engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1556 of 3573

6A Ð 6 ENGINE MECHANICAL

REASSEMBLY

6. Cylinder Head

¥ Refer to Section 6A2 ÒCylinder headÓ

5. Push Rod

4. Rocker Arm Shaft and Rocker Arm

·Tighten rocker arm shaft fixing bolts

3. Glow Plug and Glow Plug Connector

·Tighten glow plugs.

2. Injection Nozzle Holder

·Refer to Section 6C2 ÒInjection nozzleÓ.

1. Thermostat Housing Assembly

·Tighten thermostat housing assembly fixing bolt

N·m (Kg·m/lb·ft)

54 (5.5/40)

N·m (Kg·m/lb·ft)

23 (2.3/17)

N·m (Kg·m/lb·ft)

19 (1.9/14)

Page 1557 of 3573

ENGINE MECHANICAL 6A Ð 7

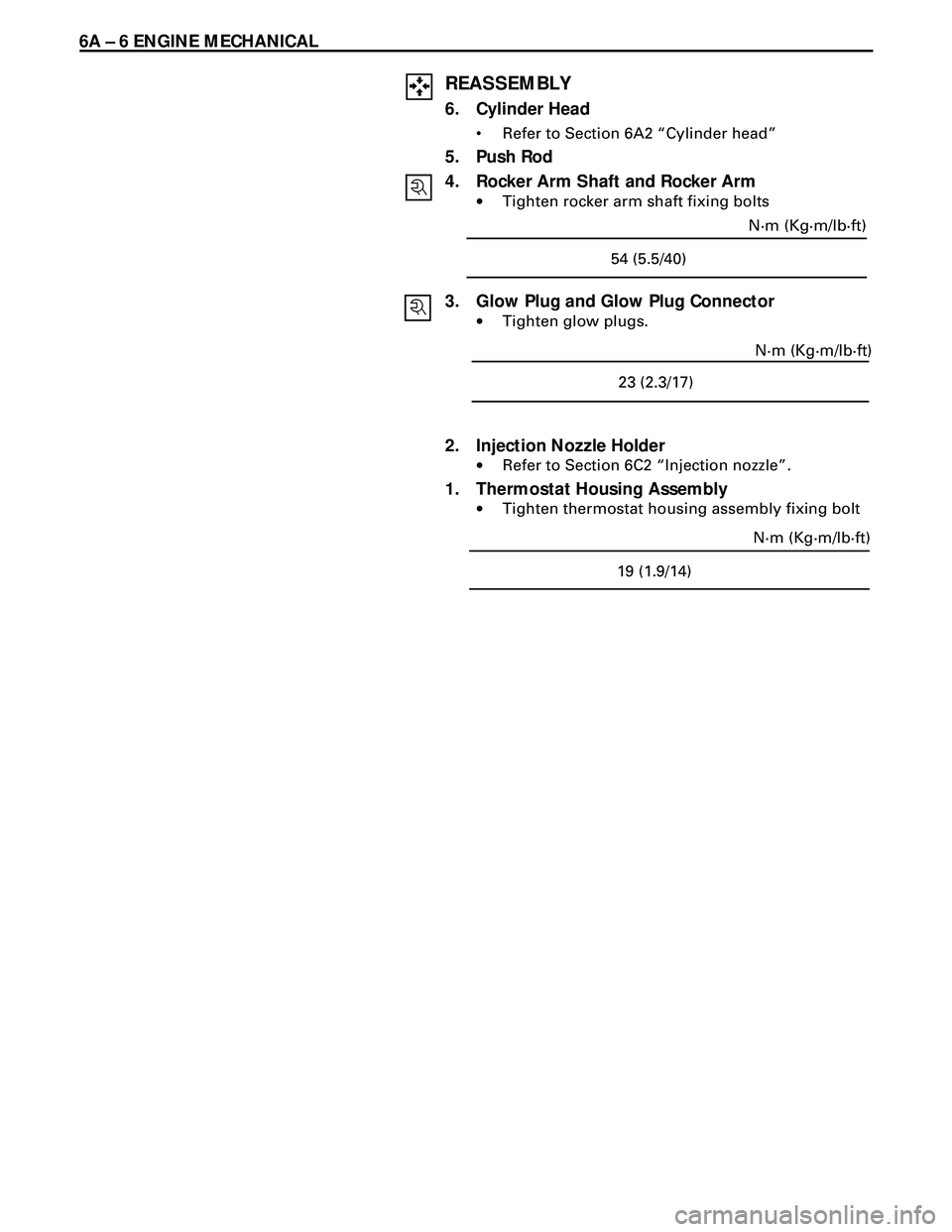

VALVE SPRING, VALVE STEM OIL SEAL, VALVE, VALVE GUIDE, PUSH ROD

DISASSEMBLY

1 Rocker Arm Asembly

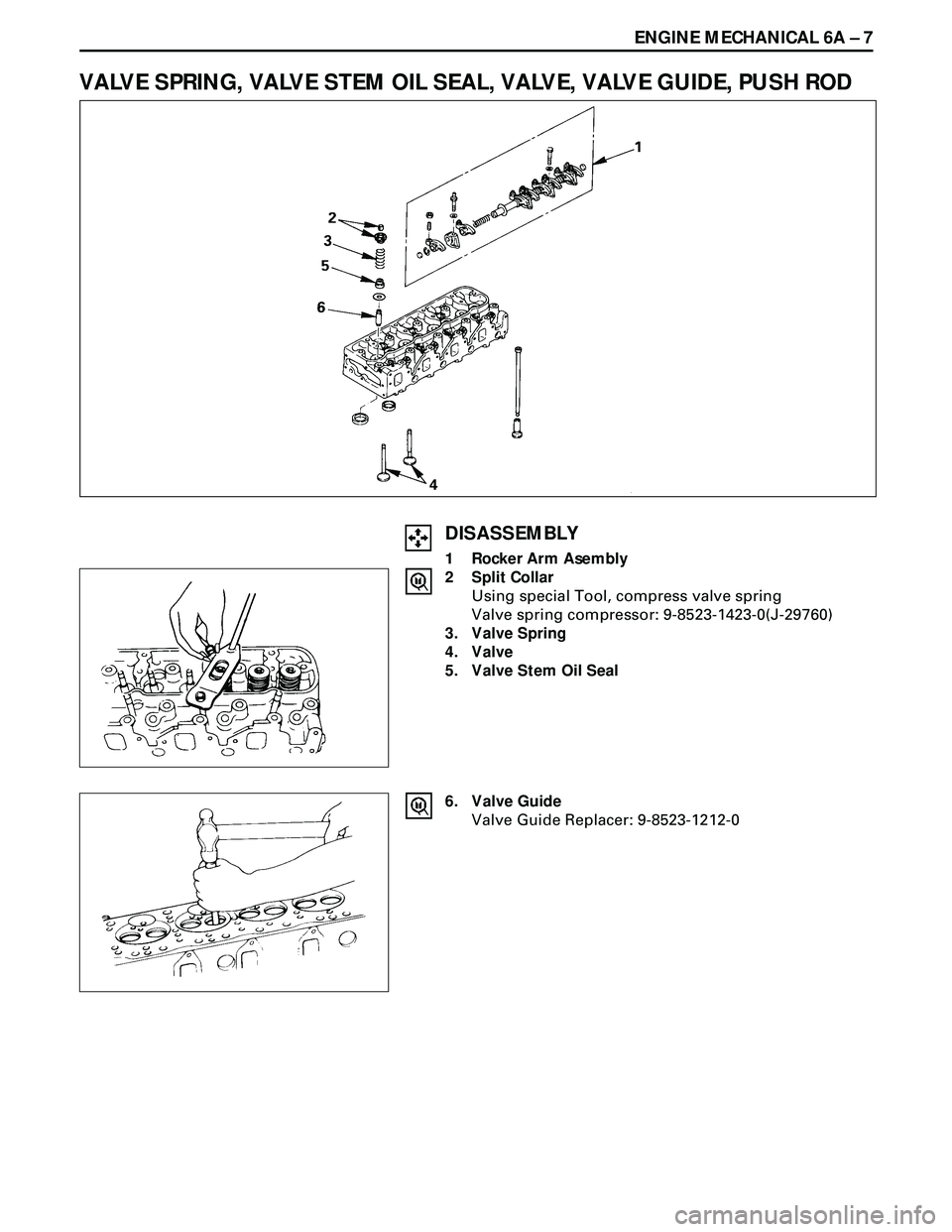

2 Split Collar

Using special Tool, compress valve spring

Valve spring compressor: 9-8523-1423-0(J-29760)

