check engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1528 of 3573

00 Ð 28 SERVICE INFORMATION

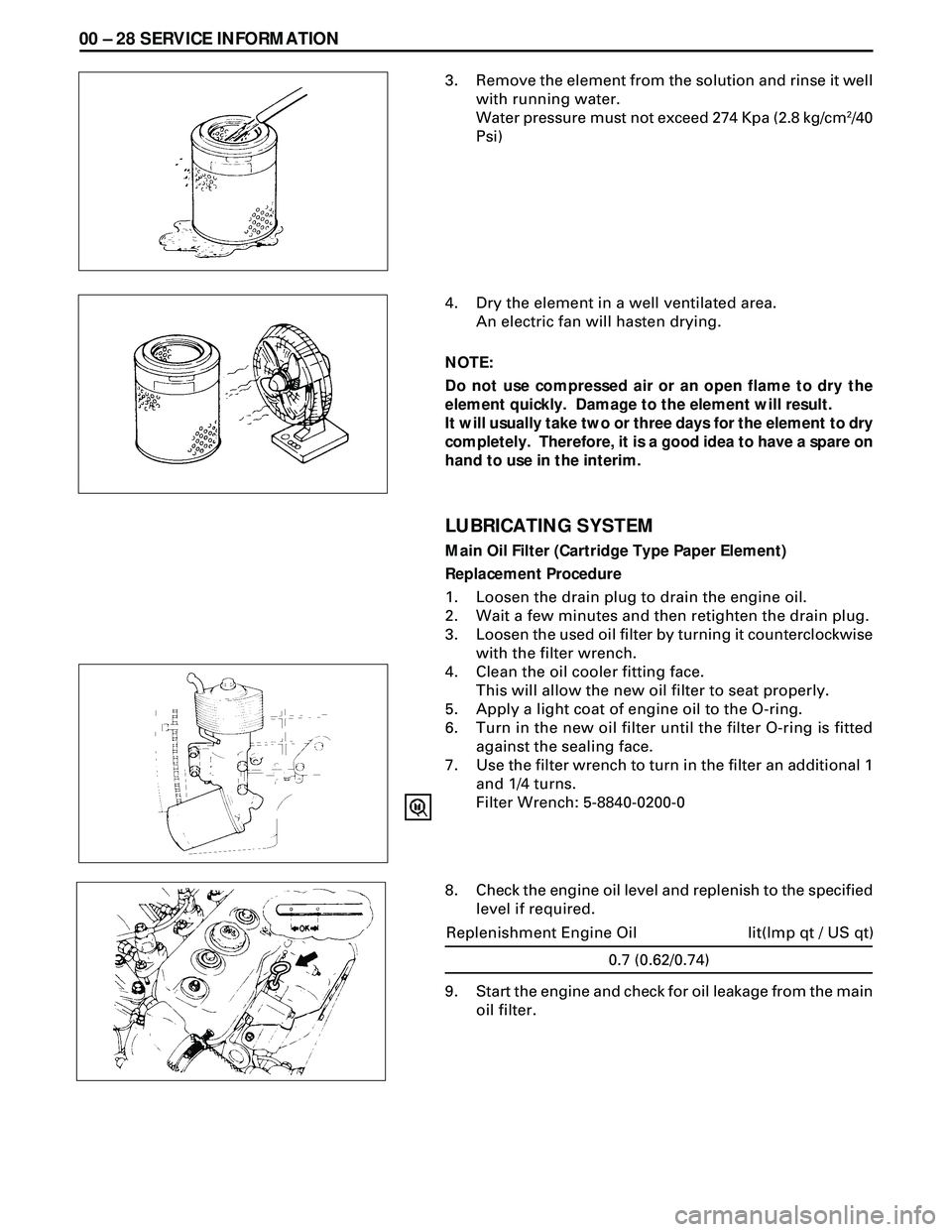

3. Remove the element from the solution and rinse it well

with running water.

Water pressure must not exceed 274 Kpa (2.8 kg/cm

2/40

Psi)

4. Dry the element in a well ventilated area.

An electric fan will hasten drying.

NOTE:

Do not use compressed air or an open flame to dry the

element quickly. Damage to the element will result.

It will usually take two or three days for the element to dry

completely. Therefore, it is a good idea to have a spare on

hand to use in the interim.

