engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 2329 of 3573

MANUAL TRANSMISSION7B±11

220RW119

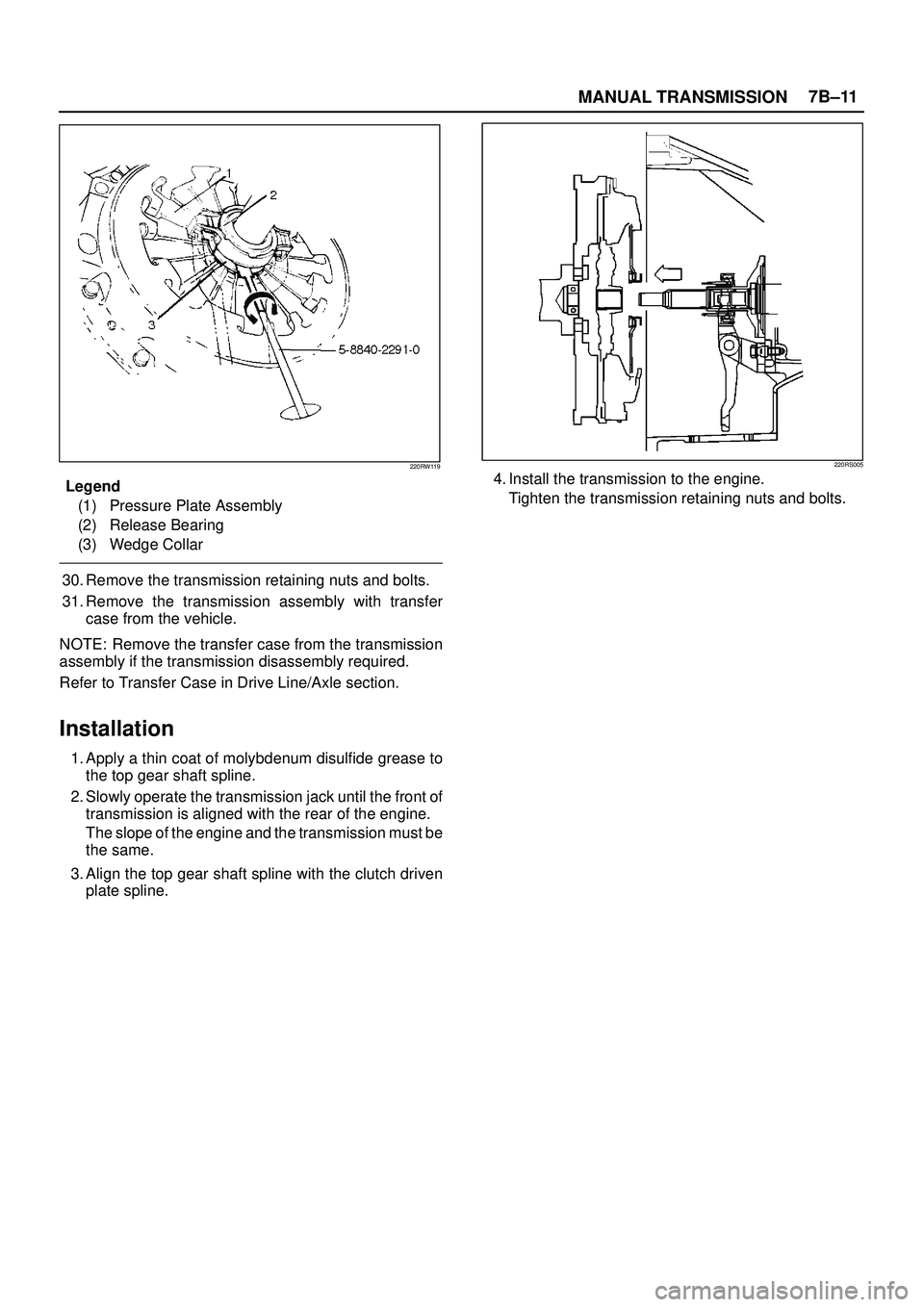

Legend

(1) Pressure Plate Assembly

(2) Release Bearing

(3) Wedge Collar

30. Remove the transmission retaining nuts and bolts.

31. Remove the transmission assembly with transfer

case from the vehicle.

NOTE: Remove the transfer case from the transmission

assembly if the transmission disassembly required.

Refer to Transfer Case in Drive Line/Axle section.

Installation

1. Apply a thin coat of molybdenum disulfide grease to

the top gear shaft spline.

2. Slowly operate the transmission jack until the front of

transmission is aligned with the rear of the engine.

The slope of the engine and the transmission must be

the same.

3. Align the top gear shaft spline with the clutch driven

plate spline.

220RS005

4. Install the transmission to the engine.

Tighten the transmission retaining nuts and bolts.

