ISUZU TROOPER 1998 Service Repair Manual

Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 3491 of 3573

RESTRAINT CONTROL SYSTEM 9J1±4

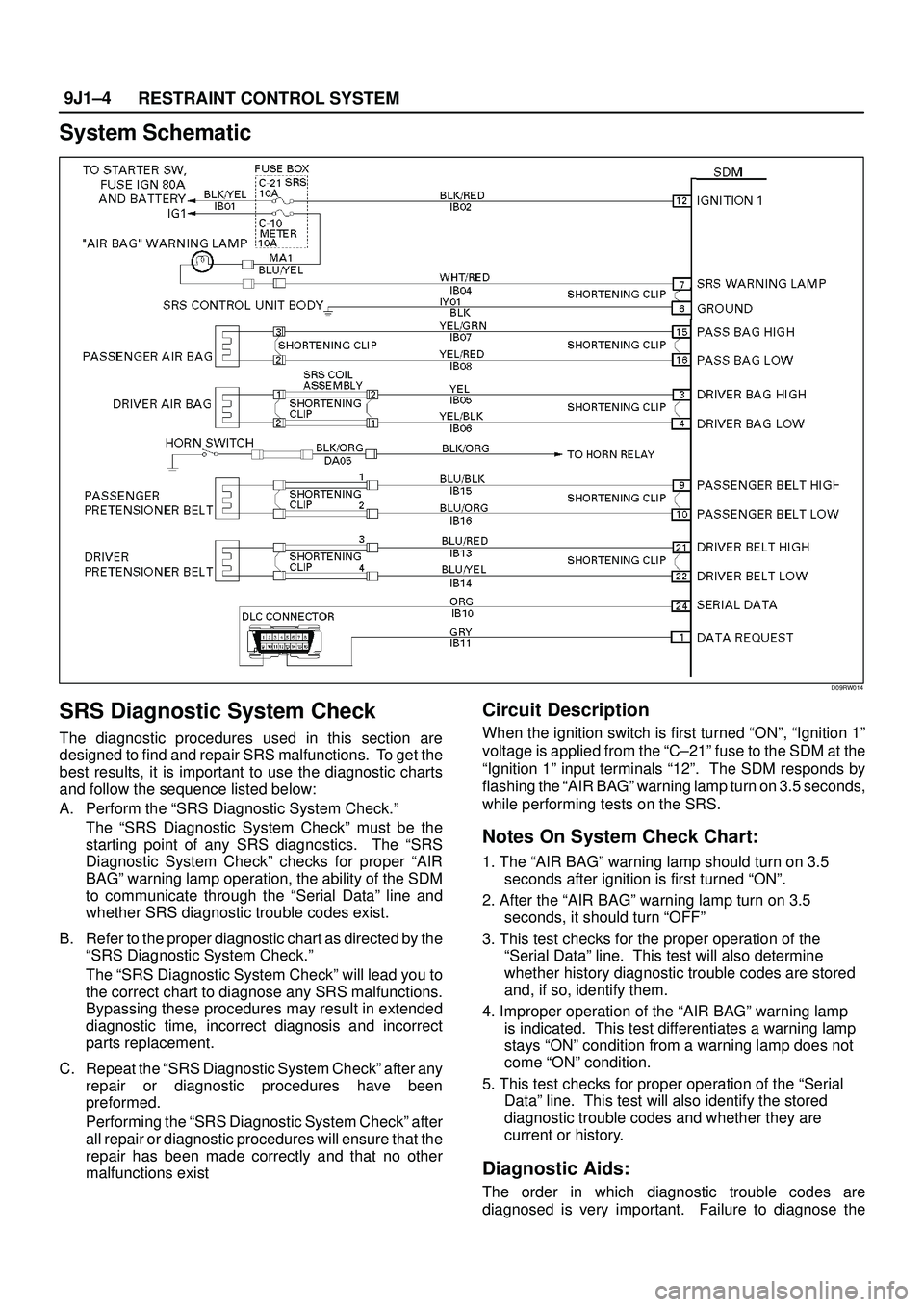

System Schematic

D09RW014

SRS Diagnostic System Check

The diagnostic procedures used in this section are

designed to find and repair SRS malfunctions. To get the

best results, it is important to use the diagnostic charts

and follow the sequence listed below:

A. Perform the ªSRS Diagnostic System Check.º

The ªSRS Diagnostic System Checkº must be the

starting point of any SRS diagnostics. The ªSRS

Diagnostic System Checkº checks for proper ªAIR

BAGº warning lamp operation, the ability of the SDM

to communicate through the ªSerial Dataº line and

whether SRS diagnostic trouble codes exist.

B. Refer to the proper diagnostic chart as directed by the

ªSRS Diagnostic System Check.º

The ªSRS Diagnostic System Checkº will lead you to

the correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect

parts replacement.

C. Repeat the ªSRS Diagnostic System Checkº after any

repair or diagnostic procedures have been

preformed.

Performing the ªSRS Diagnostic System Checkº after

all repair or diagnostic procedures will ensure that the

repair has been made correctly and that no other

malfunctions exist

Circuit Description

When the ignition switch is first turned ªONº, ªIgnition 1º

voltage is applied from the ªC±21º fuse to the SDM at the

ªIgnition 1º input terminals ª12º. The SDM responds by

flashing the ªAIR BAGº warning lamp turn on 3.5 seconds,

while performing tests on the SRS.

Notes On System Check Chart:

1. The ªAIR BAGº warning lamp should turn on 3.5

seconds after ignition is first turned ªONº.