3. Valve Spring

4. Valve

5. Valve Stem Oil Seal

6. Valve Guide

Valve Guide Replacer: 9-8523-1212-0

Page 1558 of 3573

6A Ð 8 ENGINE MECHANICAL

At installed

height 38.9mm

(1.5in)StandardN(Kg/lb)

Limit

294.0 (30/66.1)257.9 (26.3/57.9)

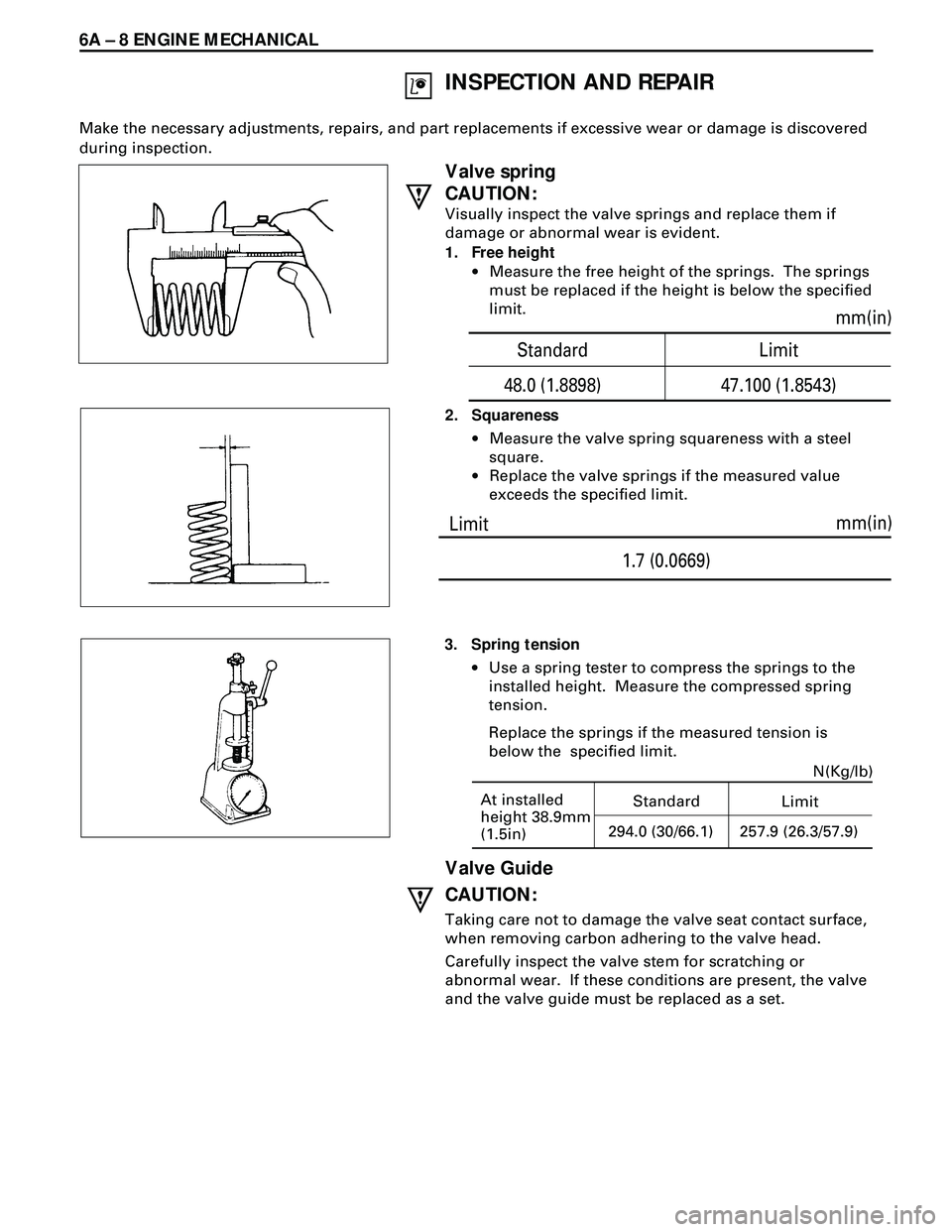

Valve spring

CAUTION:

Visually inspect the valve springs and replace them if

damage or abnormal wear is evident.

