engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1504 of 3573

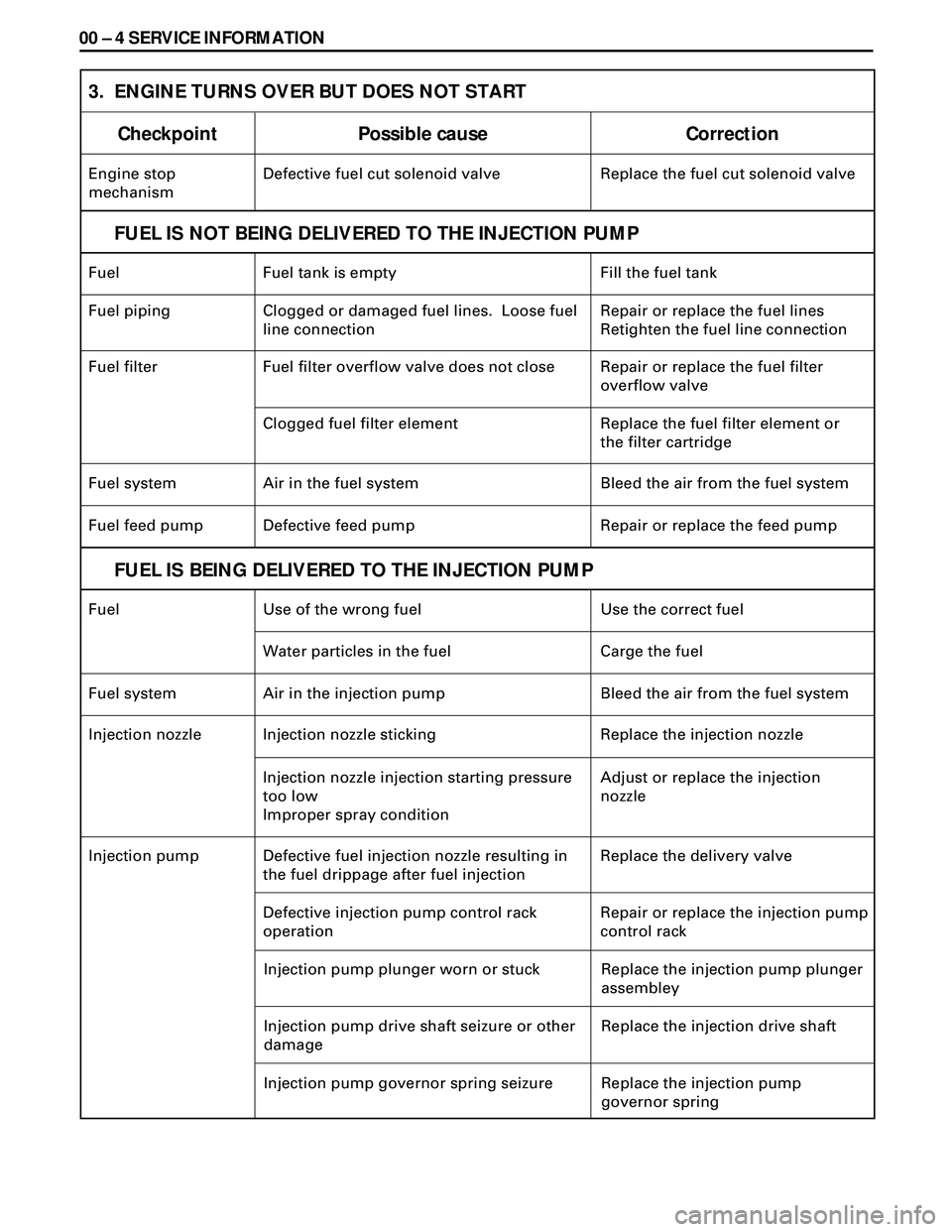

00 Ð 4 SERVICE INFORMATION

Checkpoint Possible cause Correction

Engine stop

mechanismDefective fuel cut solenoid valve Replace the fuel cut solenoid valve

3. ENGINE TURNS OVER BUT DOES NOT START

FUEL IS NOT BEING DELIVERED TO THE INJECTION PUMP

Fuel Fuel tank is empty Fill the fuel tank

Fuel piping Clogged or damaged fuel lines. Loose fuel

line connectionRepair or replace the fuel lines

Retighten the fuel line connection

Fuel filter Fuel filter overflow valve does not close Repair or replace the fuel filter

