engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 2661 of 3573

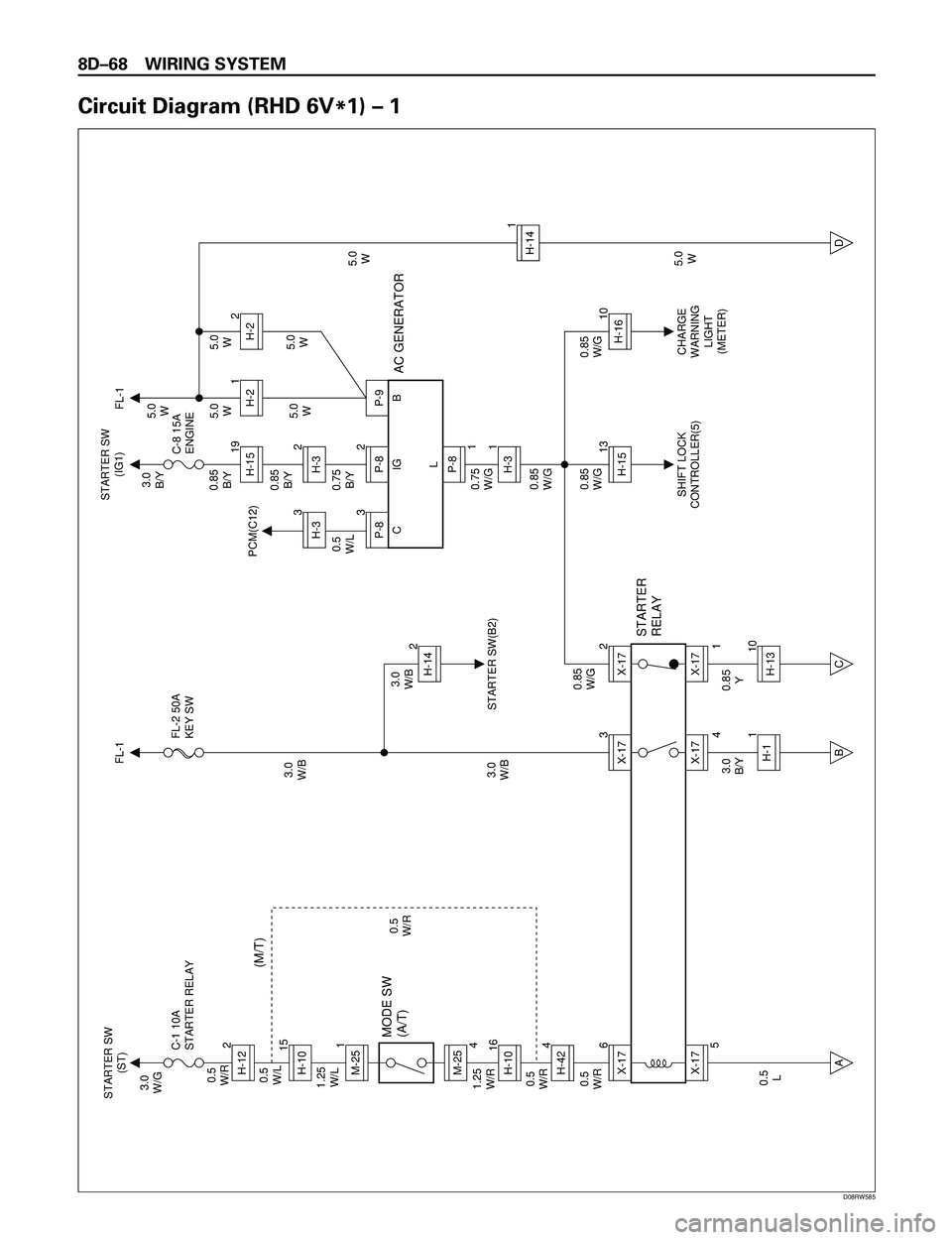

8DÐ68 WIRING SYSTEM

Circuit Diagram (RHD 6V

*1) Ð 1

X-17M-25H-10H-12M-25 3.0

W/G

C-1 10A

STARTER RELAYFL-2 50A

KEY SWC-8 15A

ENGINE

MODE SW

(A/T)(M/T)

AC GENERATOR

STARTER

RELAY

STARTER SW

(ST)FL-1

PCM(C12)STARTER SW

(IG1)

STARTER SW(B2)

