service ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 3472 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM9J±35

Driver Air Bag Assembly

Service Precautions

WARNING: S A F E T Y P R ECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY±PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: W H E N C A R RY I N G A L I V E A I R B A G

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING ALIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND TRIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.

NOTE: In the event deployment has occurred, inspect

coil assembly wire for any signs of scorching, melting or

any other damage due to excessive heat. If the coil has

been damaged, replace it.

Removal

1. Disable the SRS (Refer to ªDisabling the SRSº in this

section).

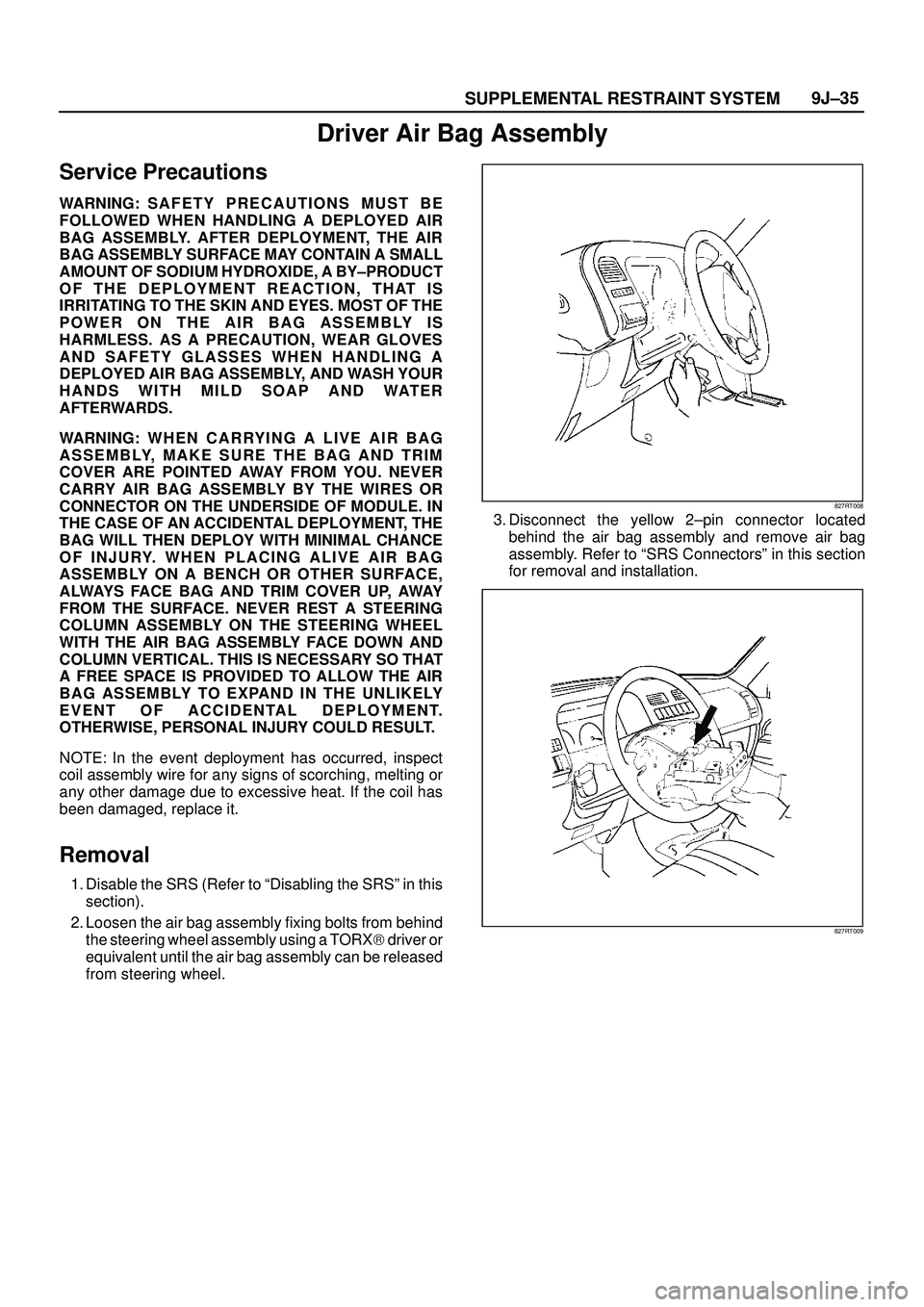

2. Loosen the air bag assembly fixing bolts from behind

the steering wheel assembly using a TORX) driver or

equivalent until the air bag assembly can be released

from steering wheel.