2. After the ªAIR BAGº warning lamp turn on 3.5

seconds, it should turn ªOFFº

3. This test checks for the proper operation of the

ªSerial Dataº line. This test will also determine

whether history diagnostic trouble codes are stored

and, if so, identify them.

4. Improper operation of the ªAIR BAGº warning lamp

is indicated. This test differentiates a warning lamp

stays ªONº condition from a warning lamp does not

come ªONº condition.

5. This test checks for proper operation of the ªSerial

Dataº line. This test will also identify the stored

diagnostic trouble codes and whether they are

current or history.

Diagnostic Aids:

The order in which diagnostic trouble codes are

diagnosed is very important. Failure to diagnose the

Page 3492 of 3573

9J1±5

RESTRAINT CONTROL SYSTEM

diagnostic trouble codes in the order specified may result in extended diagnostic time, incorrect diagnosis and

incorrect parts replacement.

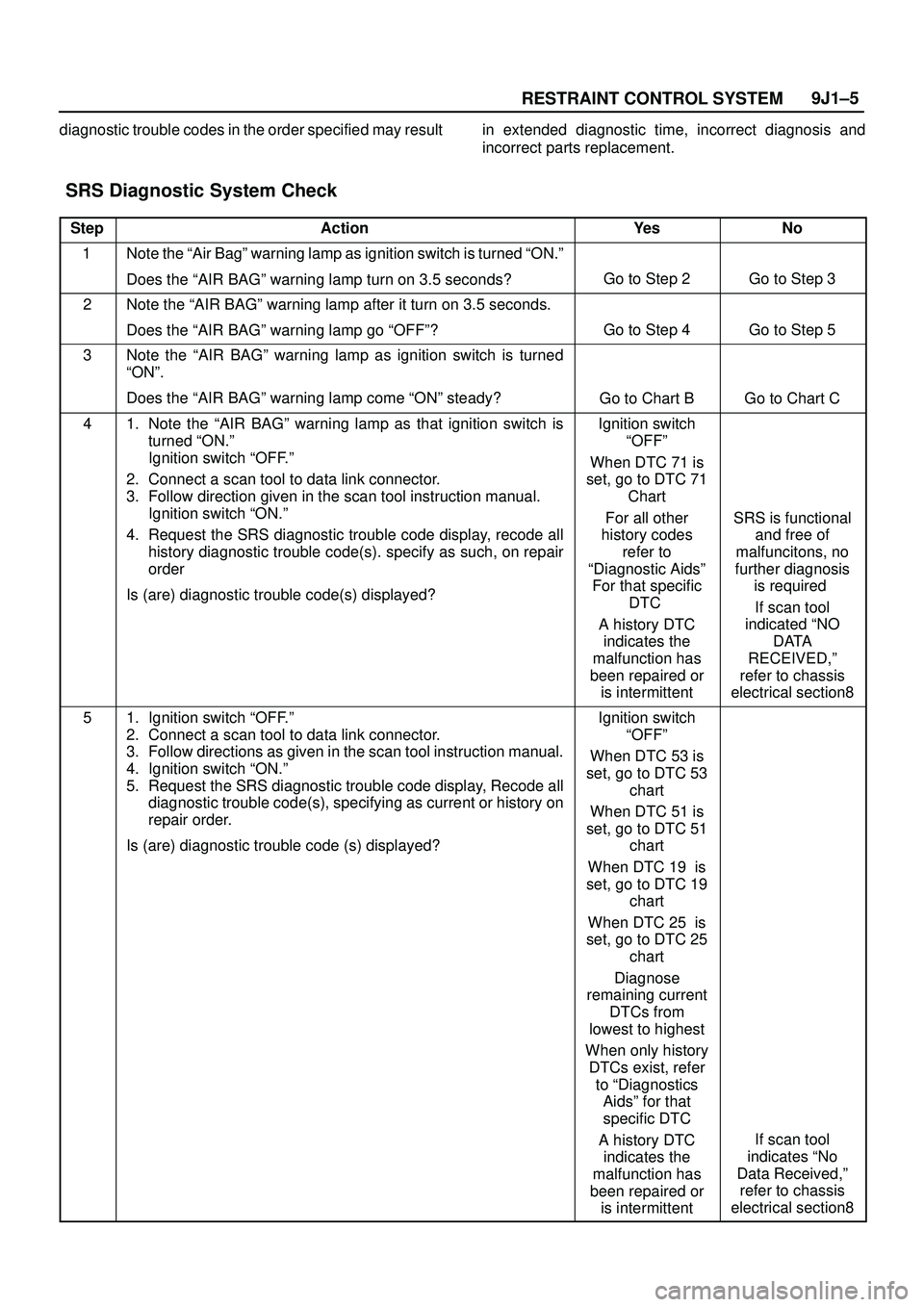

SRS Diagnostic System Check

StepActionYe sNo

1Note the ªAir Bagº warning lamp as ignition switch is turned ªON.º

Does the ªAIR BAGº warning lamp turn on 3.5 seconds?

Go to Step 2Go to Step 3

2Note the ªAIR BAGº warning lamp after it turn on 3.5 seconds.

Does the ªAIR BAGº warning lamp go ªOFFº?

Go to Step 4Go to Step 5

3Note the ªAIR BAGº warning lamp as ignition switch is turned

ªONº.

Does the ªAIR BAGº warning lamp come ªONº steady?

