wheel ISUZU TFS SERIES 1997 Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 116 of 1600

FRONT WHEEL DRIVE 4C1-53

Preload Adjustment

Tighten the hub nut at 29.4 Nm (3 kgfm / 21.716 lb.ft), then

loosen the nut to the full.

Tighten the hub nut at the value given below, using a spring

scale on the wheel pin.

Bearing Preload kg(lb)

New bearing and New oil seal 2 -2.5 (4.4 - 5.5)

Used bearing and New oil seal 1.2 - 1.8 (2.68 - 4.0)

If the measured bearing preload is outside the specifications,

adjust it by loosening or tightening the bearing nut.

6. Lock Washer

Turn the side with larger diameter of the tapered bore to the

vehicle outer side, and attach the washer.

If the bolt holes in the lock plate are not aligned with the

corresponding holes in the nut, reverse the lock plate.

If the bolt holes are still out of alignment, turn in the nut just

enough to obtain alignment,. Screw is to be fastened tightly so

its head may come lower than the surface of the washer.

8. Snap ring, shims

Adjust the clearance between the collar and the snap ring.

Clearance mm(in)

0 - 0.3 (0 - 0.01)

Adjust shims available

mm(in)

0.2, 0.3, 0.5, 1.0

(0.008, 0.011, 0.020, 0.039)

10.bolt

Torque N

m (kgfm/lbft)

10 - 14 (1.0 - 1.4 / 7 - 10)

Page 117 of 1600

4C1-54 FRONT WHEEL DRIVE

FRONT HUB AND DISC (Automatic Locking Hub)

DISASSEMBLY

Disassembly Steps

1. Bolt

2. Hub cap

3. Housing assembly

4. Snap ring and shim

5. Drive clutch assembly

6. Inner cam

7. Lock washer8. Hub nut

9. Hub and disc assembly

10. Outer bearing and outer race

11. Oil seal

12. Inner bearing and outer race

13. Bolt

14. Wheel pin

Page 118 of 1600

FRONT WHEEL DRIVE 4C1-55

Important Operations

1. Bolt

Shift the transfer lever to the “2H” position and move the

vehicle forward and rearward about one meter.

Remove the 14 mm hex bolts.

8. Hub Nut

Wrench : 5-8840-2117-0

(J-36827)

Refer to Section 5 “Brake” for disc brake

caliper removal procedure9. Hub and Disc Assembly

Before disassembly, remove the disc brake caliper assembly

and hang it on the frame with wires.

10.Outer Bearing and Outer Race

12.Inner Bearing and Outer Race

(1) Remove the outer bearing from the hub with fingers. The

inner bearing will remain in the hub and may be removed

after prying out the inner bearing lip seal assembly.

(2) Remove the outer race by driving out the race from the hub

with a brass drift inserted behind the race in the notches in

the hubs.

If necessary, replace the wheel pin in the following manner.

13.Bolt

(1) Apply a scribe mark to disc to hub.

(2) Clamp the hub and disc assembly in a vise using protective

pads and remove the 6 disc to hub retaining bolts.

Page 119 of 1600

4C1-56 FRONT WHEEL DRIVE

14.Wheel Pin

Place pins hub on a suitable work surface and remove the

wheel studs, as required, using a hammer.

Page 120 of 1600

FRONT WHEEL DRIVE 4C1-57

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear, damage or any other abnormal conditions are found

through inspection.

For inspection and servicing of disc caliper, and relative parts, refer to Section 5 “Service Brakes”.

Hub

Hub bearing, oil seal

Knuckle spindle

Disc

Caliper

Automatic locking hubs

Visual Check

Check the following parts for wear, damage or other abnormal

conditions.

Inside Diameter of Housing

mm(in)

Standard Limit

65.04 (2.61) 65.24 (2.568)

Inspect flange surface A and B for excessive wear.