827RT008

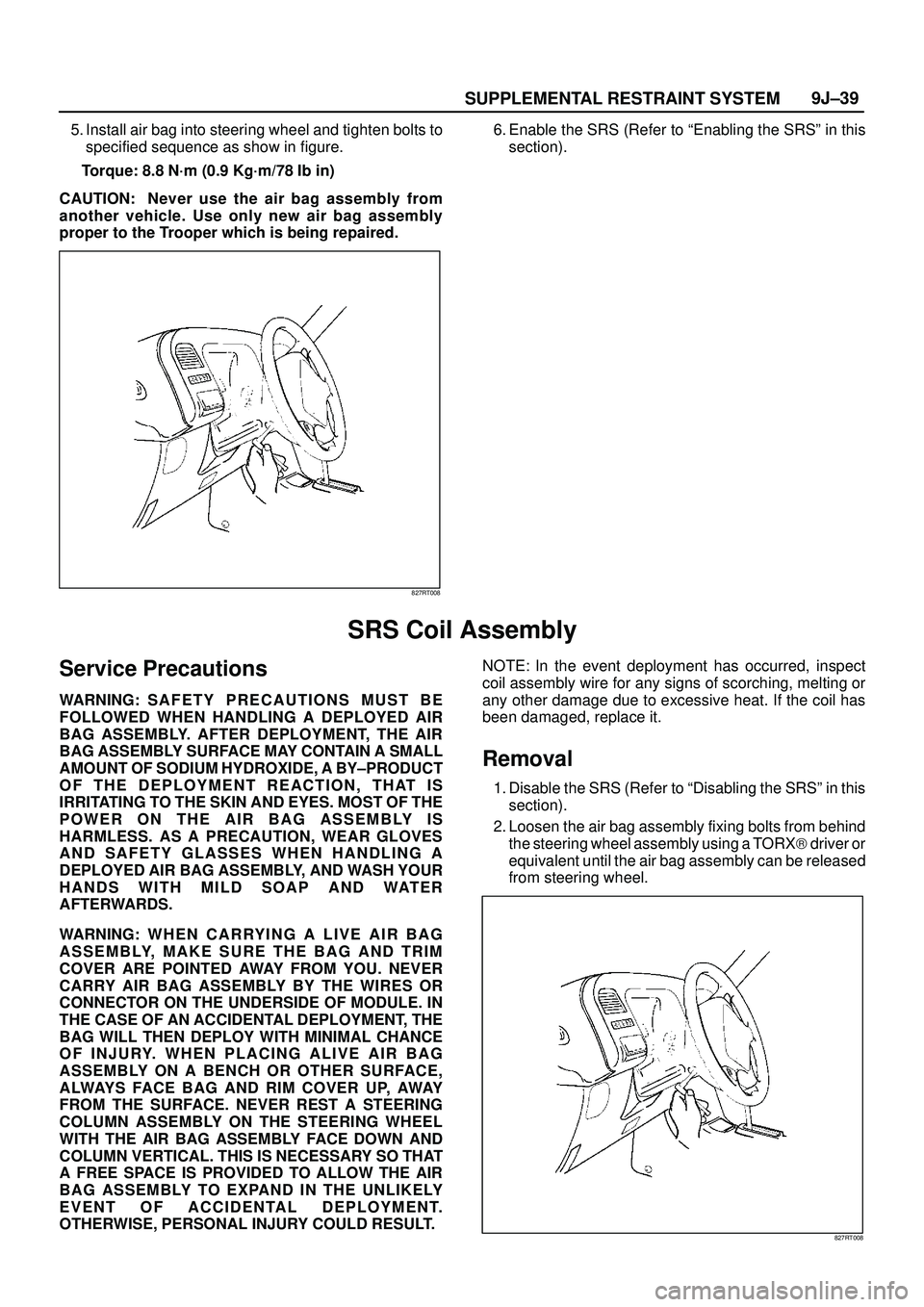

3. Disconnect the yellow 2±pin connector located

behind the air bag assembly and remove air bag

assembly. Refer to ªSRS Connectorsº in this section

for removal and installation.

827RT009

Page 3474 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM9J±37

Steering Wheel

Service Precautions

WARNING: S A F E T Y P R ECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY±PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: W H E N C A R RY I N G A L I V E A I R B A G

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING ALIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND RIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.

NOTE: In the event deployment has occurred, inspect

coil assembly wire for any signs of scorching, melting or

any other damage due to excessive heat. If the coil has

been damaged, replace it.

Removal

1. Disable the SRS (Refer to ªDisabling the SRSº in this

section).

2. Loosen the air bag assembly fixing bolts from behind

the steering wheel assembly using a TORX) driver or

equivalent until the air bag assembly can be released

from steering wheel.

827RT008

3. Disconnect the yellow 2±pin connector located

behind the air bag assembly and remove air bag

assembly.Refer to ªSRS Connectorsº in this section

for removal and installation.

