oil ISUZU TFS SERIES 1997 Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 143 of 1600

4C1-80 FRONT WHEEL DRIVE

TROUBLESHOOTING

Refer to this Section to quickly diagnose and repair front axle problems. Each troubleshooting chart has three

headings arranged from left to right.

(1) Checkpoint (2) Trouble Cause (3) Countermeasure

This Section is divided into ten sub-sections:

42 Model

1. Wanders and pulls

2. Front wheel shimmy

44 Model

1. Oil leak at front axle

2. Oil leak at pinion shaft

3. Noises in front axle drive shaft joint

4. Noises in front axle

5. Wanders and pulls

6. Front wheel shimmy

7. Automatic locking free wheel hub

1) Does not lock or locks only on one side

2) Does not freewheel or freewheels only to one side

3) Noises in automatic locking free wheel hub

Propeller shaft

1. Noise

2. Vibration

Page 146 of 1600

FRONT WHEEL DRIVE 4C1-83

44 MODEL

1. OIL LEAK AT FRONT AXLE

Checkpoint Trouble Cause Countermeasure

Front axle housingRepair or replaceCracked

Replace the oil sealW orn or defective oil seal

NG NG

OKOil seal

2. OIL LEAK AT PINION SHAFT

Oil sealReplace the oil sealW orn or defective

Correct the oil levelToo much gear oil

NG NG

OKGear oil level

Pinion flangeTighten or replaceLoose or damaged NG OK

3. NOISES IN FRONT AXLE DRIVE SHAFT JOINT

Replace the drive shaft joints

and bellowsBroken or worn NGDrive shaft joints and bellows

(B.J and DOJ)

Page 147 of 1600

4C1-84 FRONT WHEEL DRIVE

4. NOISES IN FRONT AXLE

Checkpoint Trouble Cause Countermeasure

Replenish the gear oilInsufficient gear oil NG

Replace the wheel bearing

Replace the pinion shaft

bearing

Replace the ring gear pinion

gear or side gear

Replace the gear oil

W heel bearingWorn

Pinion shaft bearingWorn

W orn or chipped

W rong or poor grade gear oil

Ring gear, pinion gear or side

gear

Adjust the backlashDrive pinion to ring gear

backlashToo much or too little backlash

NG NG NG NG NG

OK OK

OK

OK

Oil level

Tighten or replaceDifferential bearingLoose or worn NG OK

Page 155 of 1600

4C1-92 FRONT WHEEL DRIVE

ITEM NO. ILLUSTRATION PART NO. PART NAME

FAL-42

5-8840-0126-0

(J-8001)Dial indicator

(for 167mm,194mm)

FAL-37

5-8840-2086-0

(J-23597-4)Disc (2 pcs. required)

(for 167mm)

FAL-43

5-8840-0128-0

(J-23597-1)Arbor

(for 167mm, 197mm)

FAL-38

5-8840-2088-0

(J-23597-8)Disc (2 pcs. required)

(for 194mm)

FAL-59

9-8522-1165-0

(J-6133-01)Pinion bearing installer

(for 4WD)

FAL-52

9-8522-1275-0

(J-24250)Pinion oil seal installer

(for 194mm)

FAL-53

5-8522-0046-0

(J-26234)Pinion oil seal installer

(for 167mm)

FAL-55

5-8840-0138-0

(J-29036)Side bearing installer

(for 167mm)

FAL-56

9-8521-1164-0

(J-24244)Side bearing installer

(for 194mm)

Page 156 of 1600

FRONT WHEEL DRIVE 4C1-93

ITEM NO. ILLUSTRATION PART NO. PART NAME

FAL-57

5-8522-0053-0

(J-29016)Outer bearing installer

(for 2WD)

FAL-58

5-8522-0054-0

(J-29015)Inner bearing installer

(for 2WD)

FAL-54

5-8522-0051-0

(J-33161)Hub oil seal installer

(for 2WD)