overflow valve

Clogged fuel filter element Replace the fuel filter element or

the filter cartridge

Fuel system Air in the fuel system Bleed the air from the fuel system

Fuel feed pump Defective feed pump Repair or replace the feed pump

FUEL IS BEING DELIVERED TO THE INJECTION PUMP

Fuel Use of the wrong fuel Use the correct fuel

Water particles in the fuel Carge the fuel

Fuel system Air in the injection pump Bleed the air from the fuel system

Injection nozzle Injection nozzle sticking Replace the injection nozzle

Injection nozzle injection starting pressure

too low

Improper spray conditionAdjust or replace the injection

nozzle

Injection pump Defective fuel injection nozzle resulting in

the fuel drippage after fuel injectionReplace the delivery valve

Defective injection pump control rack

operationRepair or replace the injection pump

control rack

Injection pump plunger worn or stuck Replace the injection pump plunger

assembley

Injection pump drive shaft seizure or other

damageReplace the injection drive shaft

Injection pump governor spring seizure Replace the injection pump

governor spring

Page 1509 of 3573

SERVICE INFORMATION 00 Ð 9

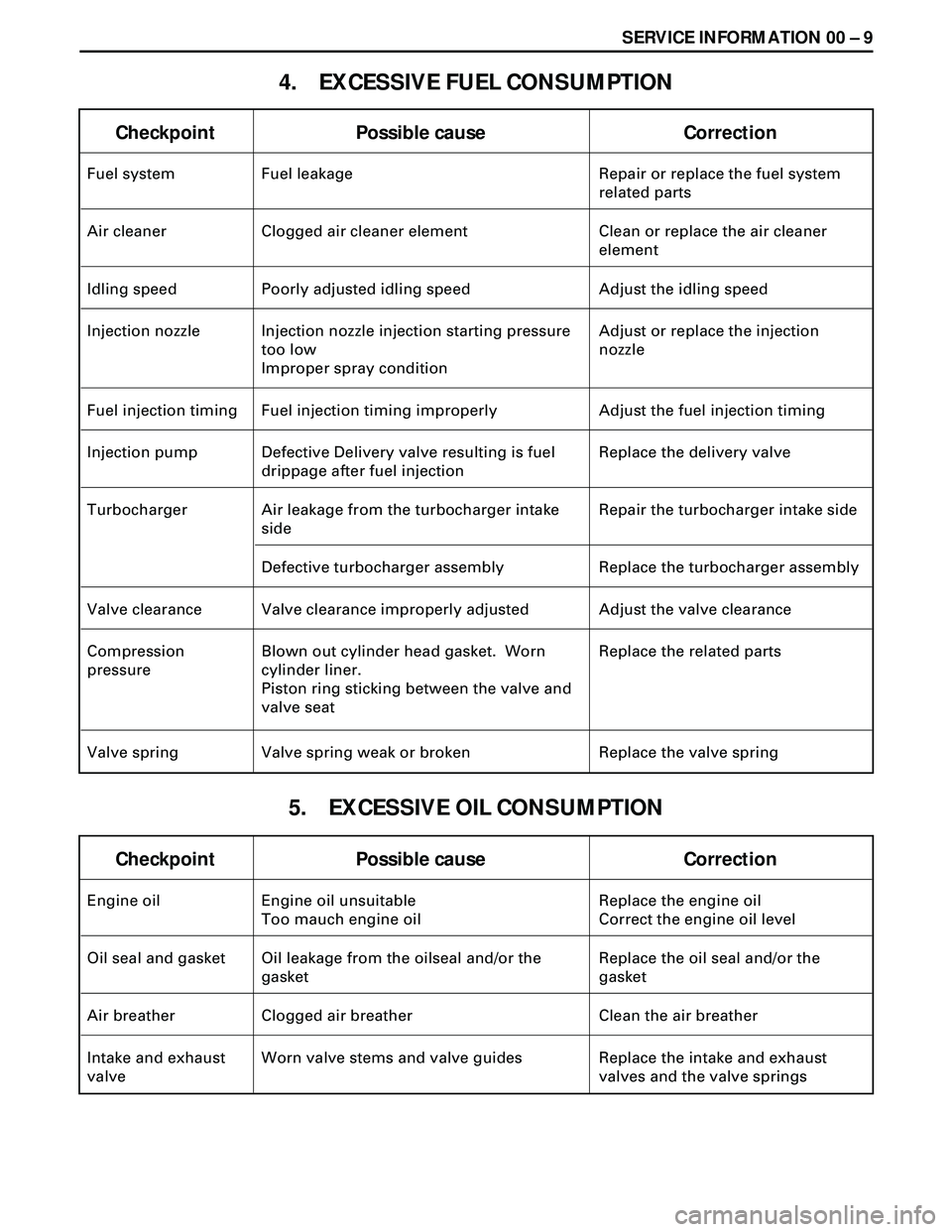

4. EXCESSIVE FUEL CONSUMPTION

5. EXCESSIVE OIL CONSUMPTION

Checkpoint Possible cause Correction

Engine oil Engine oil unsuitable

Too mauch engine oilReplace the engine oil

Correct the engine oil level

Oil seal and gasket Oil leakage from the oilseal and/or the

gasketReplace the oil seal and/or the

gasket

Air breather Clogged air breather Clean the air breather

Intake and exhaust

valveWorn valve stems and valve guides Replace the intake and exhaust

valves and the valve springs

Checkpoint Possible cause Correction

Fuel system Fuel leakage Repair or replace the fuel system

related parts

Air cleaner Clogged air cleaner element Clean or replace the air cleaner

element

Idling speed Poorly adjusted idling speed Adjust the idling speed

Injection nozzle Injection nozzle injection starting pressure

too low

Improper spray condition Adjust or replace the injection

nozzle

Fuel injection timing Fuel injection timing improperly Adjust the fuel injection timing

Injection pump Defective Delivery valve resulting is fuel

drippage after fuel injectionReplace the delivery valve

Turbocharger Air leakage from the turbocharger intake

sideRepair the turbocharger intake side

Defective turbocharger assembly Replace the turbocharger assembly

Valve clearance Valve clearance improperly adjusted Adjust the valve clearance

Compression

pressureBlown out cylinder head gasket. Worn

cylinder liner.