SHIFT LOCK

CONTROLLER(5)CHARGE

WARNING

LIGHT

(METER) FL-1

0.5

W/R

0.5

W/L

1.25

W/L

1.25

W/R

0.5

W/R0.5

W/R3.0

W/B

3.0

W/B

3.0

W/B

3.0

B/Y0.85

Y 0.5

W/R

0.85

W/G 0.85

W/G 0.85

W/G0.85

W/G0.75

W/G5.0

W 5.0

W

0.75

B/Y5.0

W 5.0

W

5.0

W

5.0

W 0.85

B/Y 0.85

B/Y3.0

B/Y

0.5

W/L

0.5

L2

15

1

4

32

10 11 423 3

2

1

1

10 1321 19 2

6

5 4

16

H-10H-42X-17

H-1X-17

H-13X-17

H-15P-8H-3

P-9

5.0

W

1

H-14

P-8H-3

X-17

H-16

H-3

H-2

H-2

H-15

H-14

P-8

A

B

C

D

X-17

IG

LB C

D08RW585

Page 2665 of 3573

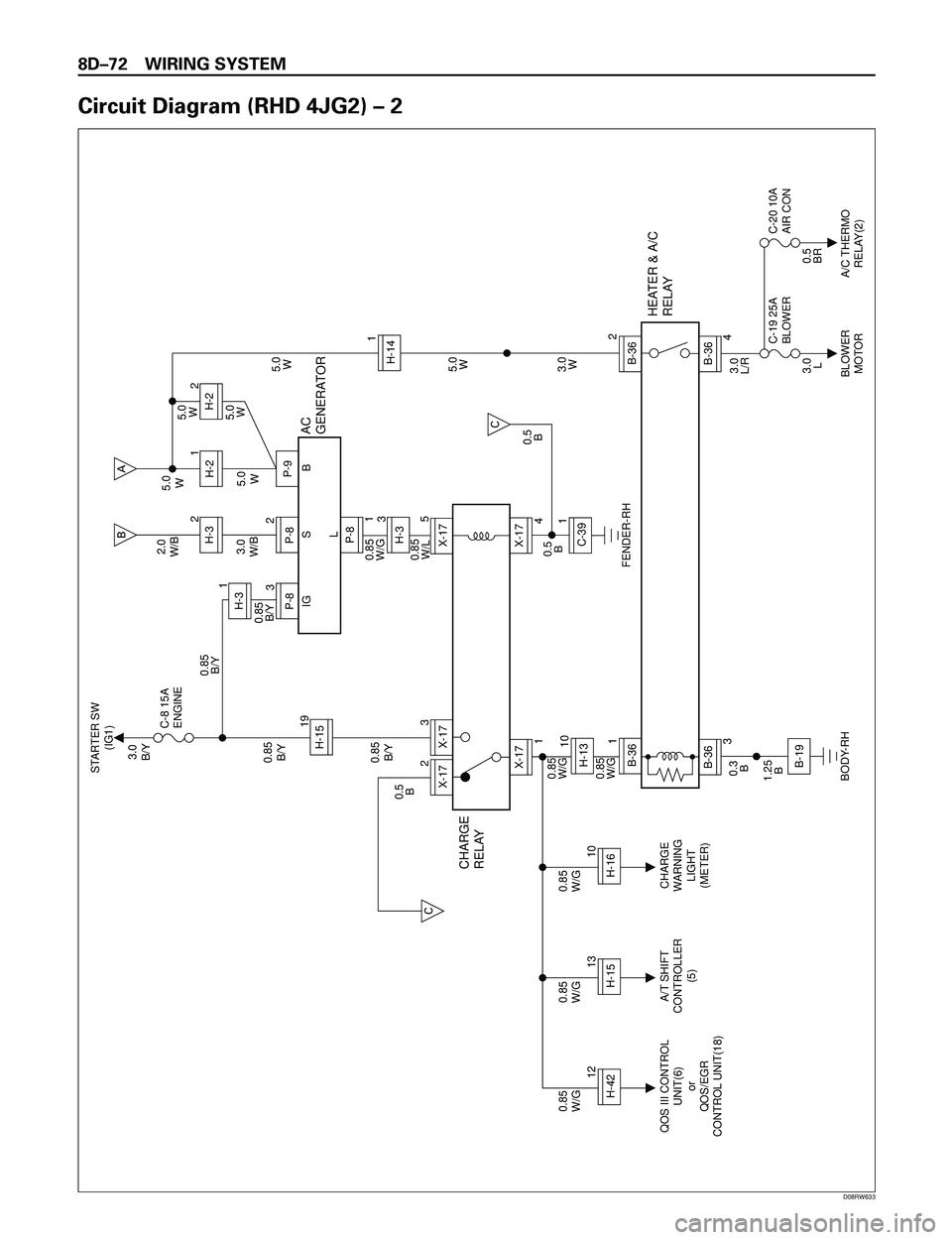

8DÐ72 WIRING SYSTEM

Circuit Diagram (RHD 4JG2) Ð 2

3.0

B/Y STARTER SW

(IG1)

C-19 25A

BLOWER C-8 15A

ENGINEB-19

BODY-RH

FENDER-RH 0.85

W/G

0.3

B

1.25

B 0.85

W/G 0.5

B

0.85

W/G0.85

W/G0.85

W/G

HEATER & A/C

RELAY AC

GENERATOR

B-36B-36

BLOWER

MOTOR

1

34

3.0

L/R

3.0

LC-20 10A

AIR CON

A/C THERMO

RELAY(2)0.5

BR B-36101 23

4

H-13

1

C-39

1

H-142

B-36

CHARGE

RELAY

X-17X-17

X-1719

H-15

X-17 X-17

1 32

P-82H-3

1

H-3

2

H-2

3

5

H-3

12

H-42

13

H-15

10

H-16

QOS III CONTROL

UNIT(6)

or

QOS/EGR

CONTROL UNIT(18)A/T SHIFT

CONTROLLER

(5)CHARGE

WARNING

LIGHT

(METER)

