length ISUZU TFS SERIES 1997 Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 32 of 1600

4B-36 REAR AXLE

Adjustment of Clearance between

Friction Disc and Plate

1) Measuring depth of differential case

mm(in)

Standard (A-B) 80.58 (3.17)

(C) 10.58 (0.41)

2) Measuring overall length of pressure ring, friction disc and

plate assembly

Assembly pinion shaft with pressure ring, then friction

disc and plate.

Measure length between plates at both ends over V-

shape groove. (D)

3) After A, B, C and D dimensions are measured, perform

adjustment with the following procedure.

Measure disc spring :

1.75 mm (0.69 in)

2 pcs (E)

Measure thickness of plate spring

Standard dimension :

1.75 mm (0.069 in)

2 pcs (F)

4) Select a friction disc or plate so that ((A-B+C) - (D+E+F) =

0.06 to 0.20 mm (0.002 to 0.008 in.) and also the difference

in total dimension of friction disc and plate, plate spring and

disc spring (left/right side) does not exceed 0.05 mm (0.002

in.).

Thickness : 1.75, 1.85 mm

Adjusting Backlash of Side Gear in Axial

Direction

1) Measuring depth of differential case

mm(in.)

Standard (F-B) 82.03 (3.23)

(G) 12.03 (0.47)