4. Disconnect horn lead.

827RT009

5. Remove steering wheel attachment nut.

Page 3476 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM9J±39

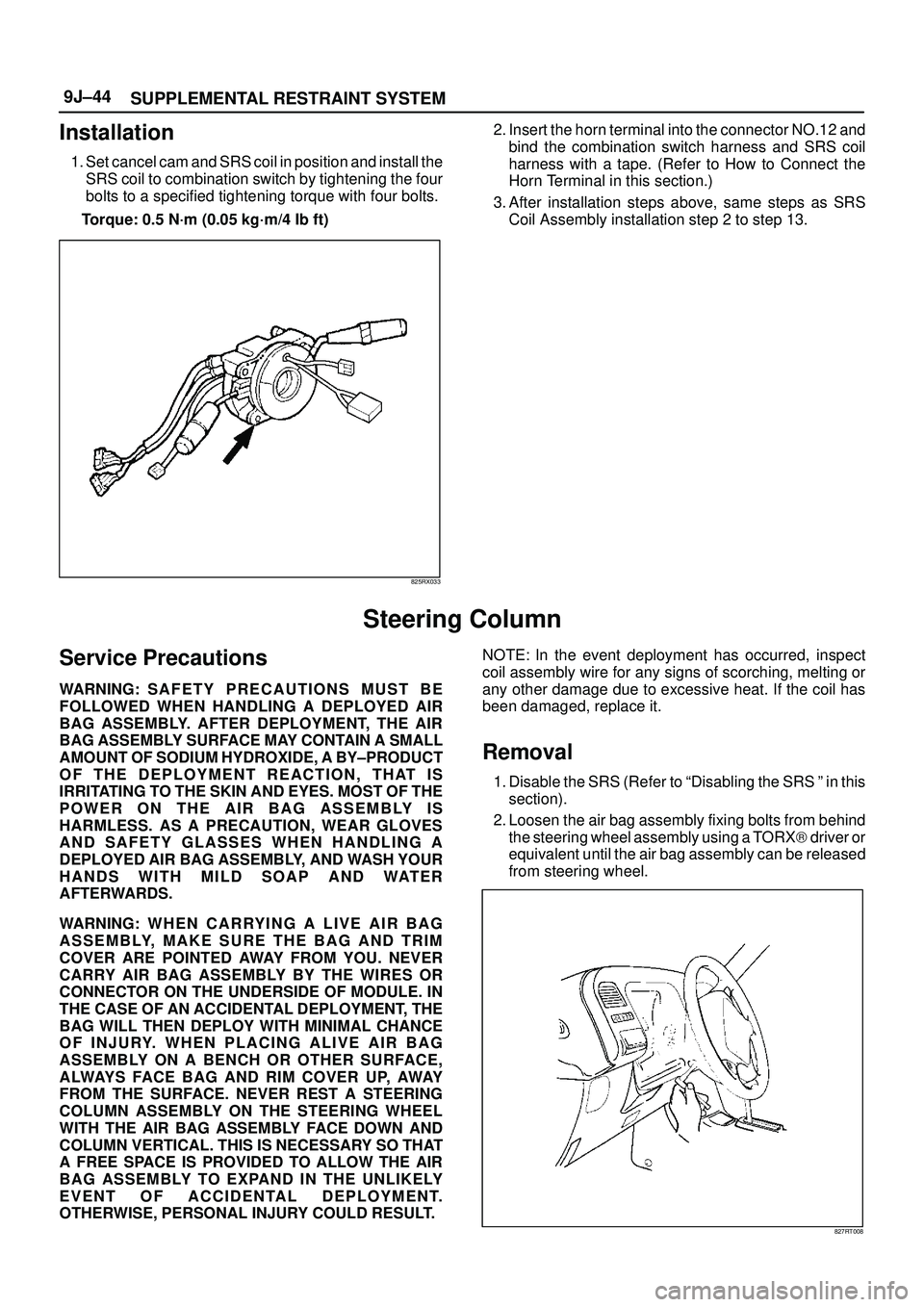

5. Install air bag into steering wheel and tighten bolts to

specified sequence as show in figure.

Torque: 8.8 N´m (0.9 Kg´m/78 Ib in)

CAUTION: Never use the air bag assembly from

another vehicle. Use only new air bag assembly

proper to the Trooper which is being repaired.

827RT008

6. Enable the SRS (Refer to ªEnabling the SRSº in this

section).

SRS Coil Assembly

Service Precautions

WARNING: S A F E T Y P R ECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY±PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: W H E N C A R RY I N G A L I V E A I R B A G

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING ALIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND RIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.NOTE: In the event deployment has occurred, inspect

coil assembly wire for any signs of scorching, melting or

any other damage due to excessive heat. If the coil has

been damaged, replace it.

Removal

1. Disable the SRS (Refer to ªDisabling the SRSº in this

section).

2. Loosen the air bag assembly fixing bolts from behind

the steering wheel assembly using a TORX) driver or

equivalent until the air bag assembly can be released

from steering wheel.

827RT008

Page 3481 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM 9J±44

Installation

1. Set cancel cam and SRS coil in position and install the

SRS coil to combination switch by tightening the four

bolts to a specified tightening torque with four bolts.

Torque: 0.5 N´m (0.05 kg´m/4 Ib ft)

825RX033

2. Insert the horn terminal into the connector NO.12 and

bind the combination switch harness and SRS coil

harness with a tape. (Refer to How to Connect the

Horn Terminal in this section.)

3. After installation steps above, same steps as SRS

Coil Assembly installation step 2 to step 13.

Steering Column

Service Precautions

WARNING: S A F E T Y P R ECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY±PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: W H E N C A R RY I N G A L I V E A I R B A G

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING ALIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND RIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.NOTE: In the event deployment has occurred, inspect

coil assembly wire for any signs of scorching, melting or

any other damage due to excessive heat. If the coil has

been damaged, replace it.

Removal

1. Disable the SRS (Refer to ªDisabling the SRS º in this

section).

2. Loosen the air bag assembly fixing bolts from behind

the steering wheel assembly using a TORX) driver or

equivalent until the air bag assembly can be released

from steering wheel.

827RT008

Page 3485 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM 9J±48

Passenger Air Bag Assembly

Service Precautions

WARNING: S A F E T Y P R ECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY±PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: W H E N C A R RY I N G A L I V E A I R B A G

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING ALIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND RIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.

NOTE: IN THE EVENT DEPLOYMENT HAS

OCCURRED, INSPECT COIL ASSEMBLY WIRE FOR

ANY SIGNS OF SCORCHING, MELTING OR ANY

OTHER DAMAGE DUE TO EXCESSIVE HEAT. IF THE

COIL HAS BEEN DAMAGED, REPLACE IT.

Removal

827RS001

1. Disable the SRS (Refer to ªDisabling the SRS º in this

section).

2. Remove gear control knob.

3. Remove front console assembly.

4. Remove rear console assembly and disconnect

harness connector.

5. Remove ECM and SDM cover.

6. Remove glove box assembly with lid.

7. Remove glove box cover.

8. Remove instrument panel assist side lower cover.

9. Disconnect engine hood opener lever.

10. Remove instrument panel door side lower cover.

11. Remove lower cluster with ashtray.

12. Remove meter cluster assembly and disconnect

harness connector.