C

B

C

P-8

IG S

LB P-8

1

H-2 5.0

W

5.0

W 2.0

W/B

3.0

W/B

0.85

B/Y

0.85

B/Y0.85

B/Y

0.85

W/G

0.85

W/L 0.85

B/Y5.0

W

5.0

W

5.0

W

5.0

W

3.0

W 0.5

B

0.5

BA

P-9

D08RW633

Page 2667 of 3573

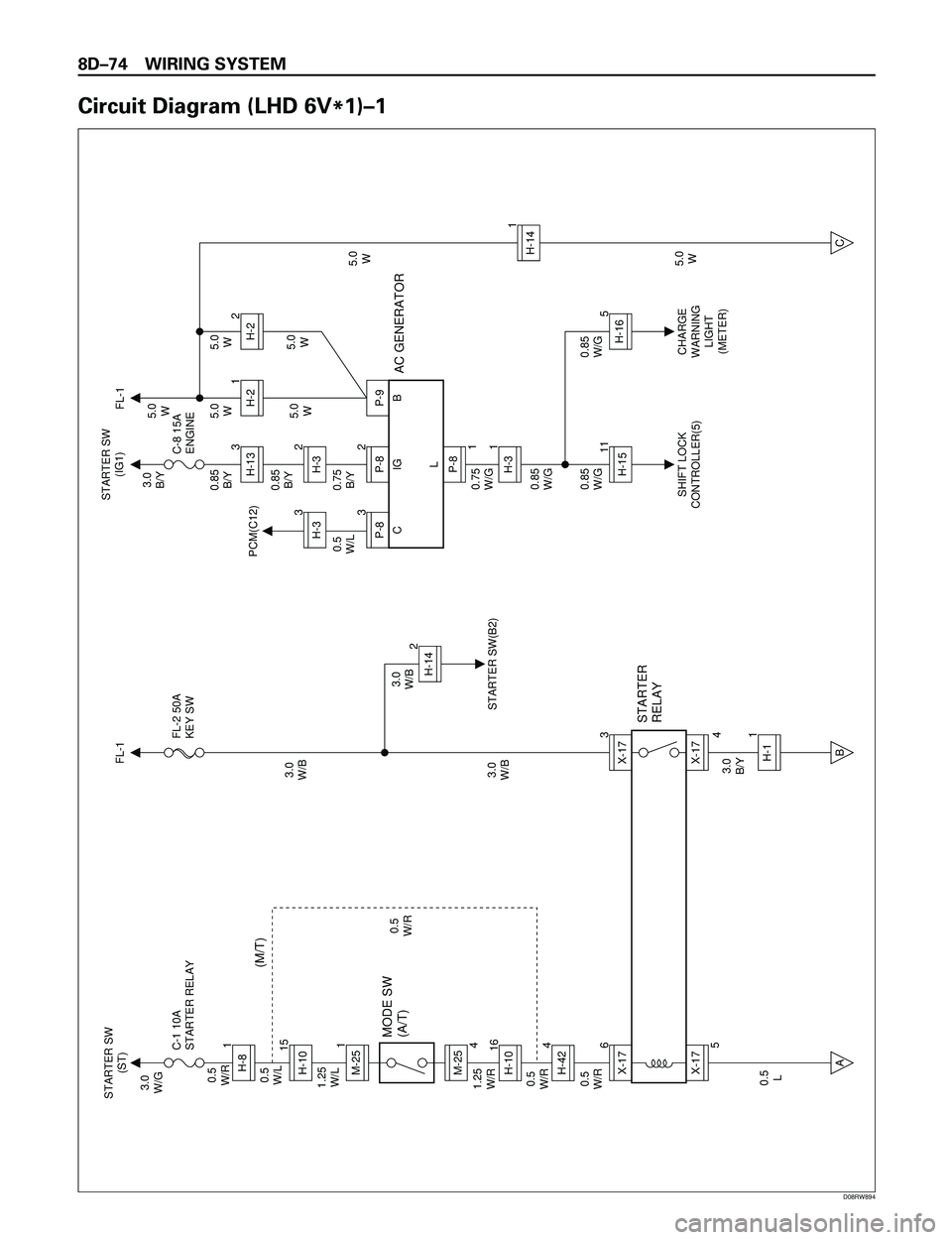

8DÐ74 WIRING SYSTEM

Circuit Diagram (LHD 6V

*1)Ð1

X-17M-25H-10H-8M-25 3.0

W/G

C-1 10A

STARTER RELAYFL-2 50A

KEY SWC-8 15A

ENGINE

MODE SW

(A/T)(M/T)

AC GENERATOR

STARTER

RELAY

STARTER SW

(ST)FL-1

PCM(C12)STARTER SW

(IG1)

STARTER SW(B2)

