warning ISUZU TROOPER 1998 Service User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 365 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A Ð 63

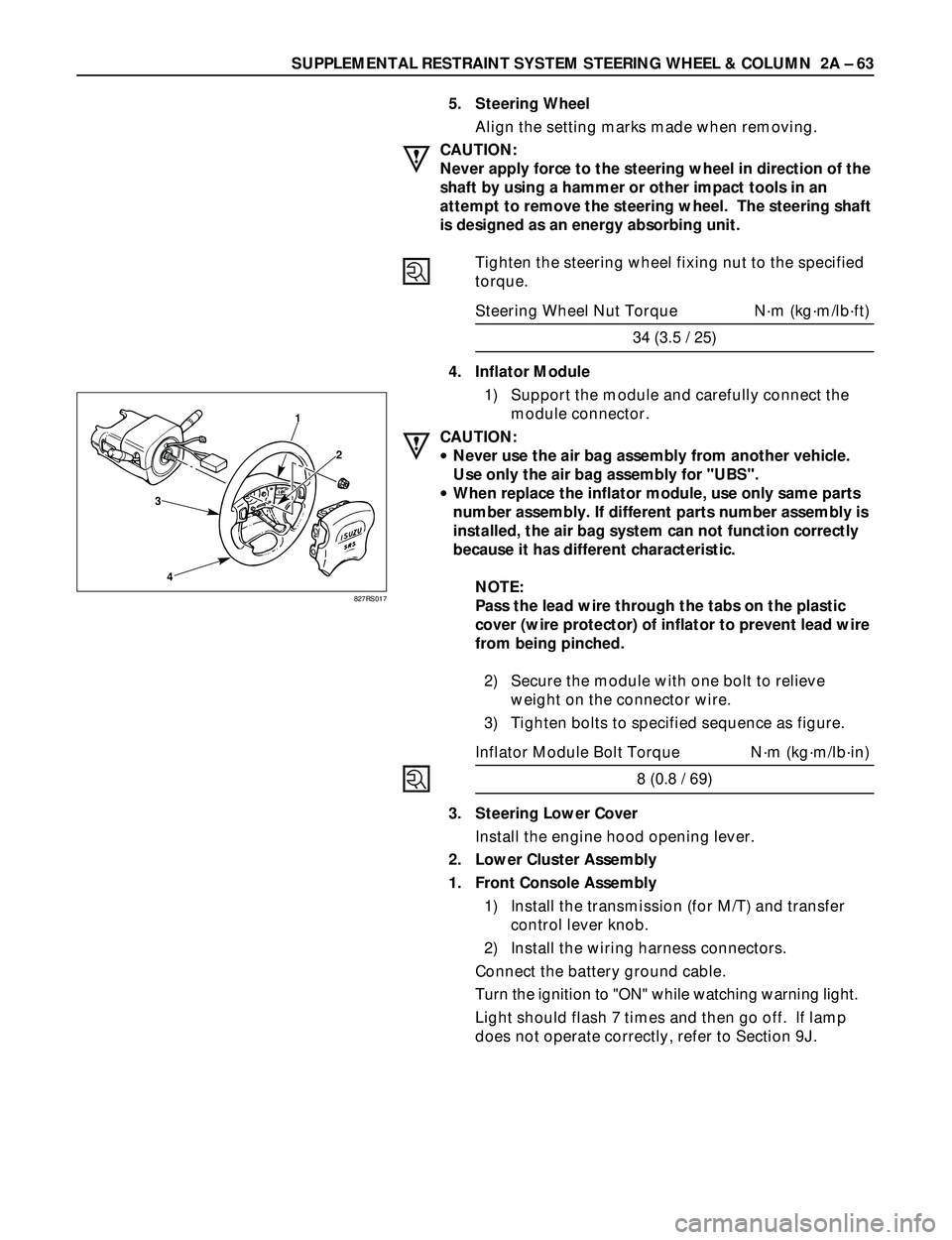

5. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering Wheel Nut Torque Nám (kgám/lbáft)

34 (3.5 / 25)

4. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator Module Bolt Torque Nám (kgám/lbáin)

8 (0.8 / 69)

3. Steering Lower Cover

Install the engine hood opening lever.