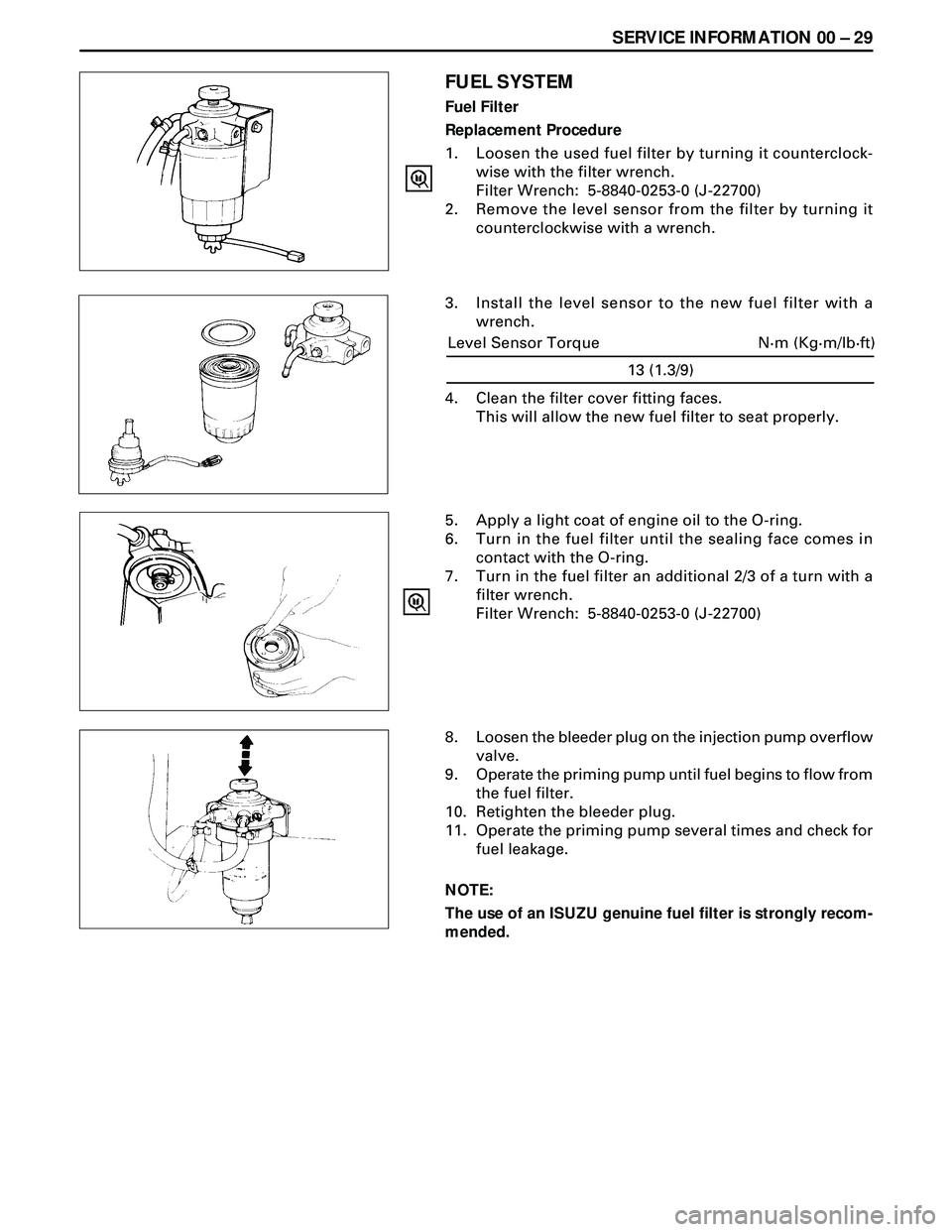

LUBRICATING SYSTEM

Main Oil Filter (Cartridge Type Paper Element)

Replacement Procedure

1. Loosen the drain plug to drain the engine oil.

2. Wait a few minutes and then retighten the drain plug.

3. Loosen the used oil filter by turning it counterclockwise

with the filter wrench.

4. Clean the oil cooler fitting face.

This will allow the new oil filter to seat properly.

5. Apply a light coat of engine oil to the O-ring.

6. Turn in the new oil filter until the filter O-ring is fitted

against the sealing face.

7. Use the filter wrench to turn in the filter an additional 1

and 1/4 turns.

Filter Wrench: 5-8840-0200-0

8. Check the engine oil level and replenish to the specified

level if required.

0.7 (0.62/0.74)

lit(Imp qt / US qt) Replenishment Engine Oil

9. Start the engine and check for oil leakage from the main

oil filter.

Page 1529 of 3573

SERVICE INFORMATION 00 Ð 29

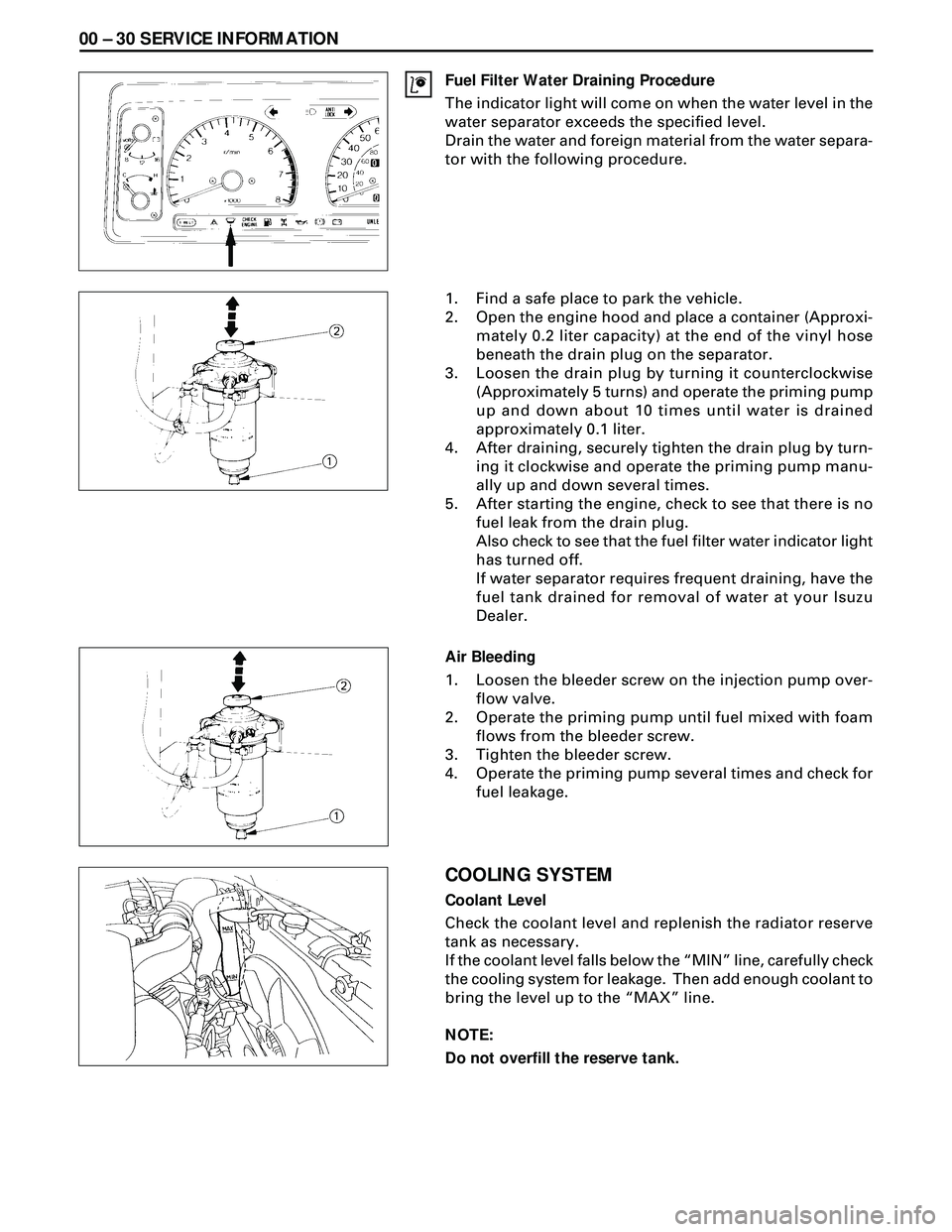

FUEL SYSTEM

Fuel Filter

Replacement Procedure

1. Loosen the used fuel filter by turning it counterclock-

wise with the filter wrench.

