the vehicle

using a lifting jack.

3. Nut

Front Axle Mounting Nut Torque N

m (kgfm/lbft)

152.1

14.7 (15.5 1.5/112.1 10.8)

2. Propeller Shaft

Align the setting marks applied the removal.

Bolt Torque N

m (kgfm/lbft)

167 mm 35.3

2.9 (3.6 0.3/26.0 2.2)

194 mm 62.8 3.9 (6.4 0.4/46.3 2.9)

Page 78 of 1600

FRONT WHEEL DRIVE 4C1-15

DISASSEMBLY

Disassembly Steps

1. Band

2. Bellows

3. Circlip

4. BJ shaft assembly

5. Ball

6. Snap ring

7. Ball retainer

8. Ball guide

9. Band

10. Bellows

11. Dust seal12. BJ shaft

13. Bolt

14. DOJ case assembly

15. Snap ring

16. Bearing

17. Snap ring

18. O-ring

19. Oil seal

20. Bracket

21. DOJ case

22. Axle case and differential

Page 79 of 1600

4C1-16 FRONT WHEEL DRIVE

Important Operations

1. Band

Raise the hooked end of the band with a screwdriver or

equivalent.

3. Circlip

Pry off with a screwdriver or equivalent.

5. Ball

Remove the six balls with a screwdriver or equivalent.

Rotate the case half a pitch to align the ball guide on the case

with the projected portion of the ball retainer, then slide the

case toward the bellows. The case can not be removed in the

reverse direction.

6. Snap Ring

Remove the snap ring fastening the ball retainer to the center

shaft.

Page 80 of 1600

FRONT WHEEL DRIVE 4C1-17

8. Band

Raise the hooked end of the band with a screwdriver or

equivalent.

Page 81 of 1600

4C1-18 FRONT WHEEL DRIVE

INSPECTION AND REPAIR

Make all necessary adjustments, repairs, and part replacements if wear, damage, or other problems are discovered

during inspection.

BJ assembly

DOJ case, ball, ball guide, ball retainer

Bellows

Bearing

Dust seal, oil seal

Visual Check

Inspect the following parts for wear, damage, or other

abnormal conditions.