SHIFT LOCK

CONTROLLER(5)CHARGE

WARNING

LIGHT

(METER) FL-1

0.5

W/R

0.5

W/L

1.25

W/L

1.25

W/R

0.5

W/R0.5

W/R3.0

W/B

3.0

W/B

3.0

W/B

3.0

B/Y 0.5

W/R

0.85

W/G 0.85

W/G0.85

W/G0.75

W/G5.0

W 5.0

W

0.75

B/Y5.0

W 5.0

W

5.0

W

5.0

W 0.85

B/Y 0.85

B/Y3.0

B/Y

0.5

W/L

0.5

L1

15

1

4

3

1 423 3

2

1

1

5 1121 32

6

5 4

16

H-10H-42X-17

H-1X-17

H-15P-8H-3

P-9

5.0

W

1

H-14

P-8H-3

H-16

H-3

H-2

H-2

H-13

H-14

P-8

A

B

C

X-17

IG

LB C

D08RW894

Page 2671 of 3573

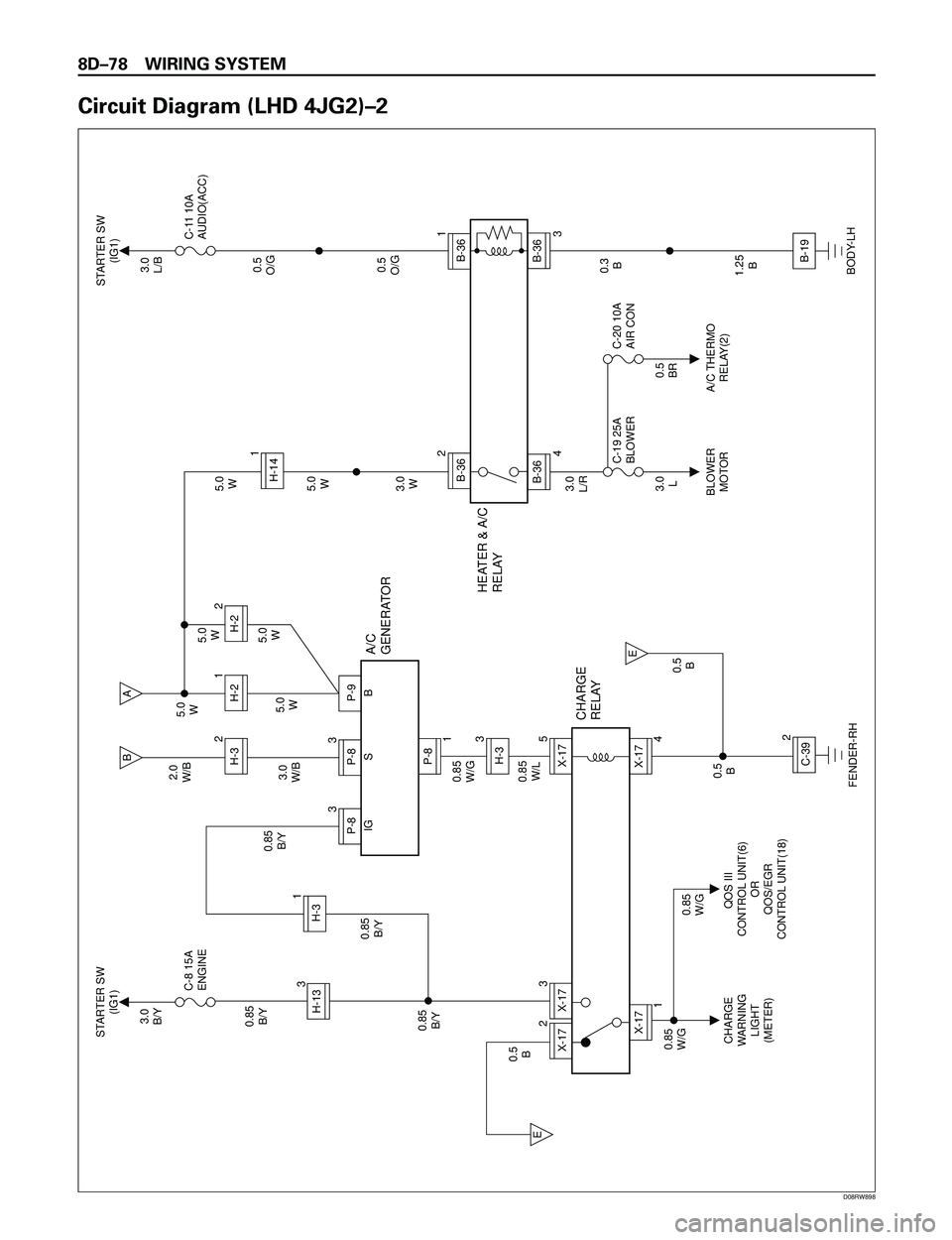

8DÐ78 WIRING SYSTEM

Circuit Diagram (LHD 4JG2)Ð2

X-17

5

4

P-8

1H-32

H-21

H-22

H-133

X-17

3

H-32

C-39

3

P-8

IG

3

P-8

S

P-9

B

3

X-17

2

X-17

E

E

HEATER & A/C

RELAY

B-36

BLOWER

MOTORA/C THERMO

RELAY(2)

B-36

1.25

B 0.3

B

1

3 B-36

FENDER-RH

B-19

BODY-LH

3.0

B/Y

0.85

B/Y

0.85

B/Y

0.85

W/G 0.5

B

0.5

B0.5

B

CHARGE

RELAYA/C

GENERATOR

0.85

W/G 0.85

B/Y0.85

B/Y2.0

W/B

3.0

W/B

0.85

W/G

0.85

W/L5.0

W

5.0

W5.0

W

5.0

W

5.0

W

3.0

W

3.0

L/R

3.0

L0.5

BR 5.0

W STARTER SW

(IG1)

C-8 15A

ENGINE

3.0

L/B

0.5

O/G

0.5

O/G STARTER SW

(IG1)

C-11 10A

AUDIO(ACC)

C-19 25A

BLOWERC-20 10A

AIR CON

1

H-3

X-17

CHARGE

WARNING

LIGHT

(METER)QOS III

CONTROL UNIT(6)

OR

QOS/EGR

CONTROL UNIT(18) 1

B

A

2

4 B-361

H-14

D08RW898

Page 2673 of 3573

8DÐ80 WIRING SYSTEM

Powertrain Control Module (PCM)

General Description

The Powertrain Control Module (PCM) is located in

the passenger compartment.

The PCM constantly monitors the information from

various sensors, and controls the systems that affect

vehicle performance.

The PCM performs the diagnostic function of the

system. It can recognize operational problems, alert

the driver through the Malfunction Indicator Light

(MIL) and store a Diagnostic Trouble Code (DTC) or

DTC(s) which identify the problem areas to aid the

technician in making repairs.

The PCM is designed to process the various input

informations and then sends the necessary

electrical responses to control fuel delivery, spark

timing and other emission control systems. The

input information has an interrelation to more than

one output, therefore, if the one input failed, it could

affect more than one system operation.