Piston ring sticking between the valve and

valve seatReplace the related parts

Valve spring Valve spring weak or broken Replace the valve spring

Page 1511 of 3573

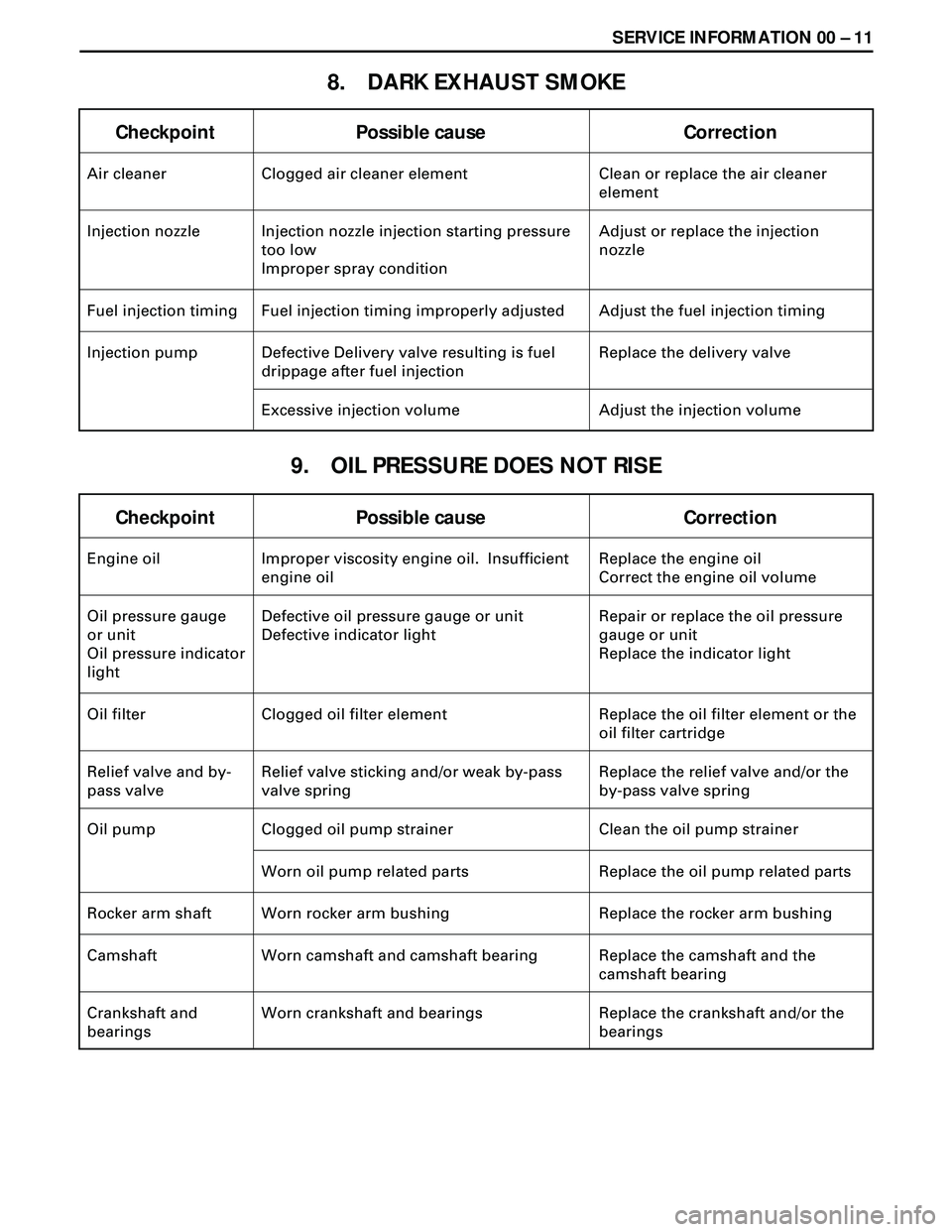

SERVICE INFORMATION 00 Ð 11

8. DARK EXHAUST SMOKE

Checkpoint Possible cause Correction

Air cleaner Clogged air cleaner element Clean or replace the air cleaner

element

Injection nozzle Injection nozzle injection starting pressure

too low

Improper spray conditionAdjust or replace the injection

nozzle

Fuel injection timing Fuel injection timing improperly adjusted Adjust the fuel injection timing

Injection pump Defective Delivery valve resulting is fuel

drippage after fuel injectionReplace the delivery valve

Excessive injection volume Adjust the injection volume

9. OIL PRESSURE DOES NOT RISE

Checkpoint Possible cause Correction

Engine oil Improper viscosity engine oil. Insufficient

engine oilReplace the engine oil

Correct the engine oil volume

Oil pressure gauge

or unit

Oil pressure indicator

lightDefective oil pressure gauge or unit

Defective indicator lightRepair or replace the oil pressure

