ISUZU TROOPER 1998 Service Repair Manual

Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1501 of 3573

SERVICE INFORMATION 00 Ð 1

SECTION 00

SERVICE INFORMATION

CONTENTS

PAGE

Troubleshooting .............................................................................................................. 00- 2

Main Data and Specifications ......................................................................................... 00-20

Service Standard .............................................................................................................. 00-23

Servicing ........................................................................................................................... 00-27

Fixing Torque .................................................................................................................... 00-38

Special Tools ..................................................................................................................... 00-47

Page 1502 of 3573

00 Ð 2 SERVICE INFORMATION

TROUBLESHOOTING

CONTENTS

PAGE

Hard Starting ................................................................................................................... 00- 3

Starter Motor Inoperative ........................................................................................... 00- 3

Starter Motor Operates but Engine does not turn over ........................................... 00- 3

Engine turns over but does not start ......................................................................... 00- 4

Quick-on Start System (QOS III) ................................................................................. 00- 5

Unstable Idling ................................................................................................................. 00- 5

Insufficient Power ............................................................................................................ 00- 7

Excessive Fuel Consumption .......................................................................................... 00- 9

Excessive Oil Consumption ............................................................................................. 00- 9

Overheating ...................................................................................................................... 00-10

White Exhaust Smoke ..................................................................................................... 00-10

Dark Exhaust Smoke ........................................................................................................ 00-11

Oil Pressure Does Not Rise .............................................................................................. 00-11

Abnormal Engine Noise ................................................................................................... 00-12

Engine Knocking .......................................................................................................... 00-12

Gas Leakage noise ....................................................................................................... 00-12

Continuous noise ......................................................................................................... 00-12

Slapping noise .............................................................................................................. 00-13

Engine Cooling Trouble ................................................................................................... 00-14

Engine Electrical ............................................................................................................... 00-15

Starter does not run .................................................................................................... 00-15

Faulty Meshing or Pinion and Ring Gear ................................................................... 00-16

Magnetic Switch does not operate though starter switch is turned to ÒStart (ST)Ó ...00-17

Pinion Meshes with ring gear but engine does not run ........................................... 00-18

Starter does not stop though starter switch is returned to ÒONÓ .......................... 00-19

