light ISUZU TFS SERIES 1997 Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 5 of 1600

REAR AXLE 4B-9

Important Operations

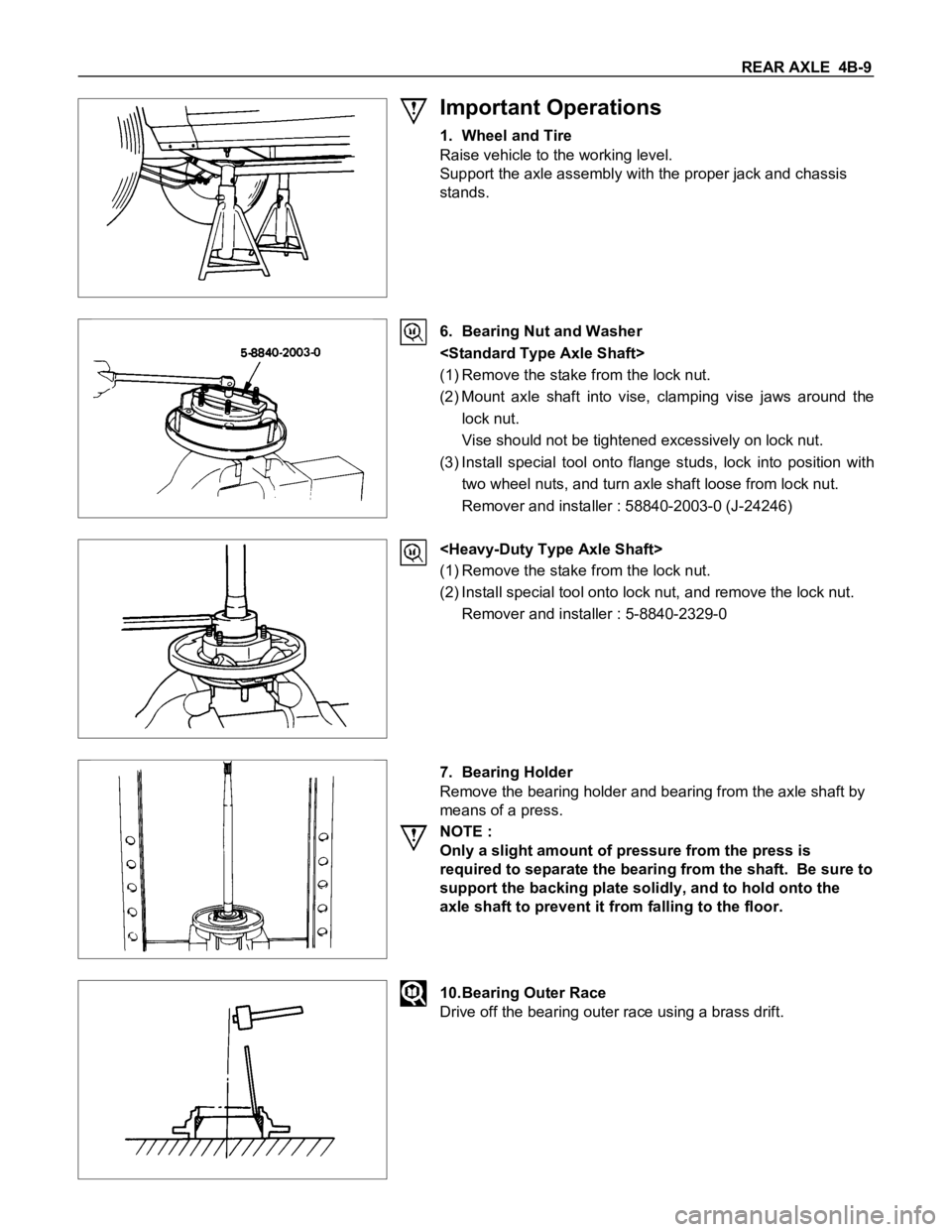

1. Wheel and Tire

Raise vehicle to the working level.

Support the axle assembly with the proper jack and chassis

stands.