2. Lower Cluster Assembly

1. Front Console Assembly

1) Install the transmission (for M/T) and transfer

control lever knob.

2) Install the wiring harness connectors.

Connect the battery ground cable.

Turn the ignition to "ON" while watching warning light.

Light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Section 9J.

3

41

2

827RS017

Page 367 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A – 65

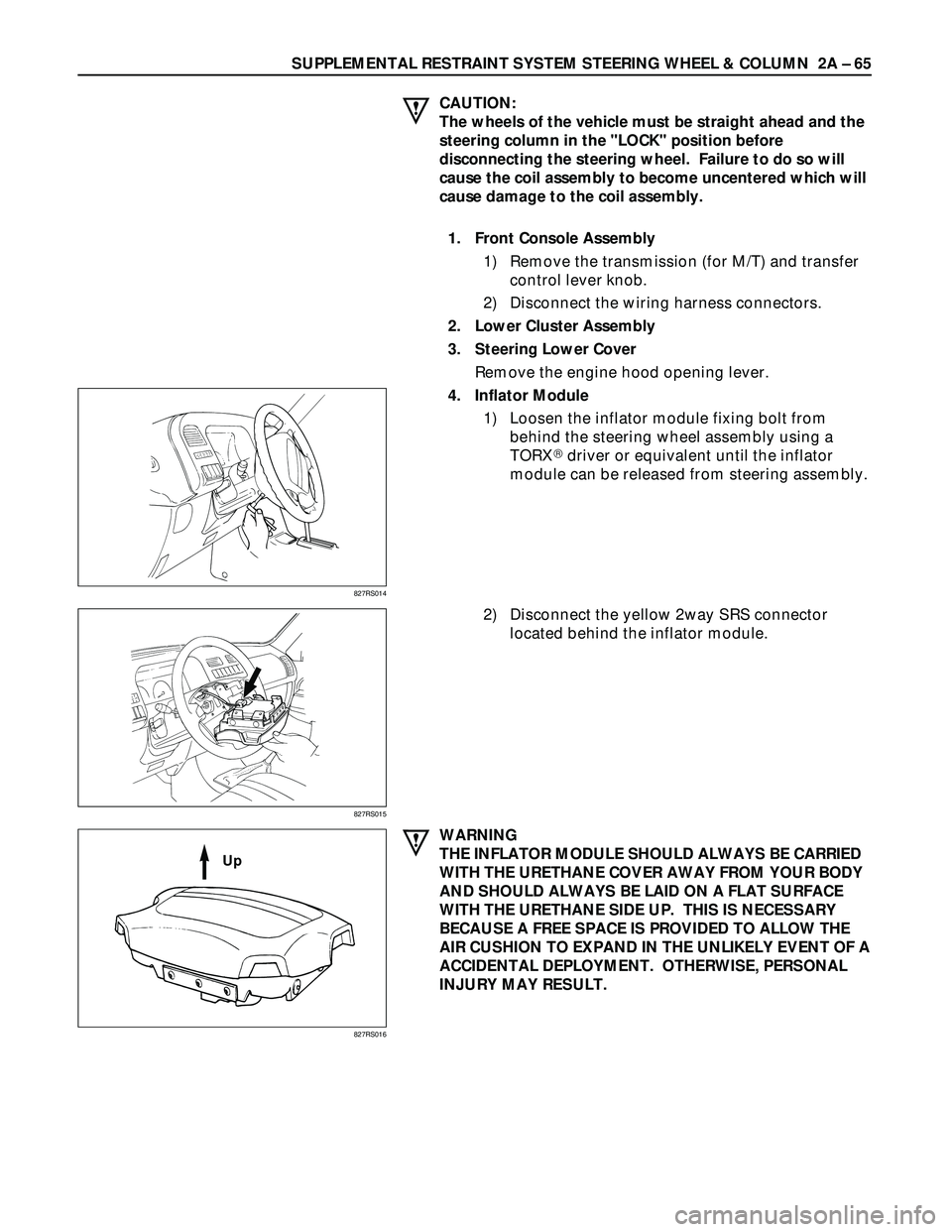

CAUTION:

The wheels of the vehicle must be straight ahead and the

steering column in the "LOCK" position before

disconnecting the steering wheel. Failure to do so will

cause the coil assembly to become uncentered which will

cause damage to the coil assembly.

1. Front Console Assembly

1) Remove the transmission (for M/T) and transfer

control lever knob.

2) Disconnect the wiring harness connectors.

2. Lower Cluster Assembly

3. Steering Lower Cover

Remove the engine hood opening lever.

4. Inflator Module

1) Loosen the inflator module fixing bolt from

behind the steering wheel assembly using a

TORX

driver or equivalent until the inflator

module can be released from steering assembly.

2) Disconnect the yellow 2way SRS connector

located behind the inflator module.

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF A

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY RESULT.

827RS014

827RS015

827RS016

Up

Page 370 of 3573

2A Ð 68 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

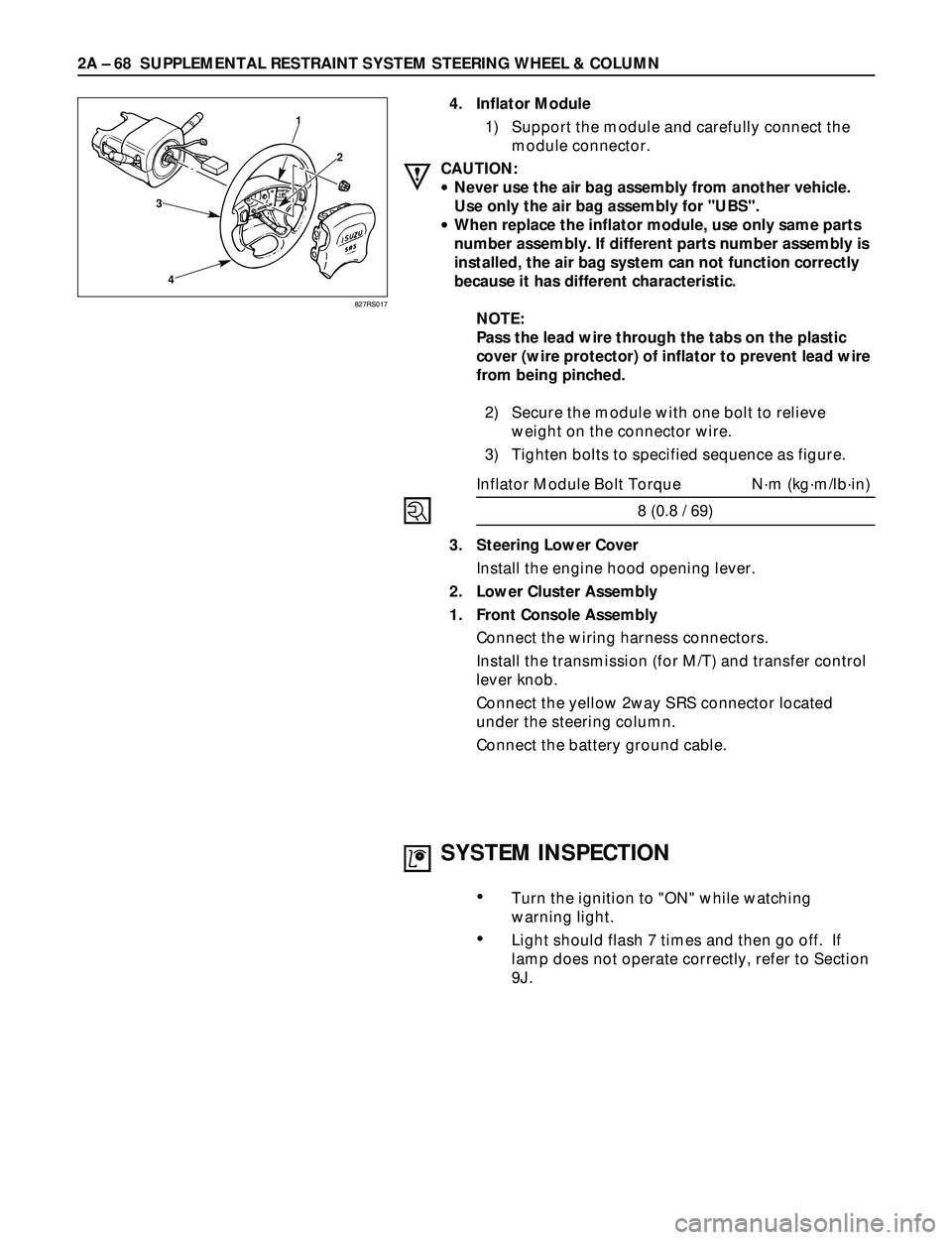

3

41

2

4. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator Module Bolt Torque Nám (kgám/lbáin)

8 (0.8 / 69)

3. Steering Lower Cover

Install the engine hood opening lever.

2. Lower Cluster Assembly

1. Front Console Assembly

Connect the wiring harness connectors.

Install the transmission (for M/T) and transfer control

lever knob.

Connect the yellow 2way SRS connector located

under the steering column.

Connect the battery ground cable.

827RS017

SYSTEM INSPECTION

¥Turn the ignition to "ON" while watching

warning light.

¥Light should flash 7 times and then go off. If

lamp does not operate correctly, refer to Section

9J.