Page 1503 of 3573

SERVICE INFORMATION 00 Ð 3

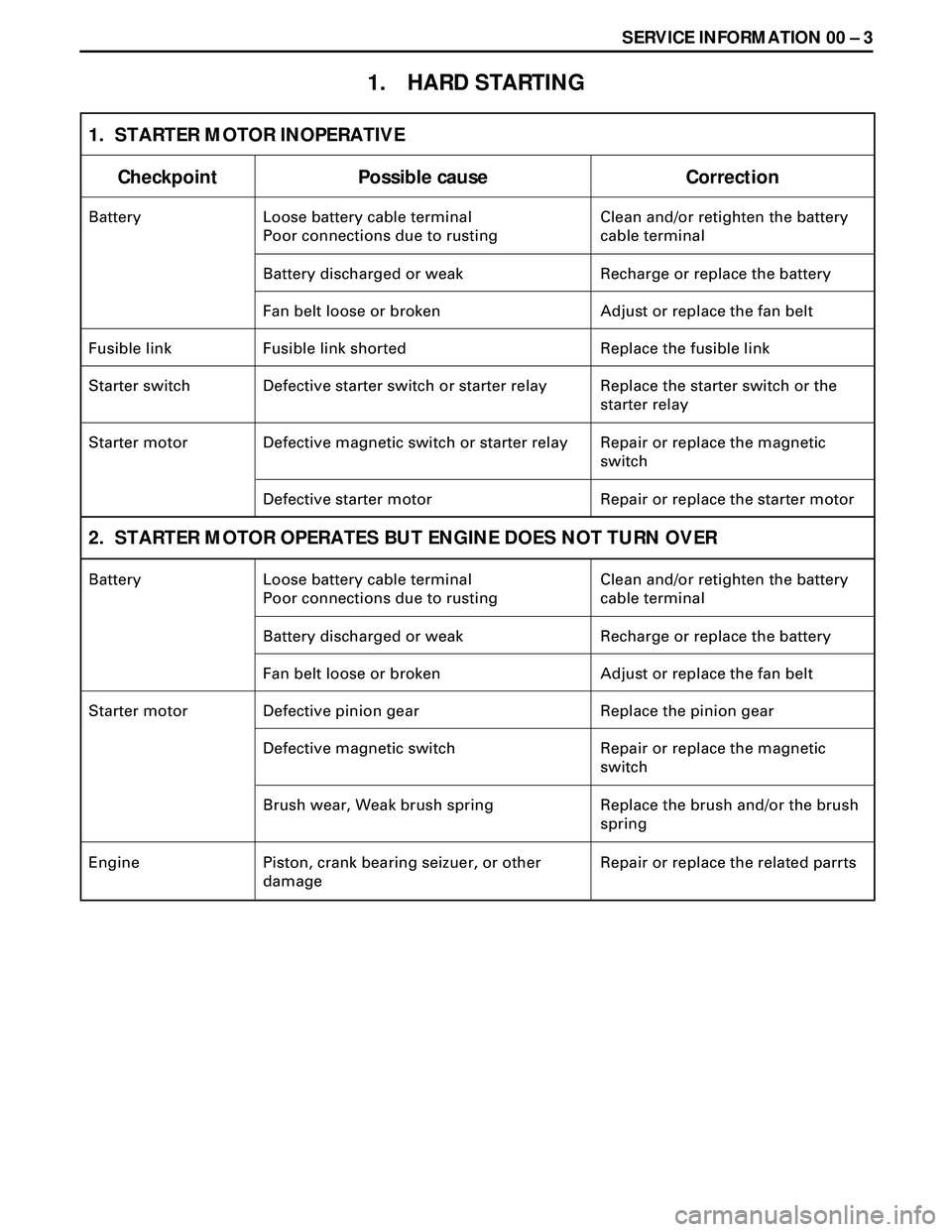

1. HARD STARTING

Checkpoint Possible cause Correction

Battery Loose battery cable terminal

Poor connections due to rustingClean and/or retighten the battery

cable terminal

1. STARTER MOTOR INOPERATIVE

Battery discharged or weak Recharge or replace the battery

Fan belt loose or broken Adjust or replace the fan belt

Fusible link Fusible link shorted Replace the fusible link

Starter switch Defective starter switch or starter relay Replace the starter switch or the

starter relay

Starter motor Defective magnetic switch or starter relay Repair or replace the magnetic

