boot ISUZU TROOPER 1998 Service User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 403 of 3573

FRONT SUSPENSION 3C – 15

REMOVAL

Preparation:

1) Raise the vehicle and support the frame with suitable

safety stands.

2) Remove wheel and tire assembly. Refer to “Wheels

and Tires” in section 3E.

3) Remove the brake caliper and disconnect flexible hose.

Refer to “Brakes” in section 5.

4) Support lower control arm with a jack.

1. Speed Sensor Cable (if equipped with ABS)

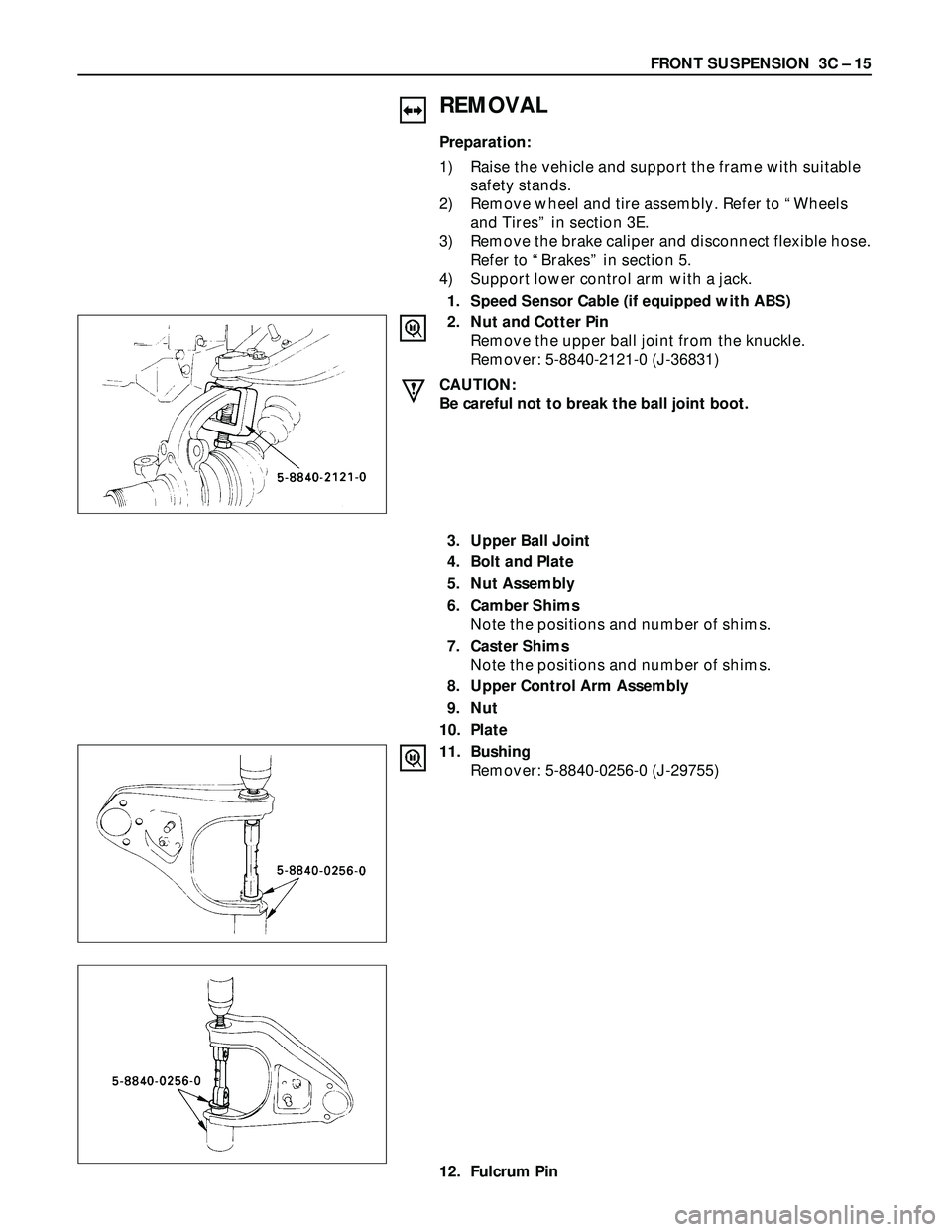

2. Nut and Cotter Pin

Remove the upper ball joint from the knuckle.

Remover: 5-8840-2121-0 (J-36831)

CAUTION:

Be careful not to break the ball joint boot.

3. Upper Ball Joint

4. Bolt and Plate

5. Nut Assembly

6. Camber Shims

Note the positions and number of shims.

7. Caster Shims

Note the positions and number of shims.