Page 373 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A – 71

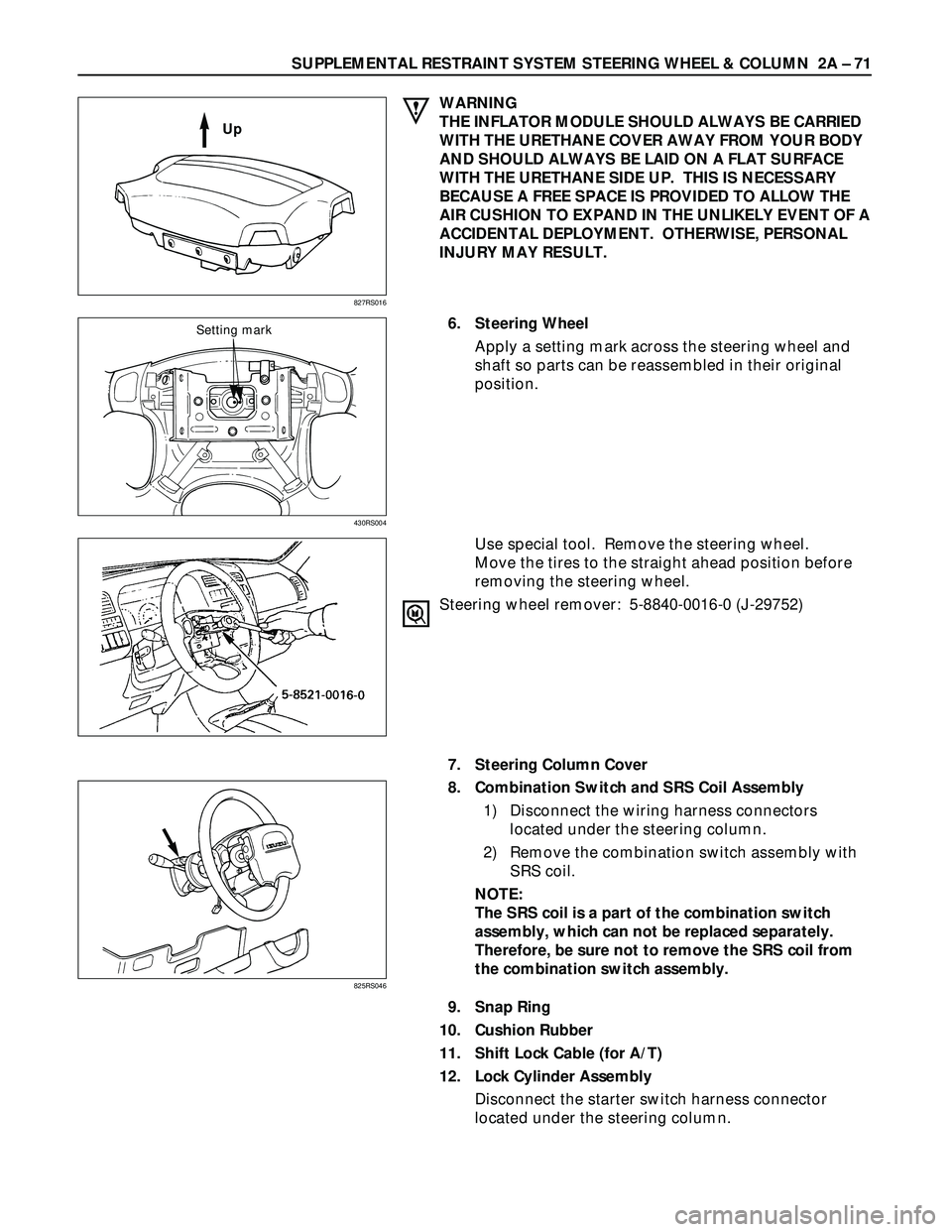

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF A

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY RESULT.

6. Steering Wheel

Apply a setting mark across the steering wheel and

shaft so parts can be reassembled in their original

position.

Use special tool. Remove the steering wheel.

Move the tires to the straight ahead position before

removing the steering wheel.

Steering wheel remover: 5-8840-0016-0 (J-29752)

7. Steering Column Cover

8. Combination Switch and SRS Coil Assembly

1) Disconnect the wiring harness connectors

located under the steering column.

2) Remove the combination switch assembly with

SRS coil.

NOTE:

The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from

the combination switch assembly.

9. Snap Ring

10. Cushion Rubber

11. Shift Lock Cable (for A/T)

12. Lock Cylinder Assembly

Disconnect the starter switch harness connector

located under the steering column.

827RS016

825RS046

Up

430RS004

Setting mark

Page 376 of 3573

2A – 74 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

SYSTEM INSPECTION

Turn the ignition to "ON" while watching warning

light.

Light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Section 9J.

Page 435 of 3573

3E – 4 WHEELS AND TIRES

TIRES

REPLACEMENT

When replacement is necessary, the original metric size

should be used. Most metric tire sizes do not have exact

corresponding alphanumeric tire sizes. It is recommended

that new tires be installed in pairs on the same axle. If

necessary to replace only one tire, it should be paired with

tire having the most tread, to equalize braking traction.

CAUTION:

Do not mix different types of tires such as radial, bias and

bias-belted tires except in emergencies, because vehicle

handling may be seriously affected and may result in loss

of control.

TIRE MOUNTING

Remove valve cap on valve stem and deflate the tire.

Then use a tire changing machine to mount or dismount

tires.

Follow the equipment manufacturer’s instruction. Do not

use hand tools or tire lever alone to change tires as they

may damage the tire beads or wheel rim.

TIRE DISMOUNTING

Rim bead seats should be cleaned with a wire brush or

coarse steel wool to remove lubricants, and light rust.