Drive Clutch Section Dimensions “L”

mm(in)

Standard Limit

8.2 (0.323) 7.8 (0.37)

Holdout Ring Axial Play of the Drive

Clutch Assembly

mm(in)

Standard Limit

0.3 (0.012) or less 0.4 (0.016)

Page 121 of 1600

4C1-58 FRONT WHEEL DRIVE

Outside Diameter of the Drive Clutch

Assembly

mm(in)

Standard Limit

64.75 (2.55) 64.55 (2.54)

Page 122 of 1600

FRONT WHEEL DRIVE 4C1-59

REASSEMBLY

Reassembly Steps

1. Wheel pin

2. Bolt

3. Inner bearing and outer race

4. Outer bearing and outer race

5. Oil seal

6. Hub and disc assembly

7. Hub nut

8. Lock washer

9. Inner cam

10. Drive clutch assembly

11. Snap ring and shim

12. Housing assembly

13. Hub cap

14. Washer and bolt

Page 123 of 1600

4C1-60 FRONT WHEEL DRIVE

Important Operations

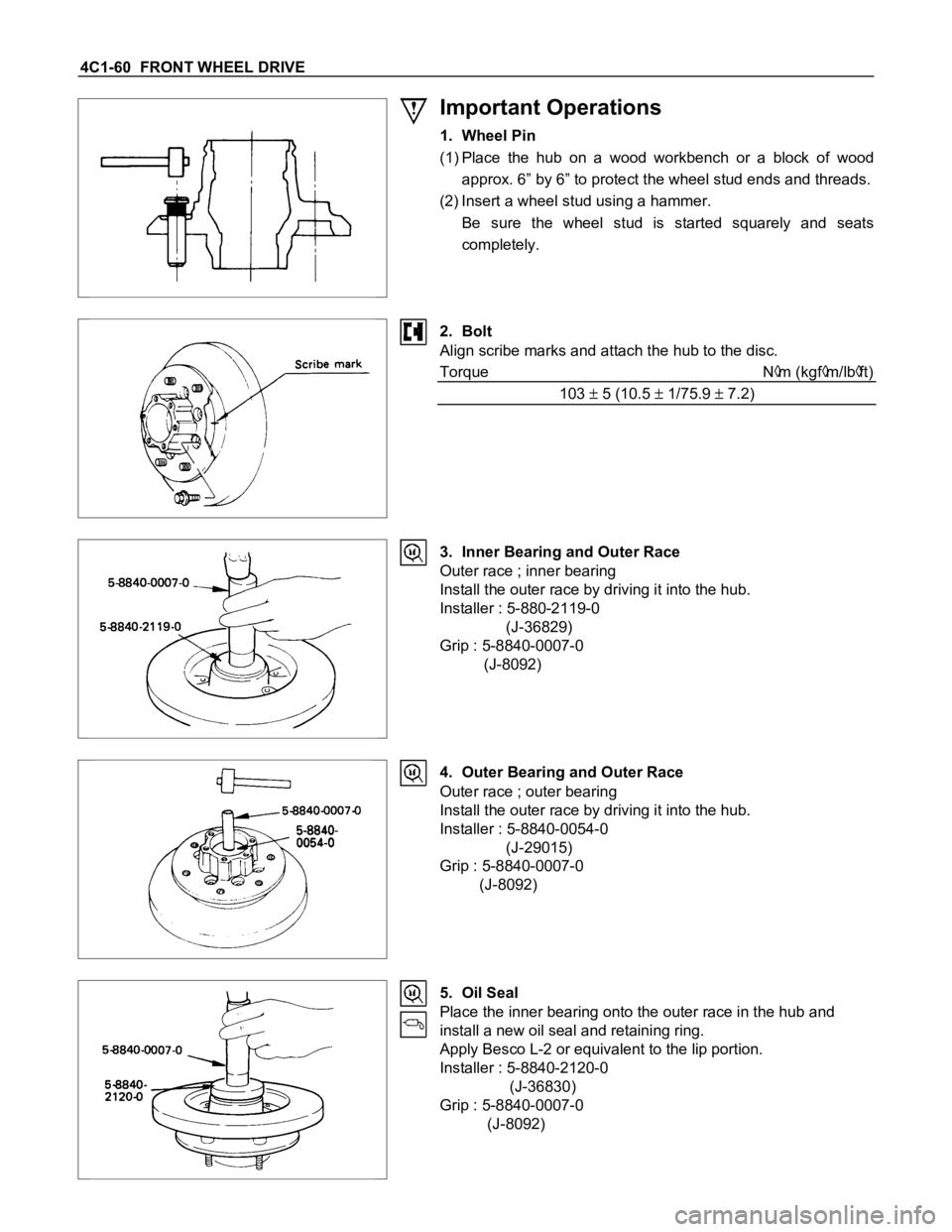

1. Wheel Pin

(1) Place the hub on a wood workbench or a block of wood

approx. 6” by 6” to protect the wheel stud ends and threads.

(2) Insert a wheel stud using a hammer.

Be sure the wheel stud is started squarely and seats

completely.

2. Bolt

Align scribe marks and attach the hub to the disc.

Torque N

m (kgfm/lbft)

103

5 (10.5 1/75.9 7.2)

3. Inner Bearing and Outer Race

Outer race ; inner bearing

Install the outer race by driving it into the hub.

Installer : 5-880-2119-0

(J-36829)

Grip : 5-8840-0007-0

(J-8092)

4. Outer Bearing and Outer Race

Outer race ; outer bearing

Install the outer race by driving it into the hub.

Installer : 5-8840-0054-0

(J-29015)

Grip : 5-8840-0007-0