8. Upper Control Arm Assembly

9. Nut

10. Plate

11. Bushing

Remover: 5-8840-0256-0 (J-29755)

12. Fulcrum Pin

Page 411 of 3573

FRONT SUSPENSION 3C – 23

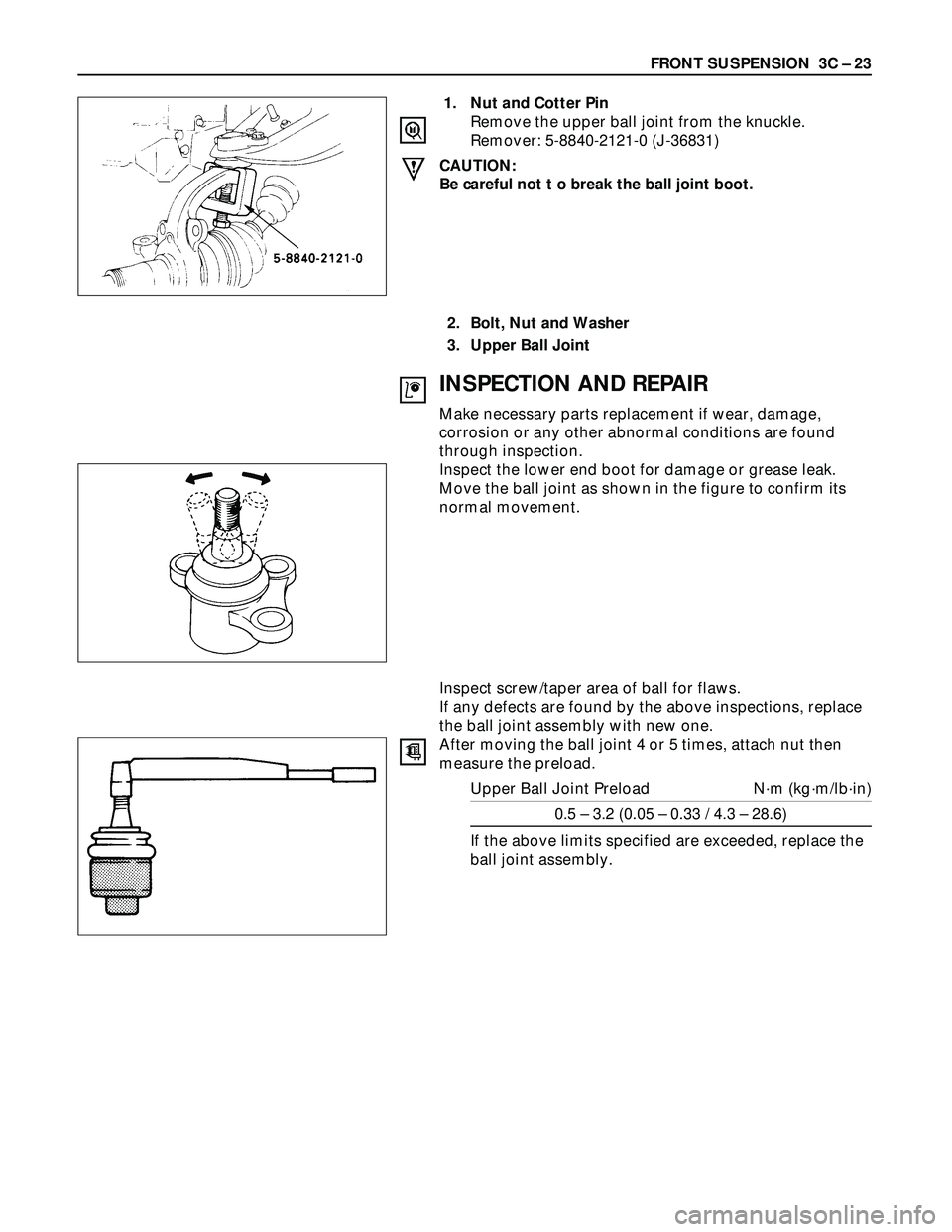

1. Nut and Cotter Pin

Remove the upper ball joint from the knuckle.

Remover: 5-8840-2121-0 (J-36831)

CAUTION:

Be careful not t o break the ball joint boot.

2. Bolt, Nut and Washer

3. Upper Ball Joint

INSPECTION AND REPAIR

Make necessary parts replacement if wear, damage,

corrosion or any other abnormal conditions are found

through inspection.

Inspect the lower end boot for damage or grease leak.

Move the ball joint as shown in the figure to confirm its

normal movement.

Inspect screw/taper area of ball for flaws.

If any defects are found by the above inspections, replace

the ball joint assembly with new one.

After moving the ball joint 4 or 5 times, attach nut then

measure the preload.

Upper Ball Joint Preload N·m (kg·m/lb·in)

0.5 – 3.2 (0.05 – 0.33 / 4.3 – 28.6)

If the above limits specified are exceeded, replace the

ball joint assembly.