Page 66 of 1600

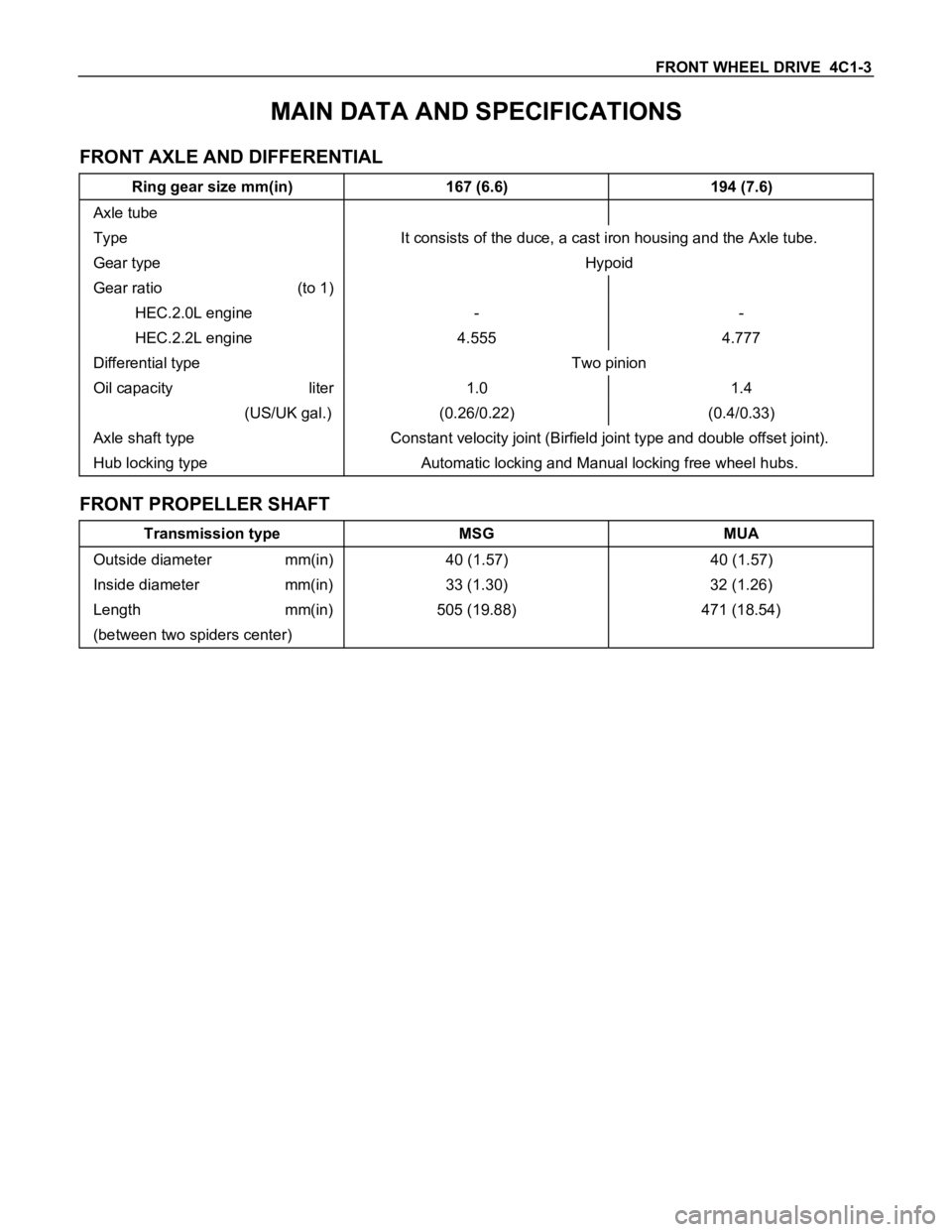

FRONT WHEEL DRIVE 4C1-3

MAIN DATA AND SPECIFICATIONS

FRONT AXLE AND DIFFERENTIAL

Ring gear size mm(in) 167 (6.6) 194 (7.6)

Axle tube

Type It consists of the duce, a cast iron housing and the Axle tube.

Gear type Hypoid

Gear ratio (to 1)

HEC.2.0L engine - -

HEC.2.2L engine 4.555 4.777

Differential type Two pinion

Oil capacity liter 1.0 1.4

(US/UK gal.) (0.26/0.22) (0.4/0.33)

Axle shaft type Constant velocity joint (Birfield joint type and double offset joint).

Hub locking type Automatic locking and Manual locking free wheel hubs.

FRONT PROPELLER SHAFT

Transmission type MSG MUA

Outside diameter mm(in) 40 (1.57) 40 (1.57)

Inside diameter mm(in) 33 (1.30) 32 (1.26)

Length mm(in) 505 (19.88) 471 (18.54)

(between two spiders center)

Page 336 of 1600

5-8 BRAKES

MAIN DATA AND SPECIFICATIONS

FRONT DISC BRAKE mm(in.)

Caliper type Pin slide

Disc outside diameter 257 (10.118)

Disc thickness 22 (0.866)

Piston diameter 60.33 (2.375)

Adjustment method Self-adjusting

REAR DRUM BRAKE mm(in.) 4 2 4 4

Type Leading and Trailing

Drum inside diameter 254(10.008) 295 (11.614)

Brake lining dimension 221 50 5 283 45 4

(Length Width Thickness) (8.71 1.97 0.20) (11.14 1.77 0.16)

Adjustment method Self-adjusting

WHEEL CYLINDER mm(in.)

Inside diameter : rear

Europe and South Africa 25.40 (1.000)

Others 22.22 (0.875)

MASTER CYLINDER mm(in.)

TypeSplit

Bore diameter 23.81 (0.938)

Piston stroke (Primary + Secondary) 19 + 12 (0.75 + 0.47)

VACUUM SERVO mm(in.)

Diaphragm diameter

Except Australia 230 (9.055)

For Australia 180 (7.087) + 205 (8.077)

Power cylinder stroke 32.5 (1.281)

PEDAL RATIO 4.04

BALANCE

Type Blend proportioning valve/Load sensing proportioning

valve

Page 368 of 1600

5-40 BRAKES

Important Operations

3. Return Spring ; Lower

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found

through inspection.

Brake drum

Back plate

Brake lining

W heel cylinder body

Piston

Piston cup

Return spring

Visual check

Inspect the following parts for wear scuffs, scratches,

corrosion, stains, deterioration, or other abnormal conditions.