FAL-62

5-8840-2117-0

(J-36827) Hub nut wrench

FAL-17

5-8840-2119-0

(J-36829)Outer bearing inner race

installer (for 4WD)

FAL-19

5-8840-2120-0

(J-36830) Oil seal installer (for 4WD)

FAL-18

5-8840-0054-0

(J-29015)Outer bearing outer race

installer (for 4WD)

FAL-61

5-8840-2137-0

(J-38194) Inner cam installer

FAL-395-8840-2126-0Auto locking shim gauge

(for 4WD)

Page 350 of 1600

5-22 BRAKES

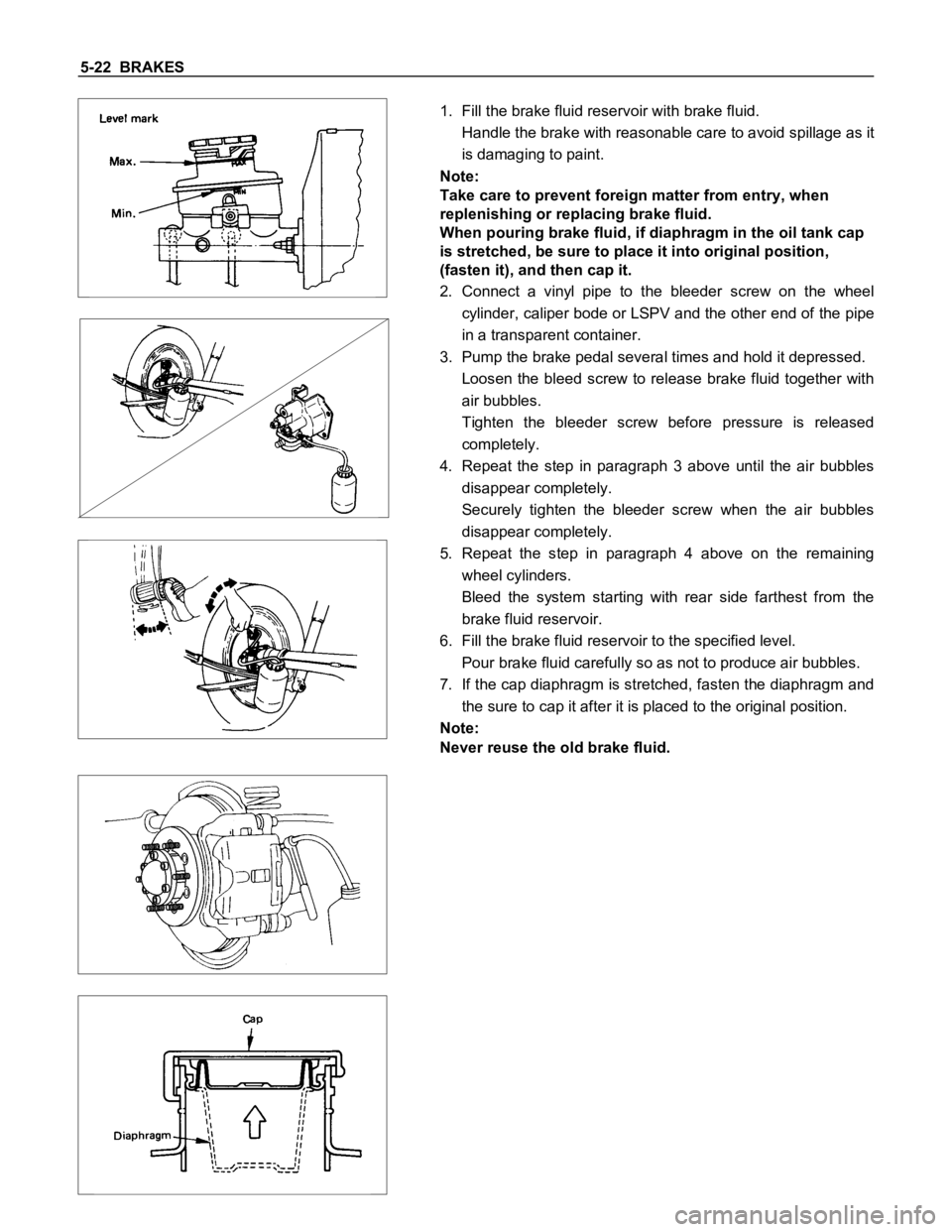

1. Fill the brake fluid reservoir with brake fluid.

Handle the brake with reasonable care to avoid spillage as it

is damaging to paint.