Go to Chart BGo to Chart C

41. Note the ªAIR BAGº warning lamp as that ignition switch is

turned ªON.º

Ignition switch ªOFF.º

2. Connect a scan tool to data link connector.

3. Follow direction given in the scan tool instruction manual.

Ignition switch ªON.º

4. Request the SRS diagnostic trouble code display, recode all

history diagnostic trouble code(s). specify as such, on repair

order

Is (are) diagnostic trouble code(s) displayed?Ignition switch

ªOFFº

When DTC 71 is

set, go to DTC 71

Chart

For all other

history codes

refer to

ªDiagnostic Aidsº

For that specific

DTC

A history DTC

indicates the

malfunction has

been repaired or

is intermittent

SRS is functional

and free of

malfuncitons, no

further diagnosis

is required

If scan tool

indicated ªNO

DATA

RECEIVED,º

refer to chassis

electrical section8

51. Ignition switch ªOFF.º

2. Connect a scan tool to data link connector.

3. Follow directions as given in the scan tool instruction manual.

4. Ignition switch ªON.º

5. Request the SRS diagnostic trouble code display, Recode all

diagnostic trouble code(s), specifying as current or history on

repair order.

Is (are) diagnostic trouble code (s) displayed?Ignition switch

ªOFFº

When DTC 53 is

set, go to DTC 53

chart

When DTC 51 is

set, go to DTC 51

chart

When DTC 19 is

set, go to DTC 19

chart

When DTC 25 is

set, go to DTC 25

chart

Diagnose

remaining current

DTCs from

lowest to highest

When only history

DTCs exist, refer

to ªDiagnostics

Aidsº for that

specific DTC

A history DTC

indicates the

malfunction has

been repaired or

is intermittent

If scan tool

indicates ªNo

Data Received,º

refer to chassis

electrical section8

Page 3493 of 3573

RESTRAINT CONTROL SYSTEM 9J1±6

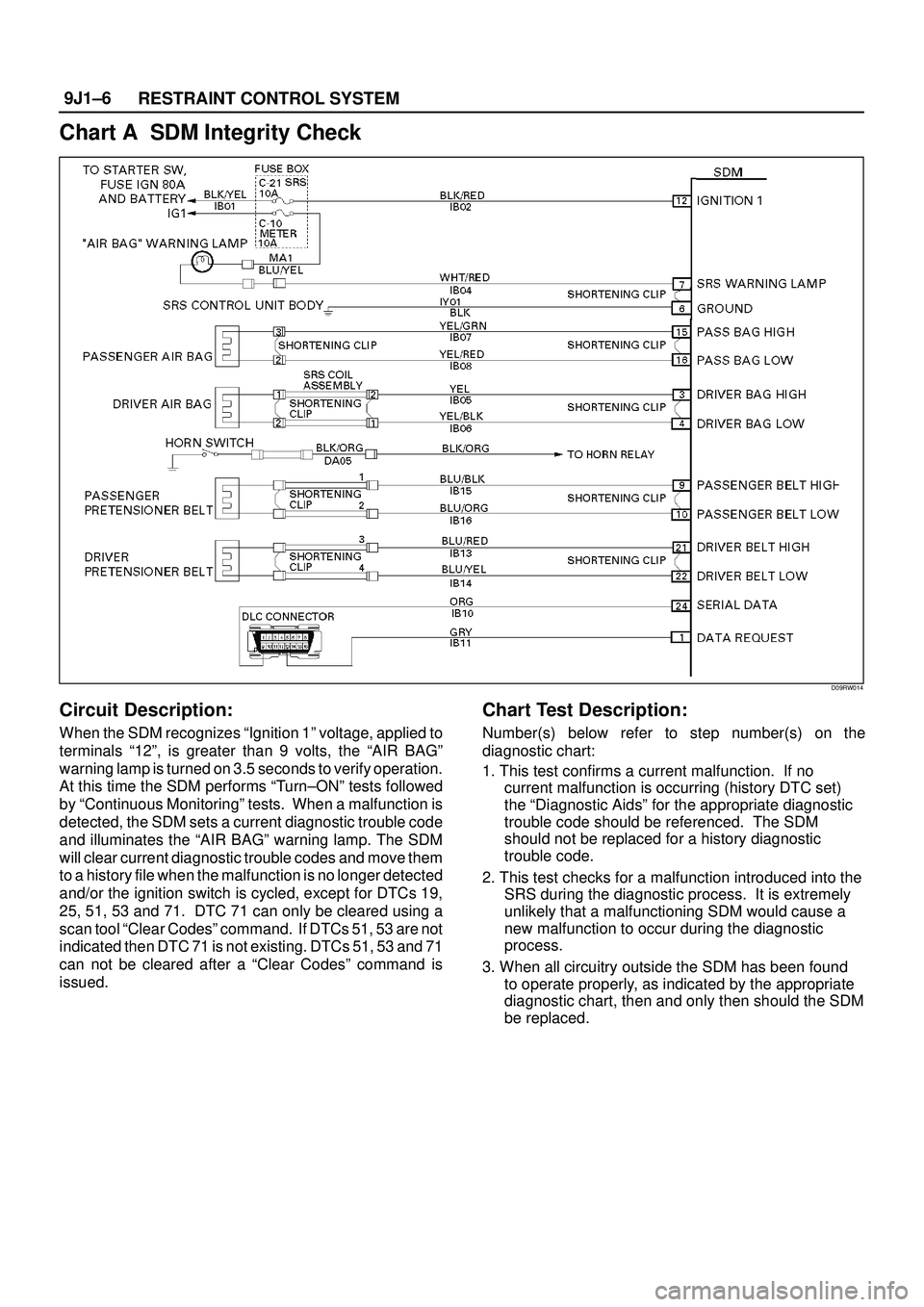

Chart A SDM Integrity Check

D09RW014

Circuit Description:

When the SDM recognizes ªIgnition 1º voltage, applied to

terminals ª12º, is greater than 9 volts, the ªAIR BAGº

warning lamp is turned on 3.5 seconds to verify operation.