Filter Wrench: 5-8840-0253-0 (J-22700)

2. Remove the level sensor from the filter by turning it

counterclockwise with a wrench.

3. Install the level sensor to the new fuel filter with a

wrench.

5. Apply a light coat of engine oil to the O-ring.

6. Turn in the fuel filter until the sealing face comes in

contact with the O-ring.

7. Turn in the fuel filter an additional 2/3 of a turn with a

filter wrench.

Filter Wrench: 5-8840-0253-0 (J-22700)

8. Loosen the bleeder plug on the injection pump overflow

valve.

9. Operate the priming pump until fuel begins to flow from

the fuel filter.

10. Retighten the bleeder plug.

11. Operate the priming pump several times and check for

fuel leakage.

NOTE:

The use of an ISUZU genuine fuel filter is strongly recom-

mended.

13 (1.3/9)

N·m (Kg·m/lb·ft) Level Sensor Torque

4. Clean the filter cover fitting faces.

This will allow the new fuel filter to seat properly.

Page 1530 of 3573

00 Ð 30 SERVICE INFORMATION

Fuel Filter Water Draining Procedure

The indicator light will come on when the water level in the

water separator exceeds the specified level.

Drain the water and foreign material from the water separa-

tor with the following procedure.

1. Find a safe place to park the vehicle.

2. Open the engine hood and place a container (Approxi-

mately 0.2 liter capacity) at the end of the vinyl hose

beneath the drain plug on the separator.

3. Loosen the drain plug by turning it counterclockwise

(Approximately 5 turns) and operate the priming pump

up and down about 10 times until water is drained

approximately 0.1 liter.

4. After draining, securely tighten the drain plug by turn-

ing it clockwise and operate the priming pump manu-

ally up and down several times.

5. After starting the engine, check to see that there is no

fuel leak from the drain plug.

Also check to see that the fuel filter water indicator light

has turned off.

If water separator requires frequent draining, have the

fuel tank drained for removal of water at your Isuzu

Dealer.

Air Bleeding

1. Loosen the bleeder screw on the injection pump over-

flow valve.

2. Operate the priming pump until fuel mixed with foam

flows from the bleeder screw.

3. Tighten the bleeder screw.

4. Operate the priming pump several times and check for

fuel leakage.

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator reserve

tank as necessary.

If the coolant level falls below the ÒMINÓ line, carefully check

the cooling system for leakage. Then add enough coolant to

bring the level up to the ÒMAXÓ line.

NOTE:

Do not overfill the reserve tank.

Page 1531 of 3573

SERVICE INFORMATION 00 Ð 31

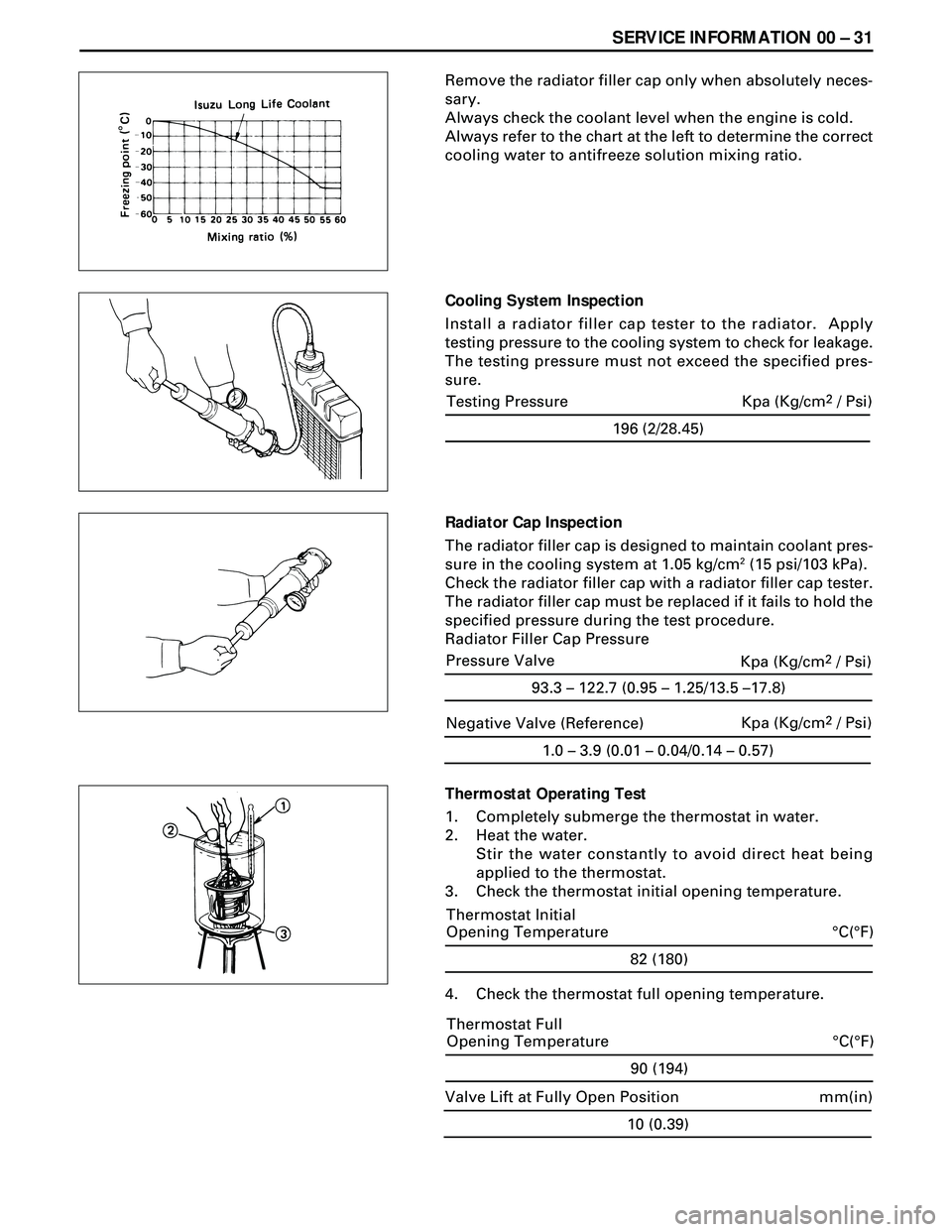

Remove the radiator filler cap only when absolutely neces-

sary.