Page 82 of 1600

FRONT WHEEL DRIVE 4C1-19

REASSEMBLY

Reassembly Steps

1. Axle case and differential

2. DOJ case

3. Bracket

4. Oil seal

5. O-ring

6. Snap ring

7. Bearing

8. Snap ring

9. DOJ case assembly

10. Bolt

11. BJ shaft12. Dust seal

13. Bellows

14. Band

15. Ball guide

16. Ball retainer

17. Snap ring

18. Ball

19. BJ shaft assembly

20. Circlip

21. Bellows

22. Band

Page 83 of 1600

4C1-20 FRONT WHEEL DRIVE

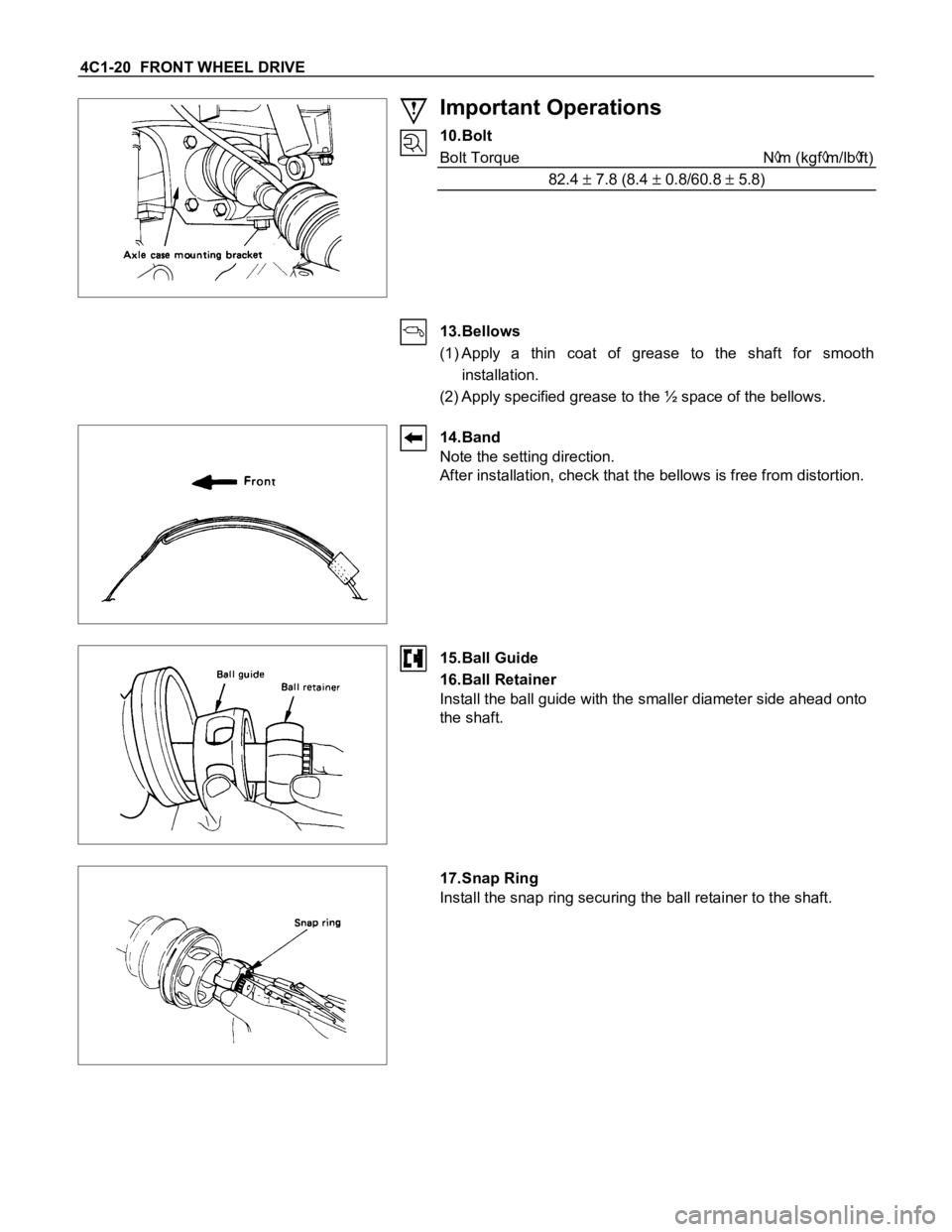

Important Operations

10.Bolt

Bolt Torque N

m (kgfm/lbft)

82.4

7.8 (8.4 0.8/60.8 5.8)

13.Bellows

(1) Apply a thin coat of grease to the shaft for smooth

installation.

(2) Apply specified grease to the ½ space of the bellows.

14.Band

Note the setting direction.

After installation, check that the bellows is free from distortion.

15.Ball Guide

16.Ball Retainer

Install the ball guide with the smaller diameter side ahead onto

the shaft.

17.Snap Ring

Install the snap ring securing the ball retainer to the shaft.

Page 84 of 1600

FRONT WHEEL DRIVE 4C1-21

18.Ball

Bring the ball guide of the cage into alignment with the

projected portion of the ring on the ball retainer, then turn the

cage ½ pitch. Align the track on the ball retainer with the

window in the cage and install the six balls into position.

19.BJ Shaft Assembly

Apply specified grease to the half of the space of the DOJ case

(Approx. 50g (1.8 oz)).

20.Circlip

Install the circlip so that open ends are positioned away from

the ball groove.

21.Bellows

(1) Before installation, insert the appropriate amount of

specified grease into the DOJ case.

(2) Adjust the air pressure within the bellows by inserting a

screwdriver or equivalent, so that it equals atmospheric

pressure.

22.Band

After installation, check that the bellows is free from distortion.

Page 85 of 1600

4C1-22 FRONT WHEEL DRIVE

DIFFERENTIAL

DISASSEMBLY

MAJOR COMPONENTS

Disassembly Steps

1. Bolt

2. Differential assembly

3. Axle case

4. Bolt

5. Bearing cap

6. Diff. cage assembly

7. Side bearing outer race

8. Side bearing

9. Adjust shims

10. Flange nut

11. Flange12. Dust cover

13. Pinion gear

14. Inner bearing

15. Adjust shim

16. Collapsible spacer

17. Inner bearing outer race

18. Oil seal

19. Outer bearing

20. Outer bearing outer race

21. Diff. carrier