REAR AXLE 4B-13

Important Operations

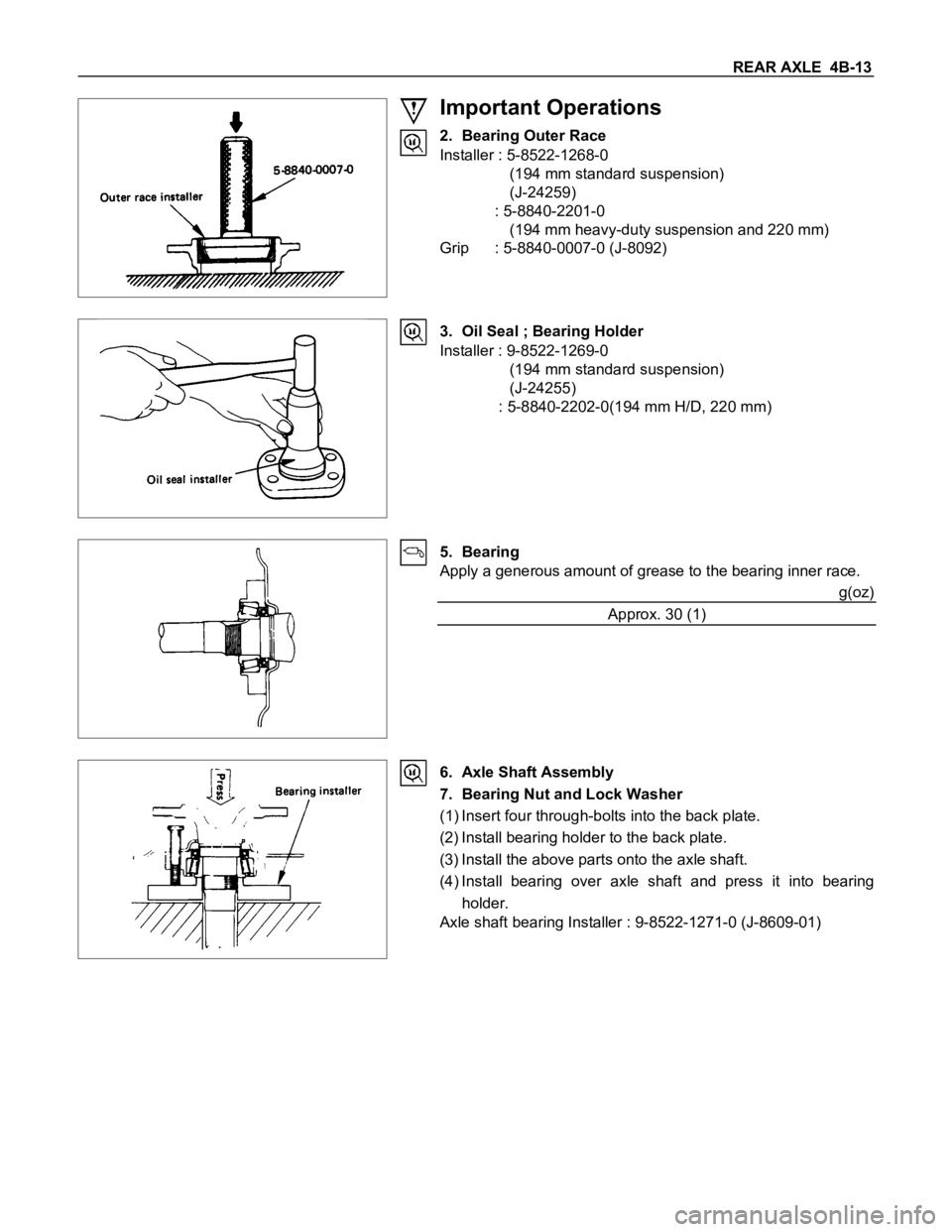

2. Bearing Outer Race

Installer : 5-8522-1268-0

(194 mm standard suspension)

(J-24259)

: 5-8840-2201-0

(194 mm heavy-duty suspension and 220 mm)

Grip : 5-8840-0007-0 (J-8092)

3. Oil Seal ; Bearing Holder

Installer : 9-8522-1269-0

(194 mm standard suspension)

(J-24255)

: 5-8840-2202-0(194 mm H/D, 220 mm)

5. Bearing

Apply a generous amount of grease to the bearing inner race.

g(oz)

Approx. 30 (1)

6. Axle Shaft Assembly

7. Bearing Nut and Lock Washer

(1) Insert four through-bolts into the back plate.

(2) Install bearing holder to the back plate.

(3) Install the above parts onto the axle shaft.

(4) Install bearing over axle shaft and press it into bearing

holder.