gauge or unit

Replace the indicator light

Oil filter Clogged oil filter element Replace the oil filter element or the

oil filter cartridge

Relief valve and by-

pass valveRelief valve sticking and/or weak by-pass

valve springReplace the relief valve and/or the

by-pass valve spring

Oil pump Clogged oil pump strainer Clean the oil pump strainer

Worn oil pump related parts Replace the oil pump related parts

Rocker arm shaft Worn rocker arm bushing Replace the rocker arm bushing

Camshaft Worn camshaft and camshaft bearing Replace the camshaft and the

camshaft bearing

Crankshaft and

bearingsWorn crankshaft and bearings Replace the crankshaft and/or the

bearings

Page 1512 of 3573

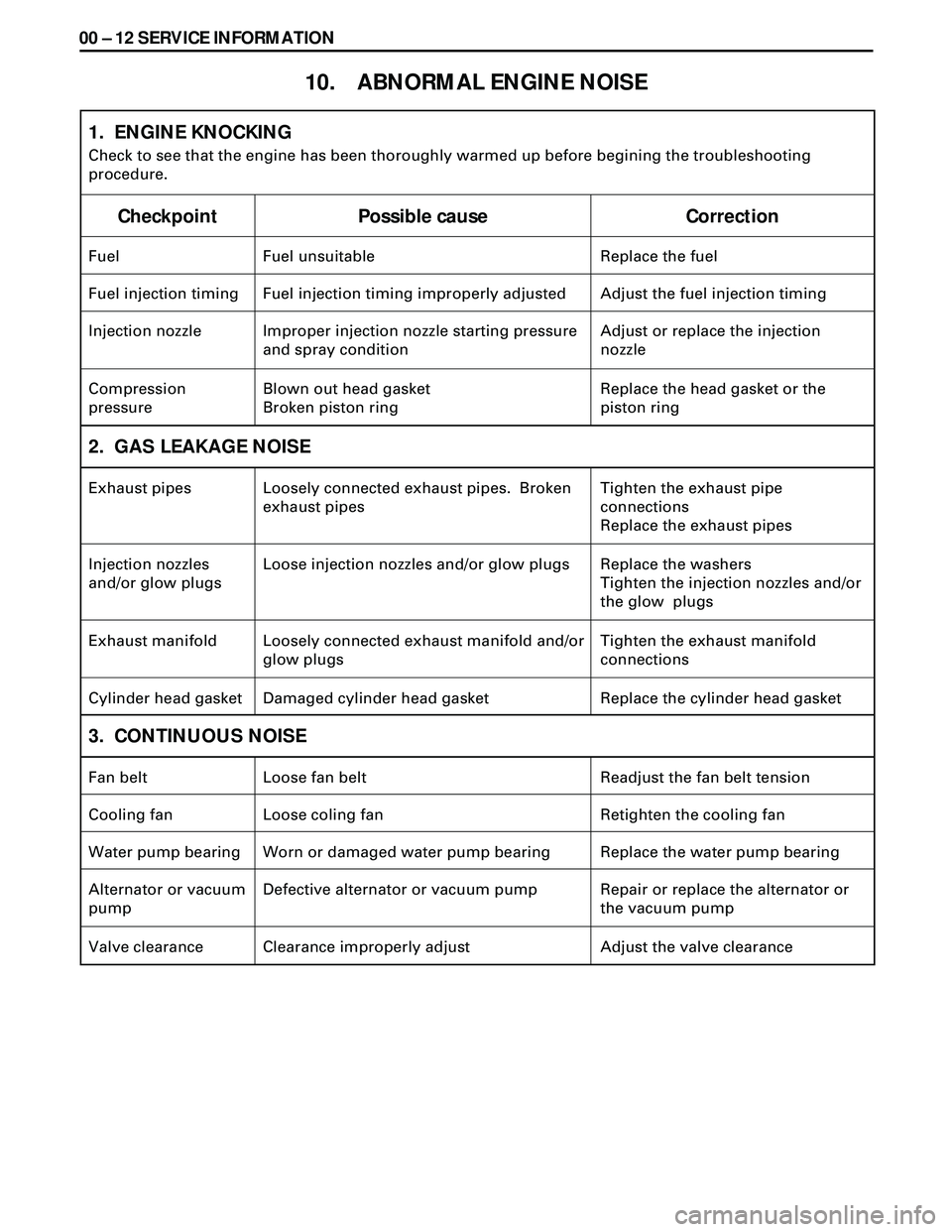

00 Ð 12 SERVICE INFORMATION

10. ABNORMAL ENGINE NOISE

Checkpoint Possible cause Correction

Fuel Fuel unsuitable Replace the fuel

1. ENGINE KNOCKING

2. GAS LEAKAGE NOISE

Exhaust pipes Loosely connected exhaust pipes. Broken

exhaust pipesTighten the exhaust pipe

connections

Replace the exhaust pipes Check to see that the engine has been thoroughly warmed up before begining the troubleshooting