(J-8092)

5. Oil Seal

Place the inner bearing onto the outer race in the hub and

install a new oil seal and retaining ring.

Apply Besco L-2 or equivalent to the lip portion.

Installer : 5-8840-2120-0

(J-36830)

Grip : 5-8840-0007-0

(J-8092)

Page 124 of 1600

FRONT WHEEL DRIVE 4C1-61

6. Hub and Disc Assembly

(1) Apply grease in the hub.

(2) Apply Besco L-2 or equivalent to the outer and inner

bearing.

g(oz)

Hub 35 (1.23)

Outer bearing 10 (0.35)

Inner bearing 15 (0.53)

7. Hub Nut

Turn the place where there is a chamfer in the tapped hole to

the outer side, and attach the nut.

Wrench : 5-8840-2117-0

(J-36827)

Preload Adjustment

Tighten the hub nut at 29.4 N

m (3 kgfm / 21.716 lbft), then

loosen the nut to the full.

Tighten the hub nut at the value given below, using a spring

scale on the wheel pin.

Bearing Preload kg(lb)

New bearing and New oil seal 2 -2.5 (4.4 - 5.5)

Used bearing and New oil seal 1.2 - 1.8 (2.6 - 4.0)

If the measured bearing preload is outside the specifications,

adjust it by loosening or tightening the bearing nut.

8. Lock Washer

Turn the side with larger diameter of the tapered bore to the

vehicle outer side, and attach the washer.

If the bolt holes in the lock plate are not aligned with the

corresponding holes in the nut, reverse the lock plate.

If the bolt holes are still out of alignment, turn in the nut just

enough to obtain alignment,. Screw is to be fastened tightly so

its head may come lower than the surface of the washer.

