brake ISUZU TFS SERIES 1997 Service Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 352 of 1600

5-24 BRAKES

ADJUSTMENT PROCEDURE OF SERVICE AND PARKING BRAKE

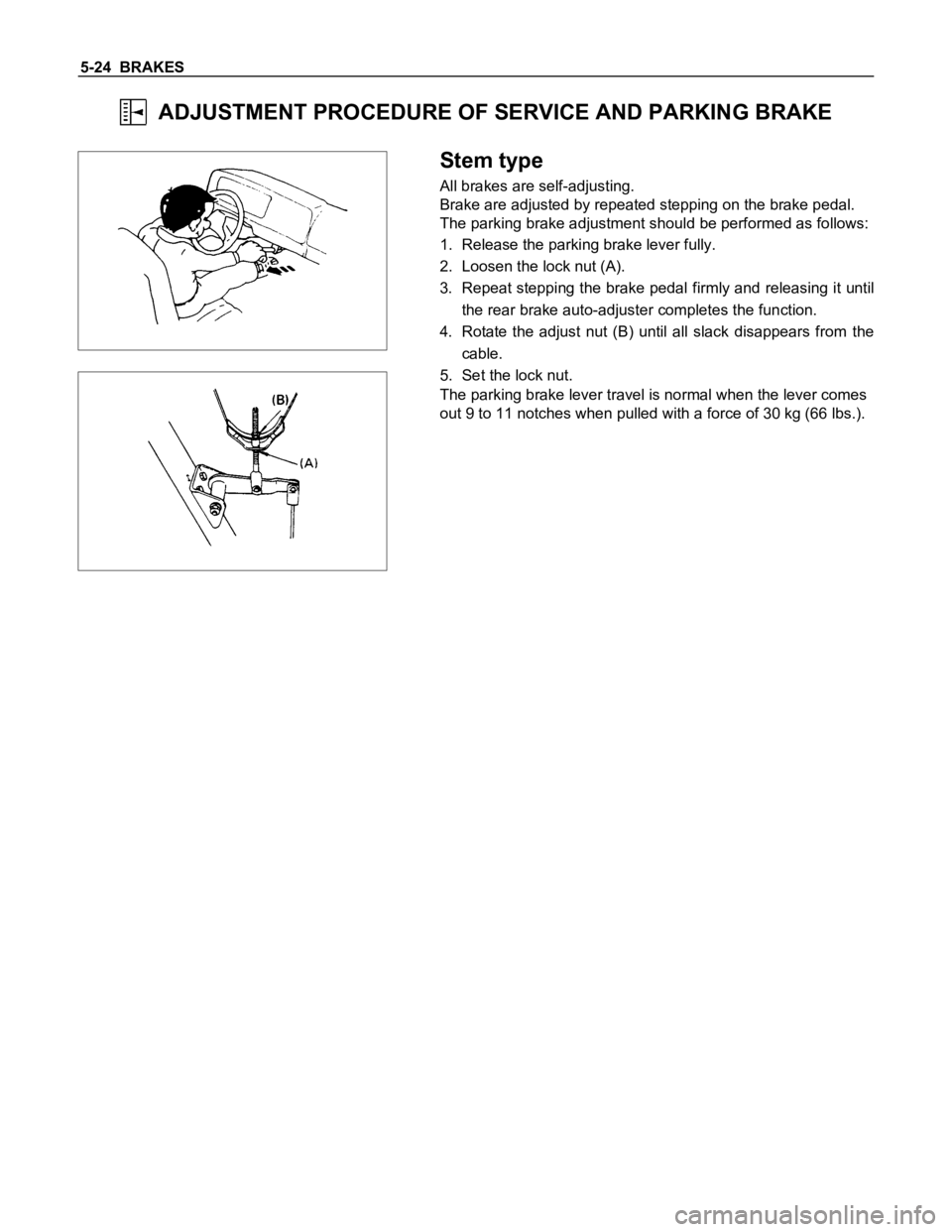

Stem type

All brakes are self-adjusting.

Brake are adjusted by repeated stepping on the brake pedal.

The parking brake adjustment should be performed as follows:

1. Release the parking brake lever fully.

2. Loosen the lock nut (A).

3. Repeat stepping the brake pedal firmly and releasing it until

the rear brake auto-adjuster completes the function.

4. Rotate the adjust nut (B) until all slack disappears from the

cable.

5. Set the lock nut.

The parking brake lever travel is normal when the lever comes

out 9 to 11 notches when pulled with a force of 30 kg (66 lbs.).