switch

Defective starter motor Repair or replace the starter motor

2. STARTER MOTOR OPERATES BUT ENGINE DOES NOT TURN OVER

Battery Loose battery cable terminal

Poor connections due to rustingClean and/or retighten the battery

cable terminal

Battery discharged or weak Recharge or replace the battery

Fan belt loose or broken Adjust or replace the fan belt

Starter motor Defective pinion gear Replace the pinion gear

Defective magnetic switch Repair or replace the magnetic

switch

Brush wear, Weak brush spring Replace the brush and/or the brush

spring

Engine Piston, crank bearing seizuer, or other

damageRepair or replace the related parrts

Page 1504 of 3573

00 Ð 4 SERVICE INFORMATION

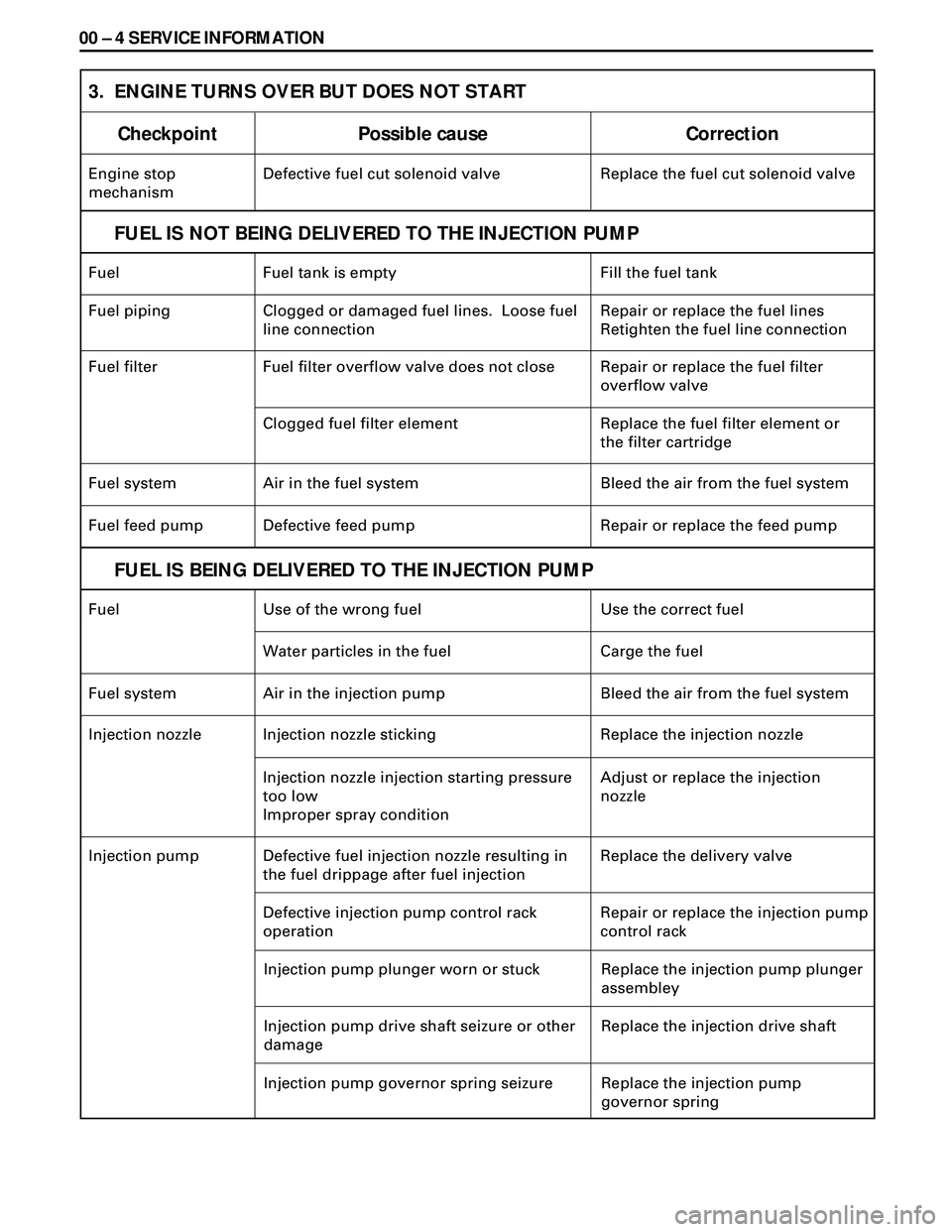

Checkpoint Possible cause Correction

Engine stop

mechanismDefective fuel cut solenoid valve Replace the fuel cut solenoid valve

3. ENGINE TURNS OVER BUT DOES NOT START

FUEL IS NOT BEING DELIVERED TO THE INJECTION PUMP

Fuel Fuel tank is empty Fill the fuel tank

Fuel piping Clogged or damaged fuel lines. Loose fuel

line connectionRepair or replace the fuel lines

Retighten the fuel line connection

Fuel filter Fuel filter overflow valve does not close Repair or replace the fuel filter