Page 2331 of 3573

MANUAL TRANSMISSION7B±13

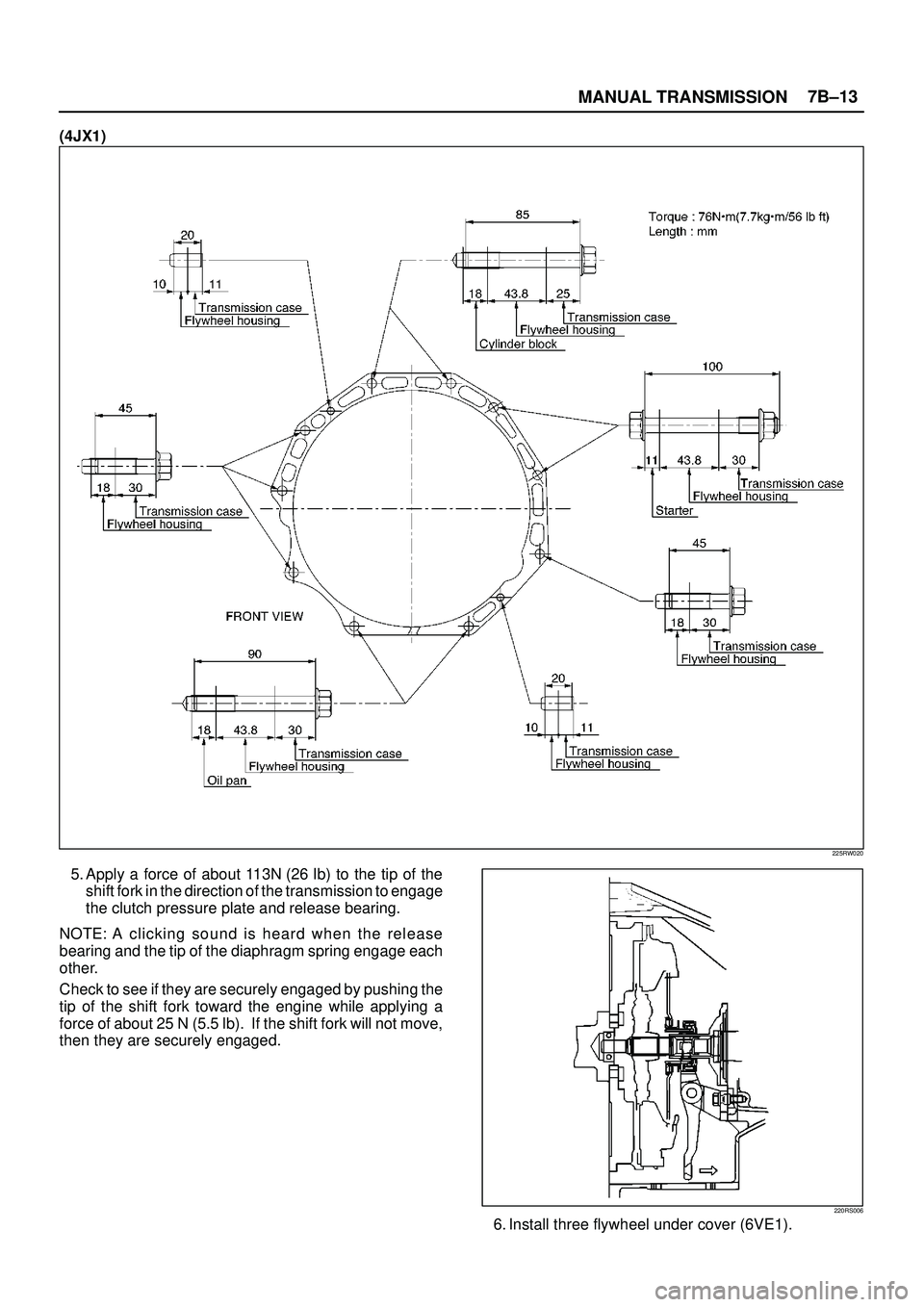

(4JX1)

225RW020

5. Apply a force of about 113N (26 Ib) to the tip of the

shift fork in the direction of the transmission to engage

the clutch pressure plate and release bearing.

NOTE: A clicking sound is heard when the release

bearing and the tip of the diaphragm spring engage each

other.

Check to see if they are securely engaged by pushing the

tip of the shift fork toward the engine while applying a

force of about 25 N (5.5 lb). If the shift fork will not move,

then they are securely engaged.

220RS006

6. Install three flywheel under cover (6VE1).

Page 2332 of 3573

7B±14MANUAL TRANSMISSION

7. Install the engine rear mount to the transmission case

and tighten the fixing bolts specified torque (6VE1).