1. Free height

·Measure the free height of the springs. The springs

must be replaced if the height is below the specified

limit.

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered

during inspection.

2. Squareness

·Measure the valve spring squareness with a steel

square.

·Replace the valve springs if the measured value

exceeds the specified limit.

3. Spring tension

·Use a spring tester to compress the springs to the

installed height. Measure the compressed spring

tension.

Replace the springs if the measured tension is

below the specified limit.

Valve Guide

CAUTION:

Taking care not to damage the valve seat contact surface,

when removing carbon adhering to the valve head.

Carefully inspect the valve stem for scratching or

abnormal wear. If these conditions are present, the valve

and the valve guide must be replaced as a set.

Limitmm(in)

1.7 (0.0669)

Standard Limit

48.0 (1.8898) 47.100 (1.8543)mm(in)

Page 1559 of 3573

ENGINE MECHANICAL 6A Ð 9

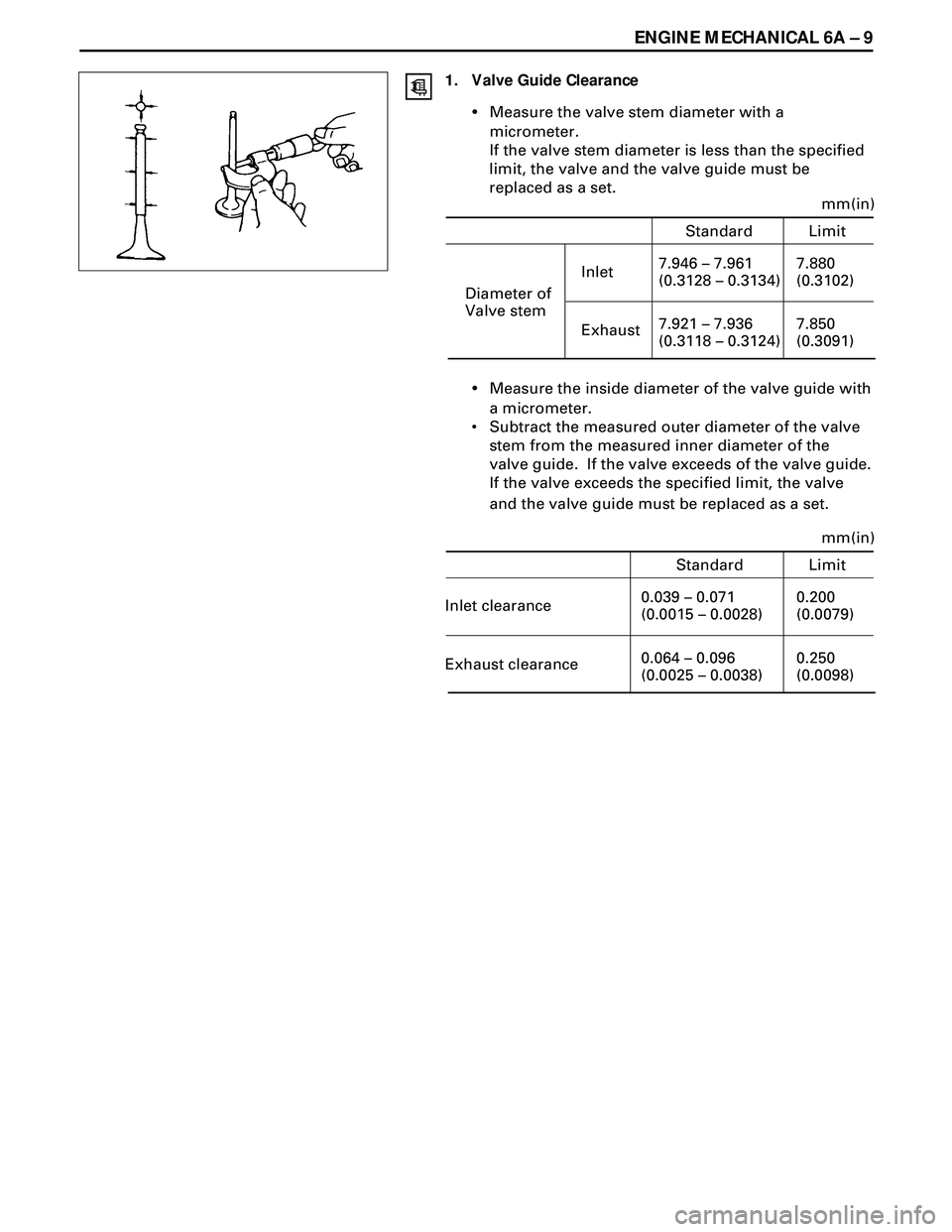

1. Valve Guide Clearance

¥Measure the valve stem diameter with a

micrometer.

If the valve stem diameter is less than the specified

limit, the valve and the valve guide must be

replaced as a set.

¥Measure the inside diameter of the valve guide with

a micrometer.

¥ Subtract the measured outer diameter of the valve

stem from the measured inner diameter of the

valve guide. If the valve exceeds of the valve guide.

If the valve exceeds the specified limit, the valve

and the valve guide must be replaced as a set. Diameter of

Valve stemInlet

mm(in)

7.880

(0.3102)

Standard Limit

Exhaust7.946 – 7.961

(0.3128 – 0.3134)

7.850

(0.3091) 7.921 – 7.936

(0.3118 – 0.3124)

Inlet clearance

mm(in)

0.200

(0.0079)

Standard Limit

Exhaust clearance0.039 – 0.071

(0.0015 – 0.0028)

0.250

(0.0098) 0.064 – 0.096

(0.0025 – 0.0038)