At this time the SDM performs ªTurn±ONº tests followed

by ªContinuous Monitoringº tests. When a malfunction is

detected, the SDM sets a current diagnostic trouble code

and illuminates the ªAIR BAGº warning lamp. The SDM

will clear current diagnostic trouble codes and move them

to a history file when the malfunction is no longer detected

and/or the ignition switch is cycled, except for DTCs 19,

25, 51, 53 and 71. DTC 71 can only be cleared using a

scan tool ªClear Codesº command. If DTCs 51, 53 are not

indicated then DTC 71 is not existing. DTCs 51, 53 and 71

can not be cleared after a ªClear Codesº command is

issued.

Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

1. This test confirms a current malfunction. If no

current malfunction is occurring (history DTC set)

the ªDiagnostic Aidsº for the appropriate diagnostic

trouble code should be referenced. The SDM

should not be replaced for a history diagnostic

trouble code.

2. This test checks for a malfunction introduced into the

SRS during the diagnostic process. It is extremely

unlikely that a malfunctioning SDM would cause a

new malfunction to occur during the diagnostic

process.

3. When all circuitry outside the SDM has been found

to operate properly, as indicated by the appropriate

diagnostic chart, then and only then should the SDM

be replaced.

Page 3494 of 3573

9J1±7

RESTRAINT CONTROL SYSTEM

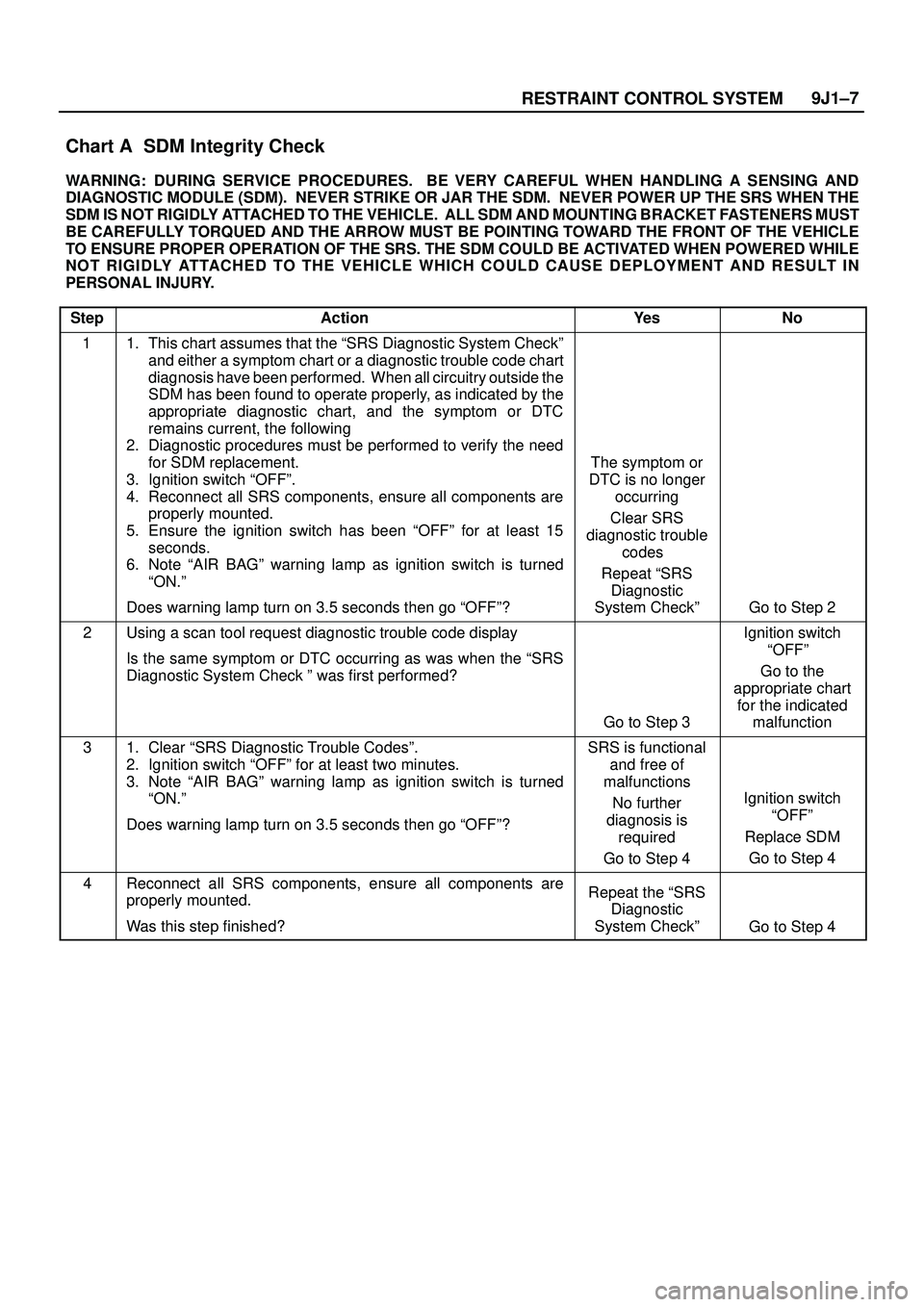

Chart A SDM Integrity Check

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE SRS WHEN THE

SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SDM AND MOUNTING BRACKET FASTENERS MUST

BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT OF THE VEHICLE

TO ENSURE PROPER OPERATION OF THE SRS. THE SDM COULD BE ACTIVATED WHEN POWERED WHILE

NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE DEPLOYMENT AND RESULT IN

PERSONAL INJURY.