Torque: 41 N´m (4.2kg´m/30 Ib ft)

8. Install the third crossmember to the frame and tighten

the fixing bolts specified torque.

Torque: 50 N´m (5.1kg´m/37 Ib ft)

9. Tighten the engine rear mount nuts specified torque.

Torque: 50 N´m (5.1kg´m/37 Ib ft)

10. Remove the transmission jack.

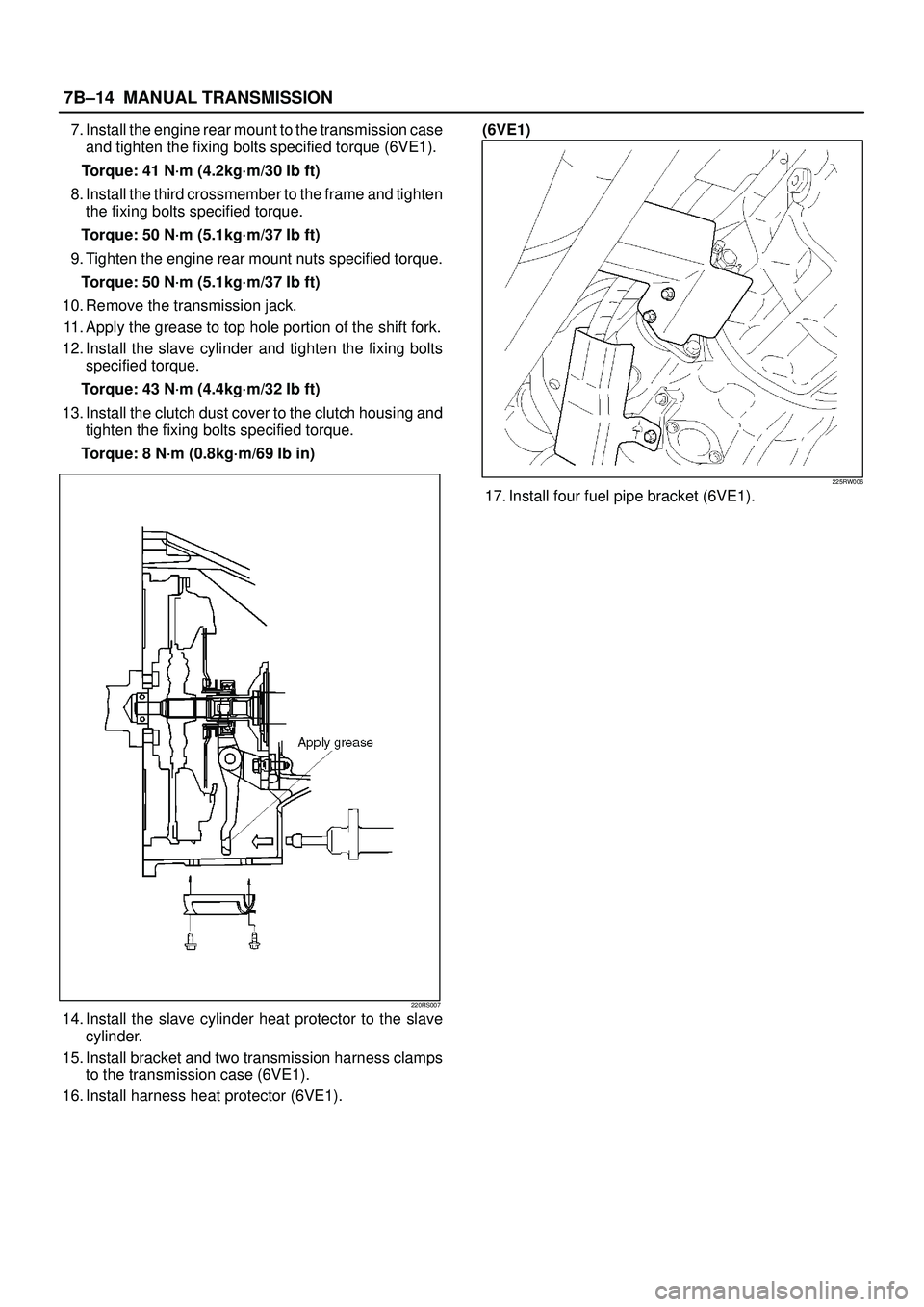

11. Apply the grease to top hole portion of the shift fork.

12. Install the slave cylinder and tighten the fixing bolts

specified torque.

Torque: 43 N´m (4.4kg´m/32 Ib ft)

13. Install the clutch dust cover to the clutch housing and

tighten the fixing bolts specified torque.

Torque: 8 N´m (0.8kg´m/69 Ib in)

220RS007

14. Install the slave cylinder heat protector to the slave

cylinder.