overflow valve

Clogged fuel filter element Replace the fuel filter element or

the filter cartridge

Fuel system Air in the fuel system Bleed the air from the fuel system

Fuel feed pump Defective feed pump Repair or replace the feed pump

FUEL IS BEING DELIVERED TO THE INJECTION PUMP

Fuel Use of the wrong fuel Use the correct fuel

Water particles in the fuel Carge the fuel

Fuel system Air in the injection pump Bleed the air from the fuel system

Injection nozzle Injection nozzle sticking Replace the injection nozzle

Injection nozzle injection starting pressure

too low

Improper spray conditionAdjust or replace the injection

nozzle

Injection pump Defective fuel injection nozzle resulting in

the fuel drippage after fuel injectionReplace the delivery valve

Defective injection pump control rack

operationRepair or replace the injection pump

control rack

Injection pump plunger worn or stuck Replace the injection pump plunger

assembley

Injection pump drive shaft seizure or other

damageReplace the injection drive shaft

Injection pump governor spring seizure Replace the injection pump

governor spring

Page 1505 of 3573

SERVICE INFORMATION 00 Ð 5

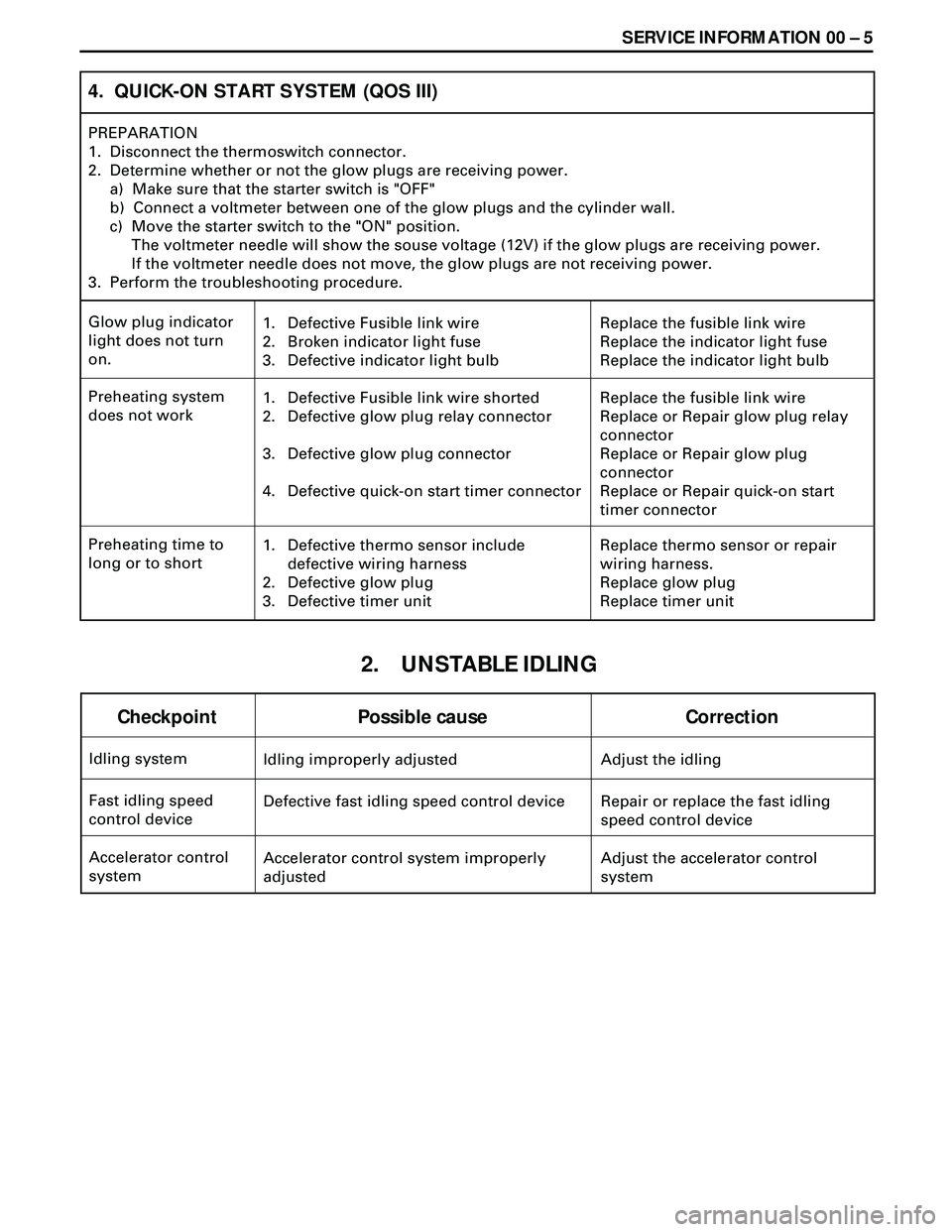

Idling improperly adjusted Adjust the idling Idling system

Checkpoint Possible cause Correction

Defective fast idling speed control device Repair or replace the fast idling

speed control device Fast idling speed

control device

Accelerator control system improperly

adjustedAdjust the accelerator control

system Accelerator control

system

2. UNSTABLE IDLING

4. QUICK-ON START SYSTEM (QOS III)

PREPARATION

1. Disconnect the thermoswitch connector.

2. Determine whether or not the glow plugs are receiving power.

a) Make sure that the starter switch is "OFF"

b) Connect a voltmeter between one of the glow plugs and the cylinder wall.

c) Move the starter switch to the "ON" position.

The voltmeter needle will show the souse voltage (12V) if the glow plugs are receiving power.

If the voltmeter needle does not move, the glow plugs are not receiving power.

3. Perform the troubleshooting procedure.

1.

2.

3.Replace the fusible link wire

Replace the indicator light fuse

Replace the indicator light bulb Glow plug indicator

light does not turn

on.Defective Fusible link wire

Broken indicator light fuse

Defective indicator light bulb

1.

2.

3.

4.Replace the fusible link wire

Replace or Repair glow plug relay

connector

Replace or Repair glow plug

connector

Replace or Repair quick-on start

timer connector Preheating system

does not workDefective Fusible link wire shorted

Defective glow plug relay connector

Defective glow plug connector

Defective quick-on start timer connector

1.

2.

3.Replace thermo sensor or repair

wiring harness.

Replace glow plug

Replace timer unit Preheating time to

long or to shortDefective thermo sensor include

defective wiring harness

Defective glow plug

Defective timer unit

Page 1506 of 3573

00 Ð 6 SERVICE INFORMATION

Checkpoint Possible cause Correction

Injection timing improperly adjusted Adjust the injection timing

Insufficient injection volume Adjust the injection volume

Defective idle spring Replace the idle spring

Defective governor lever operation Repair or replace the governor

lever

Regulator valve improperly adjustment Adjust or replace the regulator valve

Broken plunger spring Replace the plunger spring

Worn plunger Replace the plunger assembly

Worn cam disc Replace the cam disc

Valve clearance improperly adjusted Adjust the valve clearance Valve clearance

Blown out cylinder head gasket. Worn

cylinder liner.