Refer to Driveability and Emission in Engine section

and Automatic Transmission in Transmission

section.

Page 2674 of 3573

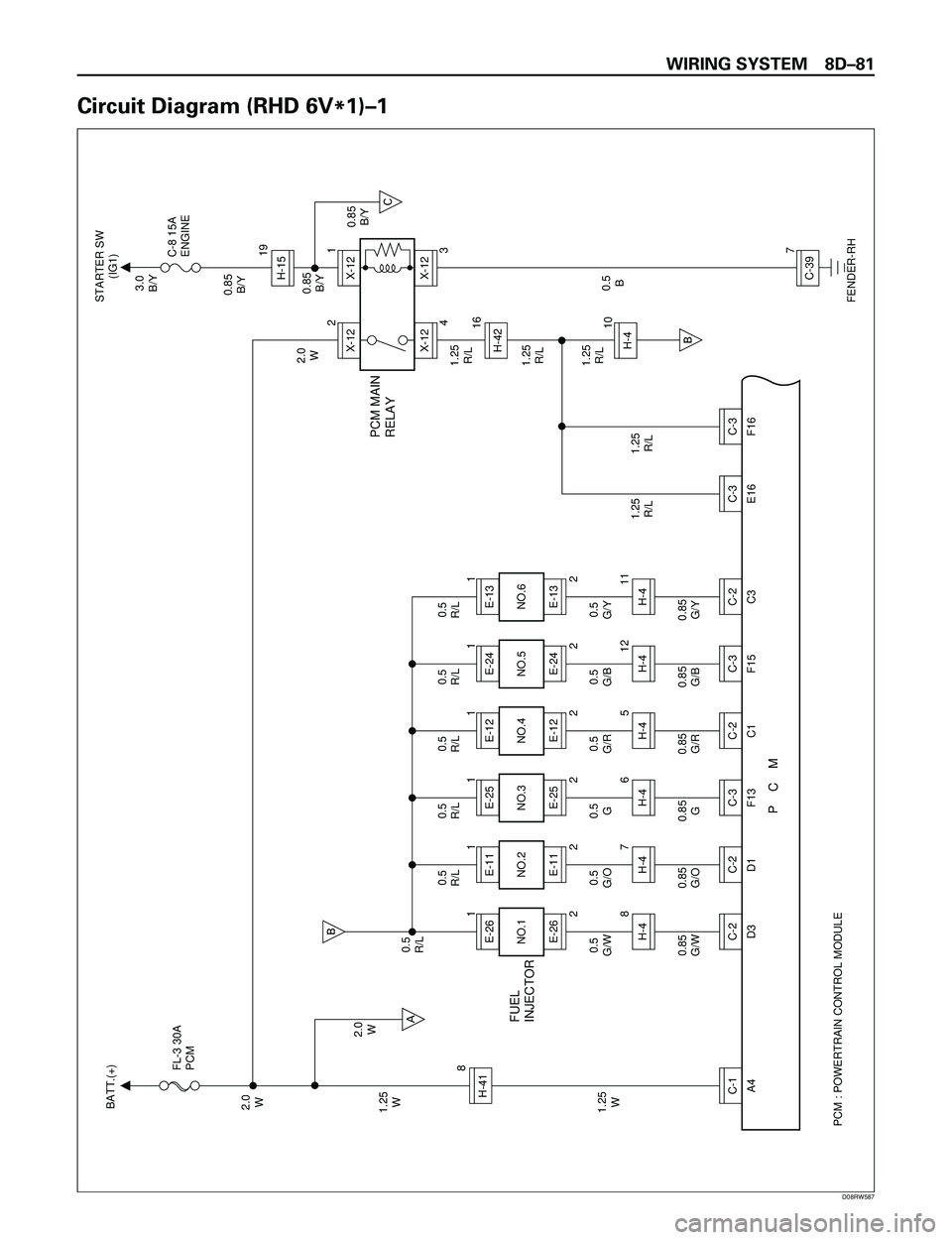

WIRING SYSTEM 8DÐ81

Circuit Diagram (RHD 6V

*1)Ð1

PCM : POWERTRAIN CONTROL MODULE 1.25

W 1.25

W 2.0

W BATT.(+)

2.0

W

0.5

R/L

C-18

H-41

C-21E-26

2

8H-4B

A0.85

B/Y

C

B

E-26

FUEL

INJECTOR

FL-3 30A

PCM

NO.10.5

R/L

C-21E-11

2

7H-4E-11NO.20.5

R/L

C-31E-25

2

6H-4E-25NO.30.5

R/L

C-21E-12

2

5H-4E-12NO.40.5

R/L

C-31E-24

2

12H-4E-24NO.50.5

R/L

0.5

G/O 0.5

G/W0.5

G0.5

G/R0.5

G/B0.5

G/Y

0.85

G/O 0.85

G/W0.85

G0.85

G/R0.85

G/B0.85

G/Y1.25

R/L1.25

R/L1.25

R/L 1.25

R/L 1.25

R/L2.0

W

C-21E-13

2

11H-4

H-416

10X-122H-424X-12

E-13NO.6

C-3

C-3

P C M

D3 D1 F13 C1 F15 C3 E16 F16 A4

PCM MAIN

RELAY

0.5

B

FENDER-RH3.0

B/Y STARTER SW

(IG1)