Step

ActionYe sNo

11. This chart assumes that the ªSRS Diagnostic System Checkº

and either a symptom chart or a diagnostic trouble code chart

diagnosis have been performed. When all circuitry outside the

SDM has been found to operate properly, as indicated by the

appropriate diagnostic chart, and the symptom or DTC

remains current, the following

2. Diagnostic procedures must be performed to verify the need

for SDM replacement.

3. Ignition switch ªOFFº.

4. Reconnect all SRS components, ensure all components are

properly mounted.

5. Ensure the ignition switch has been ªOFFº for at least 15

seconds.

6. Note ªAIR BAGº warning lamp as ignition switch is turned

ªON.º

Does warning lamp turn on 3.5 seconds then go ªOFFº?

The symptom or

DTC is no longer

occurring

Clear SRS

diagnostic trouble

codes

Repeat ªSRS

Diagnostic

System Checkº

Go to Step 2

2Using a scan tool request diagnostic trouble code display

Is the same symptom or DTC occurring as was when the ªSRS

Diagnostic System Check º was first performed?

Go to Step 3

Ignition switch

ªOFFº

Go to the

appropriate chart

for the indicated

malfunction

31. Clear ªSRS Diagnostic Trouble Codesº.

2. Ignition switch ªOFFº for at least two minutes.

3. Note ªAIR BAGº warning lamp as ignition switch is turned

ªON.º

Does warning lamp turn on 3.5 seconds then go ªOFFº?SRS is functional

and free of

malfunctions

No further

diagnosis is

required

Go to Step 4

Ignition switch

ªOFFº

Replace SDM

Go to Step 4

4Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?Repeat the ªSRS

Diagnostic

System Checkº

Go to Step 4

Page 3495 of 3573

RESTRAINT CONTROL SYSTEM 9J1±8

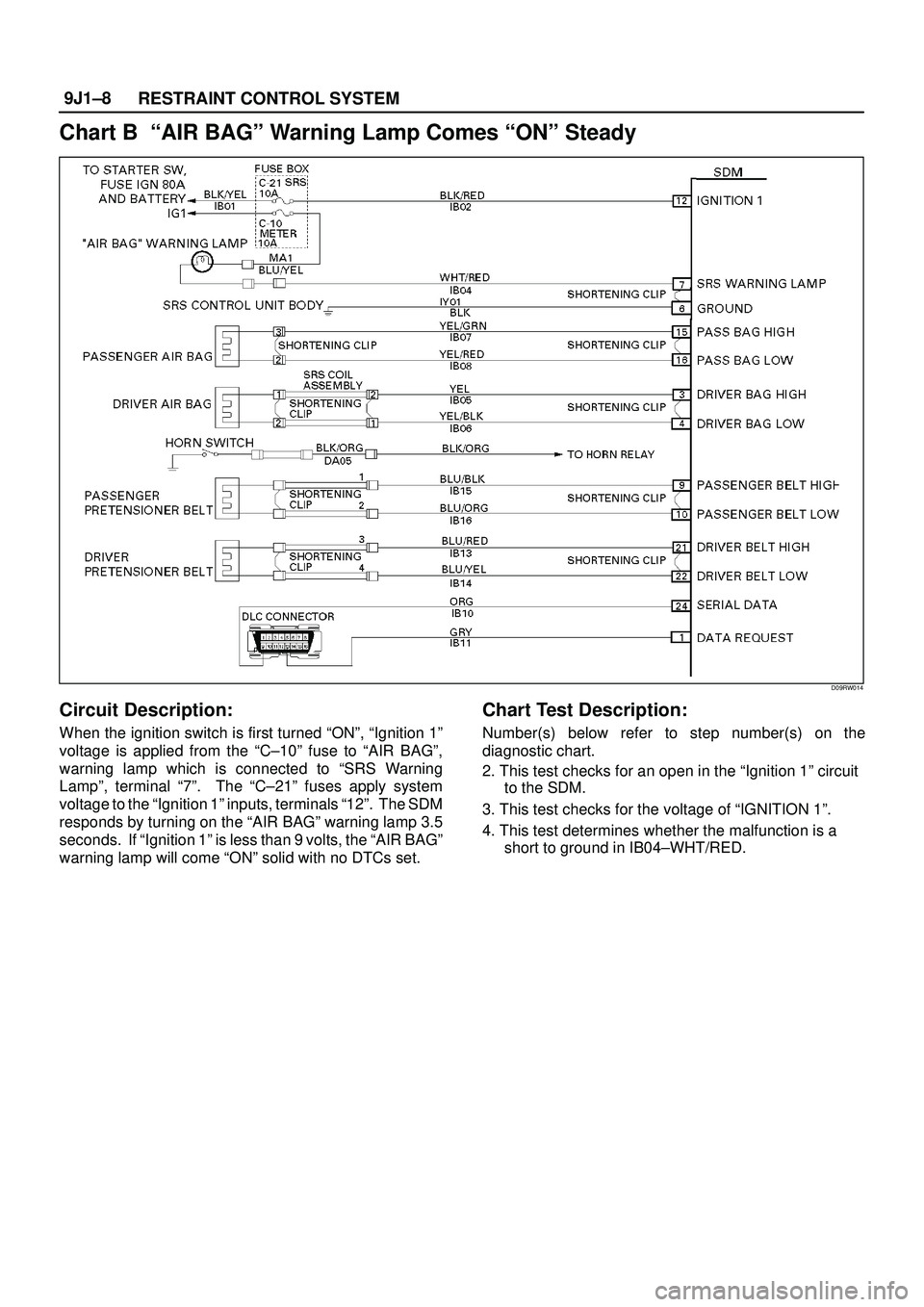

Chart B ªAIR BAGº Warning Lamp Comes ªONº Steady

D09RW014

Circuit Description:

When the ignition switch is first turned ªONº, ªIgnition 1º

voltage is applied from the ªC±10º fuse to ªAIR BAGº,

warning lamp which is connected to ªSRS Warning

Lampº, terminal ª7º. The ªC±21º fuses apply system

voltage to the ªIgnition 1º inputs, terminals ª12º. The SDM

responds by turning on the ªAIR BAGº warning lamp 3.5

seconds. If ªIgnition 1º is less than 9 volts, the ªAIR BAGº

warning lamp will come ªONº solid with no DTCs set.

Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart.

2. This test checks for an open in the ªIgnition 1º circuit

to the SDM.

3. This test checks for the voltage of ªIGNITION 1º.

4. This test determines whether the malfunction is a

short to ground in IB04±WHT/RED.

Page 3496 of 3573

9J1±9

RESTRAINT CONTROL SYSTEM

Chart B ªAIR BAGº warning lamp comes ªONº Steady

StepActionYe sNo

11. When measurements are requested in this chart use

5±8840±0285±0 DVM with correct terminal adapter from

5±8840±0385±0.

2. Ignition switch ªOFF.º

3. Connect scan tool to data link connector, follow directions as

given in the scan tool instruction MANUAL.

4. Ignition switch ªON.º

5. Request SRS diagnostic trouble code display.

Dose scan tool indicate ªNo Data Receivedº?

Go to Step 2Go to Step 3

21. Ignition switch ªOFFº.

2. Inspect SDM harness connector connection to SDM.

Is it securely connected to the SDM?

Ignition switch

ªOFFº

Replace SDM

Go to Step 5

Connect SDM

securely to

de±activate

shorting clip in

SDM harness

connector

Go to Step 5

3Using scan tool, request SRS data list.

Is ªignitionº less than 9 volts?

Go to Step 4

Ignition switch

ªOFFº

Replace SDM

Go to Step 5

41. Ignition switch ªOFF.º

2. Disconnect SRS coil and passenger air bag assemblies.

yellow 2±pin connector located at base of steering column and

behind the glove box assembly.

Disconnect SDM.

3. Disconnect the connector of ªSRS Warning Lampº of

instrument cluster.

4. Measure resistance from SDM harness connector terminal ª7º

to ground ª6º.

Does 5±8840±0285±0 display ªOLº (Infinite)?