Page 414 of 3573

3C – 26 FRONT SUSPENSION

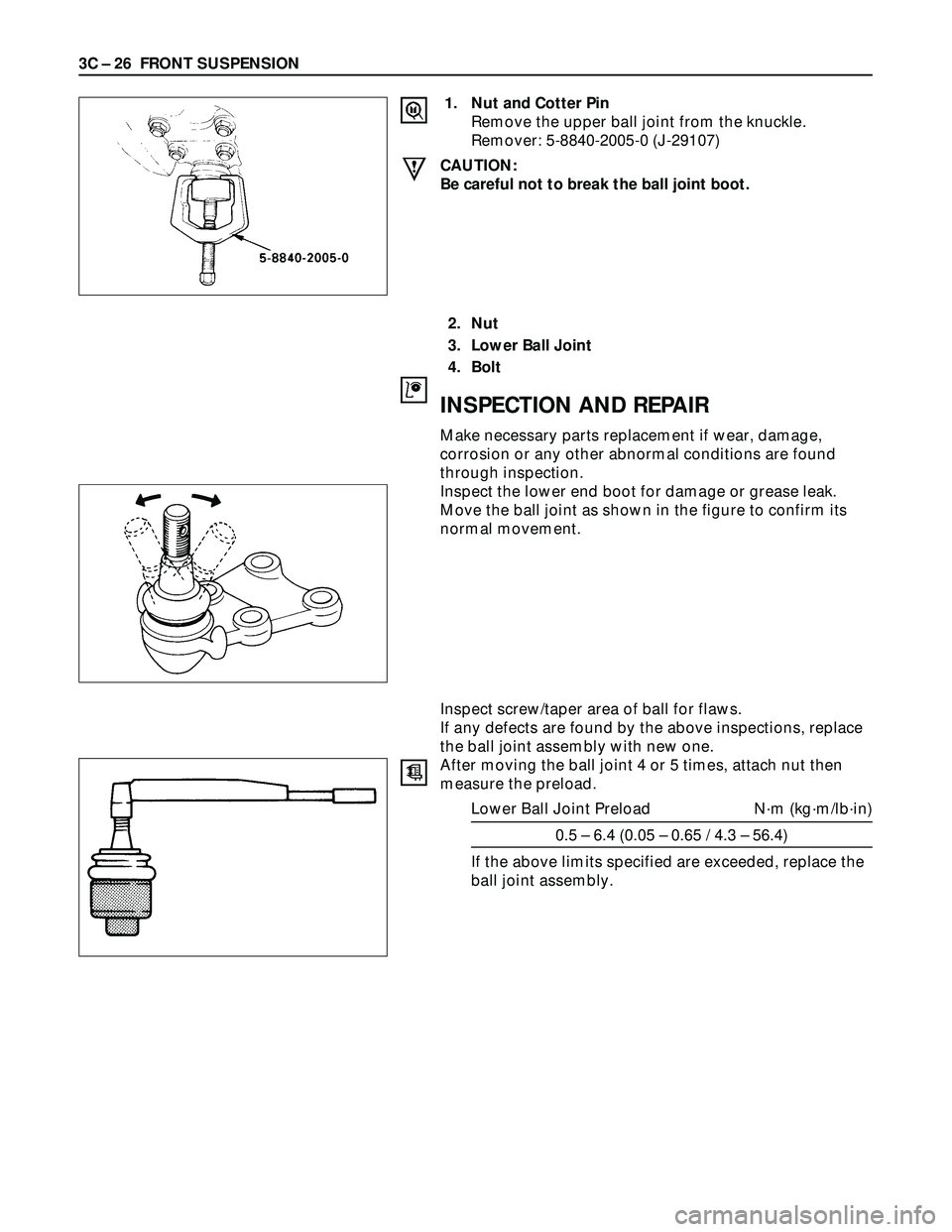

1. Nut and Cotter Pin

Remove the upper ball joint from the knuckle.

Remover: 5-8840-2005-0 (J-29107)

CAUTION:

Be careful not to break the ball joint boot.

2. Nut

3. Lower Ball Joint

4. Bolt

INSPECTION AND REPAIR

Make necessary parts replacement if wear, damage,

corrosion or any other abnormal conditions are found

through inspection.

Inspect the lower end boot for damage or grease leak.

Move the ball joint as shown in the figure to confirm its

normal movement.

Inspect screw/taper area of ball for flaws.

If any defects are found by the above inspections, replace

the ball joint assembly with new one.

After moving the ball joint 4 or 5 times, attach nut then

measure the preload.

Lower Ball Joint Preload N·m (kg·m/lb·in)

0.5 – 6.4 (0.05 – 0.65 / 4.3 – 56.4)

If the above limits specified are exceeded, replace the

ball joint assembly.

