engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 887 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 9

SERVICING

FILLING MASTER CYLINDER RESERVOIR

CAUTION:

1) Use only specified brake fluid. Do not use any

fluid which contains a petroleum base. Do not

use a container which has been used for

petroleum based fluids or a container which is

wet with water. Petroleum based fluids will

cause swelling and distortion of rubber parts in

the hydraulic brake system. Water mixed with

brake fluid lowers the fluid boiling point. Keep all

fluid containers capped to prevent

contamination.

2) Always fill the master cylinder reservoid when

the engine is cold.

3) Never allow the brake fluid to come in contact

with the painted surfaced.

The master cylinder reservoir must be kept properly

filled to ensure adequate reserve and to prevent air

and moisture from entering the hydraulic system.

However, because of expansion due to heat absorbed

from the brakes and the engine, the reservoir must not

be overfilled. The brake fluid reservoir is on the

master cylinder, which is located under the hood on

the driver side of the cowl. Thoroughly clean reservoir

cap before removal to avoid getting dirt into reservoir.

Remove cap and diaphragm. Add fluid as required to

bring level to the “MAX” mark on the reservoir tank.

Use “DOT 3“ Hydraulic Brake Fluid. If the fluid cap

diaphragm is stretched, return it to the original

position before installing.

DETERIORATION OF BRAKE FLUID

Using any other brake fluid than speficied or brake

fluid with mineral oil or water mixed in will drop the

boiling point of brake fluid. It may, in turn, reuslt in

vapor lock or deteriorated rubber parts of the

hydraulic system. Be sure to change brake fluid at

specified intervals.

If rubber parts are deteriorated, remover all the

system parts and clean them with alcohol. Prior to

reassembly, dry the cleaned parts with air to remove

the alcohol. Replace all hoses and rubber parts of the

system.

LEAKAGE OF BRAKE FLUID

With engine idling, set shift lever in the neutral

position and continue to depress brake pedal at a

constant pedal application force.

Should the pedal stroke become deeper gradually,

leak from the hydraulic pressure system is possible.

Make sure by visual check that there is no leak.

Page 888 of 3573

5C – 10 POWER ASSISTED BRAKE SYSTEM

BLEEDING BRAKE HYDRAULIC SYSTEM

A bleeding operation is necessary to remove air from

the hydraulic brake system whenever air is introduced

into the hydraulic system. It may be necessary to

bleed the hydraulic system at all four brakes if air has

been introduced through a low fluid level or by

disconnecting brake pipes at the master cylinder. If a

brake pipe is disconneted at one wheel, only that

wheel cylinder/caliper needs to be bled. If pipes are

disconnected at any fitting located between master

cylinder and brakes, then the brake system served by

the disconnected pipe must be bled.

1. For 4-wheel Antilock Brake System (ABS)

equipped vehicle, be sure to remove the ABS main

fuse 40A located at the relay and fuse box before

bleeding air. If you attempt to bleed air without

removing the main fuse, air cannot be let out

thoroughly, and this may cause damage to the

hydraulic unit. After bleeding air, be sure to

replace the ABS main fuse back to its original

position.

2. Set the parking brake completely, then start the

engine.

NOTE:

The vacuum booster will be damaged if the bleeding

operation is performed with the engine off.

3. Remove the master cylinder reservoir cap.

4. Fill the master cylinder reservoir with brake fluid.

Keep the reservoir at least half full during the air

bleeding operation.

5. Always use new brake fluid for replenishment.

6. In replenishing brake fluid, take care that air

bubbles do not enter the brake fluid.

•When the master cylinder is replaced or

overhauled, first bleed the air from the master

cylinder, then from each wheel cylinder and

caliper following the procedures described

below.