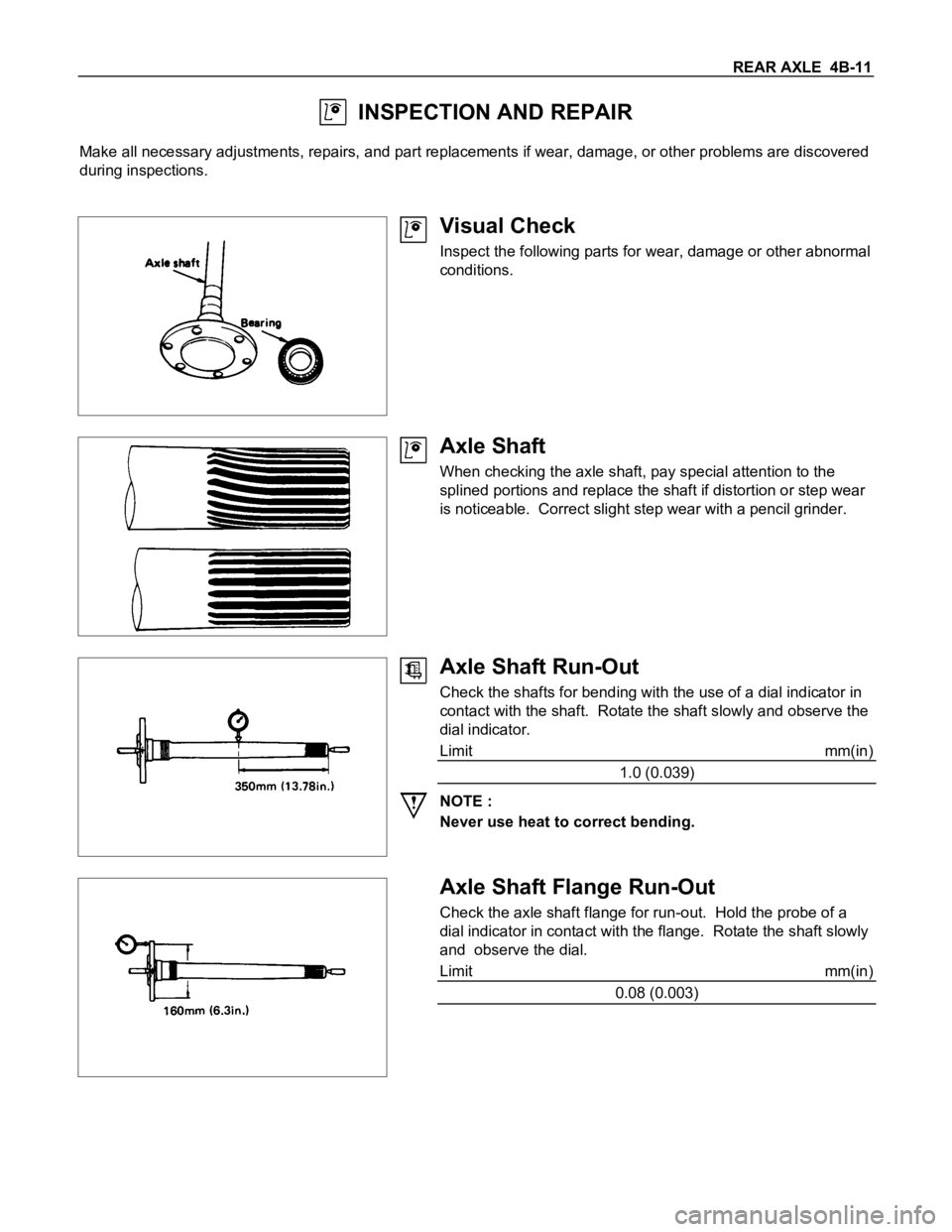

6. Bearing Nut and Washer

(1) Remove the stake from the lock nut.

(2) Mount axle shaft into vise, clamping vise jaws around the

lock nut.

Vise should not be tightened excessively on lock nut.

(3) Install special tool onto flange studs, lock into position with

two wheel nuts, and turn axle shaft loose from lock nut.

Remover and installer : 58840-2003-0 (J-24246)

(1) Remove the stake from the lock nut.

(2) Install special tool onto lock nut, and remove the lock nut.

Remover and installer : 5-8840-2329-0

7. Bearing Holder

Remove the bearing holder and bearing from the axle shaft by

means of a press.

NOTE :

Only a slight amount of pressure from the press is

required to separate the bearing from the shaft. Be sure to

support the backing plate solidly, and to hold onto the

axle shaft to prevent it from falling to the floor.

10.Bearing Outer Race

Drive off the bearing outer race using a brass drift.

Page 7 of 1600

REAR AXLE 4B-11

INSPECTION AND REPAIR

Make all necessary adjustments, repairs, and part replacements if wear, damage, or other problems are discovered

during inspections.

Visual Check

Inspect the following parts for wear, damage or other abnormal

conditions.