Page 1560 of 3573

6A Ð 10 ENGINE MECHANICAL

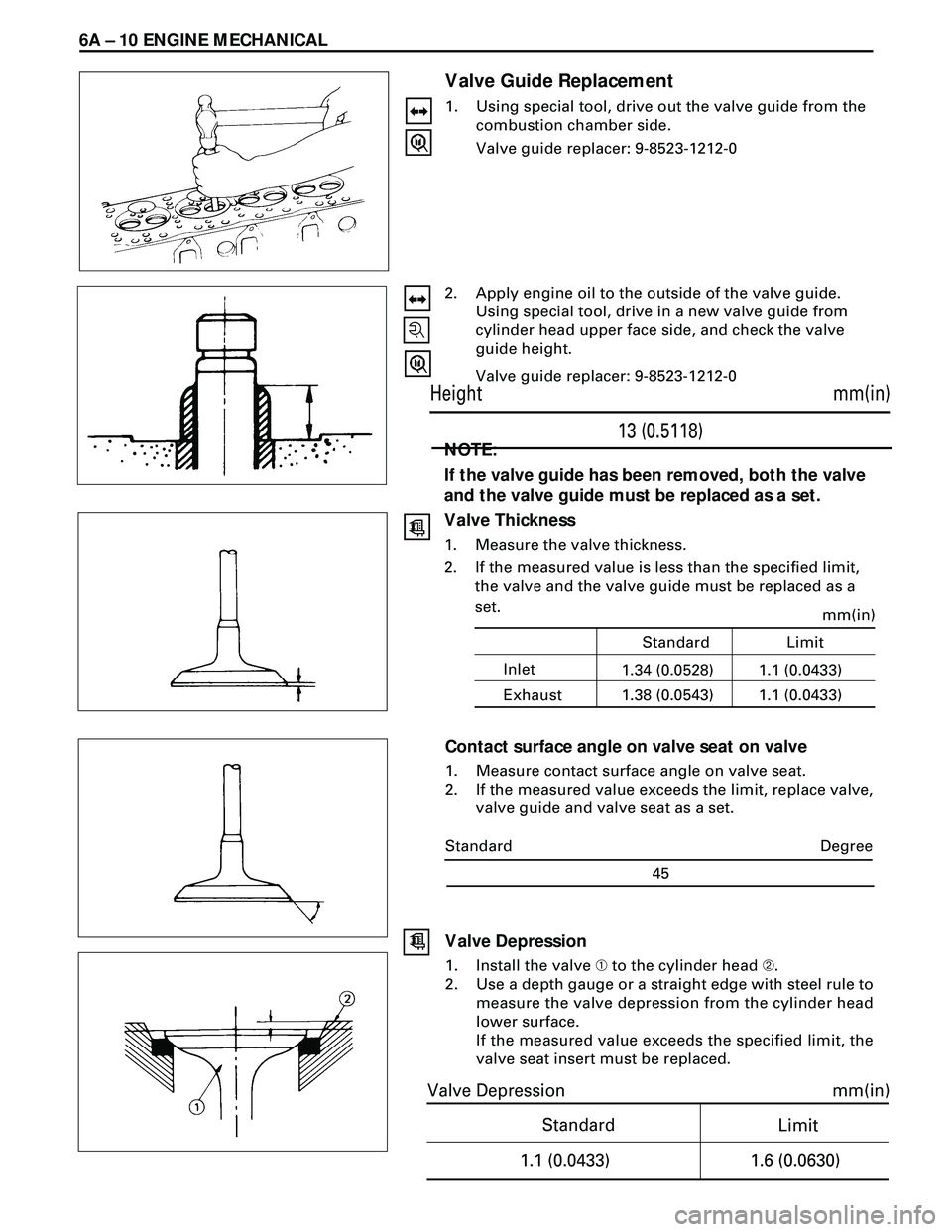

Valve Guide Replacement

1. Using special tool, drive out the valve guide from the

combustion chamber side.

Valve guide replacer: 9-8523-1212-0

2. Apply engine oil to the outside of the valve guide.

Using special tool, drive in a new valve guide from

cylinder head upper face side, and check the valve

guide height.

Valve guide replacer: 9-8523-1212-0

NOTE:

If the valve guide has been removed, both the valve

and the valve guide must be replaced as a set.

Valve Thickness

1. Measure the valve thickness.

2. If the measured value is less than the specified limit,

the valve and the valve guide must be replaced as a

set.

Contact surface angle on valve seat on valve

1. Measure contact surface angle on valve seat.

2. If the measured value exceeds the limit, replace valve,

valve guide and valve seat as a set.

mm(in)

13 (0.5118) Height

Standard

mm(in)

Limit

1.1 (0.0433)

1.6 (0.0630)

Valve Depression

Degree

45 Standard

Valve Depression

1. Install the valve À to the cylinder head Á.

2. Use a depth gauge or a straight edge with steel rule to

measure the valve depression from the cylinder head

lower surface.

If the measured value exceeds the specified limit, the

valve seat insert must be replaced.

Inletmm(in)1.1 (0.0433) Standard Limit

Exhaust1.34 (0.0528)

1.1 (0.0433) 1.38 (0.0543)