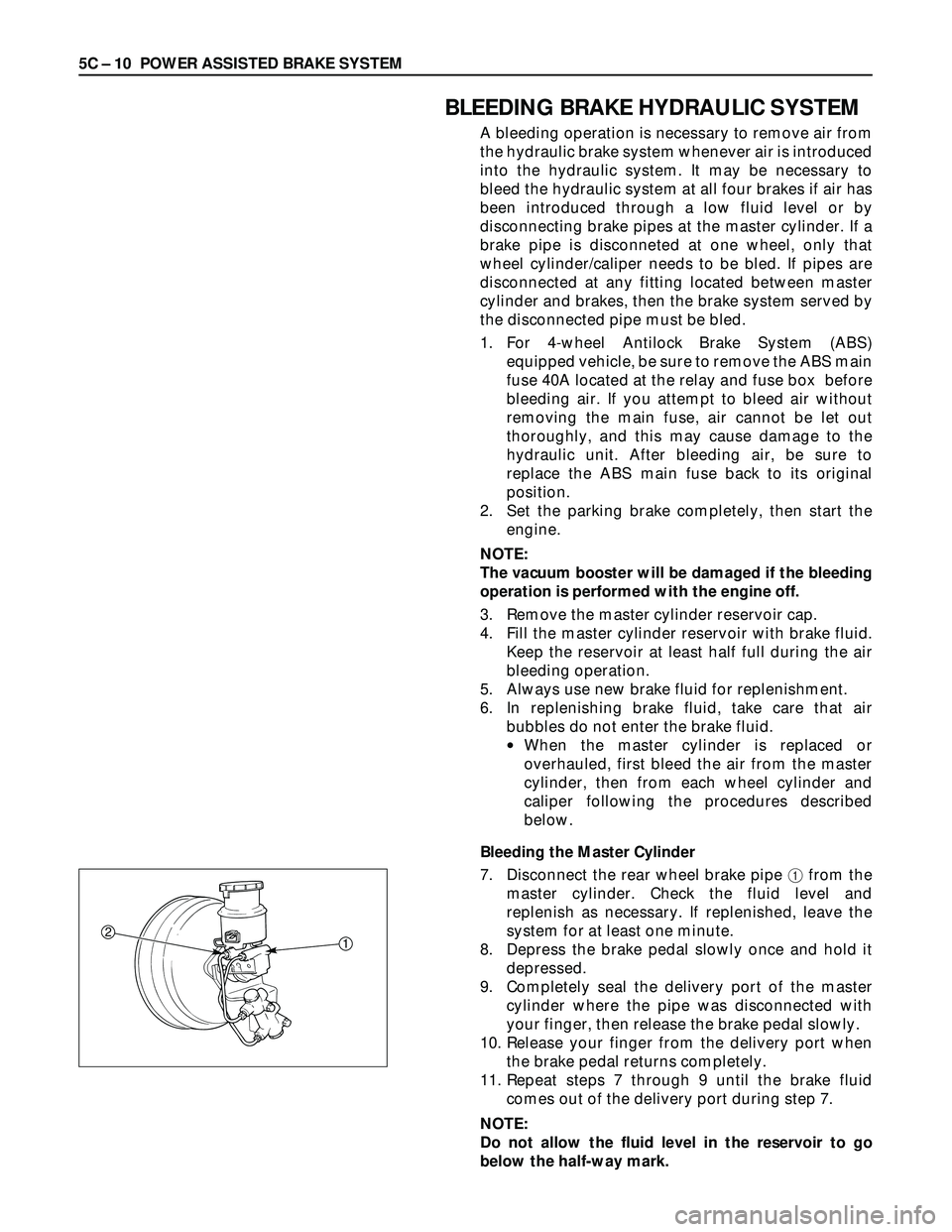

Bleeding the Master Cylinder

7. Disconnect the rear wheel brake pipe 1from the

master cylinder. Check the fluid level and

replenish as necessary. If replenished, leave the

system for at least one minute.

8. Depress the brake pedal slowly once and hold it

depressed.

9. Completely seal the delivery port of the master

cylinder where the pipe was disconnected with

your finger, then release the brake pedal slowly.

10. Release your finger from the delivery port when

the brake pedal returns completely.

11. Repeat steps 7 through 9 until the brake fluid

comes out of the delivery port during step 7.

NOTE:

Do not allow the fluid level in the reservoir to go

below the half-way mark.

21

Page 890 of 3573

5C – 12 POWER ASSISTED BRAKE SYSTEM

27. Depress the brake pedal to check if you feel

“sponginess” after the air has been removed from

all wheel cylinders and calipers. If the pedal feels

“spongy”, the entire bleeding procedure must be

repeated.

28. After the bleeding operation is completed on each

individual wheel, check the level of brake fluid in

the reservoir and replenish up to the “MAX” level if

necessary.

29. Attach the reservoir cap.

•If the diaphragm inside the cap is deformed,

reform it and install.

30. Stop the engine.

FLUSHING BRAKE HYDRAULIC SYSTEM

It is recommended that the entire hydraulic system be

thoroughly flushed with clean brake fluid whenever

new parts are installed in the hydraluic system.

Approximately one quart of fluid is required to flush

the hydraulic system.