13. Remove instrument panel lower center cover.

14. Disconnect passenger air bag assembly harness

connector.

15. Remove air bag assembly fixing bolts and nuts.

16. Remove passenger air bag assembly.

Installation

827RS001

1. Install passenger air bag assembly.

2. Install air bag assembly fixing bolts, nuts and tighten

to specified torque.

Torque: 6 N´m (0.6 Kg´m/52 Ib in)

3. Connect air bag assembly harness connector.

4. Install instrument panel lower center cover.

5. Install meter cluster assembly and connect harness

connector.

6. Install lower cluster with ashtray.

7. Install instrument panel door side lower cover.

8. Connect engine hood opener lever.

9. Install instrument panel assist side lower cover.

Page 3486 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM9J±49

10. Install glove box cover.

11. Install glove box assembly with lid.

12. Install ECM and SDM cover.

13. Install rear console assembly and connect harness

connector.14. Install front console assembly.

15. Install gear control knob.

16. Enable the SRS (Refer to ªEnabling the SRSº in this

section).

Pretensioner Seat Belt (If so equipped)

Service Precaution

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND THE PRETENSIONER SEAT BELT OR THE

PRETENSIONER SEAT BELT WIRING, FOLLOW THE

PROCEDURES LISTED BELOW TO TEMPORARILY

DISABLE THE PRETENSIONER SEAT BELT.

FAILURE TO FOLLOW PROCEDURES COULD

RESULT IN POSSIBLE THE PRETENSIONER SEAT

BELT DEPLOYMENT, PERSONAL INJURY OR

OTHERWISE UNNEEDED THE PRETENSIONER

SEAT BELT REPAIR.

AS A PRECAUTION, WEAR GLOVES AND SAFETY

GLASSES WHEN PERFORMING THE

PRETENSIONER SEAT BELT. WHEN DEPLOY A LIVE

PRETENSIONER SEAT BELT AT OUTSIDE THE

VEHICLE, DEPLOYMENT HARNESS SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE PRETENSIONER SEAT BELT IS

TO BE DEPLOYED. THE PRETENSIONER SEAT

BELT WILL IMMEDIATELY DEPLOY WHEN A POWER

SOURCE IS CONNECTED TO IT. CONNECTING THE

DEPLOYMENT HARNESS SHOULED ALWAYS BE

THE FINAL STEP IN THE PRETENSIONER SEAT

BELT DEPLOYMENT PROCEDURE. FAILURE TO

FOLLOW PROCEDURES IN THE ORDER LISTED

COULD RESULT IN PERSONAL INJURY.