15. Install bracket and two transmission harness clamps

to the transmission case (6VE1).

16. Install harness heat protector (6VE1).(6VE1)

225RW006

17. Install four fuel pipe bracket (6VE1).

Page 2334 of 3573

7B±16MANUAL TRANSMISSION

19. Connect the backup lamp switch, 4WD indicator

switch, and 1-2 indicator switch harness connectors.

826RW023

20. Install the front and 3 way exhaust pipe (6VE1).

Install the exhaust pipe with catalytic converter

(4JX1).

Torque:

Exhaust pipe to exhaust manifold:

67 N´m (6.8 kg´m/49 Ib ft)

Exhaust pipe flange bolt:

43 N´m (4.4 kg´m/32 Ib ft)

(4JX1)

150RW041

21. Connect two oxygen sensor connectors to the

transmission harness (6VE1).

22. Install the front propeller shaft and tighten the fixing

bolts and nuts specified torque.

Torque: 63 N´m (6.4 kg´m/46 Ib ft)

23. Install the rear propeller shaft and tighten the fixing

bolts and nuts specified torque.

Torque: 63 N´m (6.4 kg´m/46 Ib ft)24. Install transfer protector and tighten the fixing bolts

specified torque.

Torque: 37 N´m (3.8 kg´m/27 Ib ft)

25. Install the transmission control lever and transfer

control lever.