Page 430 of 3573

REAR SUSPENSION; COIL SPRING 3D – 15

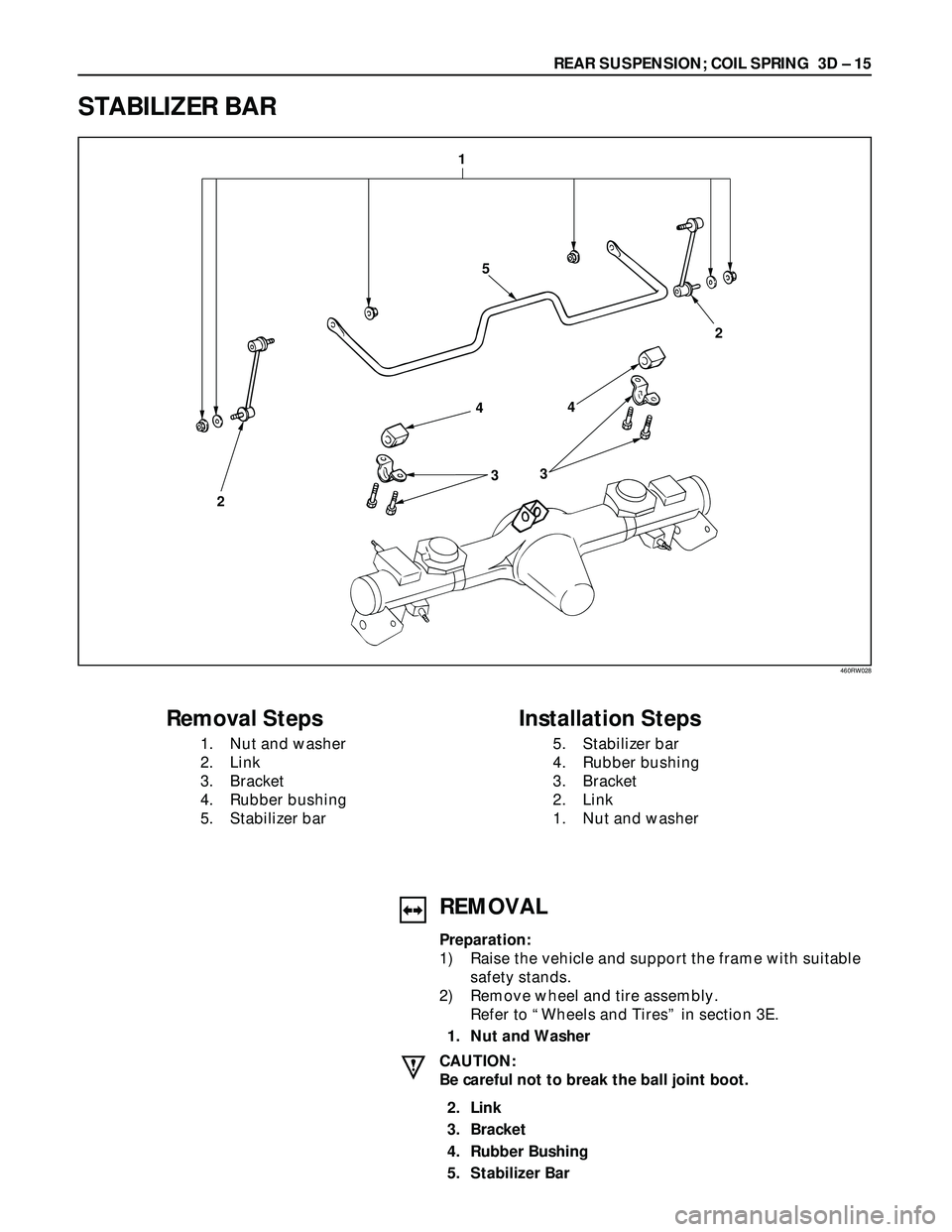

STABILIZER BAR

1

5

2

44

33

2

Removal Steps

1. Nut and washer

2. Link

3. Bracket

4. Rubber bushing

5. Stabilizer bar

Installation Steps

5. Stabilizer bar

4. Rubber bushing

3. Bracket

2. Link

1. Nut and washer

REMOVAL

Preparation:

1) Raise the vehicle and support the frame with suitable

safety stands.

2) Remove wheel and tire assembly.

Refer to “Wheels and Tires” in section 3E.

1. Nut and Washer

CAUTION:

Be careful not to break the ball joint boot.