Axle shaft bearing Installer : 9-8522-1271-0 (J-8609-01)

FRONT WHEEL DRIVE 4C1-81

42 Model

1. WANDERS AND PULLS

Checkpoint Trouble Cause Countermeasure

Adjust the wheel bearing

preloadToo tight NG

SuspensionTighten or replace

Replace or adjust the inflation

Adjust the steering gear out of

adjustment or replace

Adjust the front alignment

Front or rear suspension parts

loose or broken

TireW orn or improperly inflated

Incorrect or broken

Front alignmentIncorrect

Steering linkage

Steering gear out of

adjustment

Tighten or replaceLoose or worn

OK

NG NG NG NG NG

OK OK

OK

OK

W heel bearing preload

FRONT WHEEL DRIVE 4C1-85

5. WANDERS AND PULLS

Checkpoint Trouble Cause Countermeasure

Adjust the wheel bearing

preloadToo tight NG

Tighten or replace

Replace or adjust the inflation

Adjust the steering gear out of

adjustment or replace

Adjust the front alignment

SuspensionFront or rear suspension parts

loose or broken

TabW orn or improperly inflated

Incorrect or broken

Front alignmentIncorrect

Steering gear out of

adjustment

Tighten or replaceSteering linkageLoose or worn

NG NG NG NG NG

OK OK OK

OK

OK

W heel bearing preload

BRAKES 5-23

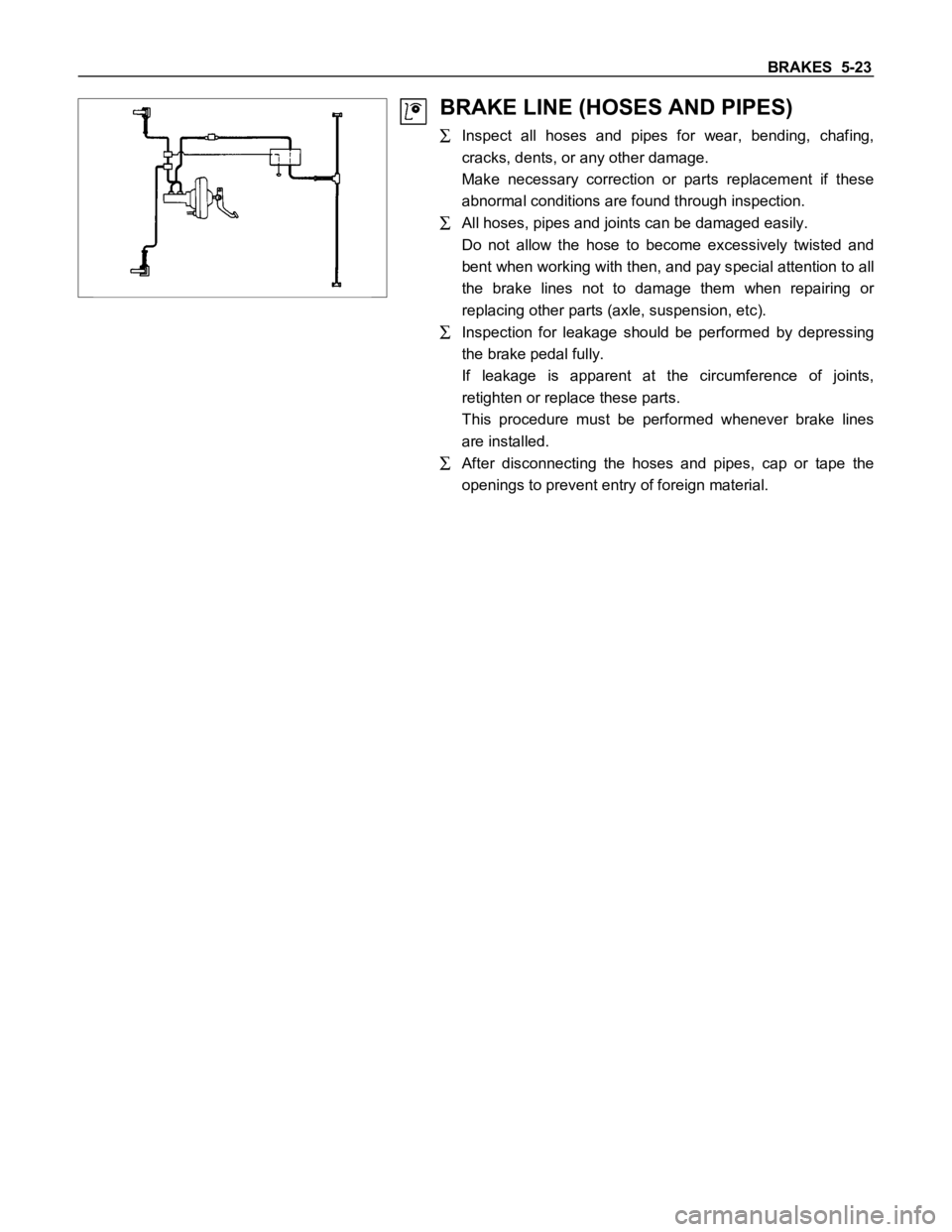

BRAKE LINE (HOSES AND PIPES)

Inspect all hoses and pipes for wear, bending, chafing,

cracks, dents, or any other damage.

Make necessary correction or parts replacement if these

abnormal conditions are found through inspection.

All hoses, pipes and joints can be damaged easily.

Do not allow the hose to become excessively twisted and

bent when working with then, and pay special attention to all

the brake lines not to damage them when repairing or

replacing other parts (axle, suspension, etc).

Inspection for leakage should be performed by depressing

the brake pedal fully.

If leakage is apparent at the circumference of joints,

retighten or replace these parts.

This procedure must be performed whenever brake lines

are installed.

After disconnecting the hoses and pipes, cap or tape the

openings to prevent entry of foreign material.