Always check the coolant level when the engine is cold.

Always refer to the chart at the left to determine the correct

cooling water to antifreeze solution mixing ratio.

Cooling System Inspection

Install a radiator filler cap tester to the radiator. Apply

testing pressure to the cooling system to check for leakage.

The testing pressure must not exceed the specified pres-

sure.

Radiator Cap Inspection

The radiator filler cap is designed to maintain coolant pres-

sure in the cooling system at 1.05 kg/cm

2 (15 psi/103 kPa).

Check the radiator filler cap with a radiator filler cap tester.

The radiator filler cap must be replaced if it fails to hold the

specified pressure during the test procedure.

Radiator Filler Cap Pressure

Thermostat Operating Test

1. Completely submerge the thermostat in water.

2. Heat the water.

Stir the water constantly to avoid direct heat being

applied to the thermostat.

3. Check the thermostat initial opening temperature.

82 (180)

°C(°F) Thermostat Initial

Opening Temperature

4. Check the thermostat full opening temperature.

1.0 – 3.9 (0.01 – 0.04/0.14 – 0.57)

Negative Valve (Reference)Kpa (Kg/cm2 / Psi)

90 (194)

°C(°F) Thermostat Full

Opening Temperature

10 (0.39)

mm(in) Valve Lift at Fully Open Position

196 (2/28.45)

Testing Pressure Kpa (Kg/cm2 / Psi)

93.3 – 122.7 (0.95 – 1.25/13.5 –17.8)

Pressure Valve

Kpa (Kg/cm2 / Psi)

Page 1533 of 3573

SERVICE INFORMATION 00 Ð 33

ENGINE CONTROL

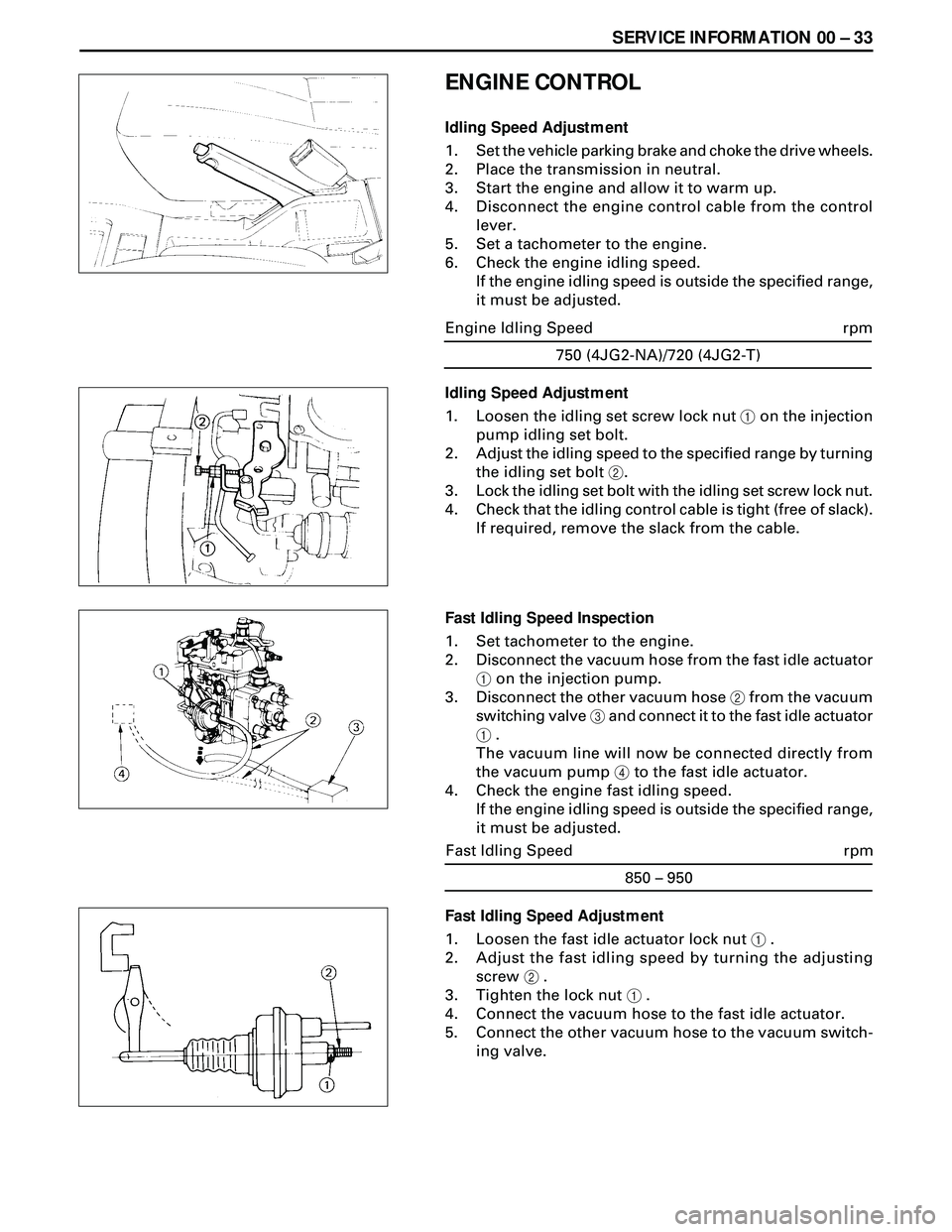

Idling Speed Adjustment

1. Set the vehicle parking brake and choke the drive wheels.

2. Place the transmission in neutral.

3. Start the engine and allow it to warm up.

4. Disconnect the engine control cable from the control

lever.