Page 353 of 1600

BRAKES 5-25

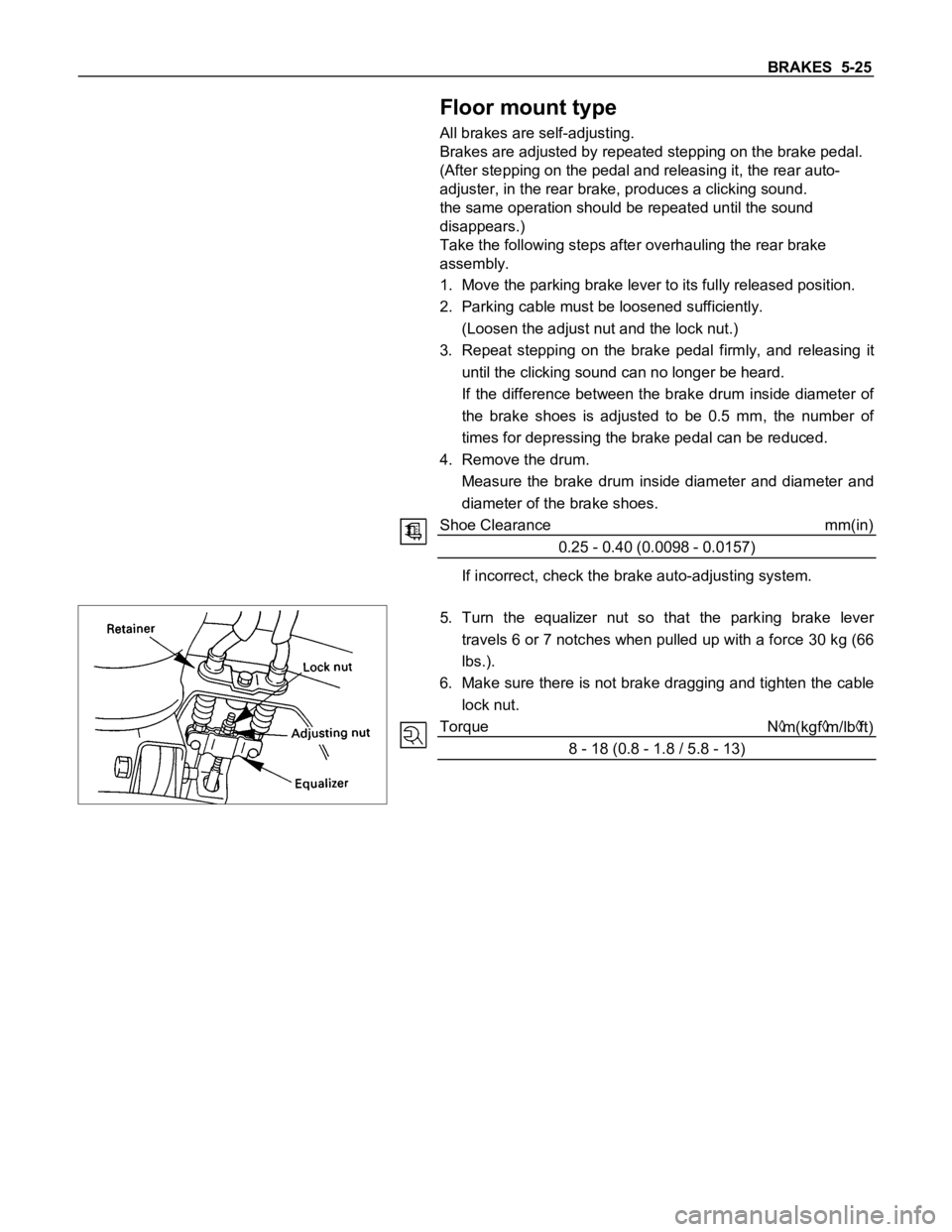

Floor mount type

All brakes are self-adjusting.

Brakes are adjusted by repeated stepping on the brake pedal.

(After stepping on the pedal and releasing it, the rear auto-

adjuster, in the rear brake, produces a clicking sound.

the same operation should be repeated until the sound

disappears.)

Take the following steps after overhauling the rear brake

assembly.

1. Move the parking brake lever to its fully released position.

2. Parking cable must be loosened sufficiently.

(Loosen the adjust nut and the lock nut.)

3. Repeat stepping on the brake pedal firmly, and releasing it

until the clicking sound can no longer be heard.

If the difference between the brake drum inside diameter of

the brake shoes is adjusted to be 0.5 mm, the number of

times for depressing the brake pedal can be reduced.

4. Remove the drum.

Measure the brake drum inside diameter and diameter and

diameter of the brake shoes.

Shoe Clearance mm(in)

0.25 - 0.40 (0.0098 - 0.0157)

If incorrect, check the brake auto-adjusting system.