2. Link

3. Bracket

4. Rubber Bushing

5. Stabilizer Bar

460RW028

Page 705 of 3573

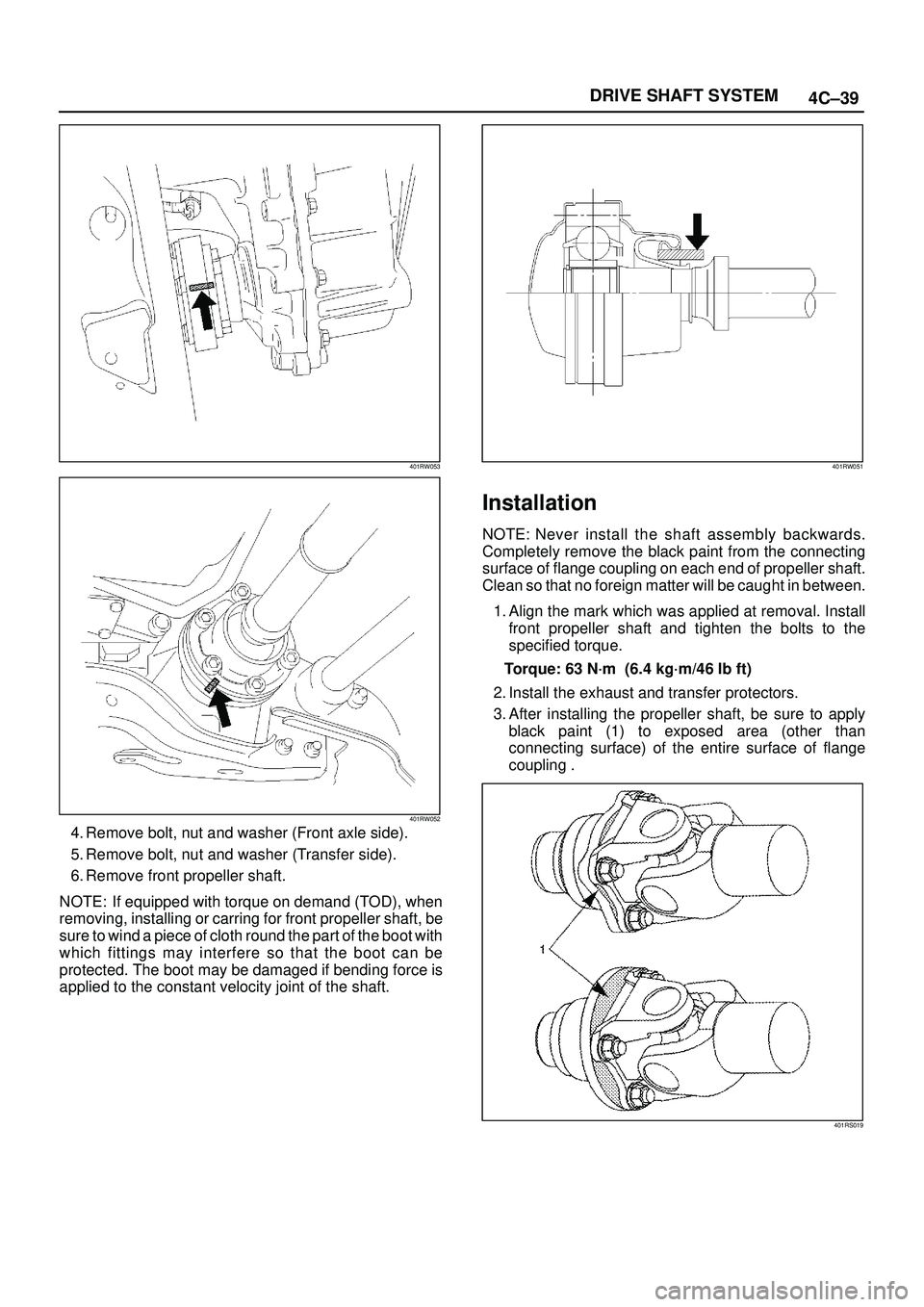

4C±39 DRIVE SHAFT SYSTEM

401RW053

401RW052

4. Remove bolt, nut and washer (Front axle side).

5. Remove bolt, nut and washer (Transfer side).

6. Remove front propeller shaft.

NOTE: If equipped with torque on demand (TOD), when

removing, installing or carring for front propeller shaft, be

sure to wind a piece of cloth round the part of the boot with

which fittings may interfere so that the boot can be

protected. The boot may be damaged if bending force is

applied to the constant velocity joint of the shaft.

401RW051

Installation

NOTE: Never install the shaft assembly backwards.

Completely remove the black paint from the connecting

surface of flange coupling on each end of propeller shaft.

Clean so that no foreign matter will be caught in between.

1. Align the mark which was applied at removal. Install

front propeller shaft and tighten the bolts to the

specified torque.

Torque: 63 N´m (6.4 kg´m/46 lb ft)

2. Install the exhaust and transfer protectors.

3. After installing the propeller shaft, be sure to apply

black paint (1) to exposed area (other than

connecting surface) of the entire surface of flange

coupling .