procedure.

Fuel injection timing Fuel injection timing improperly adjusted Adjust the fuel injection timing

Injection nozzle Improper injection nozzle starting pressure

and spray conditionAdjust or replace the injection

nozzle

Compression

pressureBlown out head gasket

Broken piston ringReplace the head gasket or the

piston ring

Injection nozzles

and/or glow plugsLoose injection nozzles and/or glow plugs Replace the washers

Tighten the injection nozzles and/or

the glow plugs

Exhaust manifold Loosely connected exhaust manifold and/or

glow plugsTighten the exhaust manifold

connections

Cylinder head gasket Damaged cylinder head gasket Replace the cylinder head gasket

3. CONTINUOUS NOISE

Fan belt Loose fan belt Readjust the fan belt tension

Cooling fan Loose coling fan Retighten the cooling fan

Water pump bearing Worn or damaged water pump bearing Replace the water pump bearing

Alternator or vacuum

pumpDefective alternator or vacuum pump Repair or replace the alternator or

the vacuum pump

Valve clearance Clearance improperly adjust Adjust the valve clearance

Page 1514 of 3573

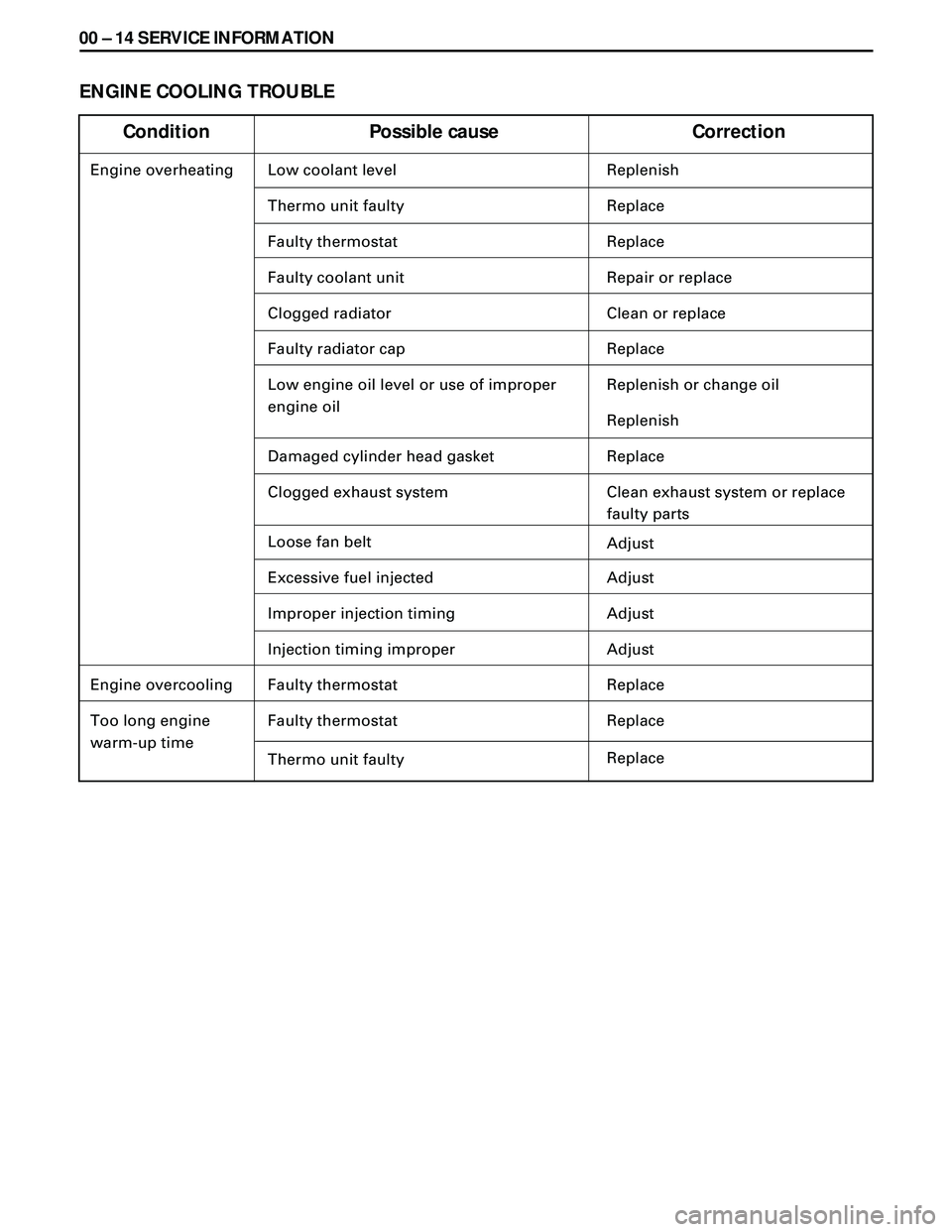

00 Ð 14 SERVICE INFORMATION

Condition Possible cause Correction

Engine overheating Low coolant level Replenish

Thermo unit faulty

Faulty thermostat

Faulty coolant unit

Clogged radiator

Faulty radiator cap

Low engine oil level or use of improper

engine oil

Damaged cylinder head gasket

Clogged exhaust system

Loose fan belt

Excessive fuel injected

Improper injection timing

Injection timing improper

Faulty thermostat

Faulty thermostatReplace

Replace

Repair or replace

Clean or replace

Replace

Replenish or change oil

Replenish

Replace

Clean exhaust system or replace

faulty parts

Adjust

Adjust

Adjust

Replace

Replace

Thermo unit faultyReplace Engine overcooling

Too long engine

warm-up time

Adjust

ENGINE COOLING TROUBLE

Page 1515 of 3573

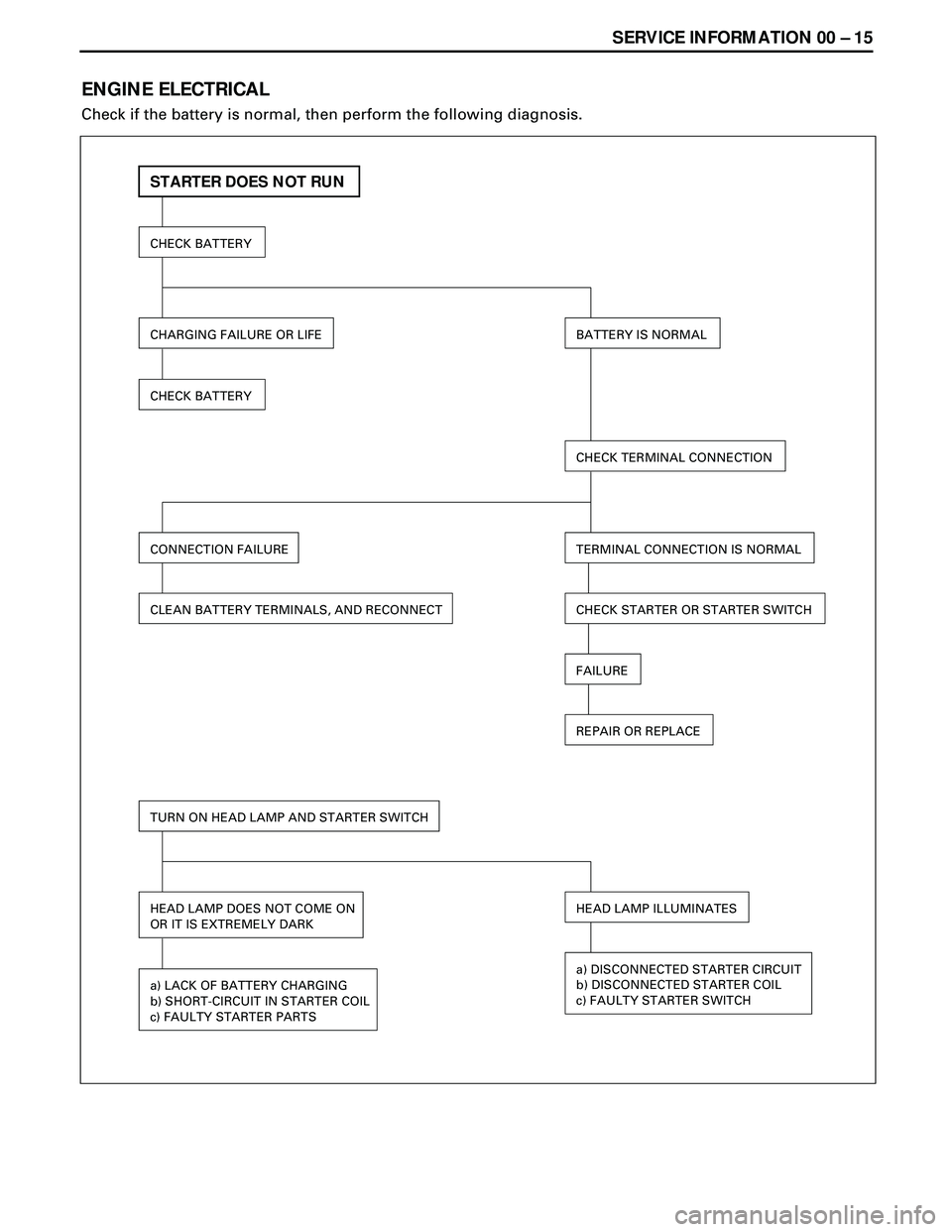

SERVICE INFORMATION 00 Ð 15

ENGINE ELECTRICAL

Check if the battery is normal, then perform the following diagnosis.