5. Turn the equalizer nut so that the parking brake lever

travels 6 or 7 notches when pulled up with a force 30 kg (66

lbs.).

6. Make sure there is not brake dragging and tighten the cable

lock nut.

Torque N

m(kgfm/lbft)

8 - 18 (0.8 - 1.8 / 5.8 - 13)

Page 354 of 1600

5-26 BRAKES

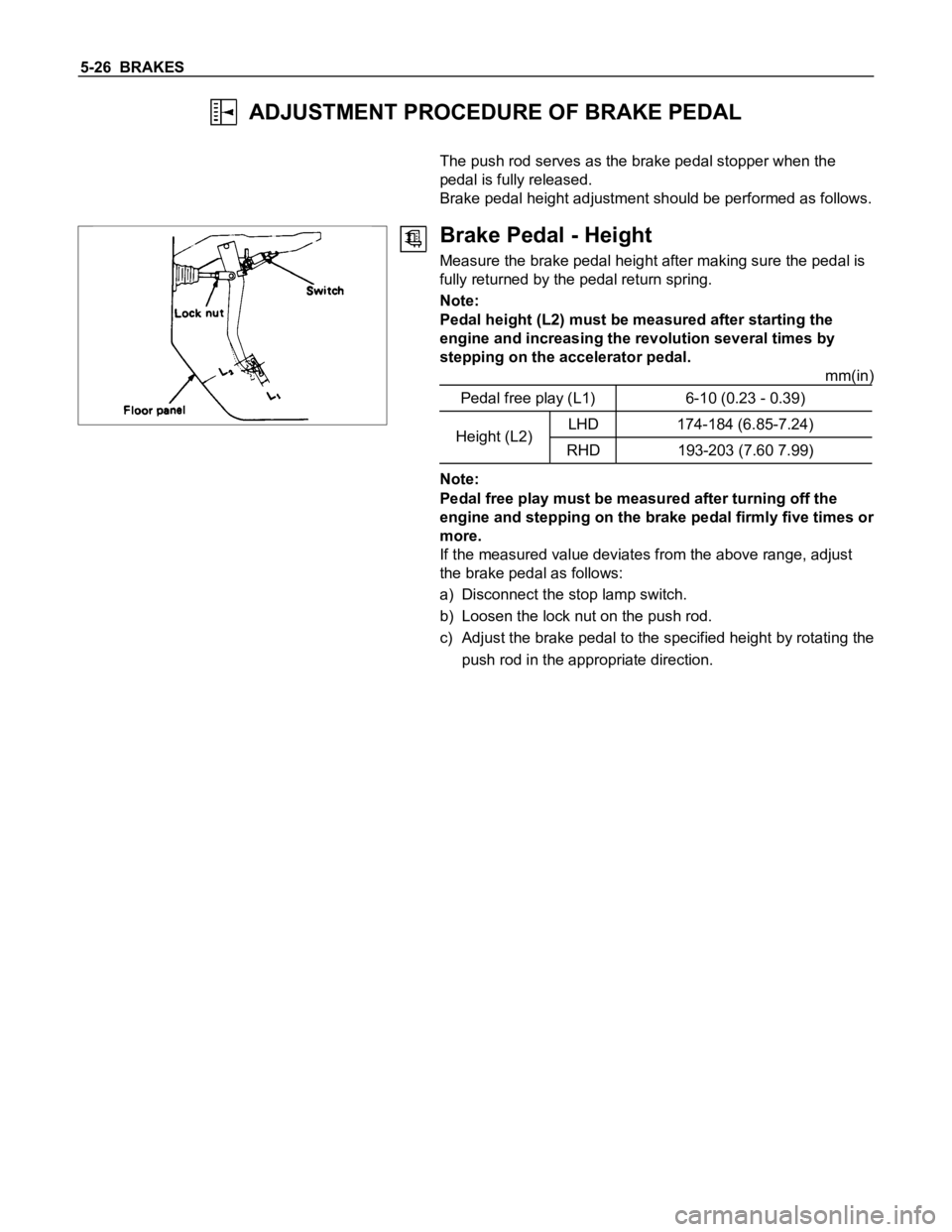

ADJUSTMENT PROCEDURE OF BRAKE PEDAL

The push rod serves as the brake pedal stopper when the

pedal is fully released.

Brake pedal height adjustment should be performed as follows.

Brake Pedal - Height

Measure the brake pedal height after making sure the pedal is

fully returned by the pedal return spring.

Note:

Pedal height (L2) must be measured after starting the

engine and increasing the revolution several times by

stepping on the accelerator pedal.

mm(in)

Pedal free play (L1) 6-10 (0.23 - 0.39)

LHD 174-184 (6.85-7.24)

RHD 193-203 (7.60 7.99)Height (L2)

Note:

Pedal free play must be measured after turning off the

engine and stepping on the brake pedal firmly five times or

more.