The system must be flushed if there is any doubt as to

the grade of fluid in the system or if fluid has been

used which contains the slightest trace of mineral oil.

All rubber parts that have been subjected to a

contaminated fluid must be replaced.

BRAKE PIPES AND HOSES

The hydraulic brake system components are

interconnected by special steel piping and flexible

hoses. Flexible hoses are used between the frame and

the front calipers, the frame and rear axle case and the

rear axle and the rear calipers.

When the hydraulic pipes have been disconnected for

any reason, the brake system must be bled after

reconnecting the pipe; refer to “Bleeding Brake

Hydraulic System” in this section.

BRAKE HOSE INSPECTION

The brake hoses should be inspected at least twice a

year. The brake hose assembly should be checked for

road hazard, cracks and chafing of the outer cover,

and for leaks and blisters. Inspect for proper routing

and mounting of the hose. A brake hose that rubs on

suspension components will wear and eventually fail.

A light and mirror may be needed for an adequate

inspection. If any of the above conditions are

observed on the brake hose, adjust or replace the

hose as necessary.

CAUTION:

Never allow brake components such as calipers to

hang from the brake hoses, as damage to the hoses

may occur.

Page 891 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 13

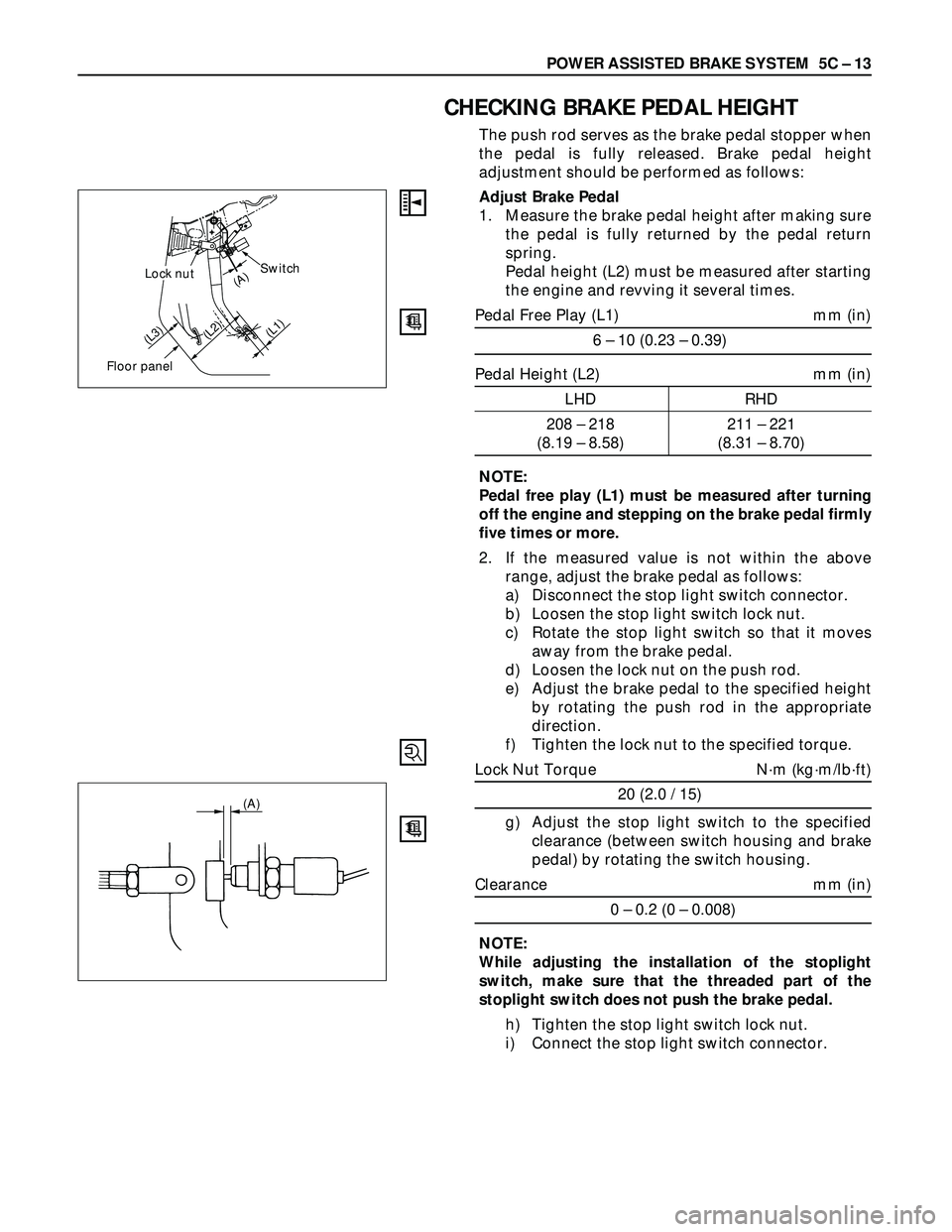

CHECKING BRAKE PEDAL HEIGHT

The push rod serves as the brake pedal stopper when

the pedal is fully released. Brake pedal height

adjustment should be performed as follows:

Adjust Brake Pedal

1. Measure the brake pedal height after making sure

the pedal is fully returned by the pedal return

spring.

Pedal height (L2) must be measured after starting

the engine and revving it several times.

Pedal Free Play (L1) mm (in)

6 – 10 (0.23 – 0.39)

Pedal Height (L2) mm (in)

LHD RHD

208 – 218 211 – 221

(8.19 – 8.58) (8.31 – 8.70)

NOTE:

Pedal free play (L1) must be measured after turning

off the engine and stepping on the brake pedal firmly

five times or more.

2. If the measured value is not within the above

range, adjust the brake pedal as follows:

a) Disconnect the stop light switch connector.

b) Loosen the stop light switch lock nut.

c) Rotate the stop light switch so that it moves

away from the brake pedal.

d) Loosen the lock nut on the push rod.

e) Adjust the brake pedal to the specified height

by rotating the push rod in the appropriate

direction.

f) Tighten the lock nut to the specified torque.

Lock Nut Torque N·m (kg·m/lb·ft)

20 (2.0 / 15)

g) Adjust the stop light switch to the specified

clearance (between switch housing and brake

pedal) by rotating the switch housing.

Clearance mm (in)

0 – 0.2 (0 – 0.008)

NOTE:

While adjusting the installation of the stoplight

switch, make sure that the threaded part of the

stoplight switch does not push the brake pedal.

h) Tighten the stop light switch lock nut.

i) Connect the stop light switch connector.

Switch

Floor panel

(L3)

(A)

(L2)(L1)

Lock nut

(A)

Page 892 of 3573

5C – 14 POWER ASSISTED BRAKE SYSTEM

CHECKING BRAKE PEDAL TRAVEL

1. Pedal height (L3) must be measured after starting

the engine and removing it several times to apply

vacuum to the vacuum booster fully.

NOTE:

Pedal height (L3) must be 100 mm (3.9 in)/85 mm (3.5

in) (LHD/RHD) or more when about 50 kg (110.25 lb)

of stepping force is applied.

2. If the measured value is lower than the above

range, air existing in the hydrauic system is

suspected and perform bleeding procedure.