235RW014

26. Install the grommet assembly.

27. Install the front console assembly.

28. Install the gear control lever knob.

29. Connect battery ground cable.

30. Install engine hood.

Page 2360 of 3573

7B±42MANUAL TRANSMISSION

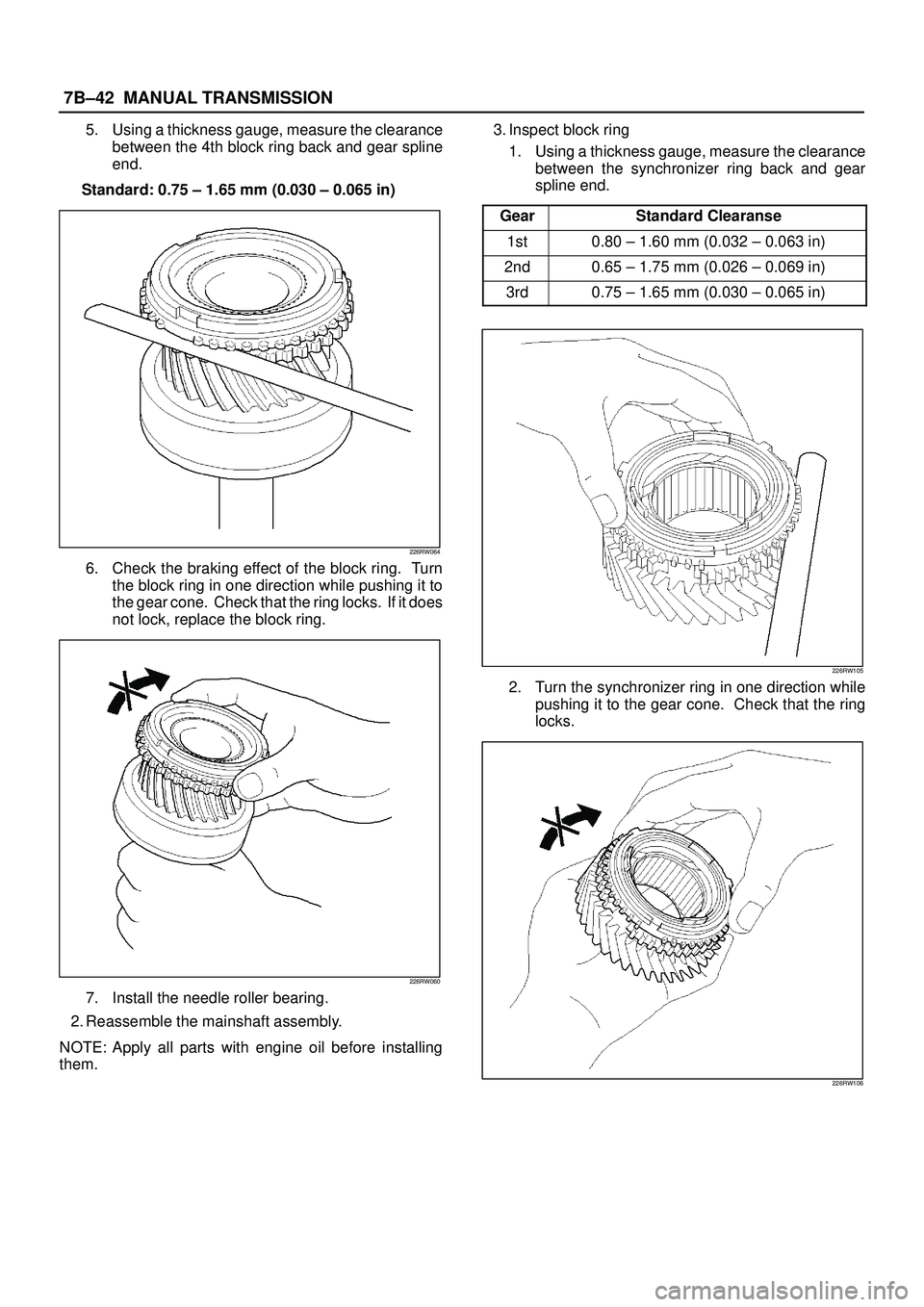

5. Using a thickness gauge, measure the clearance

between the 4th block ring back and gear spline

end.

Standard: 0.75 ± 1.65 mm (0.030 ± 0.065 in)

226RW064

6. Check the braking effect of the block ring. Turn

the block ring in one direction while pushing it to

the gear cone. Check that the ring locks. If it does

not lock, replace the block ring.

226RW060

7. Install the needle roller bearing.

2. Reassemble the mainshaft assembly.

NOTE: Apply all parts with engine oil before installing

them.3. Inspect block ring

1. Using a thickness gauge, measure the clearance

between the synchronizer ring back and gear

spline end.

Gear

Standard Clearanse

1st0.80 ± 1.60 mm (0.032 ± 0.063 in)

2nd0.65 ± 1.75 mm (0.026 ± 0.069 in)

3rd0.75 ± 1.65 mm (0.030 ± 0.065 in)

226RW105

2. Turn the synchronizer ring in one direction while

pushing it to the gear cone. Check that the ring

locks.