401RS019

Page 709 of 3573

4C±43 DRIVE SHAFT SYSTEM

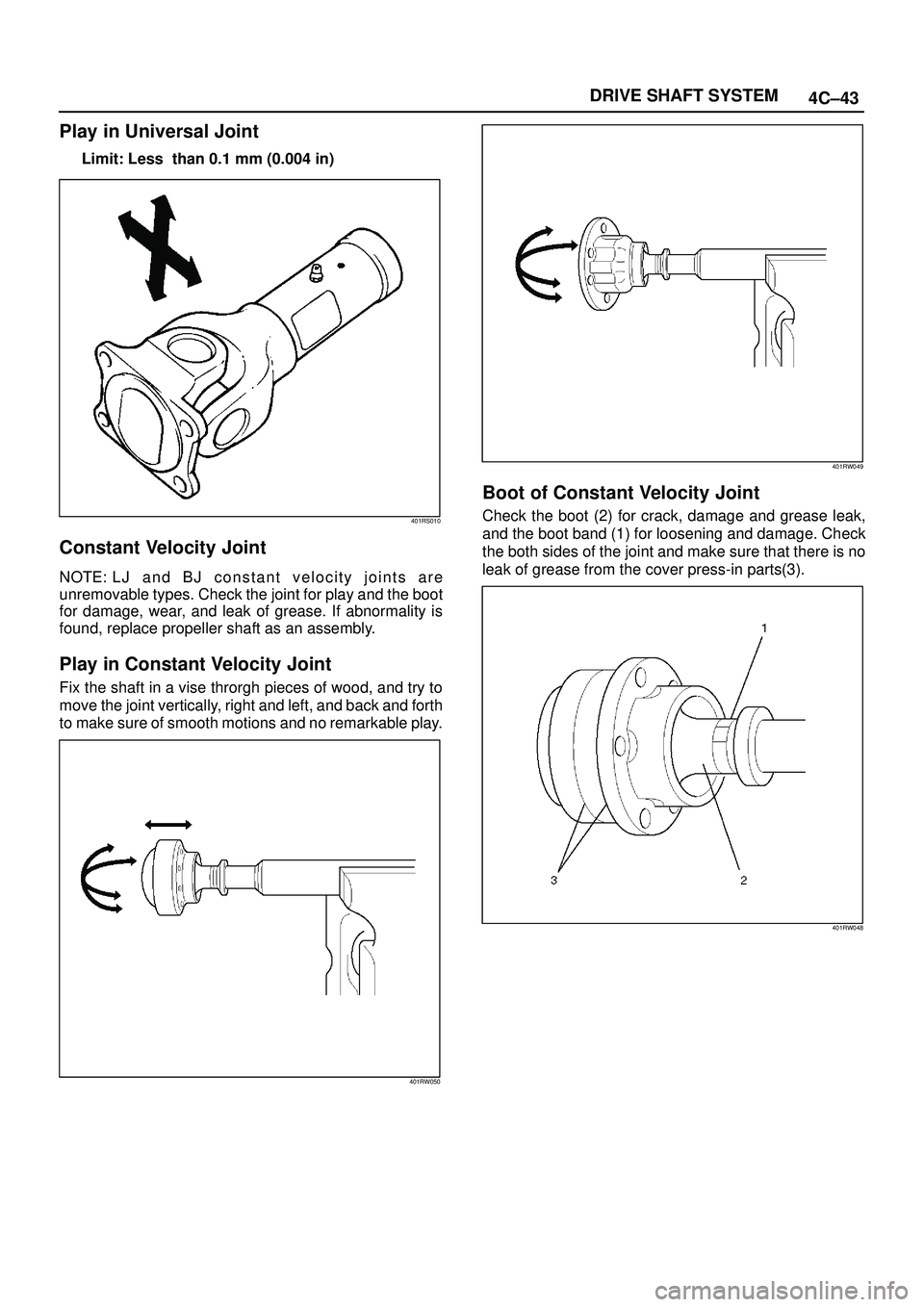

Play in Universal Joint

Limit: Less than 0.1 mm (0.004 in)

401RS010

Constant Velocity Joint

NOTE: L J a n d B J constant velocity joints are

unremovable types. Check the joint for play and the boot

for damage, wear, and leak of grease. If abnormality is

found, replace propeller shaft as an assembly.

Play in Constant Velocity Joint

Fix the shaft in a vise throrgh pieces of wood, and try to

move the joint vertically, right and left, and back and forth

to make sure of smooth motions and no remarkable play.

401RW050

401RW049

Boot of Constant Velocity Joint

Check the boot (2) for crack, damage and grease leak,

and the boot band (1) for loosening and damage. Check

the both sides of the joint and make sure that there is no

leak of grease from the cover press-in parts(3).