0.85

B/Y

0.85

B/YX-121 19H-15

3X-12

C-8 15A

ENGINE

C-397

D08RW587

Page 2680 of 3573

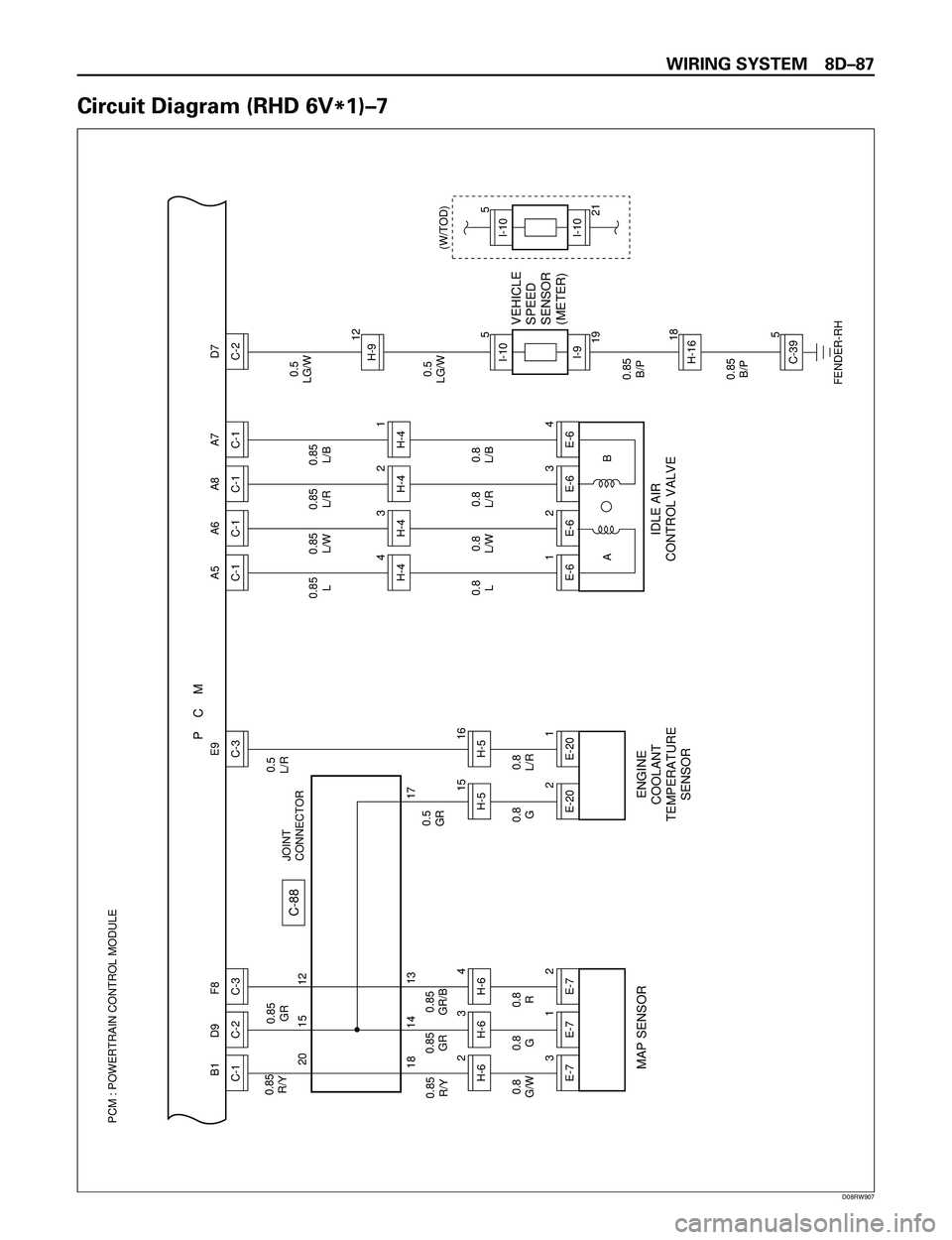

WIRING SYSTEM 8DÐ87

Circuit Diagram (RHD 6V

*1)Ð7

C-2E-61

C-22

C-23

C-2

E-64

E-6

E-6

PCM : POWERTRAIN CONTROL MODULE

P C M

0.85

R/Y0.85

GR

JOINT

CONNECTOR0.5

L/R B1 D9 F8

0.85

R/Y

0.8

G/W

C-2

H-6

H-6 0.85

GR0.85

GR/B

0.8

G0.8

R

H-6

C-1

C-2

C-3

C-2

E-7

E-7

E-7 234

312

MAP SENSOR

C-3E9

C-2

H-5 0.5

GR

0.8

G0.8

L/R

H-5

C-2

E-20

E-20 15 16

21

C-1A5

C-2H-44

ENGINE

COOLANT

TEMPERATURE

SENSORIDLE AIR

CONTROL VALVEVEHICLE

SPEED

SENSOR

(METER)

0.85

L

0.8

L

C-1A6

C-2H-43 0.85

L/W

0.8

L/W

C-1A8

C-2H-42

AB0.85

L/R

0.8

L/R

C-1A7

C-2D7

C-2

H-41 0.85

L/B

0.8

L/B

0.85

B/P 0.85

B/P0.5

LG/W

0.5

LG/W 20 15 12

18 14 13 17

C-88

5

I-10I-10

21

FENDER-RH(W/TOD)