Note:

Take care to prevent foreign matter from entry, when

replenishing or replacing brake fluid.

When pouring brake fluid, if diaphragm in the oil tank cap

is stretched, be sure to place it into original position,

(fasten it), and then cap it.

2. Connect a vinyl pipe to the bleeder screw on the wheel

cylinder, caliper bode or LSPV and the other end of the pipe

in a transparent container.

3. Pump the brake pedal several times and hold it depressed.

Loosen the bleed screw to release brake fluid together with

air bubbles.

Tighten the bleeder screw before pressure is released

completely.

4. Repeat the step in paragraph 3 above until the air bubbles

disappear completely.

Securely tighten the bleeder screw when the air bubbles

disappear completely.

5. Repeat the step in paragraph 4 above on the remaining

wheel cylinders.

Bleed the system starting with rear side farthest from the

brake fluid reservoir.

6. Fill the brake fluid reservoir to the specified level.

Pour brake fluid carefully so as not to produce air bubbles.

7. If the cap diaphragm is stretched, fasten the diaphragm and

the sure to cap it after it is placed to the original position.

Note:

Never reuse the old brake fluid.

Page 376 of 1600

5-48 BRAKES

Important Operations

When disassembling, inspecting or reassembling the master

cylinder assembly, take care not to bring the parts into contact

with mineral oil or dust. Wash the piston cups only with brake

fluid. Do not use gasoline or other mineral-base cleaning

solvents.

5. Ring ; Snap

Remove the snap ring from the cylinder body with pushing in

the primary and secondary pistons.

6. Bolt ; Stopper

Push in the primary and secondary pistons and remove the

stopper bolt completery from the cylinder body, then remove

the primary and secondary piston assemblies.

8. Piston Assembly ; Primary and Spring

9. Piston Assembly ; Secondary and Spring

Don’t remove the spring from the piston.

Page 395 of 1600

BRAKES 5-67

TROUBLESHOOTING

Condition and Cause Correction

Poor Brake Action

Master cylinder faulty Correct or replace

Power cylinder faulty Correct or replace

Level of brake fluid in reservoir too low Replenish and bleed

Air in hydraulic circuit Bleed

Front disc brake caliper faulty Clean or replace

Rear brake wheel cylinder faulty Clean or replace

Water or oil on brake pads or linings Clean or replace

Brake pads or linings hardened Replace

Brake pads or linings in poor contact with rotor or brake drum Correct

Brake pads or linings worn Replace

Brake disc or drum rusted Grind or replace

Check valve in vacuum hose faulty Correct or replace

Brake Squeak

Brake pads or linings worn Replace

Brake pads or linings hardened Replace

Brake pads or linings in poor contact with rotor or brake drum Correct

Brake disc(s) warped, worn or damaged Grind or replace

Disc brake anti-squeak shims fatigued Replace

Front hub bearings loose or preload is incorrect Adjust or replace

Brake disc or drum rusted Grind or replace

Brake Pull

Tire inflation pressures unequal Adjust

Front wheel alignment incorrect Adjust

Water or oil on brake pads or linings Clean or replace

Brake pads or linings hardened Replace

Brake pads or linings worn excessively Replace

Brake drum or rotor worn or scored Grind or replace

Front or rear wheel cylinder or disc brake caliper malfunctioning Clean or replace

Front hub bearing preload incorrect Adjust or replace

Brake pad or lining clearances unequal Adjust or replace

Brake Drag

Parking brake maladjusted Adjust

Brake pad or lining clearance insufficient Adjust

Brake pedal free play insufficient Adjust brake pedal height or power cylinder operating rod