Before mounting a tire, the bead area should be well

lubricated with an approved tire lubricant.

After mounting, inflate the tire to 196 kPa (28 psi) so that

beads are completely seated. Inflate the air to specified

pressure and install valve cap to the stem

WARNING:

NEVER STAND OVER TIRE WHEN INFLATING. BEAD MAY

BREAK WHEN BEAD SNAPS OVER RIM’S SAFETY HUMP

AND CAUSE SERIOUS PERSONAL INJURY.

NEVER EXCEED 240 kPa (35 psi) PRESSURE WHEN

INFLATING. IF 240 kPa (35 psi) PRESSURE WILL NOT

SEAT BEADS, DEFLATE, RE-LUBRICATE AND RE-INFLATE.

OVER INFLATION MAY CAUSE THE BEAD TO BREAK AND

CAUSE SERIOUS PERSONAL INJURY.

TIRE REPAIR

There are many different materials on the market used to

repair tires.

Manufacturers have published detailed instructions on

how and when to repair tires. These instructions can be

obtained from the tire manufacturer if they are not

included with the repair kit.

UNIT REPAIR

Page 436 of 3573

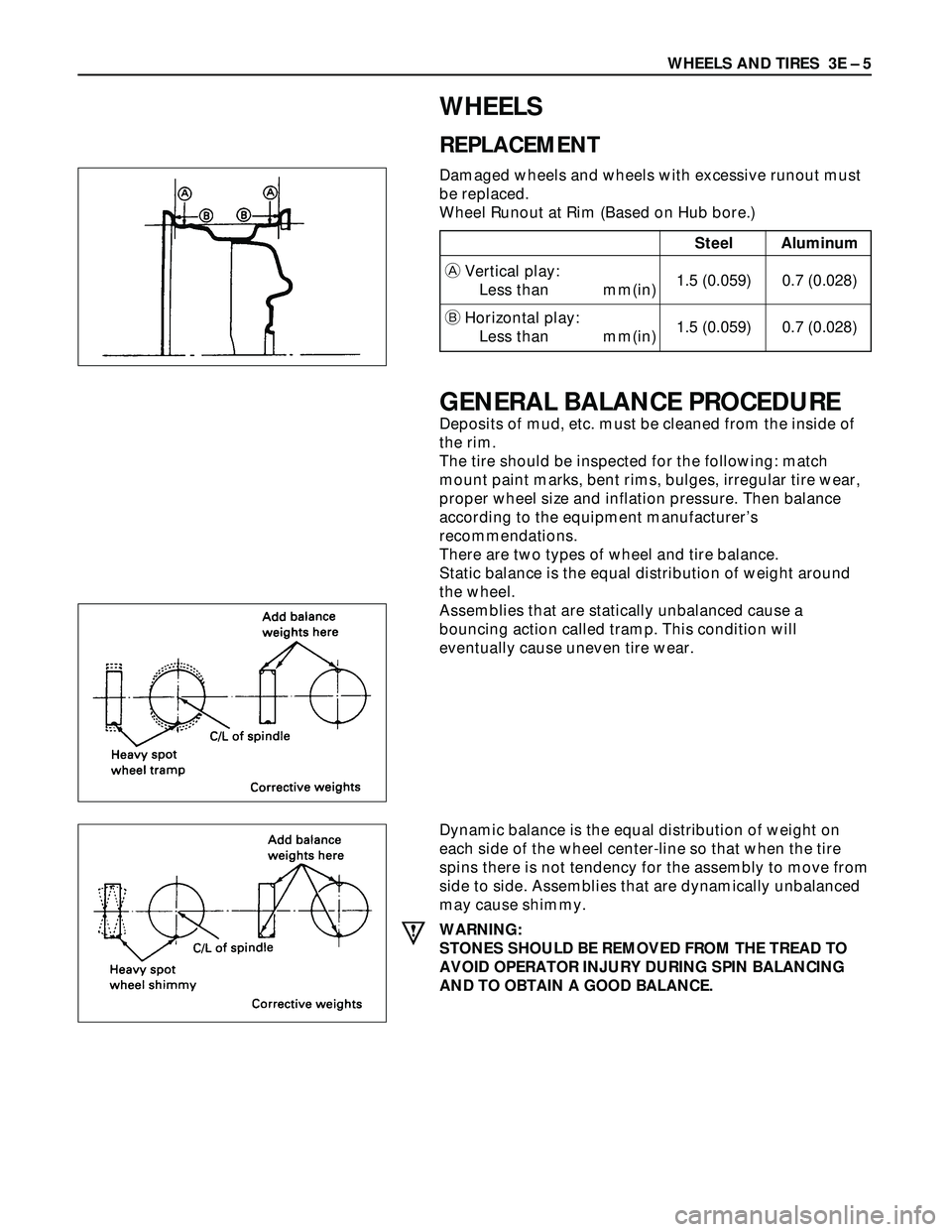

WHEELS AND TIRES 3E – 5

WHEELS

REPLACEMENT

Damaged wheels and wheels with excessive runout must

be replaced.

Wheel Runout at Rim (Based on Hub bore.)

GENERAL BALANCE PROCEDURE

Deposits of mud, etc. must be cleaned from the inside of

the rim.

The tire should be inspected for the following: match

mount paint marks, bent rims, bulges, irregular tire wear,

proper wheel size and inflation pressure. Then balance

according to the equipment manufacturer’s

recommendations.

There are two types of wheel and tire balance.

Static balance is the equal distribution of weight around

the wheel.

Assemblies that are statically unbalanced cause a

bouncing action called tramp. This condition will

eventually cause uneven tire wear.