Axle Shaft

When checking the axle shaft, pay special attention to the

splined portions and replace the shaft if distortion or step wear

is noticeable. Correct slight step wear with a pencil grinder.

Axle Shaft Run-Out

Check the shafts for bending with the use of a dial indicator in

contact with the shaft. Rotate the shaft slowly and observe the

dial indicator.

Limit mm(in)

1.0 (0.039)

NOTE :

Never use heat to correct bending.

Axle Shaft Flange Run-Out

Check the axle shaft flange for run-out. Hold the probe of a

dial indicator in contact with the flange. Rotate the shaft slowly

and observe the dial.

Limit mm(in)

0.08 (0.003)

Page 24 of 1600

4B-28 REAR AXLE

Differential cage

Check the ring gear the side gear fitting faces and the cross pin

hole for scores or roughness. Correct as necessary. Slight

scores or roughness may be corrected with an oil stone or fine

sand paper.

Friction disc and plate assembly.

Check the parts for damage or other abnormal conditions.

Check the friction plate for distortion.

Limit mm(in) 0.07 (0.0027)

Check the friction plate for wear.

Limit (A - B) mm(in) 0.1 (0.0039)

Note : A = Non-sliding face thickness

B = Sliding face thickness

Check the friction disc for distortion.

Limit mm(in) 0.07 (0.0027)