STARTER DOES NOT RUN

CHECK BATTERY

CHARGING FAILURE OR LIFE

CHECK BATTERY

BATTERY IS NORMAL

CHECK TERMINAL CONNECTION

CONNECTION FAILURE

CLEAN BATTERY TERMINALS, AND RECONNECT

TERMINAL CONNECTION IS NORMAL

CHECK STARTER OR STARTER SWITCH

FAILURE

REPAIR OR REPLACE

TURN ON HEAD LAMP AND STARTER SWITCH

HEAD LAMP DOES NOT COME ON

OR IT IS EXTREMELY DARK

a) LACK OF BATTERY CHARGING

b) SHORT-CIRCUIT IN STARTER COIL

c) FAULTY STARTER PARTS

HEAD LAMP ILLUMINATES

a) DISCONNECTED STARTER CIRCUIT

b) DISCONNECTED STARTER COIL

c) FAULTY STARTER SWITCH

Page 1518 of 3573

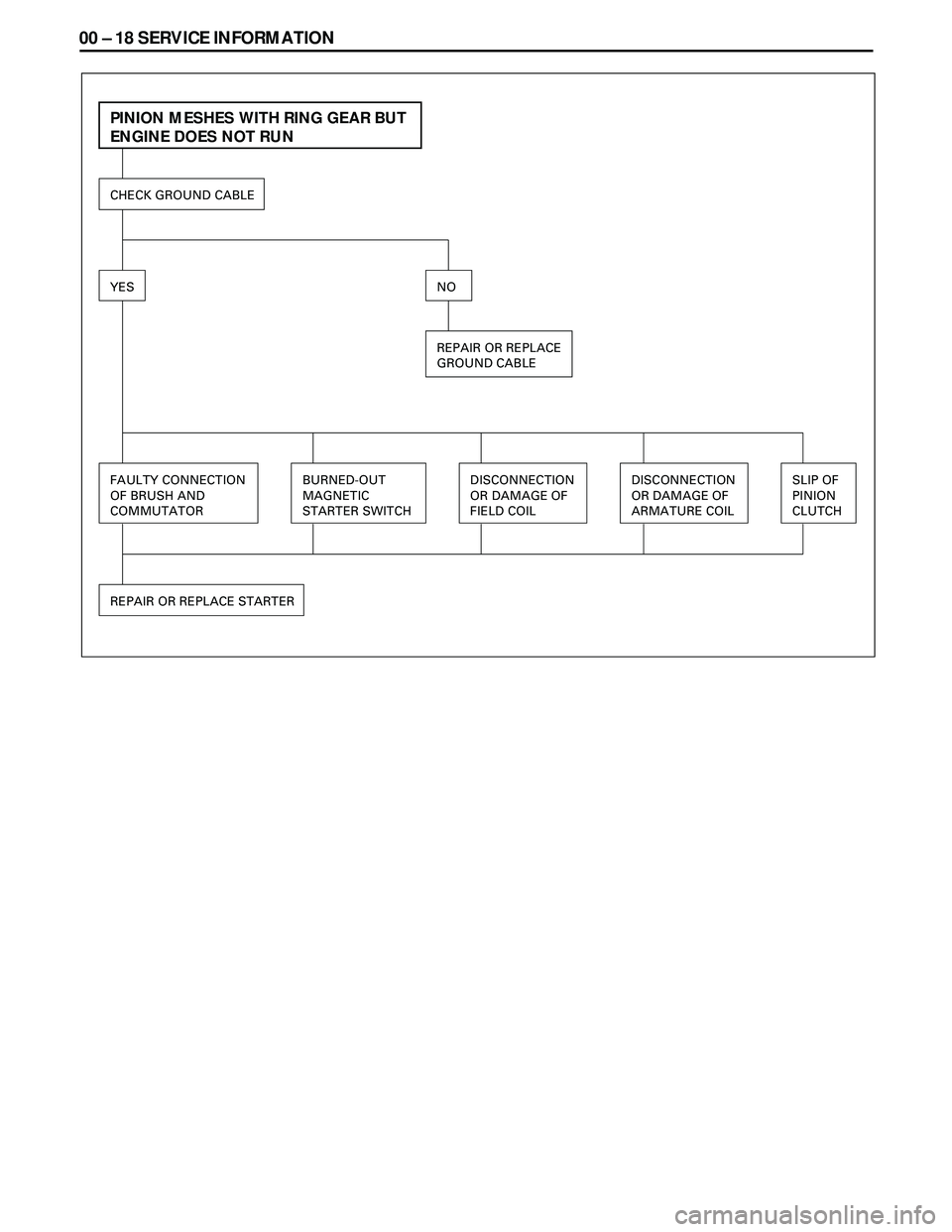

00 Ð 18 SERVICE INFORMATION

PINION MESHES WITH RING GEAR BUT

ENGINE DOES NOT RUN

CHECK GROUND CABLE

YESNO

REPAIR OR REPLACE

GROUND CABLE

FAULTY CONNECTION

OF BRUSH AND

COMMUTATORBURNED-OUT

MAGNETIC

STARTER SWITCHDISCONNECTION

OR DAMAGE OF

FIELD COILDISCONNECTION

OR DAMAGE OF

ARMATURE COILSLIP OF

PINION

CLUTCH

REPAIR OR REPLACE STARTER

Page 1520 of 3573

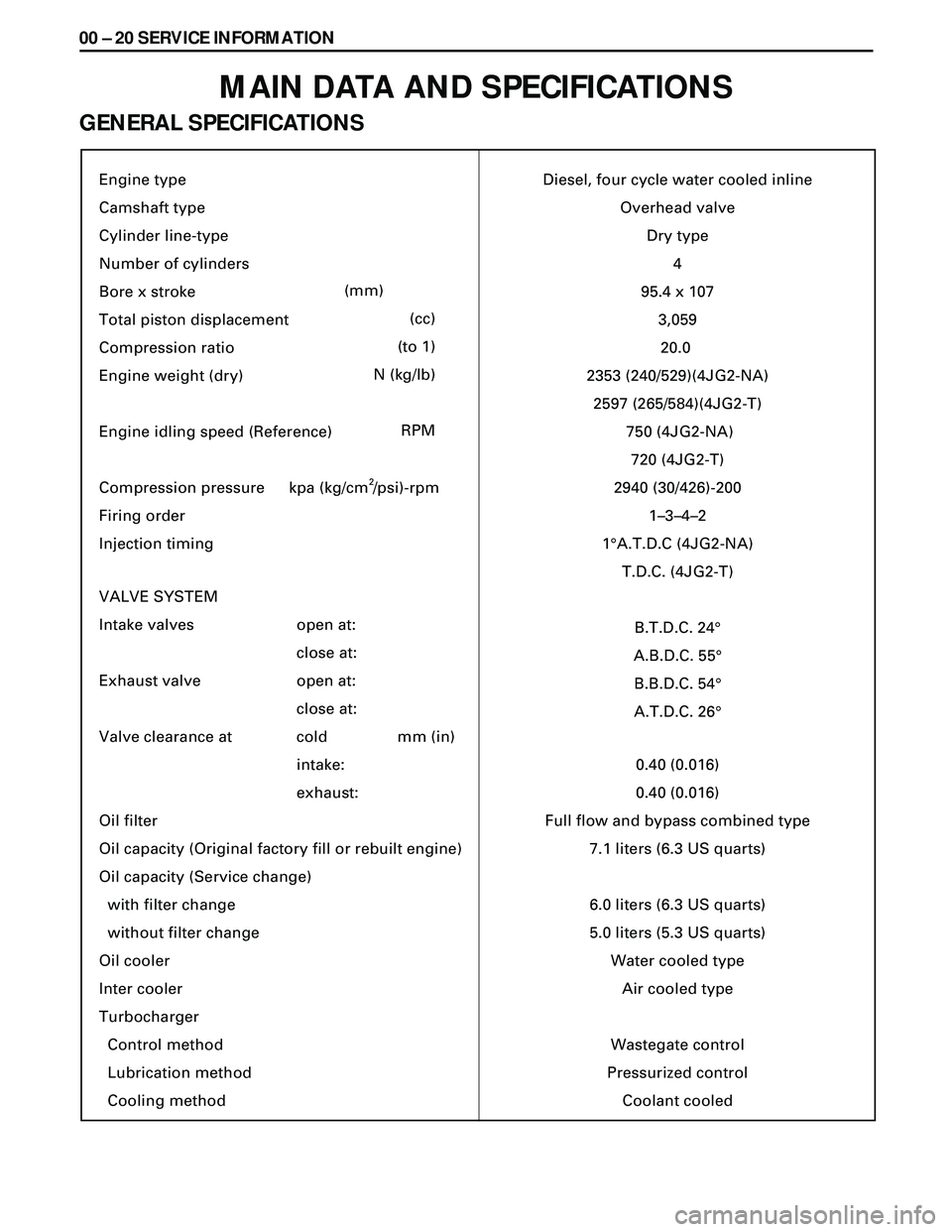

00 Ð 20 SERVICE INFORMATION

MAIN DATA AND SPECIFICATIONS

GENERAL SPECIFICATIONS

Engine type

Camshaft type

Cylinder line-type

Number of cylinders

Bore x stroke

Total piston displacement

Compression ratio

Engine weight (dry)