5. Set a tachometer to the engine.

6. Check the engine idling speed.

If the engine idling speed is outside the specified range,

it must be adjusted.

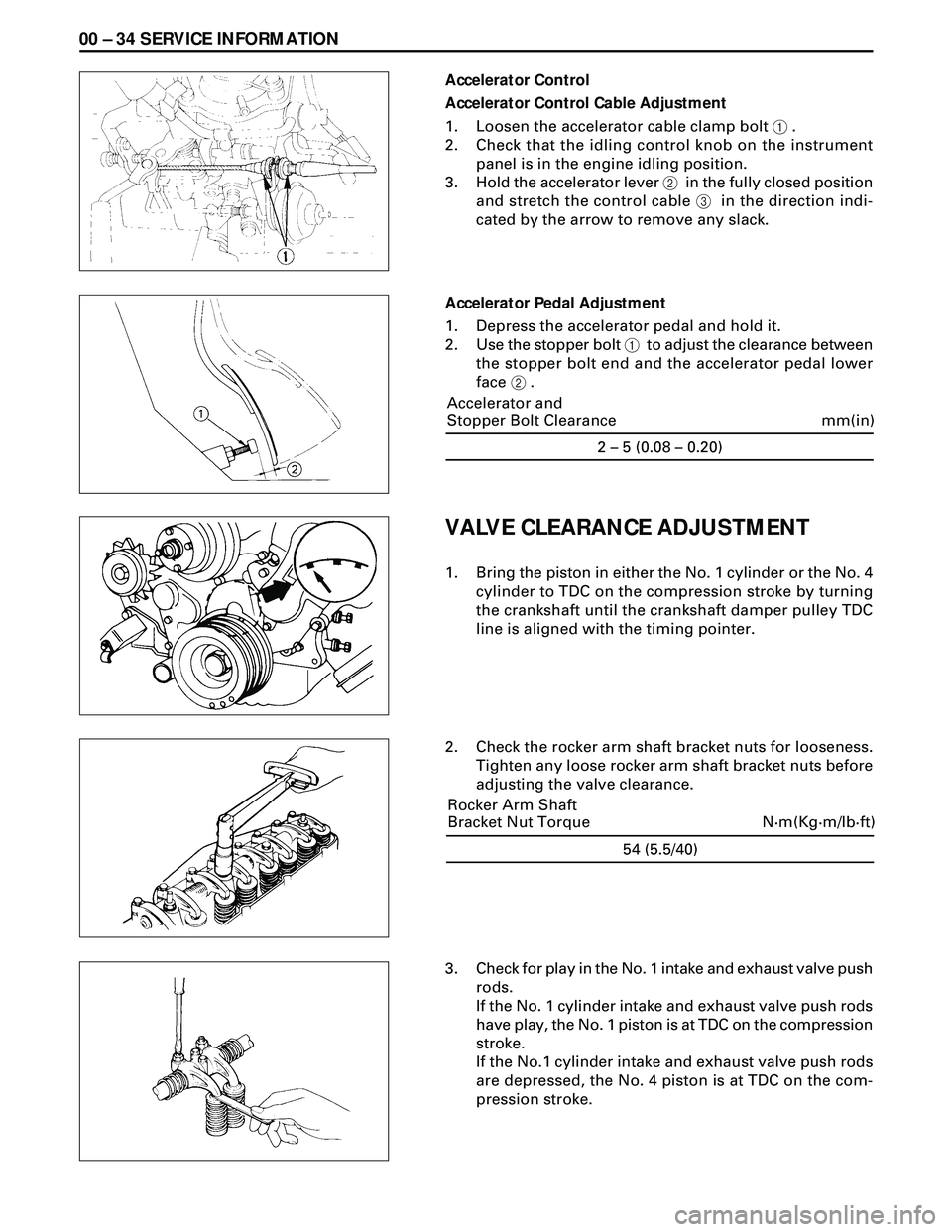

Fast Idling Speed Adjustment

1. Loosen the fast idle actuator lock nut 1 .

2. Adjust the fast idling speed by turning the adjusting

screw 2 .

3. Tighten the lock nut 1 .

4. Connect the vacuum hose to the fast idle actuator.

5. Connect the other vacuum hose to the vacuum switch-

ing valve.750 (4JG2-NA)/720 (4JG2-T)

rpm Engine Idling Speed

Idling Speed Adjustment

1. Loosen the idling set screw lock nut 1 on the injection

pump idling set bolt.

2. Adjust the idling speed to the specified range by turning

the idling set bolt 2.

3. Lock the idling set bolt with the idling set screw lock nut.

4. Check that the idling control cable is tight (free of slack).

If required, remove the slack from the cable.

Fast Idling Speed Inspection

1. Set tachometer to the engine.

2. Disconnect the vacuum hose from the fast idle actuator

1 on the injection pump.

3. Disconnect the other vacuum hose 2 from the vacuum

switching valve 3 and connect it to the fast idle actuator

1 .

The vacuum line will now be connected directly from

the vacuum pump 4 to the fast idle actuator.

4. Check the engine fast idling speed.

If the engine idling speed is outside the specified range,

it must be adjusted.

850 – 950

rpm Fast Idling Speed

Page 1534 of 3573

00 Ð 34 SERVICE INFORMATION

Accelerator Control

Accelerator Control Cable Adjustment

1. Loosen the accelerator cable clamp bolt 1 .

2. Check that the idling control knob on the instrument

panel is in the engine idling position.

3. Hold the accelerator lever 2 in the fully closed position

and stretch the control cable 3 in the direction indi-

cated by the arrow to remove any slack.

Accelerator Pedal Adjustment

1. Depress the accelerator pedal and hold it.

2. Use the stopper bolt 1 to adjust the clearance between

the stopper bolt end and the accelerator pedal lower

face 2 .