Page 125 of 1600

4C1-62 FRONT WHEEL DRIVE

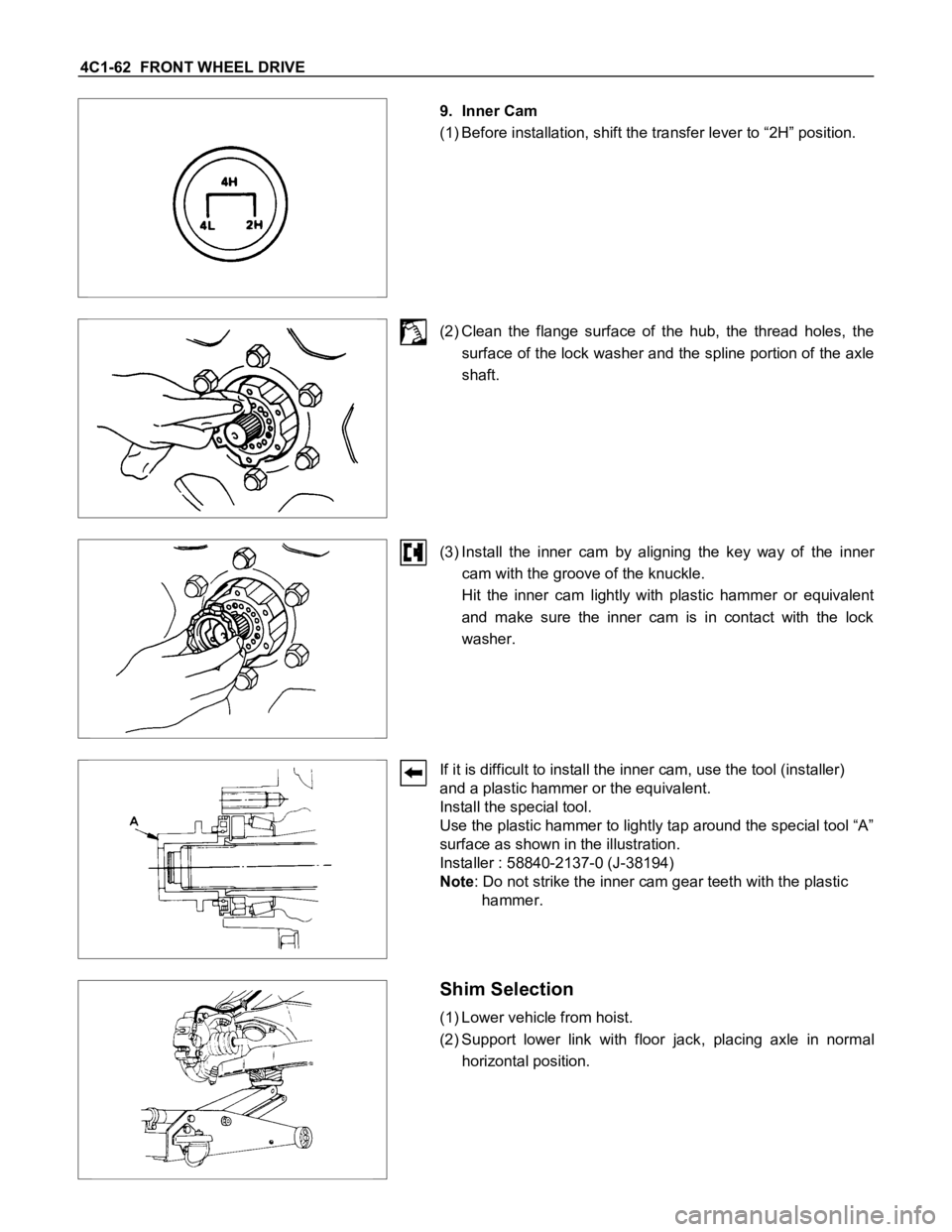

9. Inner Cam

(1) Before installation, shift the transfer lever to “2H” position.

(2) Clean the flange surface of the hub, the thread holes, the

surface of the lock washer and the spline portion of the axle

shaft.

(3) Install the inner cam by aligning the key way of the inner

cam with the groove of the knuckle.

Hit the inner cam lightly with plastic hammer or equivalent

and make sure the inner cam is in contact with the lock

washer.

If it is difficult to install the inner cam, use the tool (installer)

and a plastic hammer or the equivalent.

Install the special tool.

Use the plastic hammer to lightly tap around the special tool “A”

surface as shown in the illustration.

Installer : 58840-2137-0 (J-38194)

Note: Do not strike the inner cam gear teeth with the plastic

hammer.

Shim Selection

(1) Lower vehicle from hoist.

(2) Support lower link with floor jack, placing axle in normal

horizontal position.