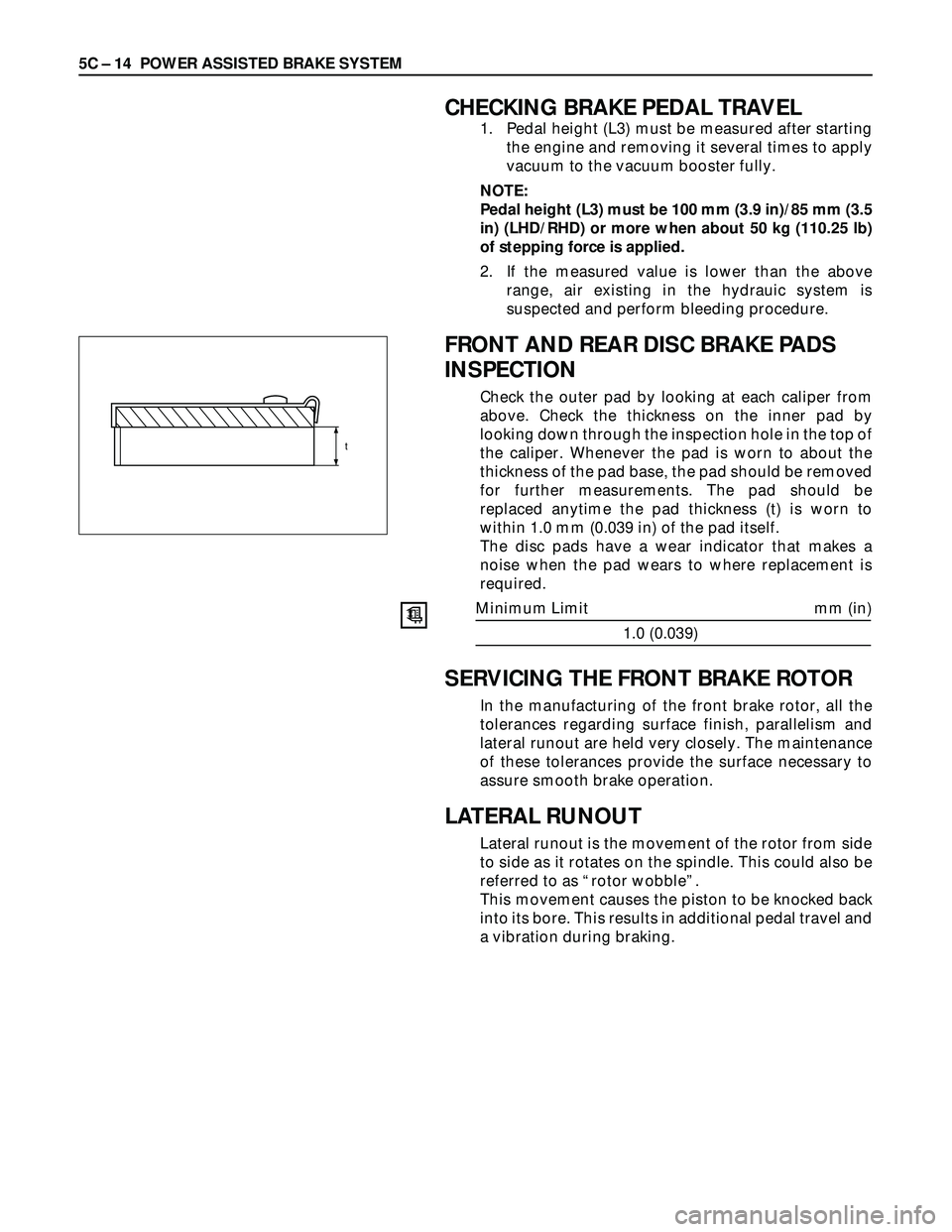

FRONT AND REAR DISC BRAKE PADS

INSPECTION

Check the outer pad by looking at each caliper from

above. Check the thickness on the inner pad by

looking down through the inspection hole in the top of

the caliper. Whenever the pad is worn to about the

thickness of the pad base, the pad should be removed

for further measurements. The pad should be

replaced anytime the pad thickness (t) is worn to

within 1.0 mm (0.039 in) of the pad itself.

The disc pads have a wear indicator that makes a

noise when the pad wears to where replacement is

required.

Minimum Limit mm (in)

1.0 (0.039)

SERVICING THE FRONT BRAKE ROTOR

In the manufacturing of the front brake rotor, all the

tolerances regarding surface finish, parallelism and

lateral runout are held very closely. The maintenance

of these tolerances provide the surface necessary to

assure smooth brake operation.

LATERAL RUNOUT

Lateral runout is the movement of the rotor from side

to side as it rotates on the spindle. This could also be

referred to as “rotor wobble”.

This movement causes the piston to be knocked back

into its bore. This results in additional pedal travel and

a vibration during braking.

t

Page 901 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 23

VACUUM BOOSTER

This booster is a tandem vacuum unit with a diaphragm effective diameter 205 mm + 230 mm (gasoline

engine model) / 180 mm + 205 mm (diesel engine model). In normal operating mode, with the service

brakes in the released position, the tandem vacuum booster operates with vacuum on both sides of its

diaphragms. When the brakes are applied, air at atmospheric pressure is admitted to one side of each

diaphragm to provide the power assist. When the service brake is released, the atmospheric air is shut

off from the one side of each diaphragm. The air is then drawn from the booster through the vacuum

check valve to the vacuum source.

CAUTION:

1) If any hydraulic component is removed or disconnected, it may be necessary to bleed all or part of

the brake system.

2) The torque values specified are for dry, unlubricated fasteners.

3) The vacuum booster is not repairable and must be replaced as complete assembly.

Page 920 of 3573

5C – 42 POWER ASSISTED BRAKE SYSTEM

REMOVAL

•Before removing the vacuum booster assembly,

disconnect and remove brake pipes.

1. Master Cylinder

•Refer to Master Cylinder Assembly in this Section.

CAUTION:

When removing master cylinder from vacuum booster,

be sure to get rid of the internal negative pressure of

the vacuum booster (by, for instance, disconnecting

vacuum hose) in advance.