Piston ring sticking between

the valve and the valve seatReplace the related parts Compression

pressure

Fuel system leakage or blockage Repair or replace the fuel system Fuel system

Air in the fuel system Bleed the air from the fuel system

Water particles in the fuel system Change the fuel

Clogged fuel filter element Replace the fuel filter element or

the fuel filter cartridge Fuel filter

Defective fuel feed pump Repair or replace the fuel feed pump Fuel feed pump

Injection nozzle sticking Replace the injection nozzle Injection nozzle

Injection nozzle injection starting pressure

too low

Improper spray conditionAdjust or replace the injection

nozzle

Defective delivery valve resulting in fuel

drippage after fuel injectionReplace the delivery valve Injection pump

Page 1507 of 3573

SERVICE INFORMATION 00 Ð 7

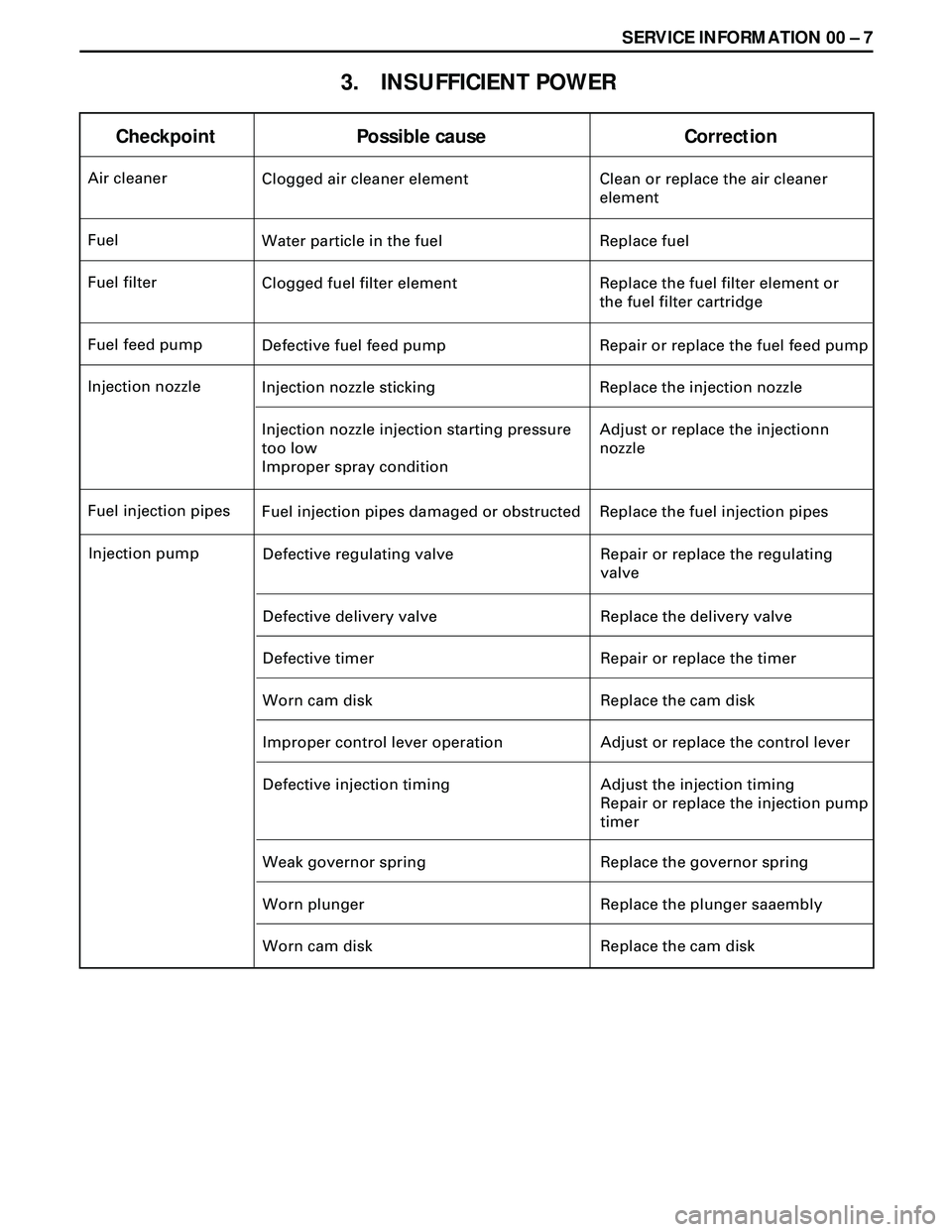

3. INSUFFICIENT POWER

Clogged air cleaner element Clean or replace the air cleaner

element Air cleaner

Checkpoint Possible cause Correction

Water particle in the fuel Replace fuel Fuel

Clogged fuel filter element Replace the fuel filter element or

the fuel filter cartridge Fuel filter

Defective fuel feed pump Repair or replace the fuel feed pump Fuel feed pump

Injection nozzle sticking Replace the injection nozzle Injection nozzle

Injection nozzle injection starting pressure

too low

Improper spray conditionAdjust or replace the injectionn

nozzle

Fuel injection pipes damaged or obstructed Replace the fuel injection pipes Fuel injection pipes