226RW106

Page 2386 of 3573

7B±68MANUAL TRANSMISSION

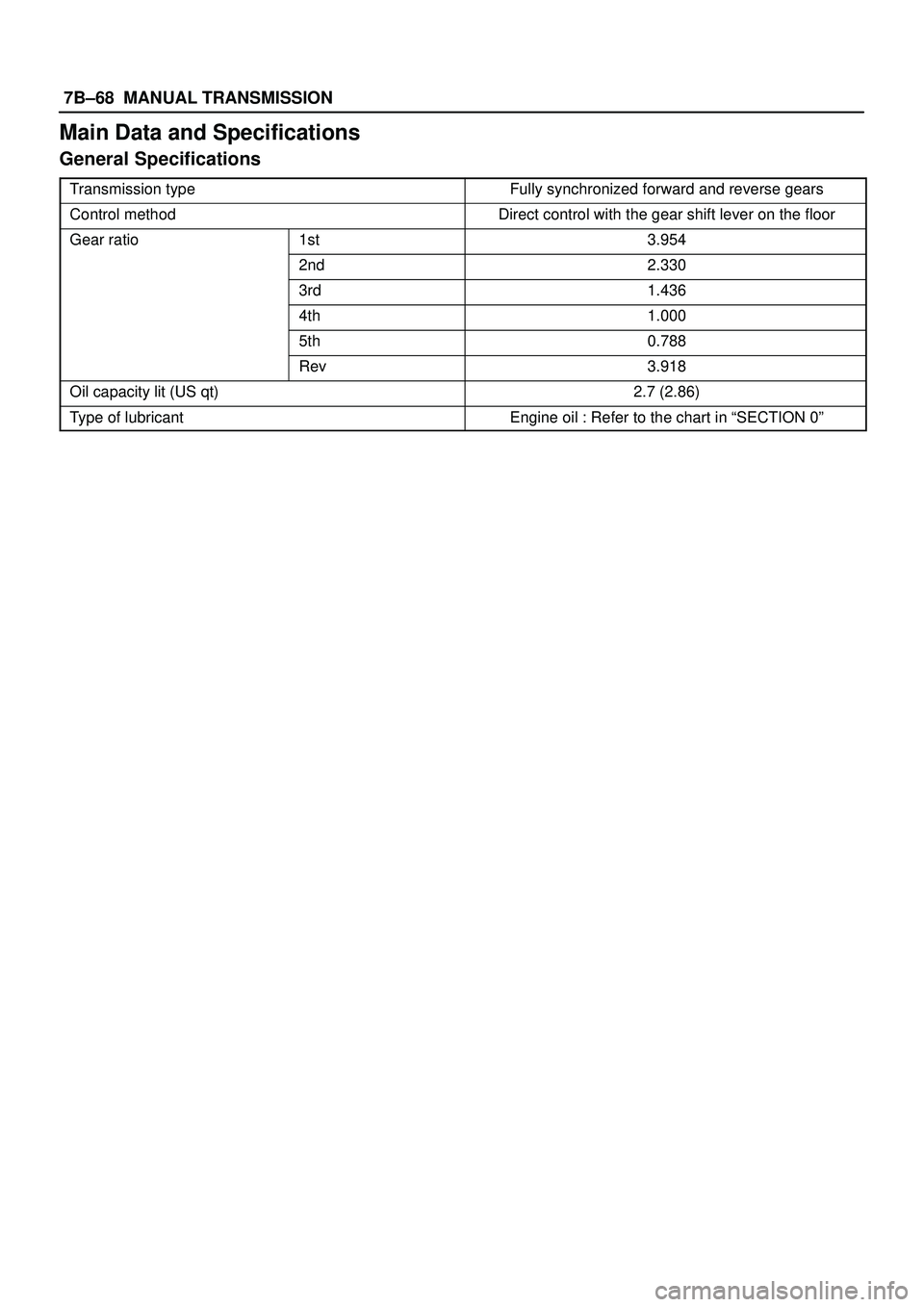

Main Data and Specifications

General Specifications

Transmission typeFully synchronized forward and reverse gears

Control methodDirect control with the gear shift lever on the floor

Gear ratio1st3.954

2nd2.330

3rd1.436

4th1.000

5th0.788

Rev3.918

Oil capacity lit (US qt)2.7 (2.86)

Type of lubricantEngine oil : Refer to the chart in ªSECTION 0º

Page 2442 of 3573

MUA MODEL 7B1 – 51

REMOVAL AND INSTALLATION

Read this Section carefully before performing any removal and installation procedure. This Section gives

you important points as well as the order of operation. Be sure that you understand everything in this

Section before you begin.

Important Operations – Removal

Battery Cable

Disconnect the negative (–) cable from the battery

terminal.

Engine Hood

Apply setting marks to the engine hood and the engine

hood hinges before removing the engine hood.