Page 346 of 1600

5-18 BRAKES

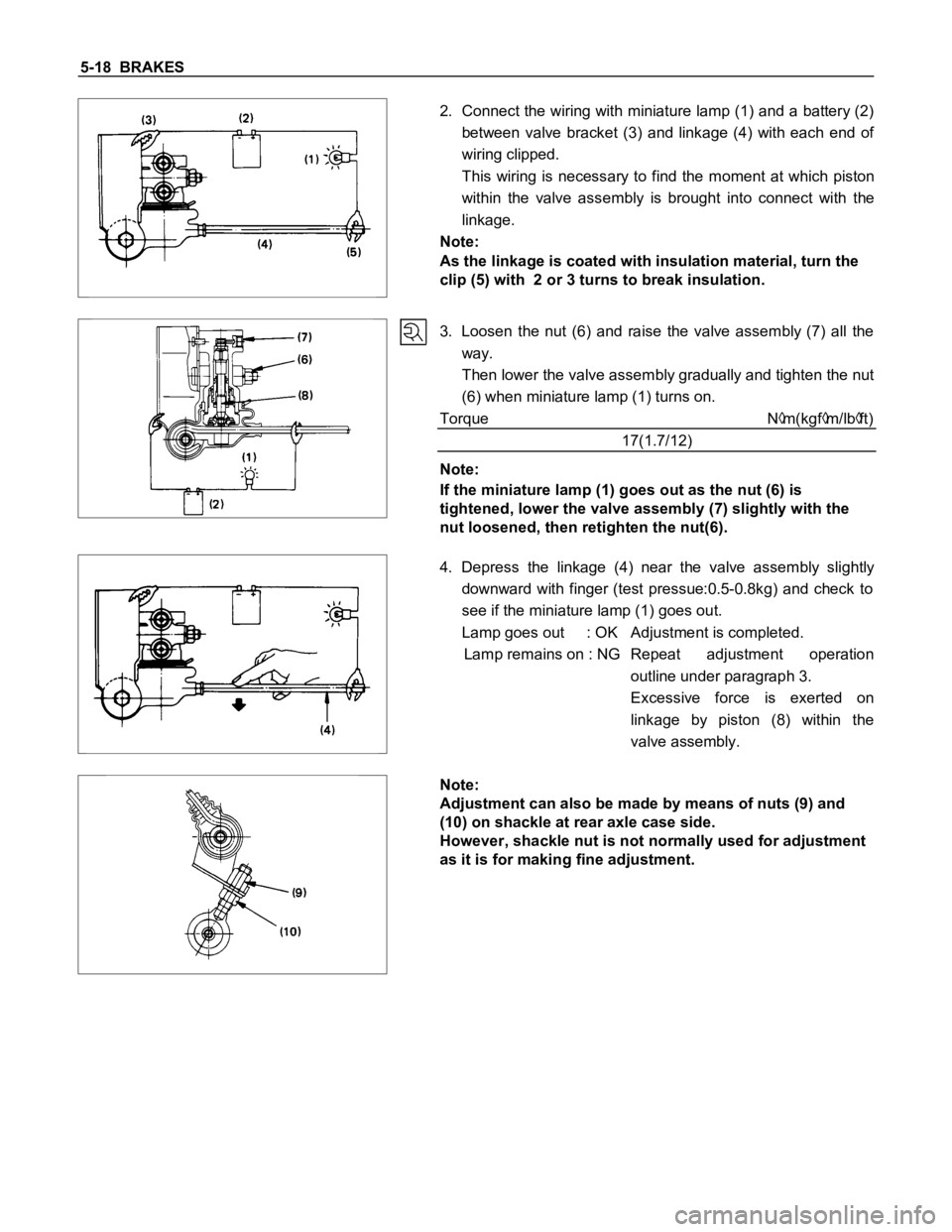

2. Connect the wiring with miniature lamp (1) and a battery (2)

between valve bracket (3) and linkage (4) with each end of

wiring clipped.

This wiring is necessary to find the moment at which piston

within the valve assembly is brought into connect with the

linkage.

Note:

As the linkage is coated with insulation material, turn the

clip (5) with 2 or 3 turns to break insulation.

3. Loosen the nut (6) and raise the valve assembly (7) all the

way.

Then lower the valve assembly gradually and tighten the nut

(6) when miniature lamp (1) turns on.

Torque N

m(kgfm/lbft)

17(1.7/12)

Note:

If the miniature lamp (1) goes out as the nut (6) is

tightened, lower the valve assembly (7) slightly with the

nut loosened, then retighten the nut(6).

4. Depress the linkage (4) near the valve assembly slightly

downward with finger (test pressue:0.5-0.8kg) and check to

see if the miniature lamp (1) goes out.

Lamp goes out : OK Adjustment is completed.

Lamp remains on : NG Repeat adjustment operation

outline under paragraph 3.

Excessive force is exerted on

linkage by piston (8) within the

valve assembly.

Note:

Adjustment can also be made by means of nuts (9) and

(10) on shackle at rear axle case side.

However, shackle nut is not normally used for adjustment

as it is for making fine adjustment.

Page 372 of 1600

5-44 BRAKES

18.Brake Line

Torque N

m(kgfm/Ibft)

13 - 19 (1.3 - 1.9 / 9 - 14)

Apply grease lightly to back plate A.

Page 387 of 1600

BRAKES 5-59

Important Operations - Removal

11.Cable Assembly ; Rear

When abrasion or wear is evident on edge protector, in must

be replaced with new one.

Important Operations - Installation

13.1st Relay Lever Assembly

Apply grease (BESCO L-2 or equivalent) to the inner and outer

surface of the bushes and cable connecting portions.

12.2nd Relay Lever Assembly with Return Spring

Apply grease (BESCO L-2 or equivalent) to the arrowed portion

in the left figure.

8. Intermediate Cable

After applying grease (BESCO L-2 or equivalent) to the cable

guide, set it to the bracket by striking lightly with a mallet.

Page 455 of 1600

CAB 10-1

SECTION 10

CAB

TABLE OF CONTENTS

PAGE

Servicing<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011001100110011[........ 10- 2

Windshield and Back Light Glasses ................................................................................ 10- 3

Sliding Rear Window Assembly ....................................................................................... 10- 8

Doors .................................................................................................................................. 10- 12

Instrument Panel...............................................<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011001100110011[.. 10- 26

Console Box ....................................................................................................................... 10- 31

Head Lining ........................................................................................................................ 10- 33

Quarter Glass (Space Cab) ............................................................................................... 10- 36

Front Seat ........................................................................................................................... 10- 37

Front and Rear Seat Belt ................................................................................................... 10-39

<002d005800500053000300360048004400570011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011001100110011[<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011001100110011[...... 10- 40

Jump Seat Belt .................................................<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011001100110011[... 10- 41