Defective regulating valve Repair or replace the regulating

valve Injection pump

Defective delivery valve Replace the delivery valve

Defective timer Repair or replace the timer

Worn cam disk Replace the cam disk

Improper control lever operation Adjust or replace the control lever

Defective injection timing Adjust the injection timing

Repair or replace the injection pump

timer

Weak governor spring Replace the governor spring

Worn plunger Replace the plunger saaembly

Worn cam disk Replace the cam disk

Page 1508 of 3573

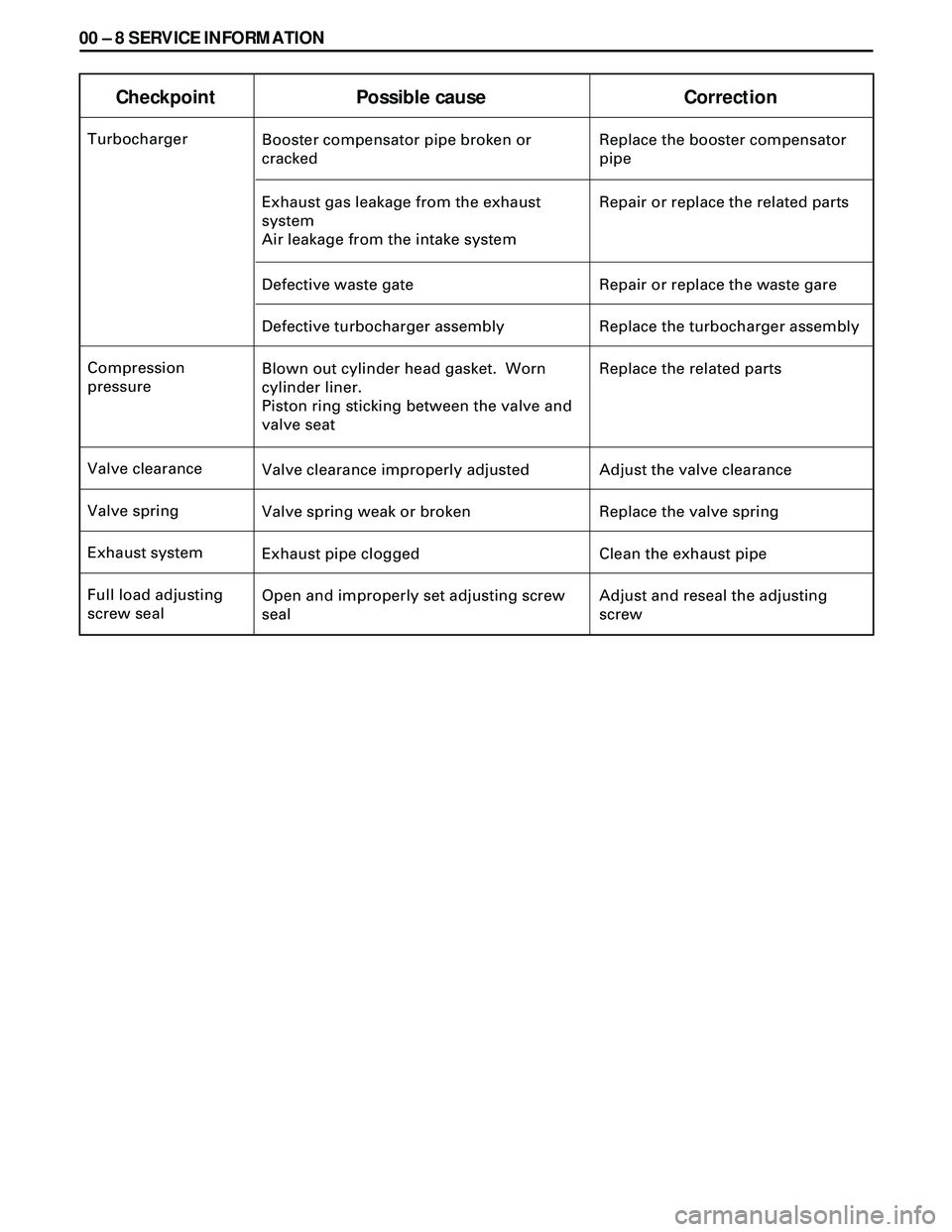

00 Ð 8 SERVICE INFORMATION

Checkpoint Possible cause Correction

Booster compensator pipe broken or

crackedReplace the booster compensator

pipe Turbocharger

Exhaust gas leakage from the exhaust

system

Air leakage from the intake systemRepair or replace the related parts

Defective waste gate Repair or replace the waste gare

Defective turbocharger assembly Replace the turbocharger assembly

Blown out cylinder head gasket. Worn

cylinder liner.