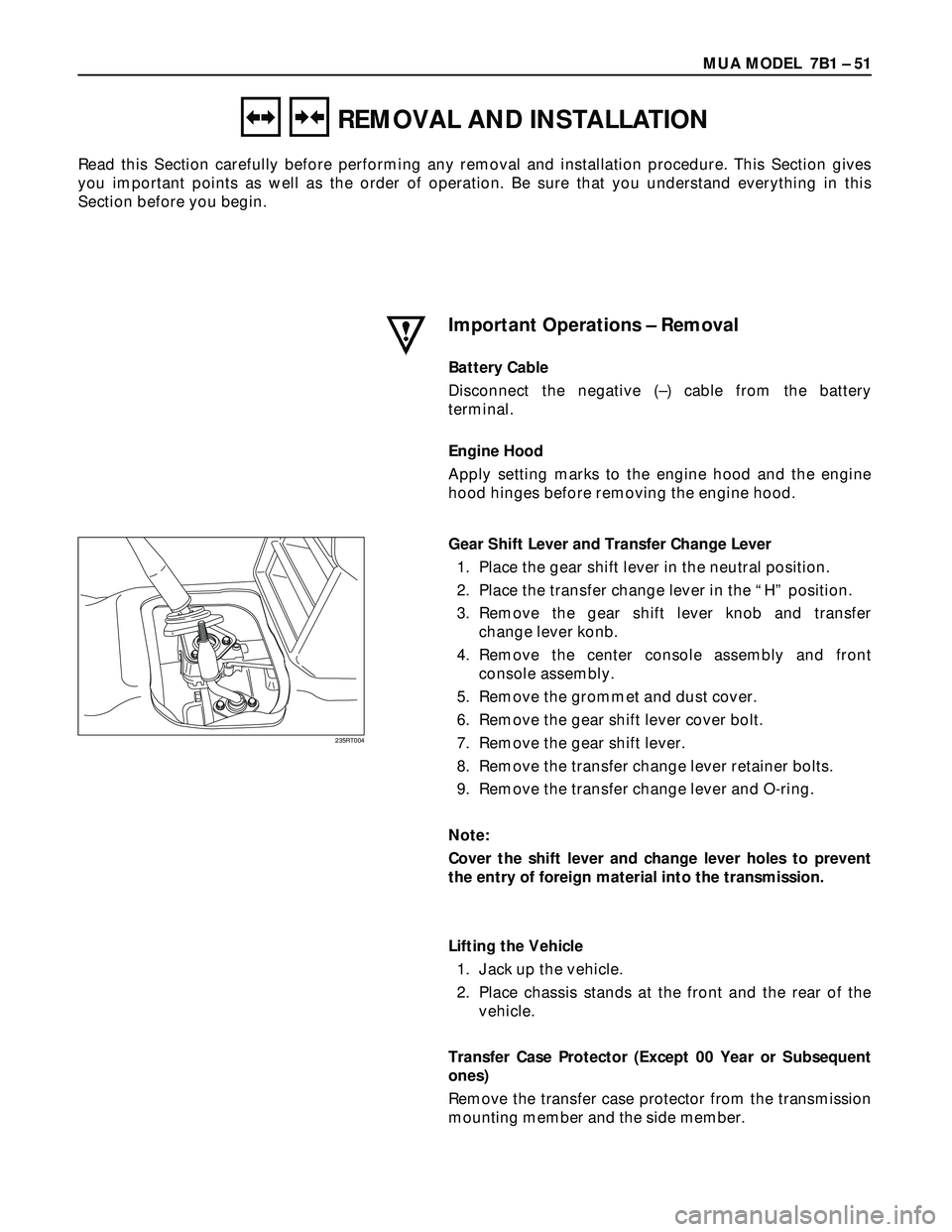

Gear Shift Lever and Transfer Change Lever

1. Place the gear shift lever in the neutral position.

2. Place the transfer change lever in the “H” position.

3. Remove the gear shift lever knob and transfer

change lever konb.

4. Remove the center console assembly and front

console assembly.

5. Remove the grommet and dust cover.

6. Remove the gear shift lever cover bolt.

7. Remove the gear shift lever.

8. Remove the transfer change lever retainer bolts.

9. Remove the transfer change lever and O-ring.

Note:

Cover the shift lever and change lever holes to prevent

the entry of foreign material into the transmission.

Lifting the Vehicle

1. Jack up the vehicle.

2. Place chassis stands at the front and the rear of the

vehicle.

Transfer Case Protector (Except 00 Year or Subsequent

ones)

Remove the transfer case protector from the transmission

mounting member and the side member.

235RT004

Page 2444 of 3573

MUA MODEL 7B1 – 53

Front Propeller Shaft

Remove the splined yoke flange bolt at the transfer case

side.

Do not allow the splined yoke to fall away from the front

propeller shaft.

If the splined yoke should fall away from the front

propeller shaft, align the setting marks

3on the splined

yoke 1and the propeller shaft 2to reassemble the two

parts.

The setting marks 3are punched circles approximately 3

mm (0.12 in) in diameter.

TDC Sensor (4JA1TC Model)

Disconnect the TDC sensor from the transmission

housing.

Harness Connector

Disconnect the 4WD switch connectors, back up light

switch connector and the speedometer sensor connector.

220R200001

Slave Cylinder

Remove the slave cylinder from the transmission case.

220LV019

Engine LIfting Hanger

1. Attach the engine lifting hanger to the front portion of

the engine.

2. Attach the lifting wire to both ends of the engine

lifting hange.

Page 2448 of 3573

MUA MODEL 7B1 – 57

Starter Motor

1. Install the starter motor to the engine rear plate.

Starter Motor Bolt Torque kg·m (lb·ft/N·m)

8.0 ± 1.6 (58 ± 12/78 ± 16)

Engine Rear Mounting and Mounting Member

1. Install the engine rear mounting to the transmission.

Rear Mounting Bolt Torque kg·m (lb·ft/N·m)

4.2 ± 0.5 (30 ± 3.6/41 ± 4.9)

2. Install the mounting member 1to the mounting

rubber 2.

Mounting Rubber Nut Torque kg·m (lb·ft/N·m)

5.1 ± 0.6 (37 ± 4.3/50 ± 6)

3. Install the mounting member to the sidemembers.

Mounting Member Bolt Torque kg·m (lb·ft/N·m)

5.1 ± 0.6 (37 ± 4.3/50 ± 6)

Slave Cylinder

Install the slave cylinder to the transmission case.

Slave Cylinder Bolt Torque kg·m (lb·ft/N·m)

4.1 ± 1.0 (30 ± 7.2/40 ± 10)

Harness Connector

Disconnect the 4WD switch connectors back up light

switch connector and speedometer sensor connector.

220LV019

TDC Sensor (4JA1TC Model)

Connect the TDC sensor from the transmission housing.