INDEX

Page 456 of 1600

10-2 CAB

SERVICING

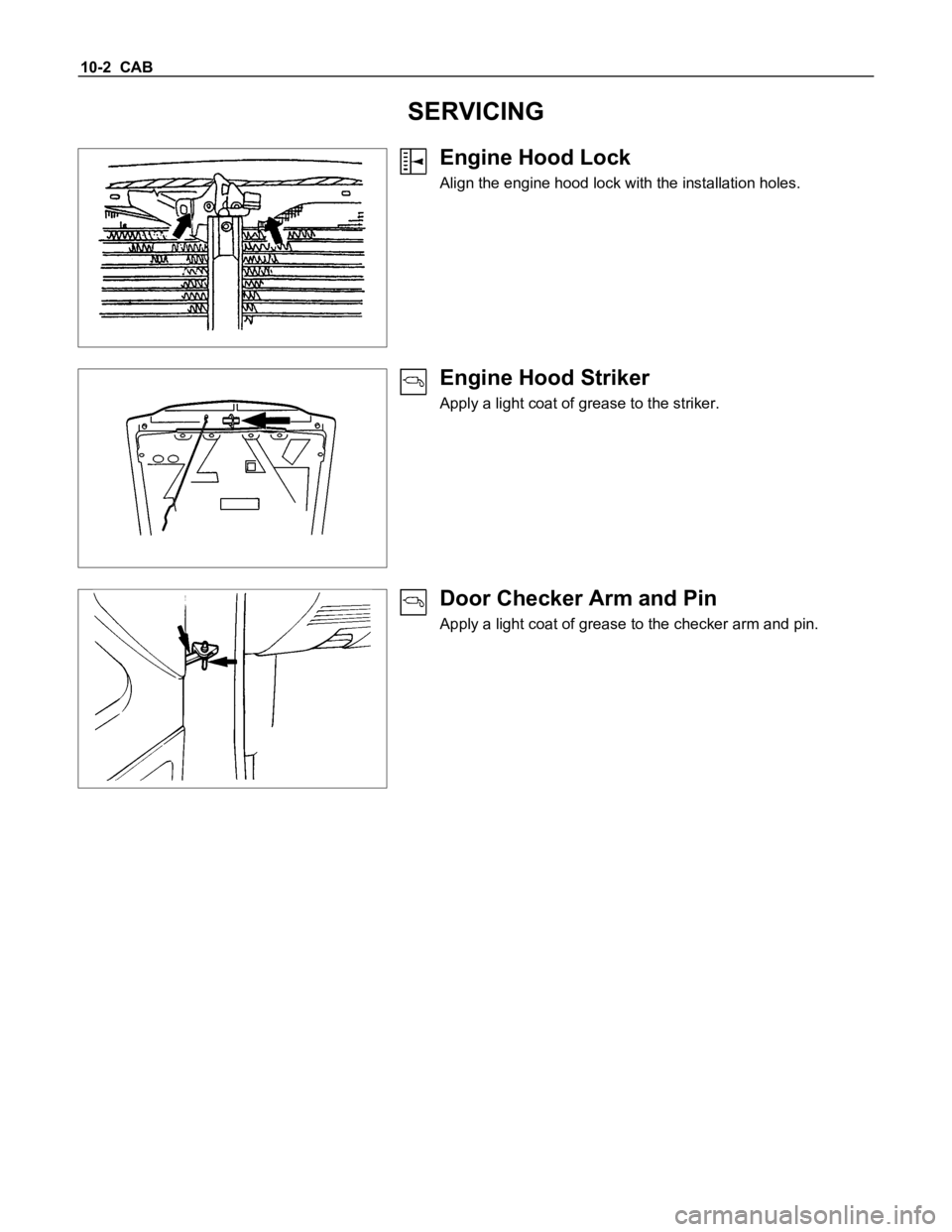

Engine Hood Lock

Align the engine hood lock with the installation holes.

Engine Hood Striker

Apply a light coat of grease to the striker.

Door Checker Arm and Pin

Apply a light coat of grease to the checker arm and pin.

Page 457 of 1600

CAB 10-3

WINDSHIELD AND BACK LIGHT GLASSES

GENERAL DESCRIPTION

This vehicle uses two types of safety glass: (1) laminated safety plate, for the windshield, and (2) solid tempered

safety plate, for the back glass.

The windshield glass is one-piece and is directly retained in the windshield opening by the adhesive.

When replacing a cracked windshield glass, it is very important that the cause of the glass breakage be determined

and the condition corrected before a new glass is installed. Otherwise, it is possible that a small obstruction or high

spot somewhere around the windshield opening will continue to crack or break the newly installed windshield. This

is especially true when the strain on the glass caused by this obstruction is increased by such conditions as wind

pressures, extremes of temperature, motion of the vehicle, etc. The procedure for removal of the windshield

applies to the complete windshield assembly.

WINDSHIELD GLASS BACK LIGHT GLASS