Dynamic balance is the equal distribution of weight on

each side of the wheel center-line so that when the tire

spins there is not tendency for the assembly to move from

side to side. Assemblies that are dynamically unbalanced

may cause shimmy.

WARNING:

STONES SHOULD BE REMOVED FROM THE TREAD TO

AVOID OPERATOR INJURY DURING SPIN BALANCING

AND TO OBTAIN A GOOD BALANCE.

Steel Aluminum

AVertical play:

Less than mm(in)1.5 (0.059) 0.7 (0.028)

BHorizontal play:

Less than mm(in)1.5 (0.059) 0.7 (0.028)

Page 438 of 3573

4A1±1 DIFFERENTIAL (FRONT)

DRIVELINE/AXLE

CONTENTS

Differential (Front) 4A1. . . . . . . . . . . . . . . . . . . . . . .

Differential (Rear/220mm) 4A2A. . . . . . . . . . . . . . . .

Differential (Rear/244mm) 4A2B. . . . . . . . . . . . . . . .

Driveline Control System (Shift on the Fly) 4B1. . Driveline Control System (TOD) 4B2. . . . . . . . . . .

Driveshaft System 4C. . . . . . . . . . . . . . . . . . . . . . .

Transfer Case (Standard Type) 4D1. . . . . . . . . . .

Transfer Case (TOD) 4D2. . . . . . . . . . . . . . . . . . . .

DIFFERENTIAL (FRONT)

CONTENTS

Service Precaution 4A1±1. . . . . . . . . . . . . . . . . . . . . .

Front Drive Axle 4A1±2. . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 4A1±2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Shaft Oil Seal 4A1±3. . . . . . . . . . . . . . . . . . . . .

Pinion Shaft Oil Seal and Associated Parts 4A1±3

Removal 4A1±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A1±4. . . . . . . . . . . . . . . . . .

Installation 4A1±4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Drive Axle Assembly 4A1±5. . . . . . . . . . . . . . .

Front Drive Axle Assembly and

Associated Parts 4A1±5. . . . . . . . . . . . . . . . . . . . . .