220R200001

Page 2450 of 3573

MUA MODEL 7B1 – 59

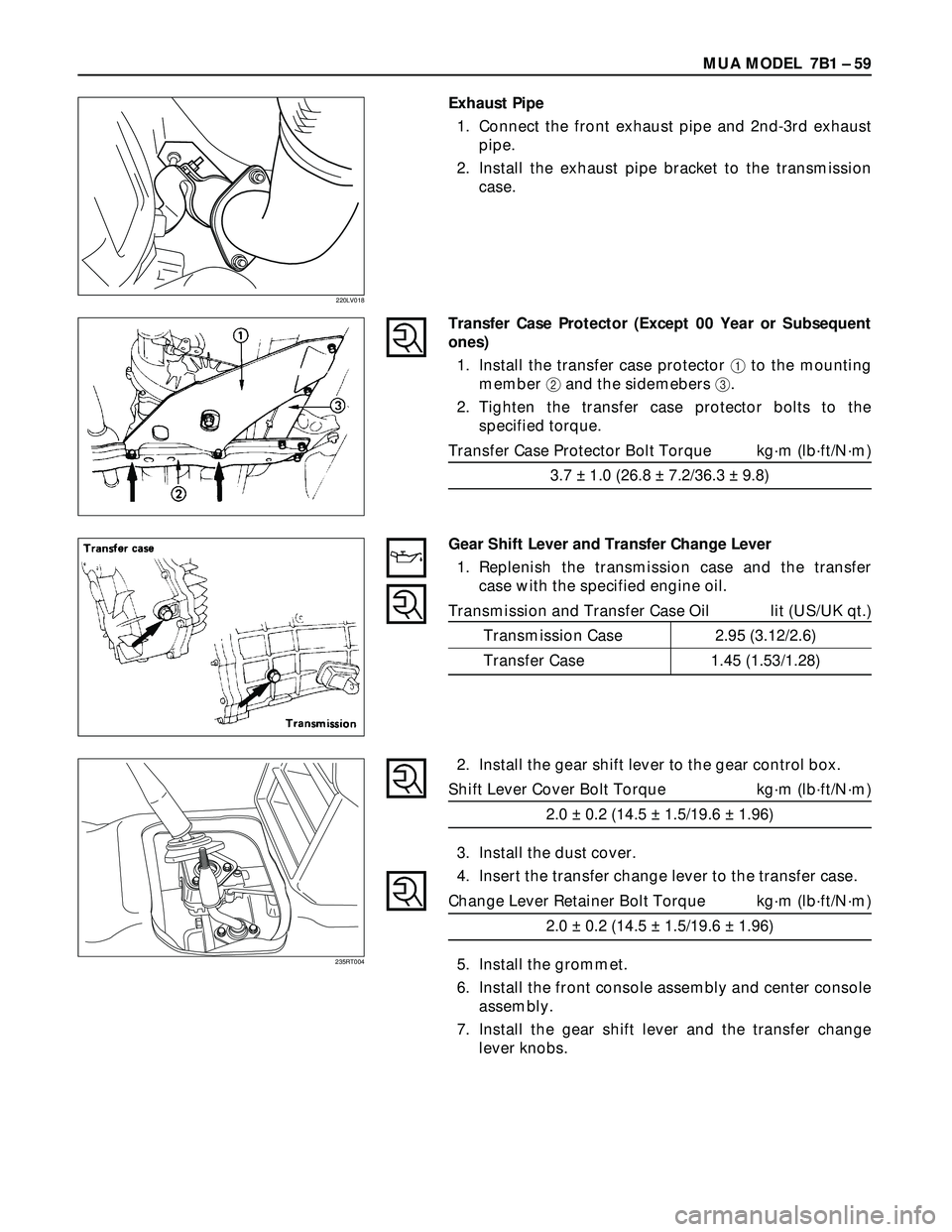

Exhaust Pipe

1. Connect the front exhaust pipe and 2nd-3rd exhaust

pipe.

2. Install the exhaust pipe bracket to the transmission

case.

220LV018

Transfer Case Protector (Except 00 Year or Subsequent

ones)

1. Install the transfer case protector 1to the mounting

member 2and the sidemebers 3.

2. Tighten the transfer case protector bolts to the

specified torque.

Transfer Case Protector Bolt Torque kg·m (lb·ft/N·m)

3.7 ± 1.0 (26.8 ± 7.2/36.3 ± 9.8)

Gear Shift Lever and Transfer Change Lever

1. Replenish the transmission case and the transfer

case with the specified engine oil.

Transmission and Transfer Case Oil lit (US/UK qt.)

Transmission Case 2.95 (3.12/2.6)

Transfer Case 1.45 (1.53/1.28)

2. Install the gear shift lever to the gear control box.

Shift Lever Cover Bolt Torque kg·m (lb·ft/N·m)

2.0 ± 0.2 (14.5 ± 1.5/19.6 ± 1.96)

3. Install the dust cover.

4. Insert the transfer change lever to the transfer case.

Change Lever Retainer Bolt Torque kg·m (lb·ft/N·m)

2.0 ± 0.2 (14.5 ± 1.5/19.6 ± 1.96)

5. Install the grommet.

6. Install the front console assembly and center console

assembly.

7. Install the gear shift lever and the transfer change

lever knobs.

235RT004