Page 125 of 1600

4C1-62 FRONT WHEEL DRIVE

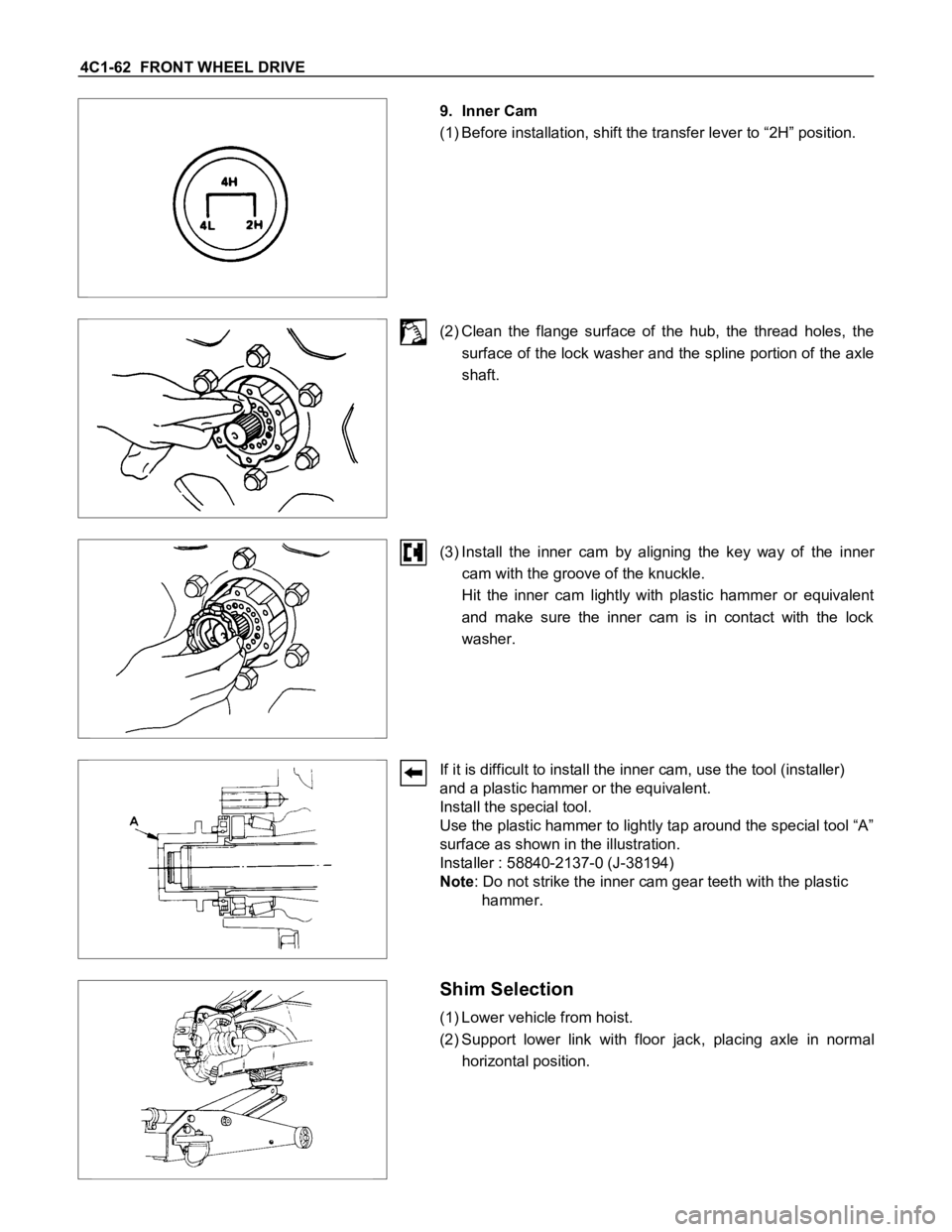

9. Inner Cam

(1) Before installation, shift the transfer lever to “2H” position.

(2) Clean the flange surface of the hub, the thread holes, the

surface of the lock washer and the spline portion of the axle

shaft.

(3) Install the inner cam by aligning the key way of the inner

cam with the groove of the knuckle.

Hit the inner cam lightly with plastic hammer or equivalent

and make sure the inner cam is in contact with the lock

washer.

If it is difficult to install the inner cam, use the tool (installer)

and a plastic hammer or the equivalent.

Install the special tool.

Use the plastic hammer to lightly tap around the special tool “A”

surface as shown in the illustration.

Installer : 58840-2137-0 (J-38194)

Note: Do not strike the inner cam gear teeth with the plastic

hammer.

Shim Selection

(1) Lower vehicle from hoist.

(2) Support lower link with floor jack, placing axle in normal

horizontal position.