VALVE CLEARANCE ADJUSTMENT

1. Bring the piston in either the No. 1 cylinder or the No. 4

cylinder to TDC on the compression stroke by turning

the crankshaft until the crankshaft damper pulley TDC

line is aligned with the timing pointer.

2. Check the rocker arm shaft bracket nuts for looseness.

Tighten any loose rocker arm shaft bracket nuts before

adjusting the valve clearance.

3. Check for play in the No. 1 intake and exhaust valve push

rods.

If the No. 1 cylinder intake and exhaust valve push rods

have play, the No. 1 piston is at TDC on the compression

stroke.

If the No.1 cylinder intake and exhaust valve push rods

are depressed, the No. 4 piston is at TDC on the com-

pression stroke.

54 (5.5/40)

N·m(Kg·m/lb·ft) Rocker Arm Shaft

Bracket Nut Torque2 – 5 (0.08 – 0.20)

mm(in) Accelerator and

Stopper Bolt Clearance

Page 1560 of 3573

6A Ð 10 ENGINE MECHANICAL

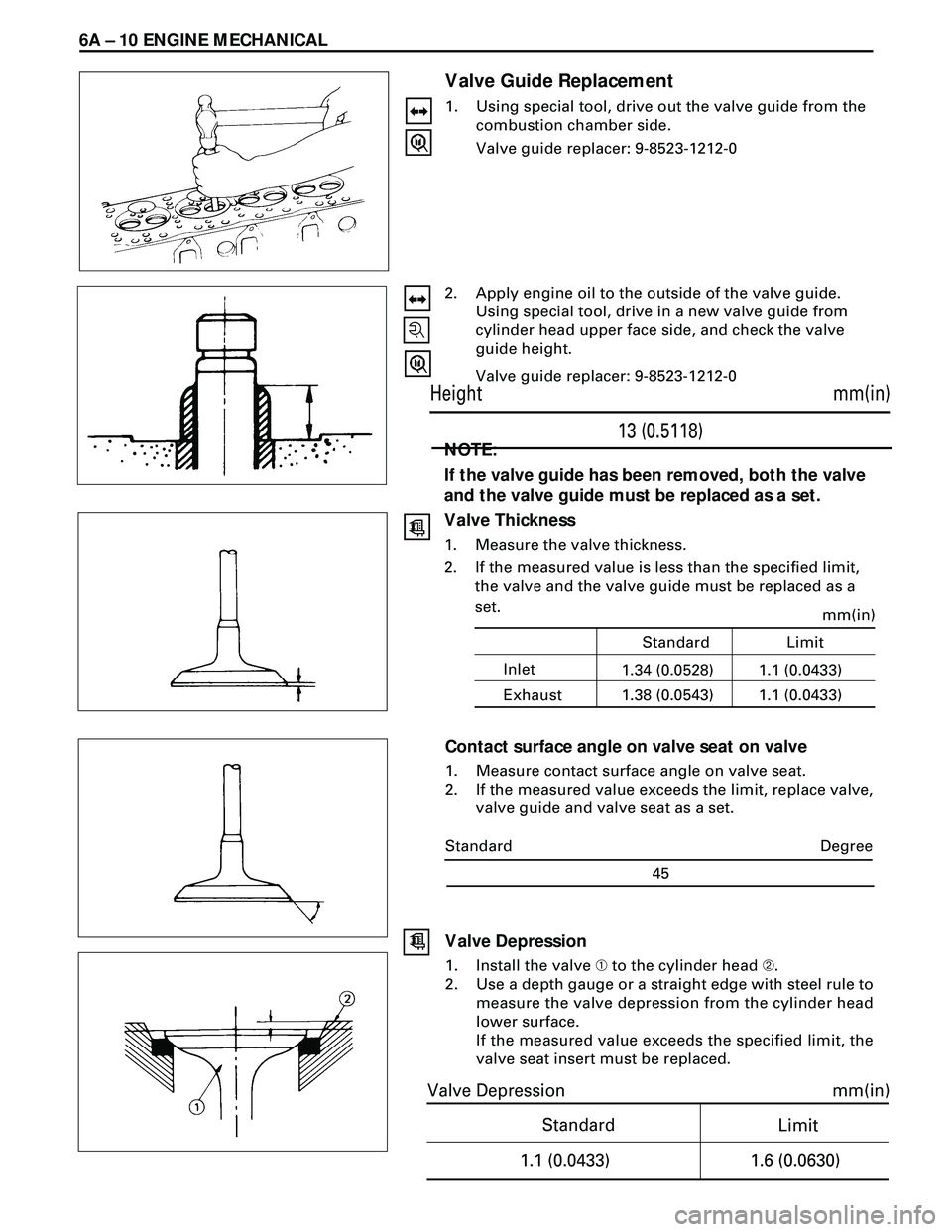

Valve Guide Replacement

1. Using special tool, drive out the valve guide from the

combustion chamber side.

Valve guide replacer: 9-8523-1212-0

2. Apply engine oil to the outside of the valve guide.

Using special tool, drive in a new valve guide from

cylinder head upper face side, and check the valve

guide height.

Valve guide replacer: 9-8523-1212-0

NOTE:

If the valve guide has been removed, both the valve

and the valve guide must be replaced as a set.

Valve Thickness

1. Measure the valve thickness.

2. If the measured value is less than the specified limit,

the valve and the valve guide must be replaced as a

set.

Contact surface angle on valve seat on valve

1. Measure contact surface angle on valve seat.

2. If the measured value exceeds the limit, replace valve,

valve guide and valve seat as a set.

mm(in)

13 (0.5118) Height

Standard

mm(in)

Limit

1.1 (0.0433)

1.6 (0.0630)

Valve Depression

Degree

45 Standard

Valve Depression

1. Install the valve À to the cylinder head Á.

2. Use a depth gauge or a straight edge with steel rule to

measure the valve depression from the cylinder head

lower surface.

If the measured value exceeds the specified limit, the

valve seat insert must be replaced.