401RW048

Page 927 of 3573

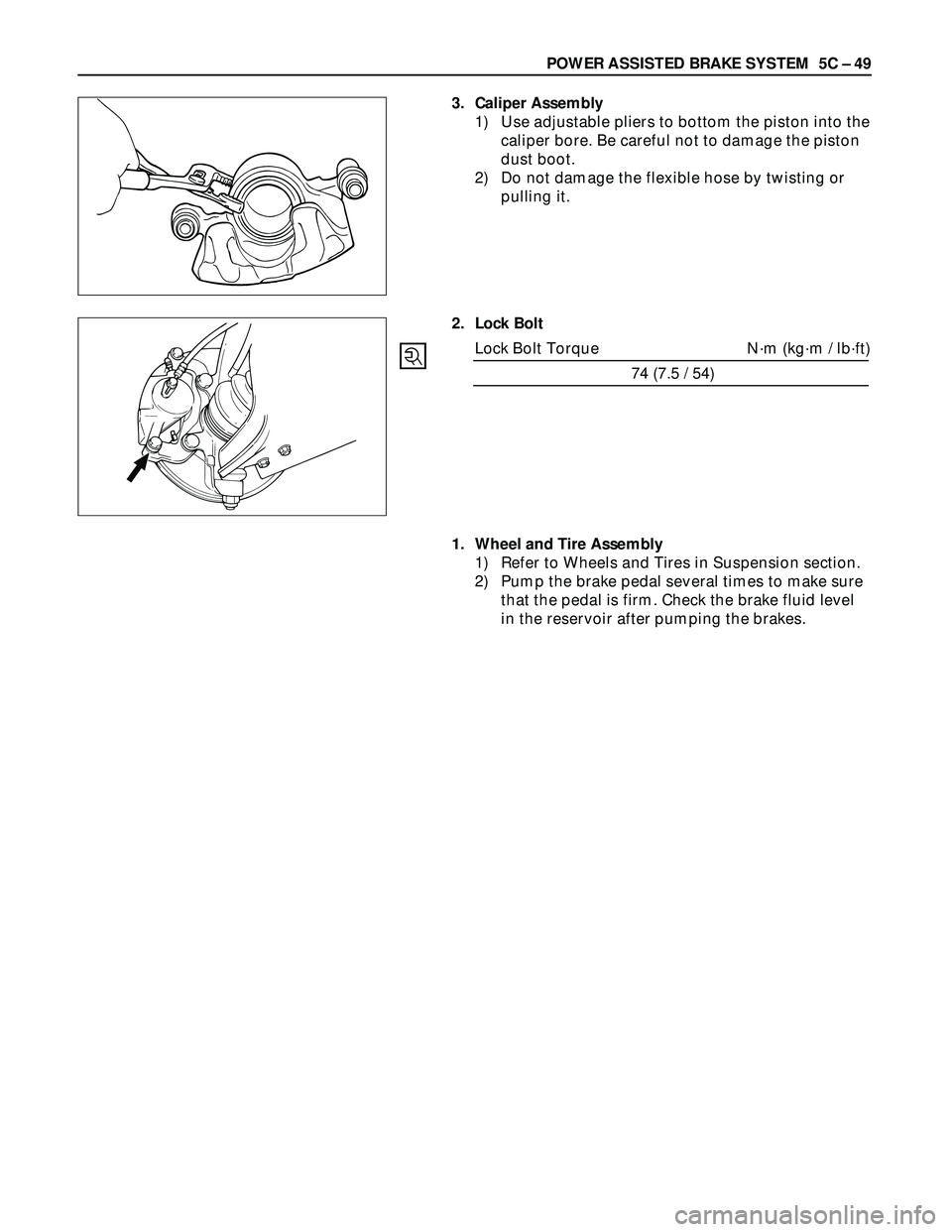

POWER ASSISTED BRAKE SYSTEM 5C – 49

3. Caliper Assembly

1) Use adjustable pliers to bottom the piston into the

caliper bore. Be careful not to damage the piston

dust boot.

2) Do not damage the flexible hose by twisting or

pulling it.

2. Lock Bolt

Lock Bolt Torque N·m (kg·m / lb·ft)

74 (7.5 / 54)

1. Wheel and Tire Assembly

1) Refer to Wheels and Tires in Suspension section.

2) Pump the brake pedal several times to make sure

that the pedal is firm. Check the brake fluid level

in the reservoir after pumping the brakes.