If the measured value deviates from the above range, adjust

the brake pedal as follows:

a) Disconnect the stop lamp switch.

b) Loosen the lock nut on the push rod.

c) Adjust the brake pedal to the specified height by rotating the

push rod in the appropriate direction.

Page 355 of 1600

BRAKES 5-27

Lock Nut Torque Nm(kgfm/lbft)

15- 25 (1.5 - 2.5 / 11 - 18)

d) Install the stop lamp switch.

Note:

Pedal height (L

2) must be 95 mm (3.7 in.) or more when

applying about 50 kg (110.25 lbs.) of stepping force.

Clearance

Between the Switch Housing and the Brake Pedal (A).

mm(in)

0.5 - 1.0 (0.02 - 0.04)

Page 356 of 1600

5-28 BRAKES

FRONT BRAKE ASSEMBLY

REMOVAL AND INSTALLATION

Removal Steps

1. Brake flexible hose

2. Lock bolt

3. Pad assembly with shim

4. Clip ; pad

5. Caliper assembly

6. Support bracket

7. Front hub and disc assembly

Installation Steps

7. Front hub and disc assembly

6. Support bracket

5. Caliper assembly

4. Clip ; pad

3. Pad assembly with shim

2. Lock bolt

1. Brake flexible hose

Important Operations - Removal

1. Brake Flexible hose

Remove the bolt and gasket and disconnect the brake flexible

hose from the caliper.

After disconnecting the flexible hose, cap or tape the openings

to prevent entry of foreign material.

Page 357 of 1600

BRAKES 5-29

2. Lock Bolt

Remove the lock bolt from the caliper.

3. Pad Assembly with Shim

Rotate the caliper upward.

Mark the lining locations if they are to be reinstalled.

6. Support Bracket

Take care not to damage the flexible brake hose when

removing the support bracket.

7. Front Hub and Disc Assembly

For the removal procedure, refer to Section 4C "FRONT

WHEEL DRIVE".

Page 358 of 1600

5-30 BRAKES

Important Operations - Installation

7. Front Hub and Disc Assembly

For the installation procedure, refer to the front hub and disc

reassembly procedure in Section 4C "FRONT WHEEL DRIVE".

6. Support Bracket

Torque N

m(kgfm/lbft)

139 - 171 (14.2 - 17.4 / 103 - 126)

Set up the clip and pad before installation of the support racket.

4. Clip ; Pad

Install new parts if necessary.

2. Lock Bolt

Torque N

m(kgfm/lbft)

27 - 37 (2.8 - 3.8 / 20 - 27)

1. Brake Flexible Hose

Attach the bolt and new gasket

Torque N

m(kgfm/lbft)

29 -39 (3.0 - 4.0 / 22 - 29)

After installation, bleeding and replenishing procedure must be

performed.

Wipe the circumference of the hose clean.

Note:

Always use new gaskets.

Be sure to put the hooked edge of the flexible hose end

into the anti-rotation cavity.

Page 359 of 1600

BRAKES 5-31

REMOVAL AND INSTALLATION OF DISC PAD

Removal Steps

1. Lock Bolt

Remove the lock bolt from the caliper.

Note:

Don't remove the brake hose from caliper when replacing

pads.

2. Rotate the Caliper Upward

Remove the caliper from the support bracket and ire the caliper

to the upper link or the frame.

Note:

While caliper is removed from support bracket, never step

on the brake pedal or the piston will protrude rapidly.

3. Pad Assembly with Shim

Remove the pad assembly with the shim.

Mark the pad locations if they are to be reinstalled.

4. Clip ; Pad

Discard the used clip and install a new one.

Page 360 of 1600

5-32 BRAKES

Installation Steps

1. Clip ; Pad

2. Pad Assembly with Shim

After attaching the pad assembly with the shim to the support

bracket, position the wear indicator to the lower side of the pad.

3. Caliper Assembly

Lower the caliper into its original position.

Do not damage the flexible hose by twisting or pulling it.

4. Lock Bolt

Attach the lock bolt to the caliper.

Torque N

m(kgfm/lbft)

27 - 37 (2.8 - 3.8 / 20 - 27)

Page 361 of 1600

BRAKES 5-33

DISASSEMBLY

CALIPER ASSEMBLY

Disassembly Steps

1. Sleeve

2. Dust boot ; sleeve

3. Dust boot ; guide pin

4. Bleeder with cap

5. Dust seal ring6. Dust seal ; piston

7. Piston (with seal ring)

8. Ring seal

9. Body ; caliper