Inletmm(in)1.1 (0.0433) Standard Limit

Exhaust1.34 (0.0528)

1.1 (0.0433) 1.38 (0.0543)

Page 1561 of 3573

ENGINE MECHANICAL 6A Ð 11

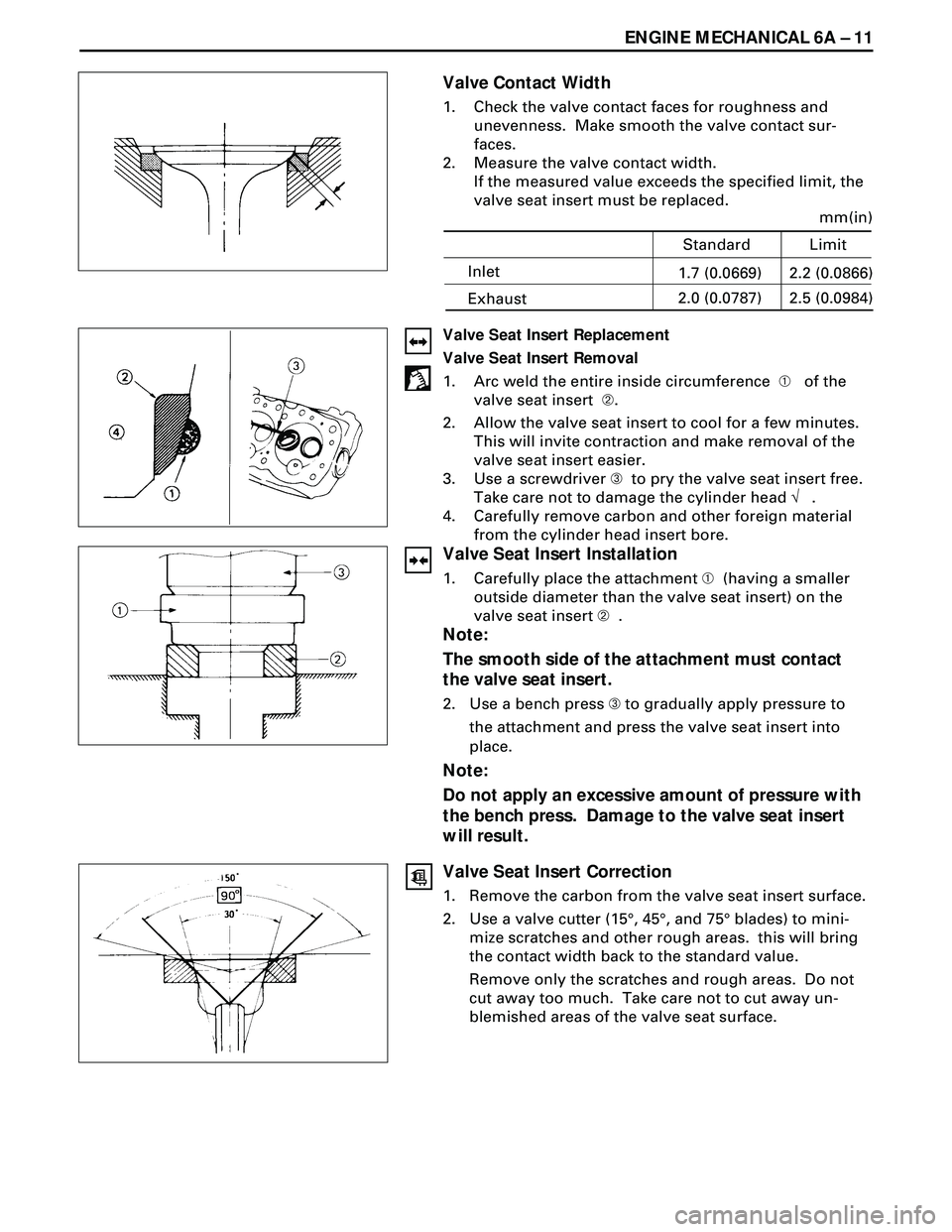

Valve Contact Width

1. Check the valve contact faces for roughness and

unevenness. Make smooth the valve contact sur-

faces.

2. Measure the valve contact width.

If the measured value exceeds the specified limit, the

valve seat insert must be replaced.

Valve Seat Insert Replacement

Valve Seat Insert Removal

1. Arc weld the entire inside circumference À of the

valve seat insert Á.

2. Allow the valve seat insert to cool for a few minutes.

This will invite contraction and make removal of the

valve seat insert easier.

3. Use a screwdriver  to pry the valve seat insert free.

Take care not to damage the cylinder head Ö .

4. Carefully remove carbon and other foreign material

from the cylinder head insert bore.

Valve Seat Insert Installation

1. Carefully place the attachment À (having a smaller

outside diameter than the valve seat insert) on the

valve seat insert Á .

Note:

The smooth side of the attachment must contact

the valve seat insert.

2. Use a bench press  to gradually apply pressure to

the attachment and press the valve seat insert into

place.

Note:

Do not apply an excessive amount of pressure with

the bench press. Damage to the valve seat insert

will result.

Valve Seat Insert Correction

1. Remove the carbon from the valve seat insert surface.

2. Use a valve cutter (15°, 45°, and 75° blades) to mini-

mize scratches and other rough areas. this will bring

the contact width back to the standard value.

Remove only the scratches and rough areas. Do not

cut away too much. Take care not to cut away un-

blemished areas of the valve seat surface.

Inlet

mm(in)

2.2 (0.0866)

Standard Limit

Exhaust1.7 (0.0669)

2.5 (0.0984) 2.0 (0.0787)

Page 1562 of 3573

6A Ð 12 ENGINE MECHANICAL

3. Visually inspect both ends of the push rod for exces-

sive wear and damage. The push rod must be re-

placed if these conditions are discovered during

inspection.

REASSEMBLY

6. Valve Guide

·Apply engine oil to the outside of the valve guide.

Using special tool, drive in a new valve guide from

the cmashft side.

Valve guide replacer: 9-8523-1212-0

5. Valve Stem Oil Seal

·Using special tool, drive in a new oil seal

Oil special tool, drive in anew oil seal

Oil seal installer: 5-8840-2033-0

4. Valve

·Apply engine oil to the outside of the valve stem.