Piston ring sticking between the valve and

valve seatReplace the related parts Compression

pressure

Valve clearance improperly adjusted Adjust the valve clearance Valve clearance

Valve spring weak or broken Replace the valve spring Valve spring

Exhaust pipe clogged Clean the exhaust pipe Exhaust system

Open and improperly set adjusting screw

sealAdjust and reseal the adjusting

screw Full load adjusting

screw seal

Page 1509 of 3573

SERVICE INFORMATION 00 Ð 9

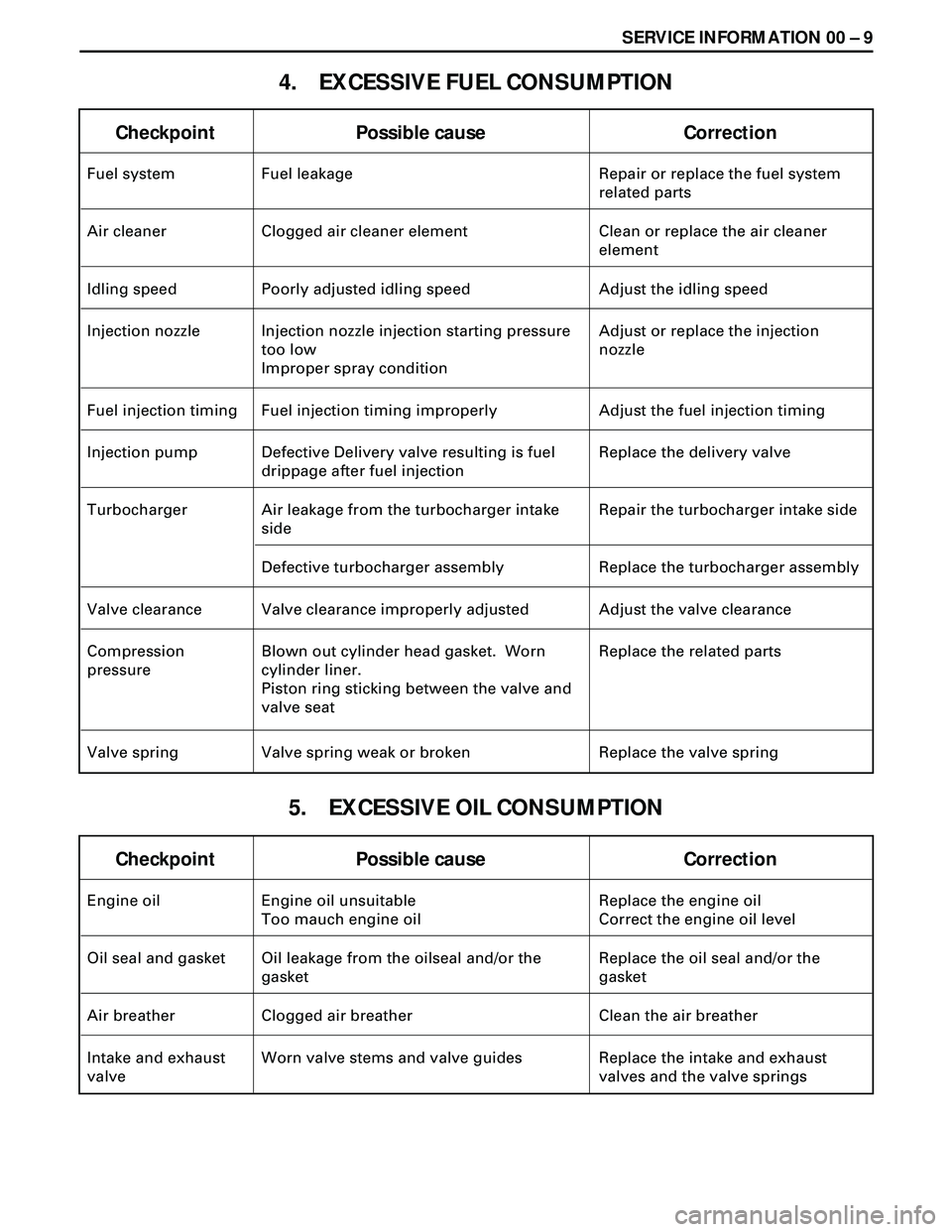

4. EXCESSIVE FUEL CONSUMPTION

5. EXCESSIVE OIL CONSUMPTION

Checkpoint Possible cause Correction

Engine oil Engine oil unsuitable

Too mauch engine oilReplace the engine oil

Correct the engine oil level

Oil seal and gasket Oil leakage from the oilseal and/or the

gasketReplace the oil seal and/or the

gasket

Air breather Clogged air breather Clean the air breather

Intake and exhaust

valveWorn valve stems and valve guides Replace the intake and exhaust

valves and the valve springs

Checkpoint Possible cause Correction

Fuel system Fuel leakage Repair or replace the fuel system

related parts

Air cleaner Clogged air cleaner element Clean or replace the air cleaner

element

Idling speed Poorly adjusted idling speed Adjust the idling speed

Injection nozzle Injection nozzle injection starting pressure

too low

Improper spray condition Adjust or replace the injection

nozzle

Fuel injection timing Fuel injection timing improperly Adjust the fuel injection timing

Injection pump Defective Delivery valve resulting is fuel

drippage after fuel injectionReplace the delivery valve

Turbocharger Air leakage from the turbocharger intake

sideRepair the turbocharger intake side

Defective turbocharger assembly Replace the turbocharger assembly

Valve clearance Valve clearance improperly adjusted Adjust the valve clearance

Compression

pressureBlown out cylinder head gasket. Worn

cylinder liner.