Engine idling speed (Reference)

Compression pressure

Firing order

Injection timing

VALVE SYSTEM

Intake valves

Exhaust valve

Valve clearance at

Oil filter

Oil capacity (Original factory fill or rebuilt engine)

Oil capacity (Service change)

with filter change

without filter change

Oil cooler

Inter cooler

Turbocharger

Control method

Lubrication method

Cooling method

(mm)

(cc)

(to 1)

N (kg/lb)

RPM

open at:

close at:

open at:

close at:

cold

intake:

exhaust:mm (in)Diesel, four cycle water cooled inline

Overhead valve

Dry type

4

95.4 x 107

3,059

20.0

2353 (240/529)(4JG2-NA)

2597 (265/584)(4JG2-T)

750 (4JG2-NA)

720 (4JG2-T)

2940 (30/426)-200

1–3–4–2

1¡A.T.D.C (4JG2-NA)

T.D.C. (4JG2-T)

B.T.D.C. 24¡

A.B.D.C. 55¡

B.B.D.C. 54¡

A.T.D.C. 26¡

0.40 (0.016)

0.40 (0.016)

Full flow and bypass combined type

7.1 liters (6.3 US quarts)

6.0 liters (6.3 US quarts)

5.0 liters (5.3 US quarts)

Water cooled type

Air cooled type

Wastegate control

Pressurized control

Coolant cooled kpa (kg/cm /psi)-rpm

2

Page 1521 of 3573

SERVICE INFORMATION 00 Ð 21

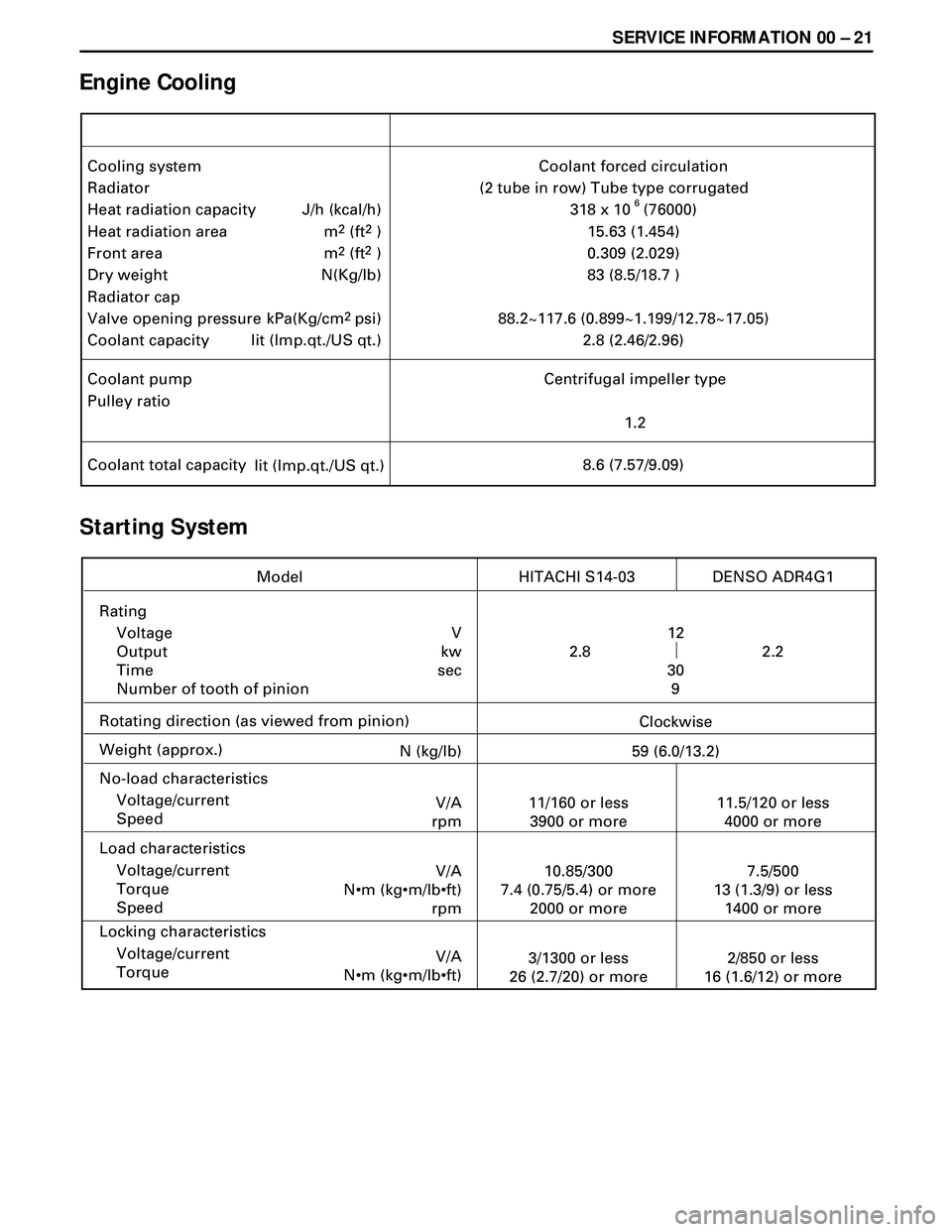

Engine Cooling

Starting System

Cooling system

Radiator

Heat radiation capacity

Heat radiation area

Front area

Dry weight

Radiator cap

Valve opening pressure

Coolant capacityCoolant forced circulation

(2 tube in row) Tube type corrugated

318 x 10 (76000)

15.63 (1.454)

0.309 (2.029)

83 (8.5/18.7 )

88.2~117.6 (0.899~1.199/12.78~17.05)

2.8 (2.46/2.96) J/h (kcal/h)

m

2 (ft2 )

m

2 (ft2 )

N(Kg/lb)

kPa(Kg/cm

2psi)

lit (Imp.qt./US qt.)