Push Rod Curvature

1. Lay the push rod on a surface plate.

2. Roll the push rod along the surface plate and measure

the push rod cuvature with a thickness gauge.

If the mesure value exceeds the specified limit, the

push rod must be replaced.

NOTE:

Use an adjustable valve cutter pilot.

Do not allow the valve cutter pilot to wobble inside the

valve guide.

3. Apply abrasive compound to the valve seat insert

surface.

4. Insert the valve into the valve guide.

5. Turn the valve while tapping it to fit the valve seat

insert.

6. Check that the valve contract width is correct.

7. Check that the valve seat insert surface is in contact

with the entire circumference of the valve.

mm(in)

0.3 (0.0118) Push Rod Curvature Limit

degree

45 Valve Seat Angle

Page 1570 of 3573

6A Ð 20 ENGINE MECHANICAL

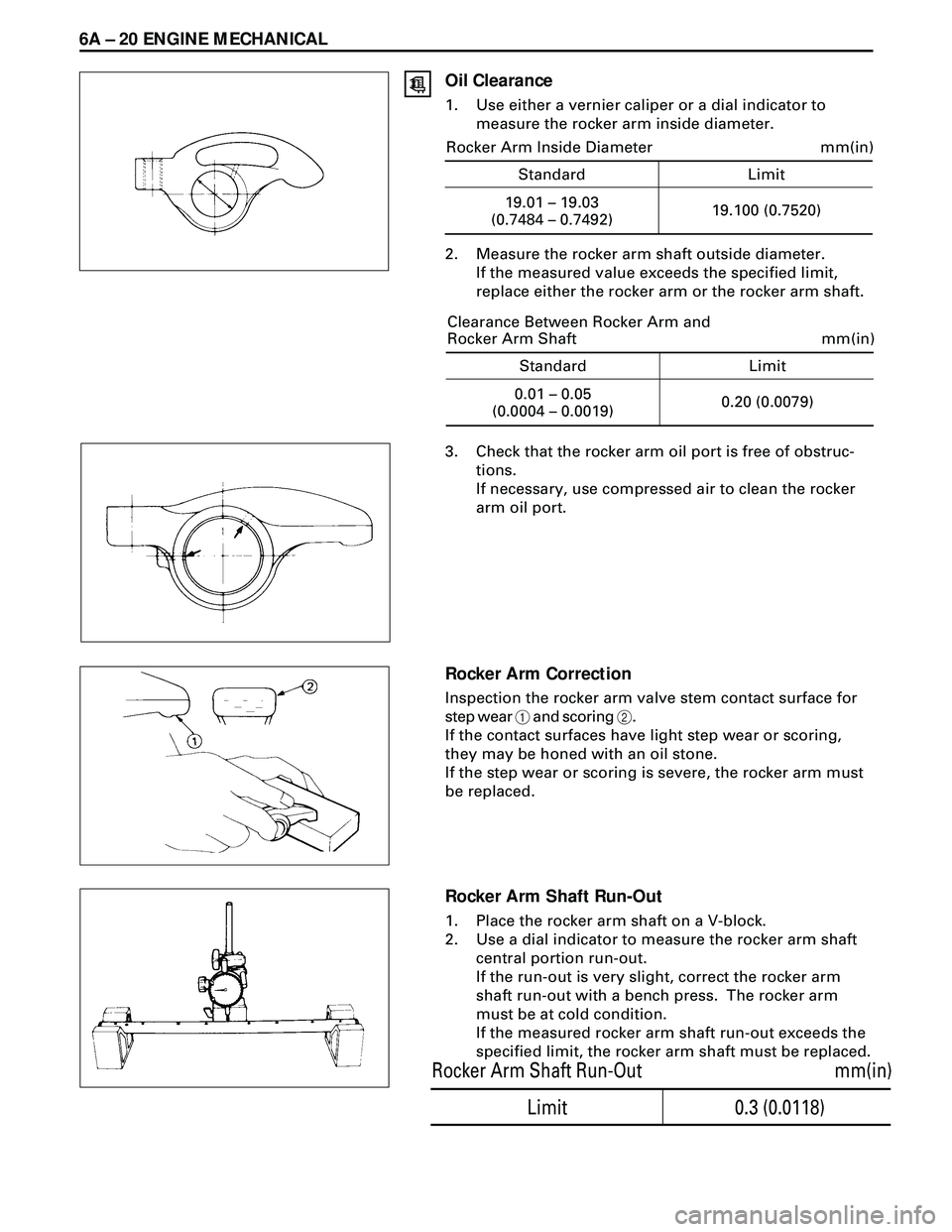

Oil Clearance

1. Use either a vernier caliper or a dial indicator to

measure the rocker arm inside diameter.

2. Measure the rocker arm shaft outside diameter.

If the measured value exceeds the specified limit,

replace either the rocker arm or the rocker arm shaft.

3. Check that the rocker arm oil port is free of obstruc-

tions.

If necessary, use compressed air to clean the rocker

arm oil port.

Rocker Arm Correction

Inspection the rocker arm valve stem contact surface for

step wear 1 and scoring 2.

If the contact surfaces have light step wear or scoring,

they may be honed with an oil stone.

If the step wear or scoring is severe, the rocker arm must

be replaced.

Rocker Arm Shaft Run-Out

1. Place the rocker arm shaft on a V-block.

2. Use a dial indicator to measure the rocker arm shaft

central portion run-out.

If the run-out is very slight, correct the rocker arm

shaft run-out with a bench press. The rocker arm

must be at cold condition.

If the measured rocker arm shaft run-out exceeds the

specified limit, the rocker arm shaft must be replaced.

0.3 (0.0118)

mm(in) Rocker Arm Shaft Run-Out

Limit

Standard Limit

mm(in)

19.01 – 19.03

(0.7484 – 0.7492)19.100 (0.7520) Rocker Arm Inside Diameter

Standard Limit

mm(in)

0.01 – 0.05

(0.0004 – 0.0019)0.20 (0.0079) Clearance Between Rocker Arm and

Rocker Arm Shaft