If any negative pressure remains in the vacuum

booster, the piston may possibly come out when the

master cylinder is being removed, letting the brake

fluid run out.

While removing master cylinder, further, do not hold

the piston as it can be easily pulled out.

Outside surface of the piston is the surface on which

seals are to slide. Care should be taken to keep the

surface free of cuts and dents.

2. Vacuum Hose

3. Yoke Clevis

•Disconnect the yoke clevis from the brake pedal.

4. Vacuum Booster Fixing Nut

5. Vacuum Booster

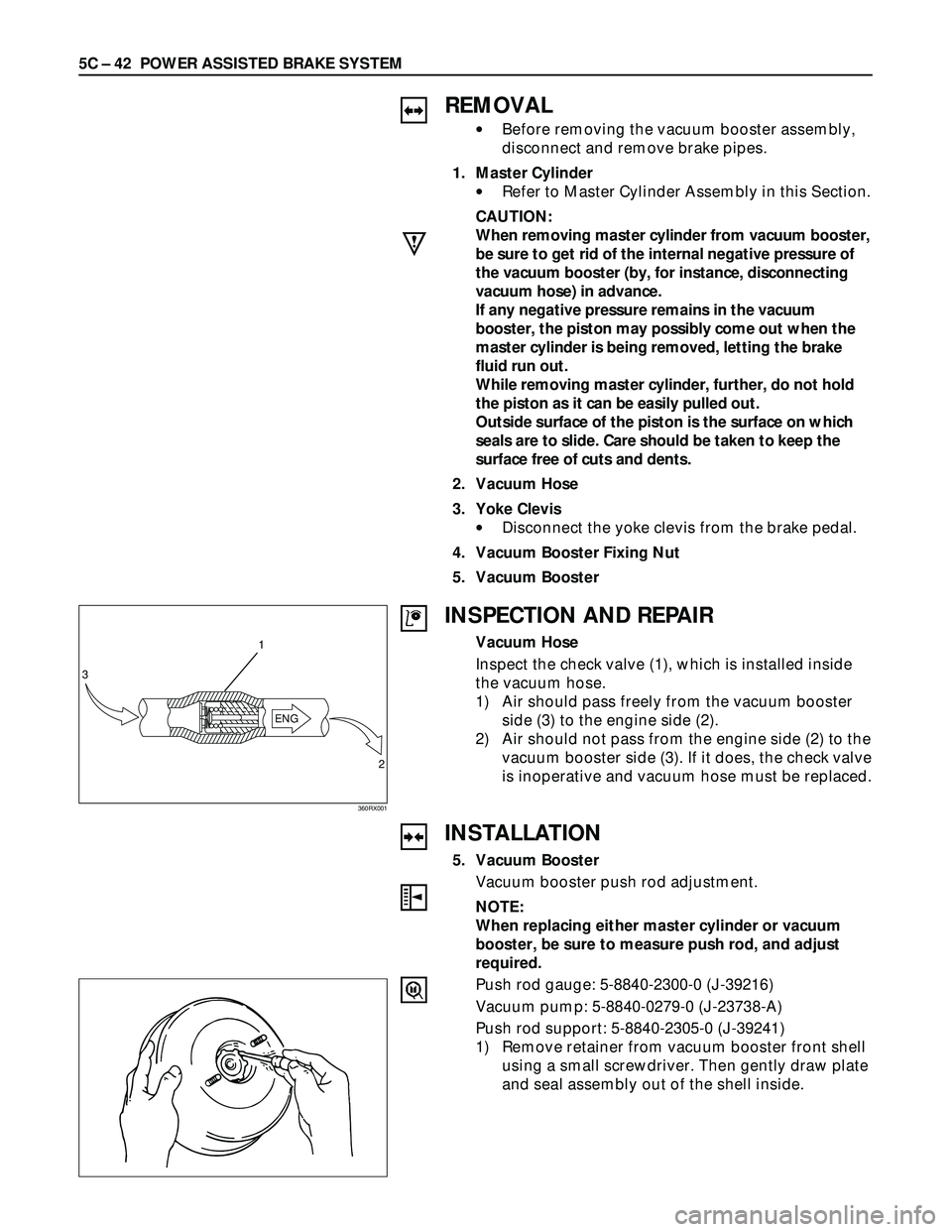

INSPECTION AND REPAIR

Vacuum Hose

Inspect the check valve (1), which is installed inside

the vacuum hose.

1) Air should pass freely from the vacuum booster

side (3) to the engine side (2).