5

I-10

5C-3918H-1612H-9I-919

D08RW907

Page 2689 of 3573

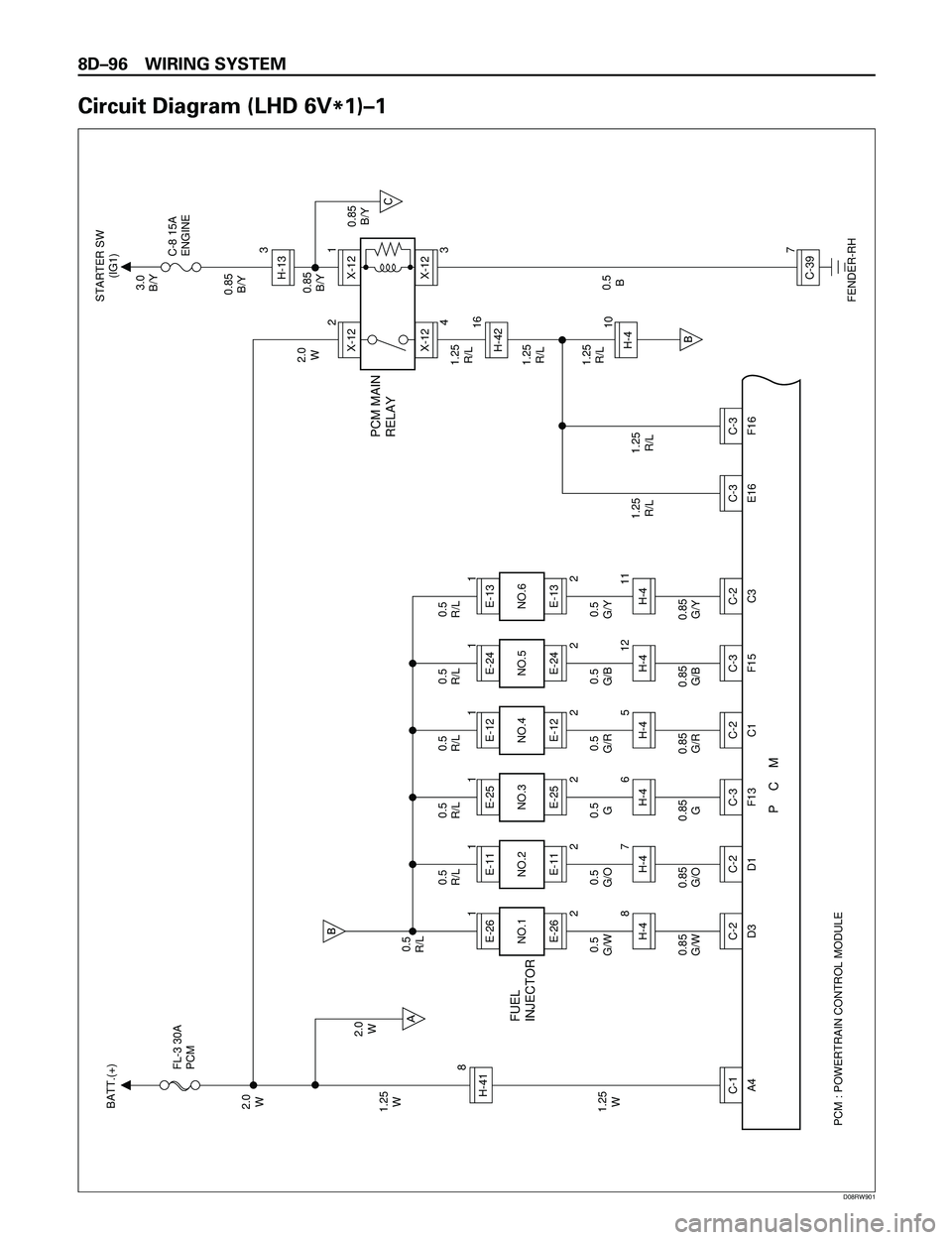

8DÐ96 WIRING SYSTEM

Circuit Diagram (LHD 6V

*1)Ð1

PCM : POWERTRAIN CONTROL MODULE 1.25

W 1.25

W 2.0

W BATT.(+)

2.0

W

0.5

R/L

C-18

H-41

C-21E-26

2

8H-4B

A0.85

B/Y

C

B

E-26

FUEL

INJECTOR

FL-3 30A

PCM

NO.10.5

R/L

C-21E-11

2

7H-4E-11NO.20.5

R/L

C-31E-25

2

6H-4E-25NO.30.5

R/L

C-21E-12

2

5H-4E-12NO.40.5

R/L

C-31E-24

2

12H-4E-24NO.50.5

R/L

0.5

G/O 0.5

G/W0.5

G0.5

G/R0.5

G/B0.5

G/Y

0.85

G/O 0.85

G/W0.85

G0.85

G/R0.85

G/B0.85

G/Y1.25

R/L1.25

R/L1.25

R/L 1.25

R/L 1.25

R/L2.0

W

C-21E-13

2

11H-4

H-416

10X-122H-424X-12

E-13NO.6

C-3

C-3

P C M

D3 D1 F13 C1 F15 C3 E16 F16 A4

PCM MAIN

RELAY

0.5

B

FENDER-RH3.0

B/Y STARTER SW

(IG1)