Thickness of the Brake Lining

Thickness mm(in)

standard (T) Limit (t)

TFR 5.0 (0.197) 1.0 (0.039)

TFS 4.0 (0.157) 1.9 (0.039)

Inspection of the Return Spring

Free length

mm(in.)Set length

mm(in.)Set load

kg (Ibs.)

Holding spring 15.0 (0.591) 11.2 (0.441)10.01.0

(22.3

2.2)

W heel cylinder

spring37.4 (1.472) 8.0 (0.315)1.00.1

(2.2

0.2)

Page 369 of 1600

BRAKES 5-41

Free length

mm(in.)Set length

mm(in.)Set load

kg(lbs.)

Return spring :

upper

(adjust lever)124.9

(4.917)134.9

(5.311)70.7

(15.4

1.6)

Shoe return

spring : upper112.4

(4.425)121.5

(4.783)20.2

(4.4

0.4)

Shoe return

spring : lower167.2

(6.583)190.2

(7.488)28.02.8

(61.7

6.4)

Clean wheel Cylinder Parts

Always use clean brake fluid to clean wheel cylinder parts.

Note:

Do not use mineral-vase cleaning solvents such as

gasoline, kerosene, acetone, paint thinner, or carbon

tetrachloride.

Clearance Between the Wheel Cylinder

and the Piston

mm(in)

Standard Limit

0.02 - 0.1(0.001 - 0.004) 0.15(0.006)

Piston Cups

Inspect the piston cups for wear, distortion, fatigue, fatigue or

other abnormal conditions.

Measuring the Brake Drum

mm(in)

Standard Limit

Inside diameter 254(10.000) 255.5(10.059)

Run out 0.05(0.002) 0.15(0.006)

Inside diameter 295(11.614) 296.5(11.673)

Run out 0.05(0.02) 0.15(0.006)TFS

TFR

Page 465 of 1600

CAB 10-11

Important Operation - Installation

1. Weather Strip ; Rear Window Corner

Using Semedain #560 (or equivalent) adhesive, glue the

weather strip to the complete circumference of the frame,

paying close attention to the corner areas.

2. Glass ; Rear Window Corner

Apply soap and water to the rim as a lubricant.

Place the channel in a vertical position. With your hand, apply

pressure to expand the channel. Insert the window glass in the

center of the channel.

3. Glass Run

Apply Semedain #560 (or equivalent) adhesive to the entire

length of both the upper window glass and the weather strip.

Apply adhesive to both sides of the extreme ends of the lower

portion for a distance of about 50 mm.

There should be no gap between the weather strip rear window

glass channel and the channel.

6. Rear Window ; Slide

Hold the window vertically. Apply an upward pressure to the

channel and insert the rear window slide.

8. Packing ; Rear Window

Apply a fast setting adhesive agent to both sides of the window

atop and insert it into the channel.

Page 508 of 1600

CAB 10-11

Important Operation - Installation

1. Weather Strip ; Rear Window Corner

Using Semedain #560 (or equivalent) adhesive, glue the

weather strip to the complete circumference of the frame,

paying close attention to the corner areas.

2. Glass ; Rear Window Corner

Apply soap and water to the rim as a lubricant.

Place the channel in a vertical position. With your hand, apply

pressure to expand the channel. Insert the window glass in the

center of the channel.

3. Glass Run

Apply Semedain #560 (or equivalent) adhesive to the entire

length of both the upper window glass and the weather strip.

Apply adhesive to both sides of the extreme ends of the lower

portion for a distance of about 50 mm.

There should be no gap between the weather strip rear window

glass channel and the channel.

6. Rear Window ; Slide

Hold the window vertically. Apply an upward pressure to the

channel and insert the rear window slide.

8. Packing ; Rear Window

Apply a fast setting adhesive agent to both sides of the window

atop and insert it into the channel.