Piston in master cylinder sticking Clean or replace

Pistons in disc brake caliper sticking Replace piston seals

Pistons in rear brake wheel cylinders sticking Clean or replace

Brake pads sticking in caliper Clean

Return springs weakened Replace

Parking brake binding Overhaul rear brakes

Front hub bearing preload incorrect Adjust or replace

Rear brake shoes not returning Correct or replace brake back plate, check automatic adjuster and

replace as necessary

Obstructions in hydraulic circuit Clean

Rotor warped excessively Grind or replace

Rear brake drum distorted Grind or replace

Piston cups swollen Replace brake fluid and piston cups

Check valve ; vacuum hose faulty Replace

Parking cable sticking Clean or replace

Rear disc brake over adjust Adjust or overhaul rear brakes

Excessive Brake Pedal Travel

Air in hydraulic circuit Bleed hydraulic circuit

Level of brake fluid in reservoir too low Replenish brake fluid reservoir to specified level and bleed hydraulic

circuit as necessary.

Master cylinder push rod clearance excessive Adjust

Leakage in hydraulic system Correct or replace defective parts

Rear disc brake autoadjuster malfunction Overhaul rear brakes

Page 564 of 1600

7C-24 CLUTCH

Wedge Collar (6VD1)

1. Visually check the surfaces of the wedge collar making

contact with the release bearing for excessive wear and

damage.

2. Replace any exhibiting excessive wear damage.

Shift Fork (Except 6VD1)

1. Visually inspect the surfaces of the shift fork making contact

with the shift block for excessive wear and damage.

2. Remove any minor stepping or abrasion from the shift block

with an oil stone.

Replace any exhibiting excessive wear or damage.

3. Apply multi-purpose type grease (NLGI No.2 or No.3) to

area.

6VD1Shift Fork (6VD1)

1. Visually check the surfaces of the shift fork making contact

with the release bearing for excessive wear and damage.

2. Remove any minor stepping or abrasion from shift fork with

an oil stone.

Replace any exhibiting excessive wear of damage.

DRIVEN PLATE ASSEMBLY

1. Visually inspect the torsion spring

1 for looseness,

breakage, and weakening.

If any of these conditions are discovered, the driven plate

assembly must be replaced.

2. Visually inspect the facing surfaces

2 for cracking and

excessive scorching.

Visually inspect the facing surfaces for the presence of oil or

grease.

If any of these conditions are discovered, the facing must be

cleaned or replaced.

Page 565 of 1600

CLUTCH 7C-25

3. Check that the driven plate moves smoothly on the

transmission top gear shaft spline.

Minor ridges on the top gear shaft spline may be removed

with an oil stone.

Driven Plate Warpage

1. Insert the clutch pilot aligner into the driven plate splined

hub.

The clutch pilot aligner must be held perfectly horizontal.

Clutch Pilot Aligner : 5-8840-2634-0 (HEC Engine Series)

5-8525-3001-0 (J-24547) (Except HEC Engine Series)

2. Set a dial indicator to the driven plate outside

circumference.

3. Slowly turn the driven plate.

Read the dial indicator as you turn the driven plate.

If the measured value exceeds the specified limit, the driven

plate assembly and/or the facing must be replaced.

Driven Plate Warpage mm(in)

Standard Limit

0.7 (0.028) 1.0 (0.039)

Driven Plate Splined Hub Spline Wear

1. Clean the driven plate splined hub.

2. Install the driven plate to the transmission top gear shaft

spline.

3. Set a surface gauge to the driven plate outside

circumference.

4. Slowly turn the driven plate counterclockwise.

Measure the spline rotation play as you turn the driven

plate.

If the measured value exceeds the specified limit, the driven

plate assembly must be replaced.

Driven Plate Splined Hub Spline Wear mm(in)

Standard Limit

0.5 (0.020) 1.0 (0.039)