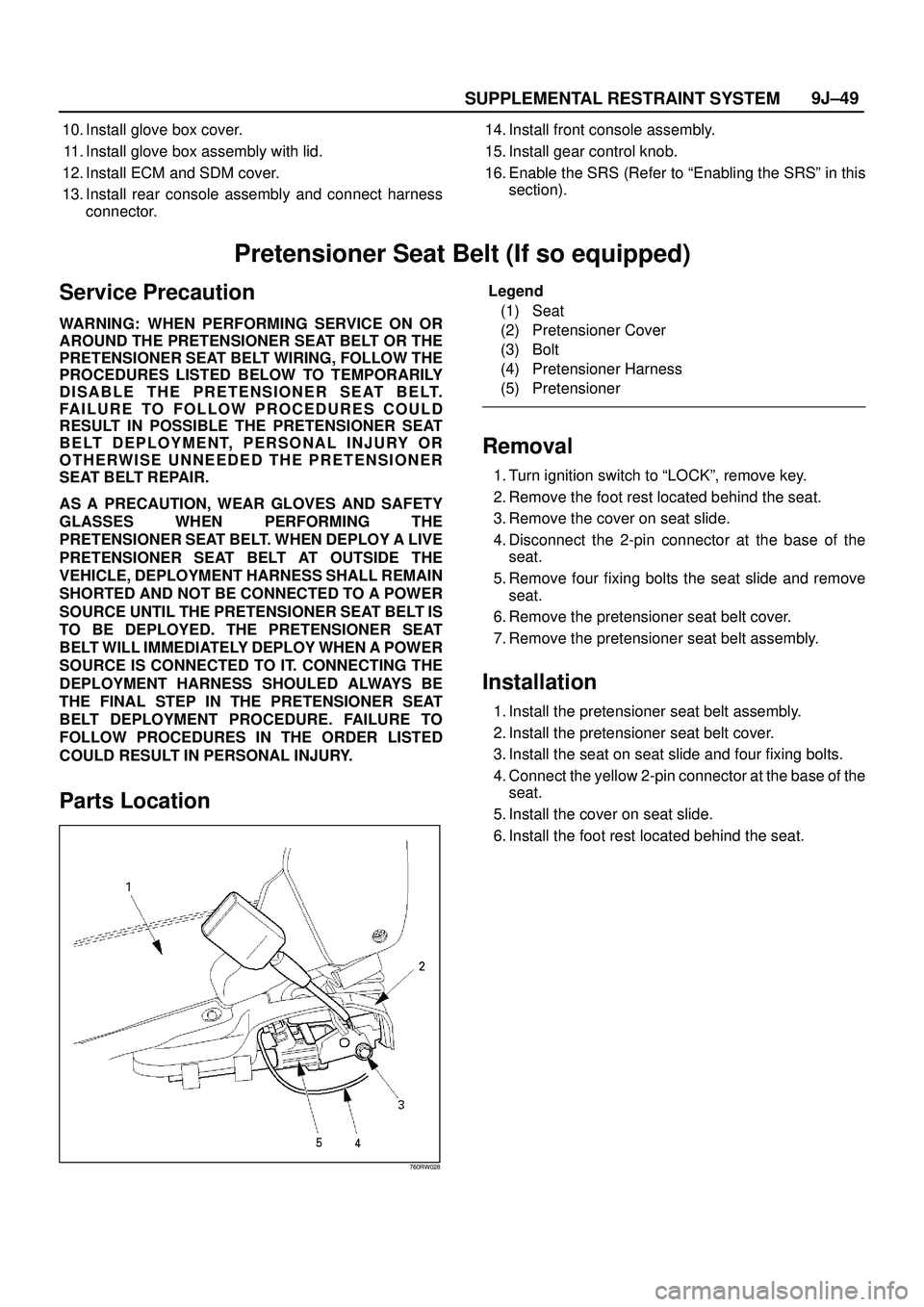

Parts Location

760RW028

Legend

(1) Seat

(2) Pretensioner Cover

(3) Bolt

(4) Pretensioner Harness

(5) Pretensioner

Removal

1. Turn ignition switch to ªLOCKº, remove key.

2. Remove the foot rest located behind the seat.

3. Remove the cover on seat slide.

4. Disconnect the 2-pin connector at the base of the

seat.

5. Remove four fixing bolts the seat slide and remove

seat.

6. Remove the pretensioner seat belt cover.

7. Remove the pretensioner seat belt assembly.

Installation

1. Install the pretensioner seat belt assembly.

2. Install the pretensioner seat belt cover.

3. Install the seat on seat slide and four fixing bolts.

4. Connect the yellow 2-pin connector at the base of the

seat.

5. Install the cover on seat slide.

6. Install the foot rest located behind the seat.

Page 3488 of 3573

9J1±1

RESTRAINT CONTROL SYSTEM

RESTRAINT CONTROL SYSTEM

CONTENTS

Service Precaution 9J1±1. . . . . . . . . . . . . . . . . . . . . .

Diagnostic Information 9J1±2. . . . . . . . . . . . . . . . . . .

System Schematic 9J1±4. . . . . . . . . . . . . . . . . . . . . .

SRS Diagnostic System Check 9J1±4. . . . . . . . . . . .

Chart A SDM Integrity Check 9J1±6. . . . . . . . . . . . .

Chart B ªAIR BAGº Warning Lamp

Comes ªONº Steady 9J1±8. . . . . . . . . . . . . . . . . . . .

Chart C ªAIR BAGº Warning Lamp

Does Not Come ªONº Steady 9J1±10. . . . . . . . . . . . .

DTC 15 Passenger Deployment Loop

Resistance High 9J1±13. . . . . . . . . . . . . . . . . . . . . . . .

DTC 16 Passenger Deployment loop

Resistance Low 9J1±15. . . . . . . . . . . . . . . . . . . . . . . .

DTC 17 Passenger Deployment Loop

Open 9J1±17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 18 Passenger Deployment Loop

Short To Ground 9J1±19. . . . . . . . . . . . . . . . . . . . . . . .

DTC 19 Passenger Deployment Loop

Short To B+ 9J1±21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 21 Driver Deployment Loop

Resistance High 9J1±23. . . . . . . . . . . . . . . . . . . . . . . .

DTC 22 Driver Deployment Loop

Resistance Low 9J1±26. . . . . . . . . . . . . . . . . . . . . . . .

DTC 24 Driver Deployment Loop

Short To Ground 9J1±29. . . . . . . . . . . . . . . . . . . . . . . .

DTC 25 Driver Deployment Loop

Short To B+ 9J1±31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 26 Driver Deployment Loop Open 9J1±33. . . . DTC 51 Air Bag Deployment Event

Commanded 9J1±35. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 53 Deployment Commanded With

Deployment Loop Fault Or Energy

Reserves Out Of Range 9J1±37. . . . . . . . . . . . . . . . .

DTC 61 Warning Lamp Circuit Failure 9J1±39. . . . .

DTC 71 Internal SDM Fault 9J1±41. . . . . . . . . . . . . .

DTC 29 Passenger Pretensioner Loop

Short To Ground 9J1±43. . . . . . . . . . . . . . . . . . . . . . . .

DTC 31 Passenger Pretensioner Loop

Resistance High 9J1±45. . . . . . . . . . . . . . . . . . . . . . . .

DTC 32 Passenger Pretensioner loop

Resistance Low 9J1±47. . . . . . . . . . . . . . . . . . . . . . . .

DTC 33 Passenger Pretensioner Loop

Short To Voltage 9J1±49. . . . . . . . . . . . . . . . . . . . . . . .

DTC 34 Passenger Pretensioner Loop

Open 9J1±51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 41 Driver Pretensioner Loop

Resistance High 9J1±53. . . . . . . . . . . . . . . . . . . . . . . .

DTC 42 Driver Pretensioner Loop

Resistance Low 9J1±55. . . . . . . . . . . . . . . . . . . . . . . .

DTC 44 Driver Pretensioner Loop

Open 9J1±57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 45 Driver Pretensioner Loop

Short To Ground 9J1±59. . . . . . . . . . . . . . . . . . . . . . . .

DTC 46 Driver Pretensioner Loop

Short To Voltage 9J1±61. . . . . . . . . . . . . . . . . . . . . . . .