Page 931 of 3573

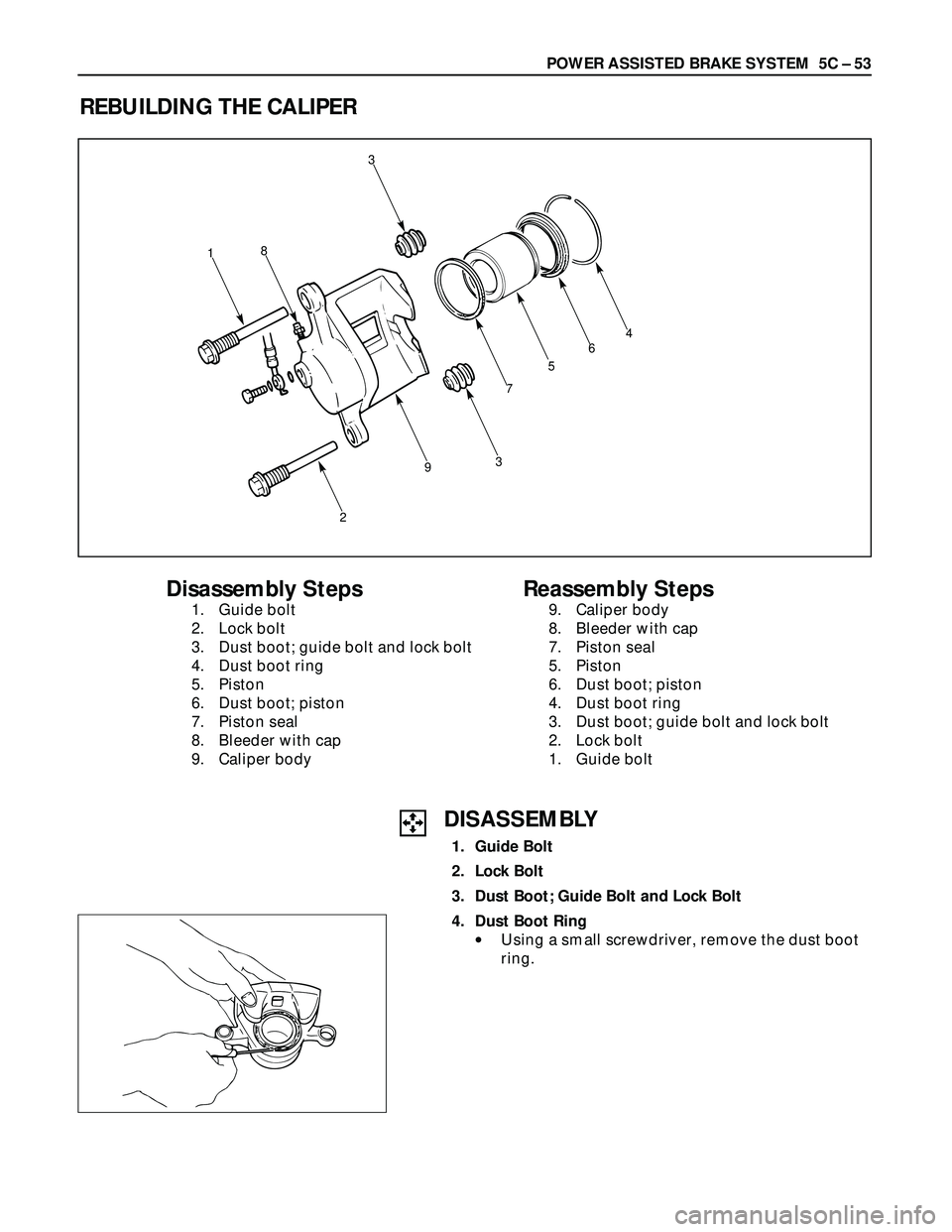

POWER ASSISTED BRAKE SYSTEM 5C – 53

DISASSEMBLY

1. Guide Bolt

2. Lock Bolt

3. Dust Boot; Guide Bolt and Lock Bolt

4. Dust Boot Ring

•Using a small screwdriver, remove the dust boot

ring.

REBUILDING THE CALIPER

4

6

5

7

3 8

3

2

1

9

Disassembly Steps

1. Guide bolt

2. Lock bolt

3. Dust boot; guide bolt and lock bolt

4. Dust boot ring

5. Piston

6. Dust boot; piston

7. Piston seal

8. Bleeder with cap

9. Caliper body

Reassembly Steps

9. Caliper body

8. Bleeder with cap

7. Piston seal

5. Piston

6. Dust boot; piston

4. Dust boot ring

3. Dust boot; guide bolt and lock bolt

2. Lock bolt

1. Guide bolt

Page 932 of 3573

5C – 54 POWER ASSISTED BRAKE SYSTEM

5. Piston

•Insert a block of wood into the caliper and force

out the piston by blowing compressed air into the

caliper at the flexible hose attachment. This

procedure must be done prior to removal of dust

boot.

WARNING:

DO NOT PLACE YOUR FINGERS IN FRONT OF THE

PISTON IN AN ATTEMPT TO CATCH OR PROTECT IT

WHEN APPLYING COMPRESSED AIR. THIS COULD

RESULT IN PERSONAL INJURY.

CAUTION:

Use just enough air to ease the piston out of the

bore. If the piston is blown out, it may be damaged.

6. Dust Boot; Piston

7. Piston Seal

8. Bleeder with Cap

9. Caliper Body

REASSEMBLY

9. Caliper Body

8. Bleeder with Cap

Bleeder Torque N·m (kg·cm / lb·in)

8 (80 / 69)

7. Piston Seal

•Apply special rubber grease to the piston seal and

cylinder wall, then insert the piston seal into the

cylinder. The special rubber grease is included in

the repair kit.

INSPECTION AND REPAIR

Make necessary parts replacement, if wear, damage,

corrosion or any other abnormal conditions are found

through inspection.

Check the following parts;

•Rotor

•Cylinder body

•Cylinder bore

•Piston

•Guide bolt, Lock bolt

•Support bracket

NOTE:

The piston seal, boot ring and dust boot are to be

replaced each time the caliper is overhauled.

Discard these used rubber parts and replace with

new ones.

5. Piston

Page 933 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 55

6. Dust Boot; Piston

•When inserting the piston into the cylinder, use

finger pressure only. Do not use a mallet or other

impact tools, since damage to the cylinder wall or

piston seal can result.

4. Dust Boot Ring

•Apply special grease (Approx. 1 g) to the piston

and attach the dust boot to the piston and caliper.

Insert the dust boot ring into the dust boot.

3. Dust Boot; Guide Bolt and Lock Bolt

2, 1. Lock Bolt and Guide Bolt

Lock and Guide Bolt Torque N·m (kg·m / lb·ft)

74 (7.5 / 54)

•Install the dust boot on the support bracket after

applying special grease (Approx. 1 g) onto the

dust boot inner surface. Also apply special grease

onto the lock bolt and guide bolt setting hole of

the support bracket.