0.85

B/Y

0.85

B/YX-121 3H-13

3X-12

C-8 15A

ENGINE

C-397

D08RW901

Page 2695 of 3573

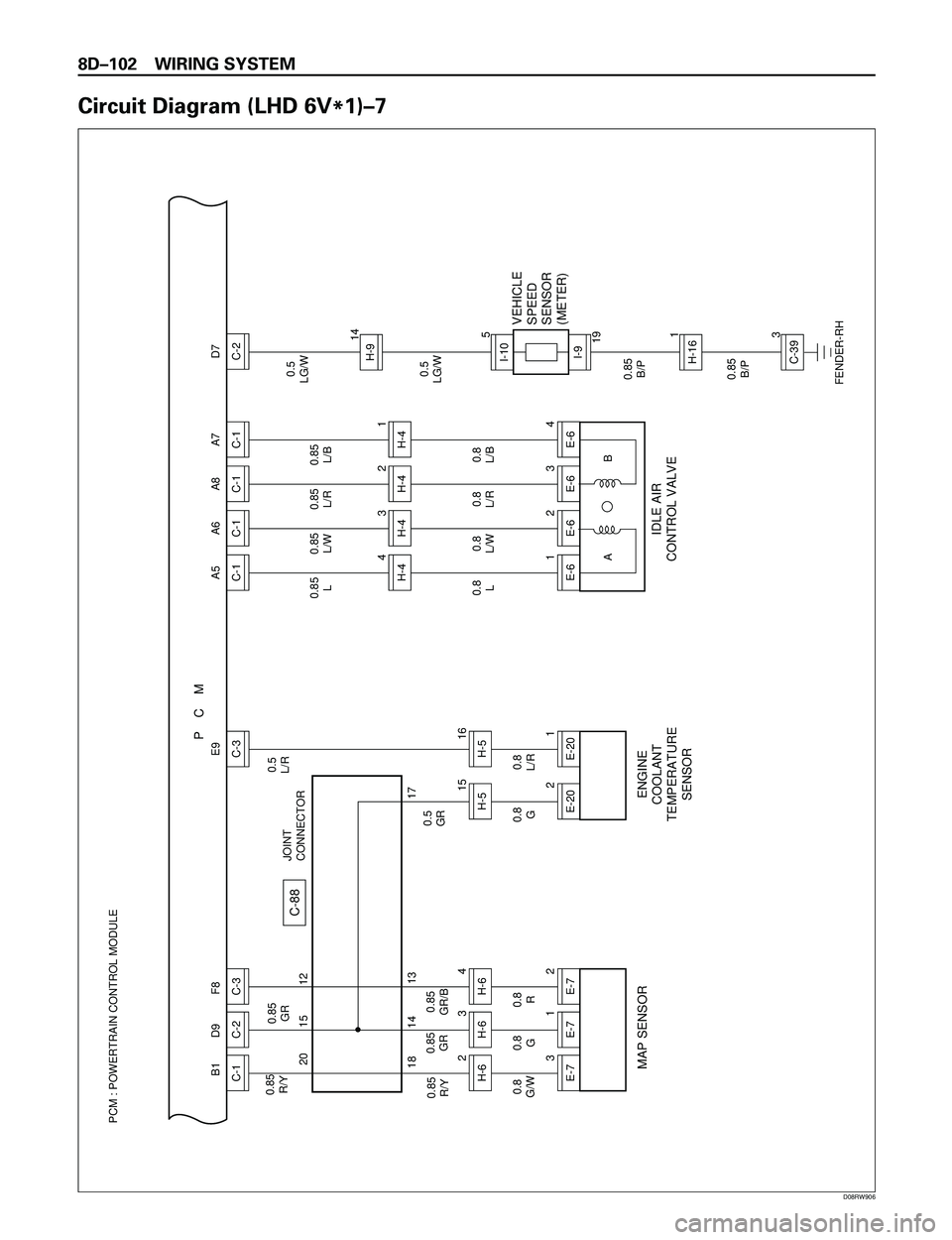

8DÐ102 WIRING SYSTEM

Circuit Diagram (LHD 6V

*1)Ð7

C-2E-61

C-22

C-23

C-2

E-64

E-6

E-6

PCM : POWERTRAIN CONTROL MODULE

P C M

0.85

R/Y0.85

GR

JOINT

CONNECTOR0.5

L/R B1 D9 F8

0.85

R/Y

0.8

G/W

C-2

H-6

H-6 0.85

GR0.85

GR/B

0.8

G0.8

R

H-6

C-1

C-2

C-3

C-2

E-7

E-7

E-7 234

312

MAP SENSOR

C-3E9

C-2

H-5 0.5

GR

0.8

G0.8

L/R

H-5

C-2

E-20

E-20 15 16

21

C-1A5

C-2H-44

ENGINE

COOLANT

TEMPERATURE

SENSORIDLE AIR

CONTROL VALVEVEHICLE

SPEED

SENSOR

(METER)

0.85

L

0.8

L

C-1A6

C-2H-43 0.85

L/W

0.8

L/W

C-1A8

C-2H-42

AB0.85

L/R

0.8

L/R

C-1A7

C-2D7

C-2

H-41 0.85

L/B

0.8

L/B

0.85

B/P 0.85

B/P0.5

LG/W

0.5

LG/W 20 15 12

18 14 13 17

C-88

FENDER-RH

5

I-10

3C-391H-1614H-9I-919

D08RW906

Page 2704 of 3573

WIRING SYSTEM 8DÐ111

QOS-III (4JG2)

General Description

The circuit consists of the starter switch, QOS-III

control unit, glow relay, charge relay, fuel cut

solenoid, dropping resistor, thermo sensor, glow

indicator light (meter), glow plug and car speed

sensor. The engine coolant temperature at the time

of the engine start-up is sensed by the thermo

sensor to change the glow time so that the optimum

starting conditions can always be obtained.

The idling speed just after the engine start-up can

also be placed in the most suitable conditions in

accordance with the coolant temperature by the

operation of the delay timer.The indicator timer is activated upon the starter

switch turned to the ON position, and the indicator

light comes on for as much time as suitable for the

engine coolant temperature at the time of the

engine start-up.