DTC 52 Pretensioner Deployment

Event Commanded 9J1±63. . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 3489 of 3573

RESTRAINT CONTROL SYSTEM 9J1±2

Diagnostic Information

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. if a fastener needs to be replaced, use

the correct part number fastener for that application.

if the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may

be used. fasteners that are not reused, and those

requiring thread locking compound will be called

out. the correct torque value must be used when

installing fasteners that require it. if the above

conditions are not followed, parts or system damage

could result.

Diagnostic Procedures

WARNING: T O AV O I D D E P L O Y M E N T W H E N

TROUBLESHOOTING THE SRS, DO NOT USE

ELECTRICAL TEST EQUIPMENT SUCH AS A

BATTERY±POWERED OR AC±POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN THAT

SPECIFIED IN THIS MANUAL. DO NOT USE A NON

POWERED, PROBE±TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

The diagnostic procedures used in this section are

designed to aid in finding and repairing SRS problems.

Outlined below are the steps to find and repair SRS

problems quickly and effectively. Failure to carefully

follow these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect parts

replacement.

1.Perform The ªSRS Diagnostic System Checkº.

The ªSRS Diagnostic System Checkº should always

be the starting point of any SRS diagnostics. The

ªSRS Diagnostic System Checkº checks for proper

ªAIR BAGº warning lamp operation and checks for

SRS trouble codes using both ªFlash Codeº and

ªScan Toolº Methods.

2.Refer To The Proper Diagnostic Chart As Directed

By The ªSRS Diagnostic System Checkº.

The ªSRS Diagnostic System Checkº will lead you to

the correct chart to diagnose any SRS problems.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect

parts replacement.

3.Repeat The ªSRS Diagnostic System Checkº

After Any Repair Or Diagnostic Procedures Have

Been Performed.

Preforming the ªSRS Diagnostic System Checkº after

all repair or diagnostic procedures will assure that the

repair has been made correctly and that no other

conditions exist.

Diagnostic Codes

The Sensing and Diagnostic Module (SDM) maintains a

history record of all diagnostic codes that have beendetected since the SRS codes were last cleared during

service.

1. Active Codes Ð Faults that are presently detected

this ignition cycle. Active codes are stored in RAM

(Random Access Memory).

2. History Codes Ð All faults detected since the last

time the history fault memory was cleared. History

codes are stored in EEPROM. (Electronically

Erasable Programmable Read only Memory)

How To Read Trouble Codes

All codes (Active and history) can be read (or cleared) by

using a scan tool or equivalent.

If a PDT is not available, have the vehicle serviced by

ISUZU dealer.

How To Clear Trouble Codes

Trouble codes can only be cleared by using a Scan Tool.

If a ªscan toolº is not available then inform the owner of the

stored codes and suggest that the codes are cleared

upon the next visit to an Isuzu dealership.

Scan Tool Diagnostics

A scan tool can be used to read current and history codes

and to clear all history codes after a repair is complete.

The scan tool must be updated to communicate with the

SRS through a memory card or a manufacturer's update

before it can be used for SRS diagnostics. To use the

scan tool, connect it to the DLC connector and turn the

ignition switch ªONº. Then follow the manufacturer's

directions for communication with the SRS. The scan tool

reads serial data from the SDM ªSerial Dataº output

(terminal 24) to the DLC connector (terminal 9).

Basic Knowledge Required

Before using this section of the Service Manual, there is

some basic knowledge which will be required. Without

this knowledge, you will have trouble using the diagnostic

procedures in this section. Use care to prevent harm or

unwanted deployment. Read all cautions in the service

manual and on warning labels attached to SRS

components.

Basic Electrical Circuits

You should understand the basic theory of electricity

including series and parallel circuits, and understand the

voltage drops across series resistors. You should know

the meaning of voltage (volts), current (amps), and

resistance (ohms). You should understand what happens

in a circuit with an open or a shorted wire. You should be

able to read and understand a wiring diagram.

ªFlash Codeº Diagnostics

Flash code diagnostics can be used to read active codes

and to determine if history codes are present but cannot

be used to clear codes or read history codes. Flash code

diagnostics is enabled by grounding by terminal 4

shorting to terminal 13 of the DLC connector with the

ignition switch ªONº. Grounding terminal 4 of the DLC

connector pulls the ªDiagnostics Requestº input (Terminal

1) of the SDM low and signals the SDM to enter the flash

code diagnostic display mode.