2) Air should not pass from the engine side (2) to the

vacuum booster side (3). If it does, the check valve

is inoperative and vacuum hose must be replaced.

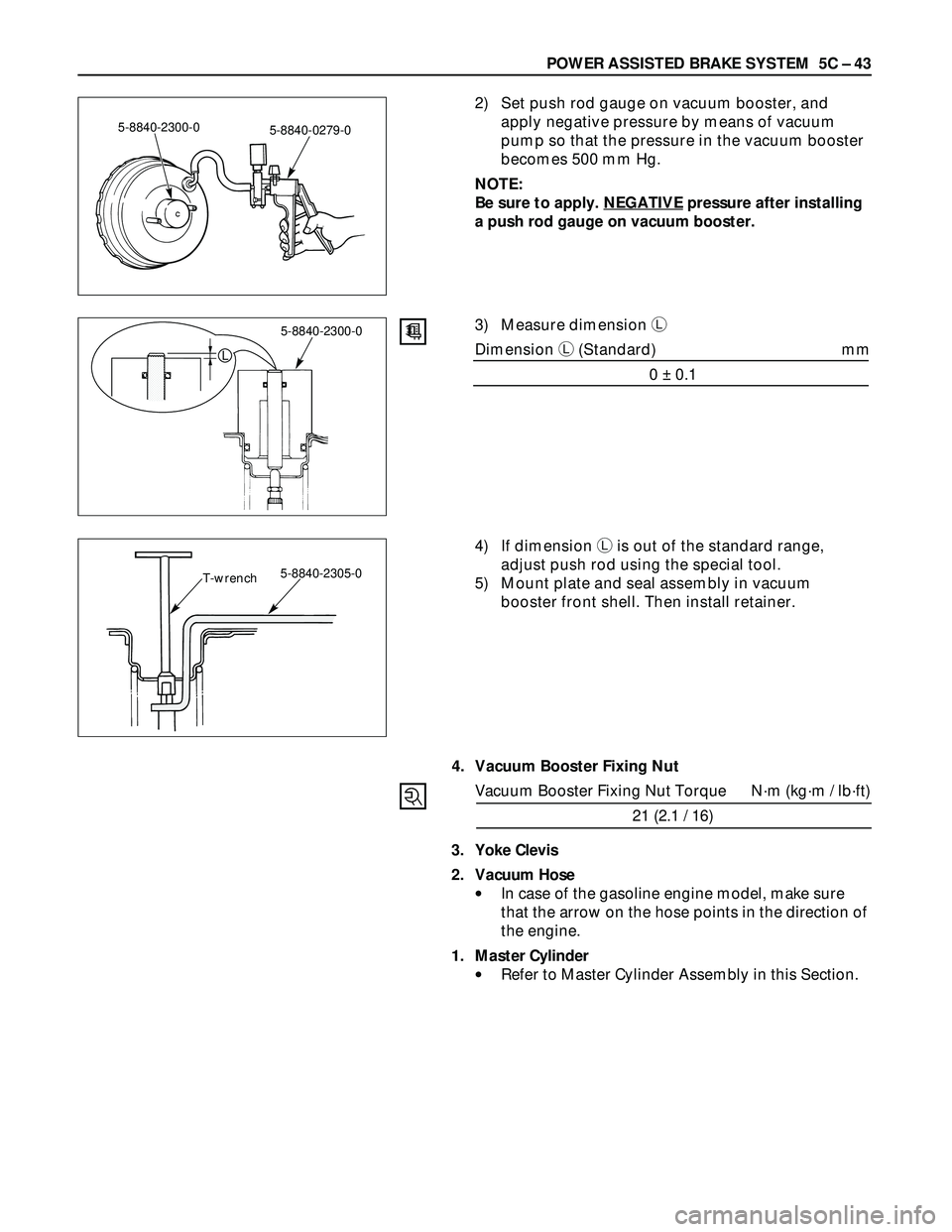

INSTALLATION

5. Vacuum Booster

Vacuum booster push rod adjustment.

NOTE:

When replacing either master cylinder or vacuum

booster, be sure to measure push rod, and adjust

required.

Push rod gauge: 5-8840-2300-0 (J-39216)

Vacuum pump: 5-8840-0279-0 (J-23738-A)

Push rod support: 5-8840-2305-0 (J-39241)

1) Remove retainer from vacuum booster front shell

using a small screwdriver. Then gently draw plate

and seal assembly out of the shell inside.