Piston ring sticking between the valve and

valve seatReplace the related parts

Valve spring Valve spring weak or broken Replace the valve spring

Page 1510 of 3573

00 Ð 10 SERVICE INFORMATION

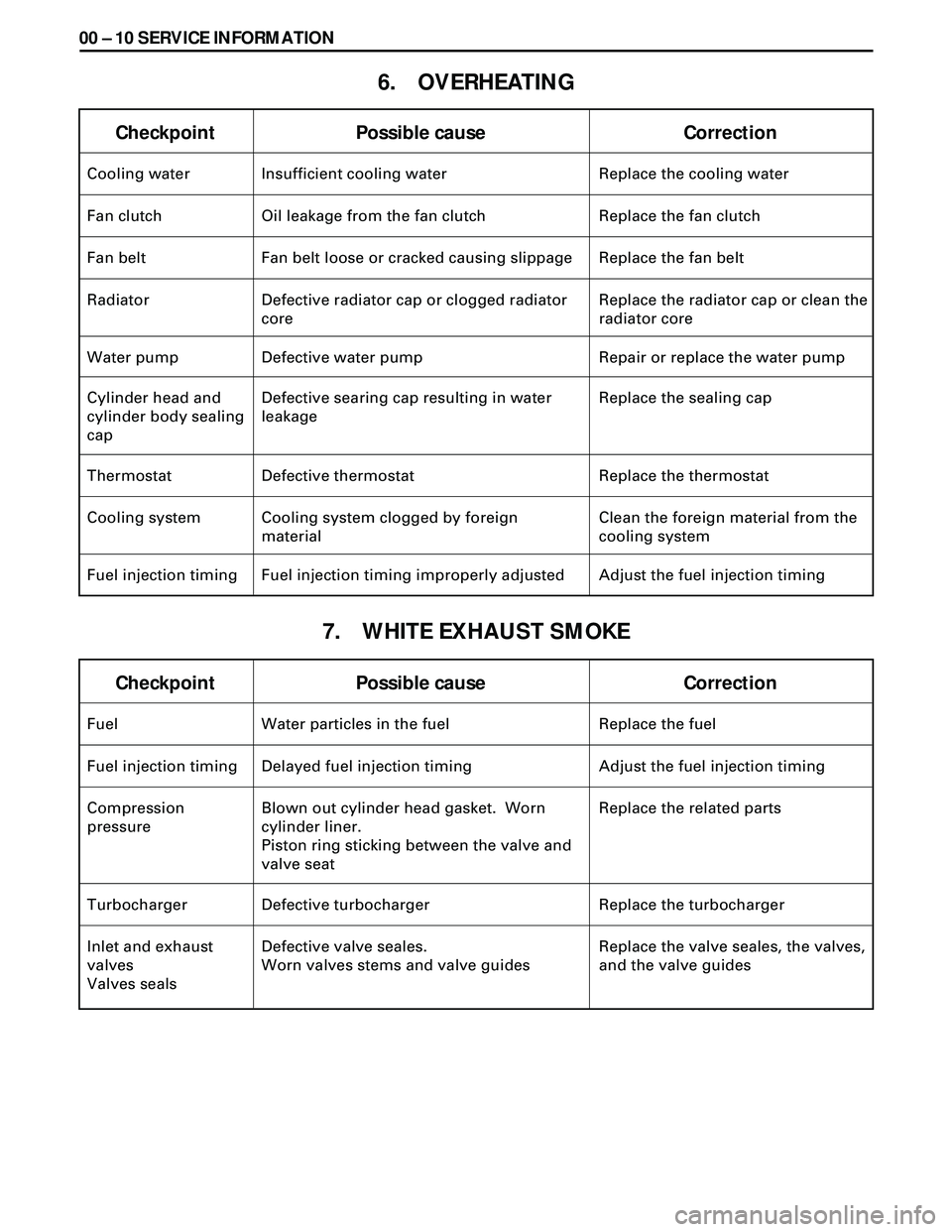

6. OVERHEATING

7. WHITE EXHAUST SMOKE

Checkpoint Possible cause Correction

Fuel Water particles in the fuel Replace the fuel

Fuel injection timing Delayed fuel injection timing Adjust the fuel injection timing

Compression

pressureBlown out cylinder head gasket. Worn

cylinder liner.

Piston ring sticking between the valve and

valve seatReplace the related parts

Turbocharger Defective turbocharger Replace the turbocharger

Inlet and exhaust

valves

Valves sealsDefective valve seales.

Worn valves stems and valve guidesReplace the valve seales, the valves,

and the valve guides

Checkpoint Possible cause Correction

Cooling water Insufficient cooling water Replace the cooling water

Fan clutch Oil leakage from the fan clutch Replace the fan clutch

Fan belt Fan belt loose or cracked causing slippage Replace the fan belt

Radiator Defective radiator cap or clogged radiator

coreReplace the radiator cap or clean the

radiator core

Water pump Defective water pump Repair or replace the water pump

Cylinder head and

cylinder body sealing

capDefective searing cap resulting in water

leakageReplace the sealing cap

Thermostat Defective thermostat Replace the thermostat

Cooling system Cooling system clogged by foreign

materialClean the foreign material from the

cooling system

Fuel injection timing Fuel injection timing improperly adjusted Adjust the fuel injection timing