Page 3494 of 3573

9J1±7

RESTRAINT CONTROL SYSTEM

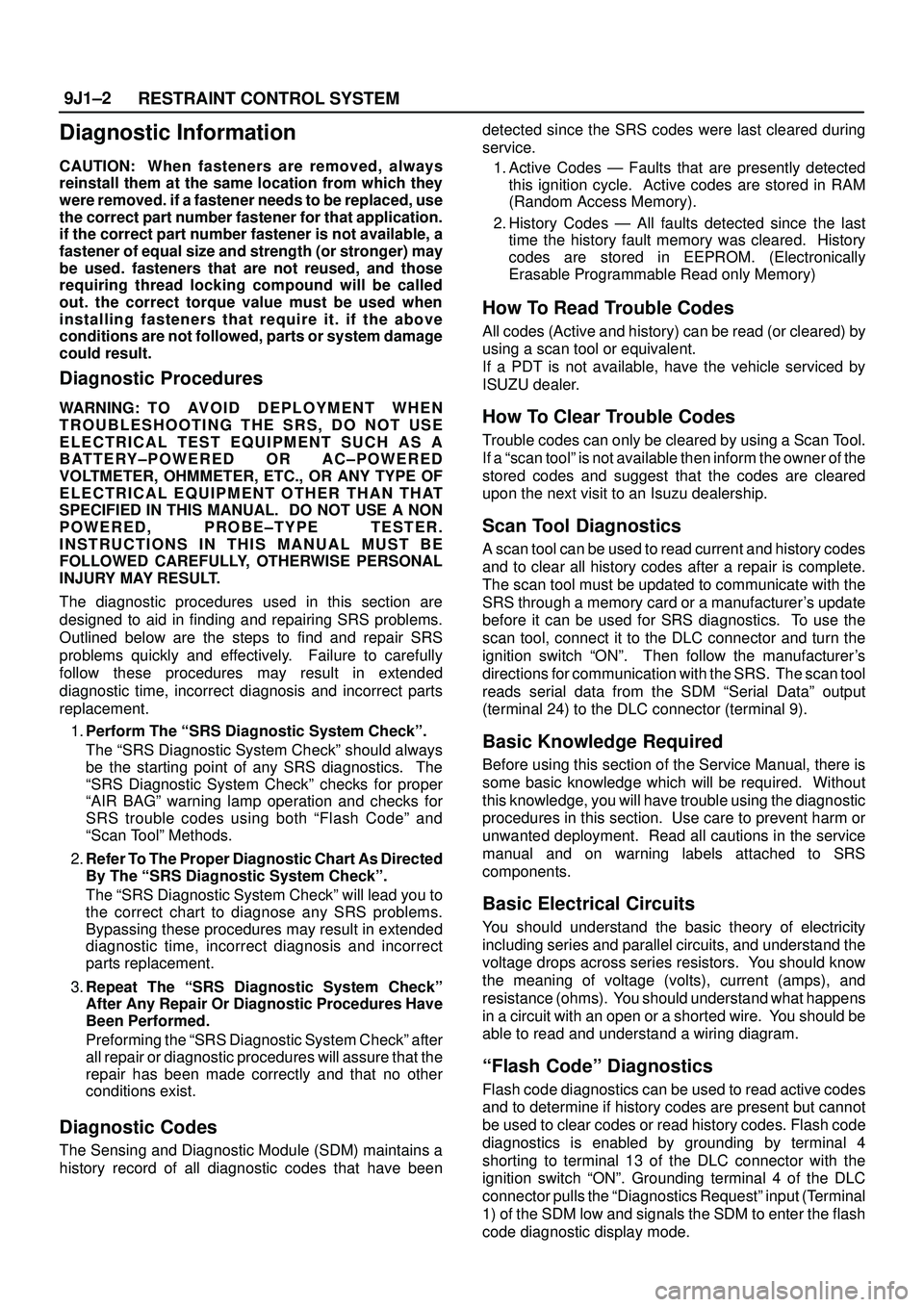

Chart A SDM Integrity Check

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SENSING AND

DIAGNOSTIC MODULE (SDM). NEVER STRIKE OR JAR THE SDM. NEVER POWER UP THE SRS WHEN THE

SDM IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SDM AND MOUNTING BRACKET FASTENERS MUST

BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE FRONT OF THE VEHICLE

TO ENSURE PROPER OPERATION OF THE SRS. THE SDM COULD BE ACTIVATED WHEN POWERED WHILE

NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD CAUSE DEPLOYMENT AND RESULT IN

PERSONAL INJURY.

Step

ActionYe sNo

11. This chart assumes that the ªSRS Diagnostic System Checkº

and either a symptom chart or a diagnostic trouble code chart

diagnosis have been performed. When all circuitry outside the

SDM has been found to operate properly, as indicated by the

appropriate diagnostic chart, and the symptom or DTC

remains current, the following

2. Diagnostic procedures must be performed to verify the need

for SDM replacement.

3. Ignition switch ªOFFº.

4. Reconnect all SRS components, ensure all components are

properly mounted.

5. Ensure the ignition switch has been ªOFFº for at least 15

seconds.

6. Note ªAIR BAGº warning lamp as ignition switch is turned

ªON.º

Does warning lamp turn on 3.5 seconds then go ªOFFº?

The symptom or

DTC is no longer

occurring

Clear SRS

diagnostic trouble

codes

Repeat ªSRS

Diagnostic

System Checkº

Go to Step 2

2Using a scan tool request diagnostic trouble code display

Is the same symptom or DTC occurring as was when the ªSRS

Diagnostic System Check º was first performed?