Removal 4A1±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 4A1±7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Assembly 4A1±9. . . . . . . . . . . . . . . . . . . .

Disassembled View 4A1±9. . . . . . . . . . . . . . . . . . . .

Disassembly 4A1±9. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4A1±12. . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Cage Assembly 4A1±21. . . . . . . . . . . . . . .

Disassembled View 4A1±21. . . . . . . . . . . . . . . . . . . .

Disassembly 4A1±21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A1±22. . . . . . . . . . . . . . . . . .

Reassembly 4A1±23. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4A1±25. . . . . . . . . . .

Special Tools 4A1±28. . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE REFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specification. Following these

instructions can help you avoid damage to parts and

systems.

Page 468 of 3573

DIFFERENTIAL (REAR 220mm)

4A2A±1

DRIVELINE/AXLE

DIFFERENTIAL (Rear 220mm)

CONTENTS

Service Precaution 4A2A±1. . . . . . . . . . . . . . . . . . . . . .

General Description 4A2A±2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 4A2A±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing 4A2A±4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing and Associated Parts 4A2A±4. . . . . .

Removal 4A2A±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Seal Replacement 4A2A±5. . . . . . . . . . . . . . . . . .

Installation 4A2A±5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal 4A2A±6. . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal and Associated Parts 4A2A±6. . . . .

Removal 4A2A±6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2A±7. . . . . . . . . . . . . . . . . .

Installation 4A2A±7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Assembly 4A2A±8. . . . . . . . . . . . . . . . . . . .

Differential Assembly and Associated Parts 4A2A±8

Removal 4A2A±8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 4A2A±9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 4A2A±10. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2A±11. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4A2A±13. . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Cage Assembly 4A2A±21. . . . . . . . . . . . . . .

Disassembled View 4A2A±21. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2A±21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2A±22. . . . . . . . . . . . . . . . . .

Reassembly 4A2A±23. . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Slip Differential 4A2A±25. . . . . . . . . . . . . . . . . . .

Disassembled View 4A2A±25. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2A±26. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2A±26. . . . . . . . . . . . . . . . . .

Reassembly 4A2A±28. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4A2A±32. . . . . . . . . . .

Special Tools 4A2A±34. . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE REFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specification. Following these

instructions can help you avoid damage to parts and

systems.

Page 504 of 3573

DIFFERENTIAL (REAR 244mm)

4A2B±1

DRIVELINE/AXLE

DIFFERENTIAL (REAR 244mm)

CONTENTS

Service Precaution 4A2B±1. . . . . . . . . . . . . . . . . . . . . .

General Description 4A2B±2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 4A2B±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing 4A2B±4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing and Associated Parts 4A2B±4. . . . . .

Removal 4A2B±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Seal Replacement 4A2B±5. . . . . . . . . . . . . . . . . .

Installation 4A2B±5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal 4A2B±6. . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal and Associated Parts 4A2B±6. . . . .

Removal 4A2B±6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2B±7. . . . . . . . . . . . . . . . . .

Installation 4A2B±7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Assembly 4A2B±8. . . . . . . . . . . . . . . . . . . .

Differential Assembly and Associated Parts 4A2B±8

Removal 4A2B±8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 4A2B±9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 4A2B±10. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2B±11. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4A2B±13. . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Cage Assembly 4A2B±20. . . . . . . . . . . . . . .

Disassembled View 4A2B±20. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2B±21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2B±21. . . . . . . . . . . . . . . . . .

Reassembly 4A2B±21. . . . . . . . . . . . . . . . . . . . . . . . . .

Locking Differential Assembly 4A2B±23. . . . . . . . . . . . .

Disassembled View 4A2B±23. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2B±23. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2B±25. . . . . . . . . . . . . . . . . .

Reassembly 4A2B±25. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4A2B±27. . . . . . . . . . . . .

Special Tools 4A2B±29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE REFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specification. Following these

instructions can help you avoid damage to parts and

systems.