Go to Chart A

Replace SRS

harness

Go to Step 5

5Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?Repeat the ªSRS

Diagnostic

System Checkº

Go to Step 5

Page 3497 of 3573

RESTRAINT CONTROL SYSTEM 9J1±10

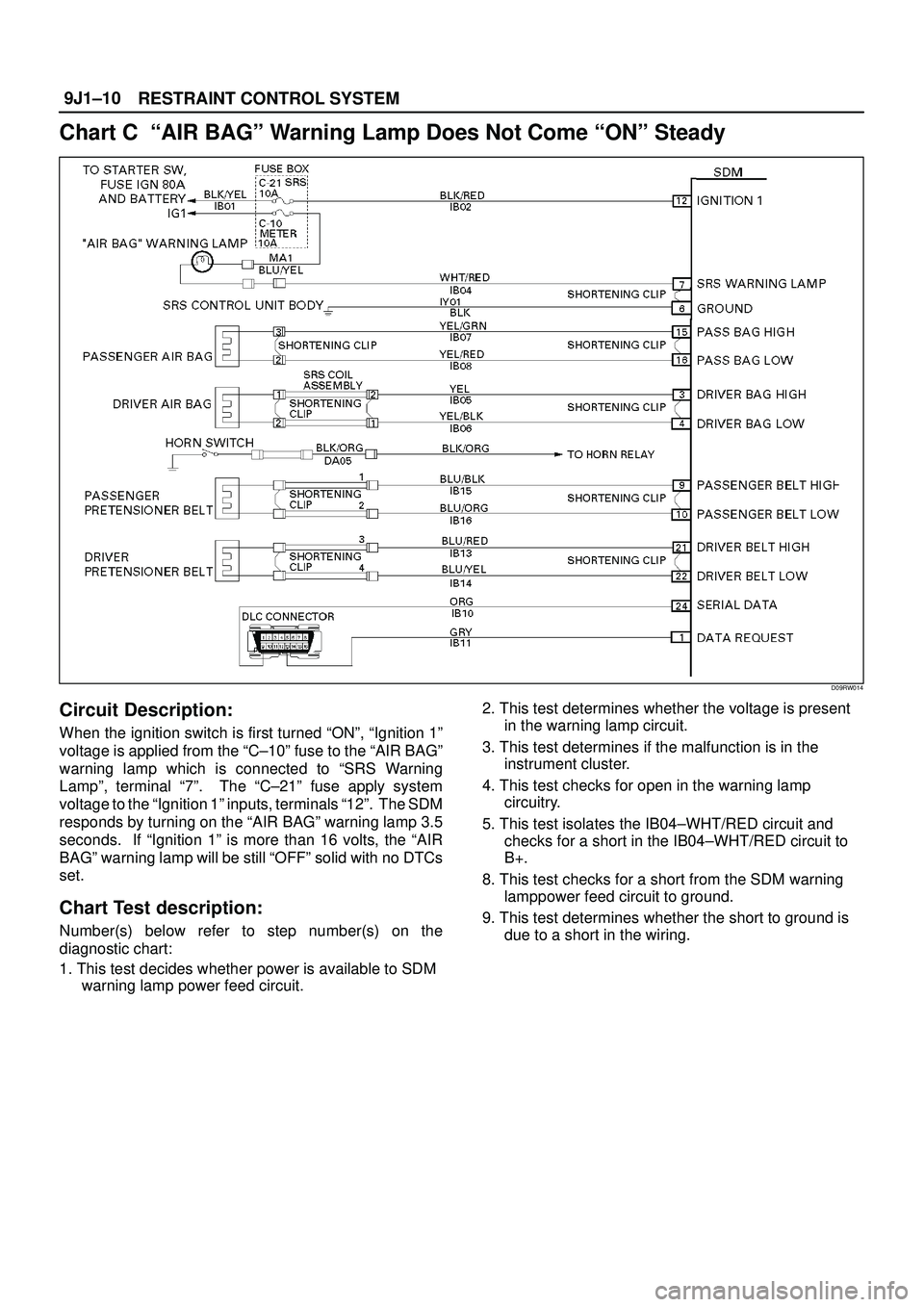

Chart C ªAIR BAGº Warning Lamp Does Not Come ªONº Steady

D09RW014

Circuit Description:

When the ignition switch is first turned ªONº, ªIgnition 1º

voltage is applied from the ªC±10º fuse to the ªAIR BAGº

warning lamp which is connected to ªSRS Warning

Lampº, terminal ª7º. The ªC±21º fuse apply system

voltage to the ªIgnition 1º inputs, terminals ª12º. The SDM

responds by turning on the ªAIR BAGº warning lamp 3.5

seconds. If ªIgnition 1º is more than 16 volts, the ªAIR

BAGº warning lamp will be still ªOFFº solid with no DTCs

set.

Chart Test description:

Number(s) below refer to step number(s) on the

diagnostic chart:

1. This test decides whether power is available to SDM

warning lamp power feed circuit.2. This test determines whether the voltage is present

in the warning lamp circuit.

3. This test determines if the malfunction is in the

instrument cluster.

4. This test checks for open in the warning lamp

circuitry.

5. This test isolates the IB04±WHT/RED circuit and

checks for a short in the IB04±WHT/RED circuit to

B+.

8. This test checks for a short from the SDM warning

lamppower feed circuit to ground.

9. This test determines whether the short to ground is

due to a short in the wiring.

Page 3498 of 3573

9J1±11

RESTRAINT CONTROL SYSTEM

Chart C ªAIR BAGº Warning Lamp Does Not Come ªONº Steady

StepActionYe sNo

11. When measurements are requested in this chart,use

5±8840±0285±0 DVM with correct terminal adapter from

5±8840±0385±0.

2. Ignition switch ªOFF.º

3. Remove and inspect ªC±10º fuse (meter) to the ªAIR BAGº

warning lamp.

Is fuse good?

Go to Step 2Go to Step 7

21. Ignition switch ªOFF.º

2. Disconnect SRS coil and passenger air bag assemblies.

Yellow 2±pin connector located at base of steering column and

behind the glove box assembly.

3. Disconnect SDM.

4. Ignition switch ªON.º

5. Measure voltage on SDM harness connector from terminal ª7º

to terminal ª6º (ground).

Is system voltage present on terminal ª7º?

Go to Step 4Go to Step 3

31. Ignition switch ªOFF.º

2. Remove instrument meter cluster.

3. Check for proper connection to instrument cluster at

IB04±WHT/RED terminal.

4. If ok, then remove and inspect ªAIR BAGº bulb.

Is bulb good?

Go to Step 5

Replace bulb

Go to Step 6

41. Ignition switch ªOFF.º

2. Disconnect instrument meter cluster harness connector.

3. Ignition switch ªON.º

4. Measure voltage on SDM harness connector from terminal ª7º

to terminal ª6º (GROUND).

Is voltage 1 volt or less?

Go to Chart A

Replace SRS

harness

Go to Step 6

51. Install bulb.

2. Measure resistance from instrument meter cluster harness

connector IB04±WHT/RED terminal to SDM harness

connector terminal ª7º.

Is resistance 5.0 ohms or less?Service

instrument meter

cluster

Install instrument

meter cluster

Go to Step 6

Replace SRS

harness

Go to Step 6

6Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?Repeat the ªSRS

Diagnostic

System Checkº

Go to Step 6

7Perform chart C.

Was this step finished?

Go to Step 8Go to Step 1

81. Replace ªC±10º fuse.

2. Ignition switch ªONº wait 10 Seconds then ignition switch ªOff.º

3. Remove and inspect ªC±10º fuse.

Is fuse good?

Install ªC±10º

fuse

Go to Step 10

Go to Step 9

Page 3499 of 3573

RESTRAINT CONTROL SYSTEM 9J1±12

Chart C ªAIR BAGº Warning Lamp Does Not Come ªONº Steady (Cont'd)

StepNo Ye s Action

91. Disconnect SRS coil and passenger air bag assemblies.

Yellow 2±pin connectors located at base of steering column

and behind the glove box assembly.

2. Disconnect SDM.

3. Replace ªC±10º fuse.

4. Ignition switch ªONº wait 10 seconds.

5. Ignition switch ªOFFº.

6. Remove and inspection ªC±10º fuse.

Is fuse good?