ENG

1

2 3

360RX001

Page 921 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 43

2) Set push rod gauge on vacuum booster, and

apply negative pressure by means of vacuum

pump so that the pressure in the vacuum booster

becomes 500 mm Hg.

NOTE:

Be sure to apply. NEGATIVE

pressure after installing

a push rod gauge on vacuum booster.

3) Measure dimension L

Dimension L(Standard) mm

0 ± 0.1

5-8840-0279-05-8840-2300-0

L

5-8840-2300-0

4) If dimension Lis out of the standard range,

adjust push rod using the special tool.

5) Mount plate and seal assembly in vacuum

booster front shell. Then install retainer.

4. Vacuum Booster Fixing Nut

Vacuum Booster Fixing Nut Torque N·m (kg·m / lb·ft)

21 (2.1 / 16)

3. Yoke Clevis

2. Vacuum Hose

•In case of the gasoline engine model, make sure

that the arrow on the hose points in the direction of

the engine.

1. Master Cylinder

•Refer to Master Cylinder Assembly in this Section.

5-8840-2305-0 T-wrench

Page 957 of 3573

6A±1

ENGINE MECHANICAL

ENGINE

CONTENTS

Engine Mechanical 6A. . . . . . . . . . . . . . . . . . . . . .

Engine Cooling 6B. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Fuel 6C. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Electrical 6D1. . . . . . . . . . . . . . . . . . . . . . . .

Ignition System 6D2. . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Charging System 6D3. . . . . . . . . . . . Driveability and Emissions 6E. . . . . . . . . . . . . . . .

Engine Exhaust 6F. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Lubrication 6G. . . . . . . . . . . . . . . . . . . . . .

Engine Speed Control System 6H. . . . . . . . . . . .

Inducton 6J. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE MECHANICAL

CONTENTS

Service Precaution 6A±2. . . . . . . . . . . . . . . . . . . . . .

General Description 6A±3. . . . . . . . . . . . . . . . . . . . .

Engine Diagnosis 6A±4. . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover LH 6A±18. . . . . . . . . . . . . . . . .

Removal 6A±18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover RH 6A±21. . . . . . . . . . . . . . . . .

Removal 6A±21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Chamber 6A±24. . . . . . . . . . . . . . . . . . . . . .

Removal 6A±24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold LH 6A±26. . . . . . . . . . . . . . . . . . . . .

Removal 6A±26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold RH 6A±27. . . . . . . . . . . . . . . . . . . .

Removal 6A±27. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Pulley 6A±28. . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt 6A±29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 6A±33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A±37. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Stem Oil Controller , Valve Spring and

Valve Guide 6A±39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston, Piston Ring and Connecting Rod 6A±40. . . Removal 6A±40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Main Bearings 6A±42. . . . . . . . . . . .

Removal 6A±42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal 6A±47. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±47. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Assembly 6A±48. . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A±48. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A±48. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A±52. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Associated Parts 6A±52. . . . .

Disassembly 6A±52. . . . . . . . . . . . . . . . . . . . . . . . . .

Clean 6A±53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A±53. . . . . . . . . . . . . . . . . .

Reassembly 6A±53. . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve,

Valve Guide 6A±56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve,

Valve Guide and Associated Parts 6A±56. . . . . . .

Disassembly 6A±56. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A±57. . . . . . . . . . . . . . . . . .

Reassembly 6A±60. . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Clearance Adjustments 6A±61. . . . . . . . . . . . .

Camshaft 6A±63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft and Associated Parts 6A±63. . . . . . . . .

Disassembly 6A±63. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A±64. . . . . . . . . . . . . . . . . .

Reassembly 6A±66. . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft 6A±69. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Associated Parts 6A±69. . . . . . . .

Disassembly 6A±69. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A±70. . . . . . . . . . . . . . . . . .

Inspection and Repair 6A±71. . . . . . . . . . . . . . . . . .

Reassembly 6A±73. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 958 of 3573

6A±2

ENGINE MECHANICAL

Piston and Connecting Rod 6A±77. . . . . . . . . . . . . . .

Piston, Connecting Rod and Associate

Parts 6A±77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 6A±77. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A±78. . . . . . . . . . . . . . . . . .

Reassembly 6A±82. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Block 6A±85. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Block and Associated Parts 6A±85. . . . .

Disassembly 6A±85. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A±86. . . . . . . . . . . . . . . . . .

Reassembly 6A±87. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specification 6A±90. . . . . . . . . . . . . .

Special Tool 6A±96. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.