Go to Step 3

Ignition switch

ªOFFº

Go to the

appropriate chart

for the indicated

malfunction

31. Clear ªSRS Diagnostic Trouble Codesº.

2. Ignition switch ªOFFº for at least two minutes.

3. Note ªAIR BAGº warning lamp as ignition switch is turned

ªON.º

Does warning lamp turn on 3.5 seconds then go ªOFFº?SRS is functional

and free of

malfunctions

No further

diagnosis is

required

Go to Step 4

Ignition switch

ªOFFº

Replace SDM

Go to Step 4

4Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?Repeat the ªSRS

Diagnostic

System Checkº

Go to Step 4

Page 3498 of 3573

9J1±11

RESTRAINT CONTROL SYSTEM

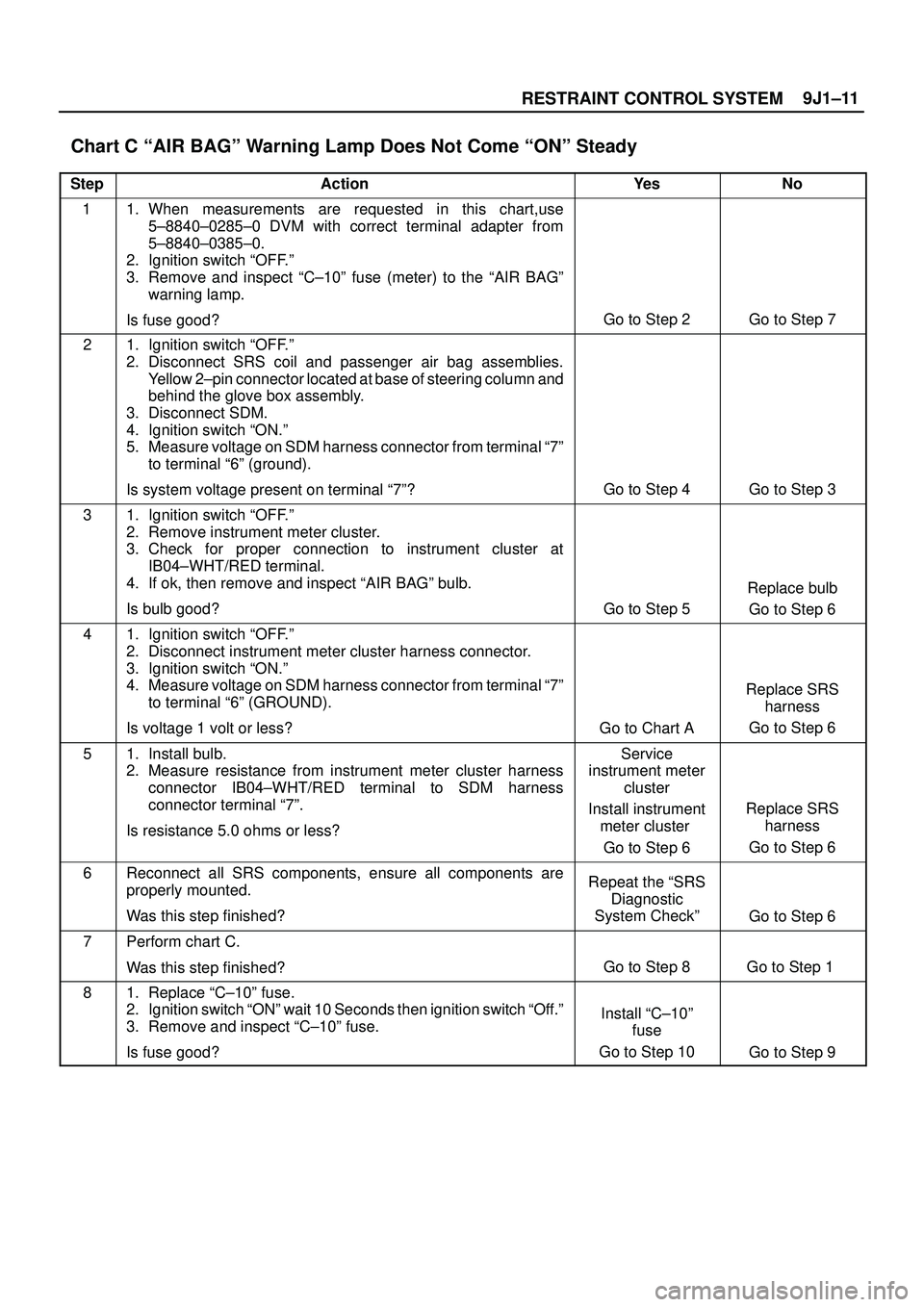

Chart C ªAIR BAGº Warning Lamp Does Not Come ªONº Steady

StepActionYe sNo

11. When measurements are requested in this chart,use

5±8840±0285±0 DVM with correct terminal adapter from

5±8840±0385±0.

2. Ignition switch ªOFF.º

3. Remove and inspect ªC±10º fuse (meter) to the ªAIR BAGº

warning lamp.

Is fuse good?

Go to Step 2Go to Step 7

21. Ignition switch ªOFF.º

2. Disconnect SRS coil and passenger air bag assemblies.

Yellow 2±pin connector located at base of steering column and

behind the glove box assembly.

3. Disconnect SDM.

4. Ignition switch ªON.º

5. Measure voltage on SDM harness connector from terminal ª7º

to terminal ª6º (ground).

Is system voltage present on terminal ª7º?

Go to Step 4Go to Step 3

31. Ignition switch ªOFF.º

2. Remove instrument meter cluster.

3. Check for proper connection to instrument cluster at

IB04±WHT/RED terminal.

4. If ok, then remove and inspect ªAIR BAGº bulb.

Is bulb good?

Go to Step 5

Replace bulb

Go to Step 6

41. Ignition switch ªOFF.º

2. Disconnect instrument meter cluster harness connector.

3. Ignition switch ªON.º

4. Measure voltage on SDM harness connector from terminal ª7º

to terminal ª6º (GROUND).

Is voltage 1 volt or less?

Go to Chart A

Replace SRS

harness

Go to Step 6

51. Install bulb.

2. Measure resistance from instrument meter cluster harness

connector IB04±WHT/RED terminal to SDM harness

connector terminal ª7º.

Is resistance 5.0 ohms or less?Service

instrument meter

cluster

Install instrument

meter cluster

Go to Step 6

Replace SRS

harness

Go to Step 6

6Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished?Repeat the ªSRS

Diagnostic

System Checkº

Go to Step 6

7Perform chart C.

Was this step finished?

Go to Step 8Go to Step 1

81. Replace ªC±10º fuse.

2. Ignition switch ªONº wait 10 Seconds then ignition switch ªOff.º

3. Remove and inspect ªC±10º fuse.

Is fuse good?

Install ªC±10º

fuse

Go to Step 10

Go to Step 9