Coolant pump

Pulley ratioCentrifugal impeller type

1.2

Coolant total capacity

lit (Imp.qt./US qt.)8.6 (7.57/9.09)

6

Rating

Voltage

Output

Time

Number of tooth of pinion

Rotating direction (as viewed from pinion)

Weight (approx.)

No-load characteristics

Voltage/current

Speed

Load characteristics

Voltage/current

Torque

Speed

Locking characteristics

Voltage/current

Torque

Model HITACHI S14-03

V

kw

sec12

30

9

Clockwise

N (kg/lb)

59 (6.0/13.2)

V/A

rpm11/160 or less

3900 or more

V/A

N•m (kg•m/lb•ft)

rpm10.85/300

7.4 (0.75/5.4) or more

2000 or more

V/A

N•m (kg•m/lb•ft)3/1300 or less

26 (2.7/20) or more

11.5/120 or less

4000 or more

7.5/500

13 (1.3/9) or less

1400 or more

2/850 or less

16 (1.6/12) or more2.2 2.8DENSO ADR4G1

Page 1523 of 3573

SERVICE INFORMATION 00 Ð 23

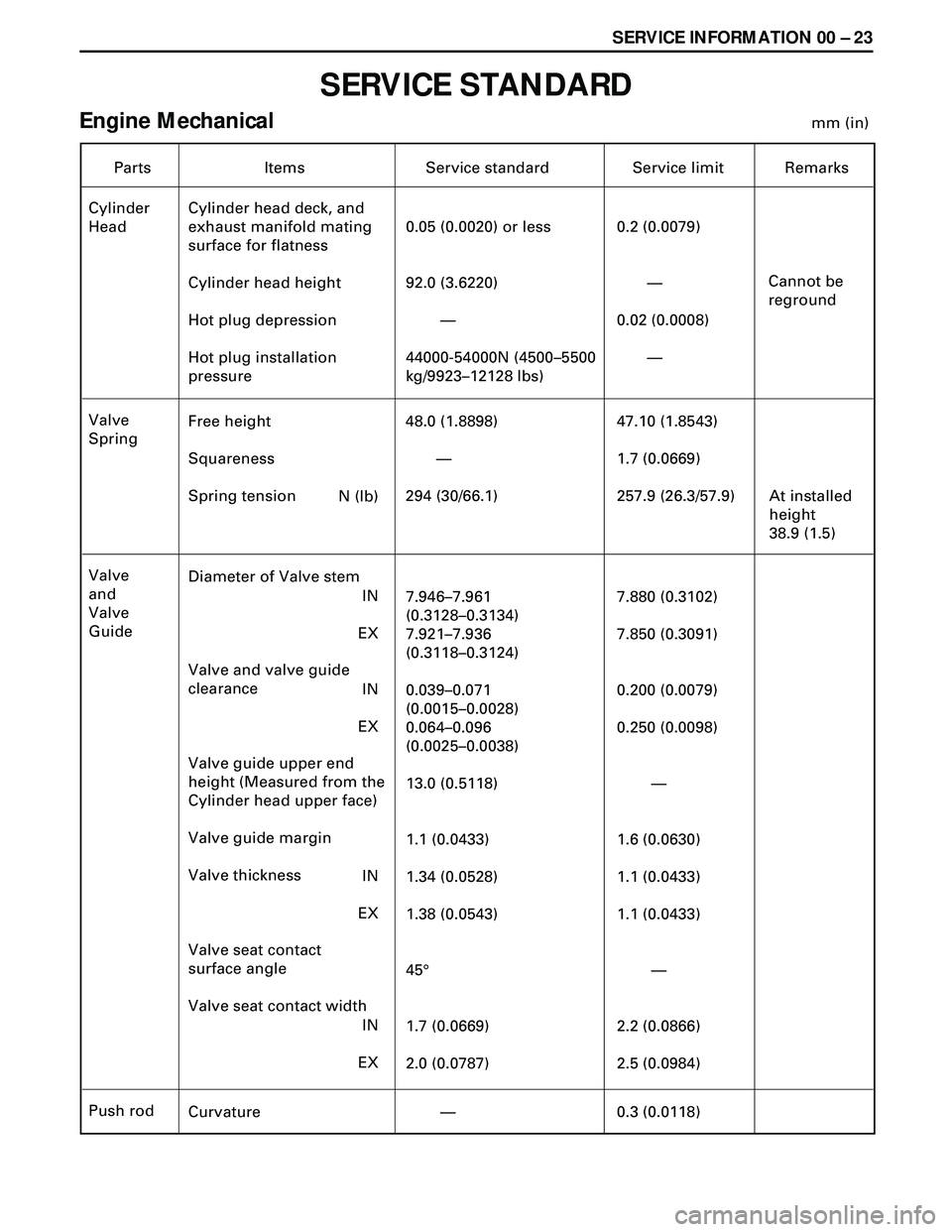

SERVICE STANDARD

Engine Mechanicalmm (in)

Parts Items Service standard

Cylinder

HeadCylinder head deck, and

exhaust manifold mating

surface for flatness

Cylinder head height

Hot plug depression

Hot plug installation

pressure0.05 (0.0020) or less

92.0 (3.6220)

—

44000-54000N (4500–5500

kg/9923–12128 lbs)

0.2 (0.0079)

—

0.02 (0.0008)

—Service limit Remarks

Cannot be

reground

Free height

Squareness

Spring tension 48.0 (1.8898)

—

294 (30/66.1) Valve

Spring47.10 (1.8543)

1.7 (0.0669)

257.9 (26.3/57.9) At installed

height

38.9 (1.5) N (lb)

Diameter of Valve stem

Valve and valve guide

clearance

Valve guide upper end

height (Measured from the

Cylinder head upper face)

Valve guide margin

Valve thickness

Valve seat contact

surface angle

Valve seat contact width7.946–7.961

(0.3128–0.3134)

7.921–7.936

(0.3118–0.3124)

0.039–0.071

(0.0015–0.0028)

0.064–0.096

(0.0025–0.0038)

13.0 (0.5118)

1.1 (0.0433)

1.34 (0.0528)

1.38 (0.0543)

45¡

1.7 (0.0669)

2.0 (0.0787) Valve

and

Valve

Guide7.880 (0.3102)

7.850 (0.3091)

0.200 (0.0079)

0.250 (0.0098)

—

1.6 (0.0630)

1.1 (0.0433)

1.1 (0.0433)

—

2.2 (0.0866)

2.5 (0.0984) IN

EX

IN

EX

IN

EX

IN

EX

Curvature — Push rod

0.3 (0.0118)