InstallªC±10º fuse

Go to Chart A

Replace SRS

harness

Replace ªC±10º

fuse

Go to Step 10

10Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?Repeat the ªSRS

Diagnostic

System Checkº

Go to Step 10

Page 3500 of 3573

9J1±13

RESTRAINT CONTROL SYSTEM

DTC 15 Passenger Deployment Loop Resistance High

D09RW014

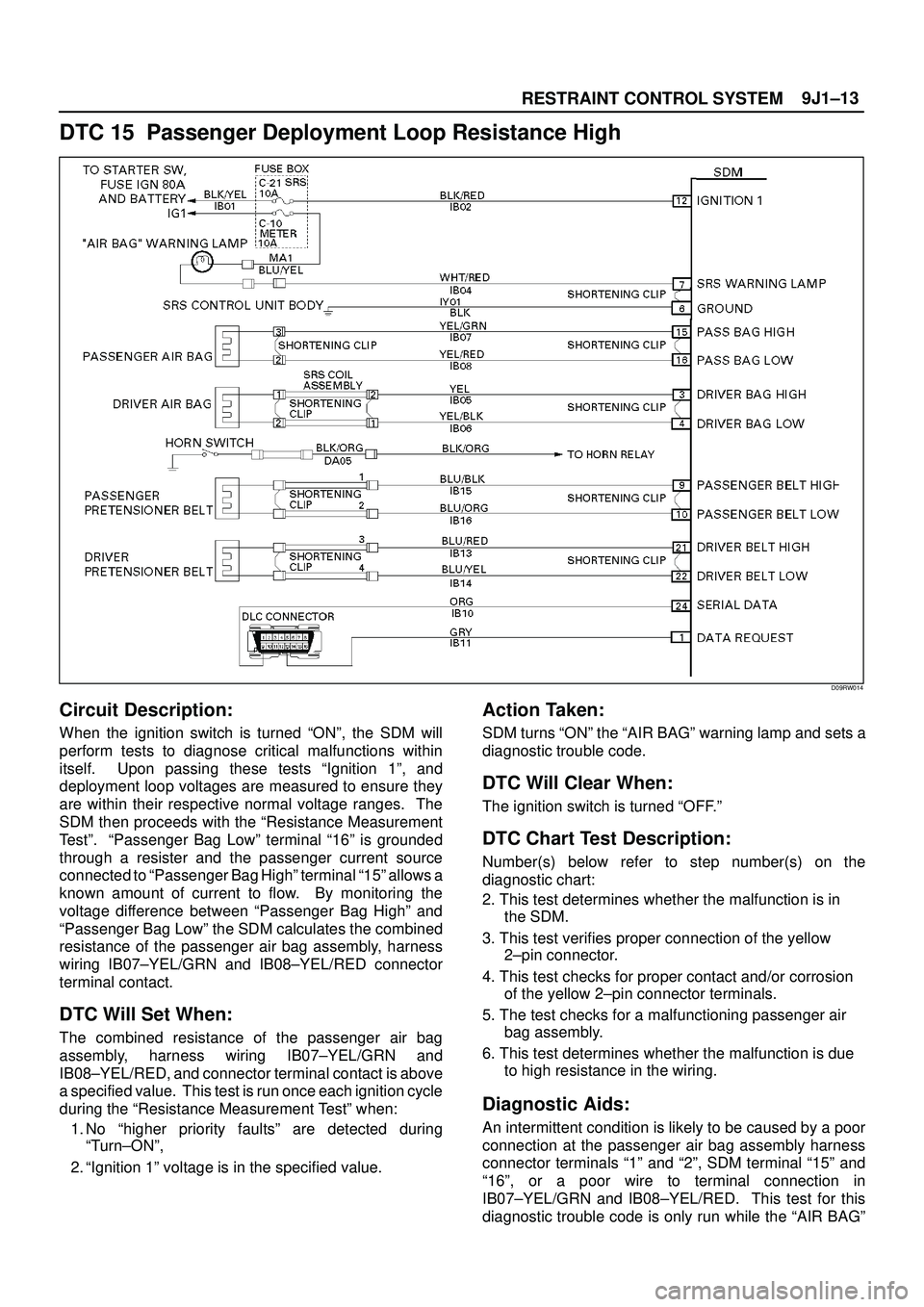

Circuit Description:

When the ignition switch is turned ªONº, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests ªIgnition 1º, and

deployment loop voltages are measured to ensure they

are within their respective normal voltage ranges. The

SDM then proceeds with the ªResistance Measurement

Testº. ªPassenger Bag Lowº terminal ª16º is grounded

through a resister and the passenger current source

connected to ªPassenger Bag Highº terminal ª15º allows a

known amount of current to flow. By monitoring the

voltage difference between ªPassenger Bag Highº and

ªPassenger Bag Lowº the SDM calculates the combined

resistance of the passenger air bag assembly, harness

wiring IB07±YEL/GRN and IB08±YEL/RED connector

terminal contact.

DTC Will Set When:

The combined resistance of the passenger air bag

assembly, harness wiring IB07±YEL/GRN and

IB08±YEL/RED, and connector terminal contact is above

a specified value. This test is run once each ignition cycle

during the ªResistance Measurement Testº when:

1. No ªhigher priority faultsº are detected during

ªTurn±ONº,

2. ªIgnition 1º voltage is in the specified value.

Action Taken:

SDM turns ªONº the ªAIR BAGº warning lamp and sets a

diagnostic trouble code.

DTC Will Clear When:

The ignition switch is turned ªOFF.º

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SDM.

3. This test verifies proper connection of the yellow

2±pin connector.

4. This test checks for proper contact and/or corrosion

of the yellow 2±pin connector terminals.

5. The test checks for a malfunctioning passenger air

bag assembly.

6. This test determines whether the malfunction is due

to high resistance in the wiring.

Diagnostic Aids:

An intermittent condition is likely to be caused by a poor

connection at the passenger air bag assembly harness

connector terminals ª1º and ª2º, SDM terminal ª15º and

ª16º, or a poor wire to terminal connection in

IB07±YEL/GRN and IB08±YEL/RED. This test for this

diagnostic trouble code is only run while the ªAIR BAGº