Page 1561 of 3573

ENGINE MECHANICAL 6A Ð 11

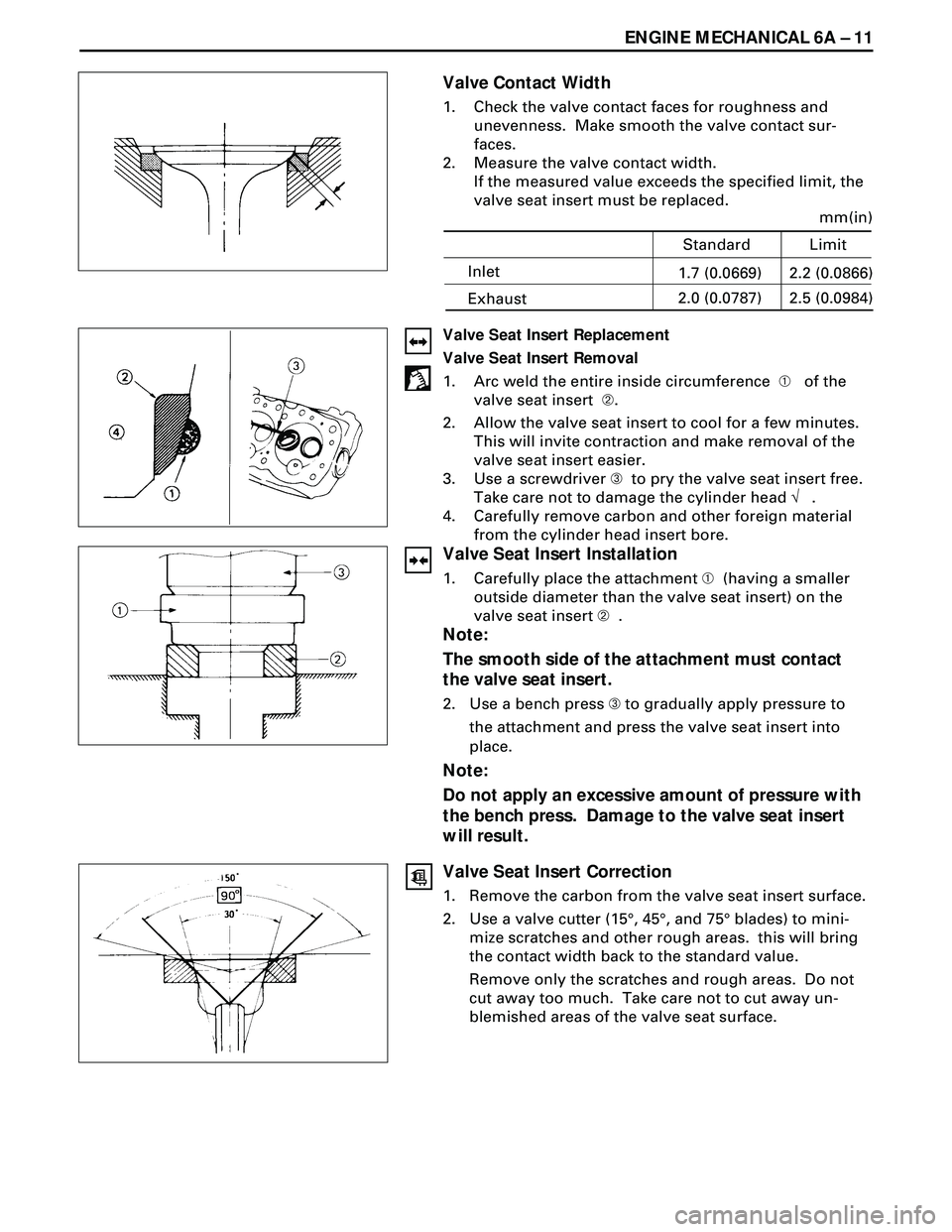

Valve Contact Width

1. Check the valve contact faces for roughness and

unevenness. Make smooth the valve contact sur-

faces.

2. Measure the valve contact width.

If the measured value exceeds the specified limit, the

valve seat insert must be replaced.

Valve Seat Insert Replacement

Valve Seat Insert Removal

1. Arc weld the entire inside circumference À of the

valve seat insert Á.

2. Allow the valve seat insert to cool for a few minutes.

This will invite contraction and make removal of the

valve seat insert easier.

3. Use a screwdriver  to pry the valve seat insert free.

Take care not to damage the cylinder head Ö .

4. Carefully remove carbon and other foreign material

from the cylinder head insert bore.

Valve Seat Insert Installation

1. Carefully place the attachment À (having a smaller

outside diameter than the valve seat insert) on the

valve seat insert Á .

Note:

The smooth side of the attachment must contact

the valve seat insert.

2. Use a bench press  to gradually apply pressure to

the attachment and press the valve seat insert into

place.

Note:

Do not apply an excessive amount of pressure with

the bench press. Damage to the valve seat insert

will result.

Valve Seat Insert Correction

1. Remove the carbon from the valve seat insert surface.

2. Use a valve cutter (15°, 45°, and 75° blades) to mini-

mize scratches and other rough areas. this will bring

the contact width back to the standard value.

Remove only the scratches and rough areas. Do not

cut away too much. Take care not to cut away un-

blemished areas of the valve seat surface.

Inlet

mm(in)

2.2 (0.0866)

Standard Limit

Exhaust1.7 (0.0669)

2.5 (0.0984) 2.0 (0.0787)

Page 1562 of 3573

6A Ð 12 ENGINE MECHANICAL

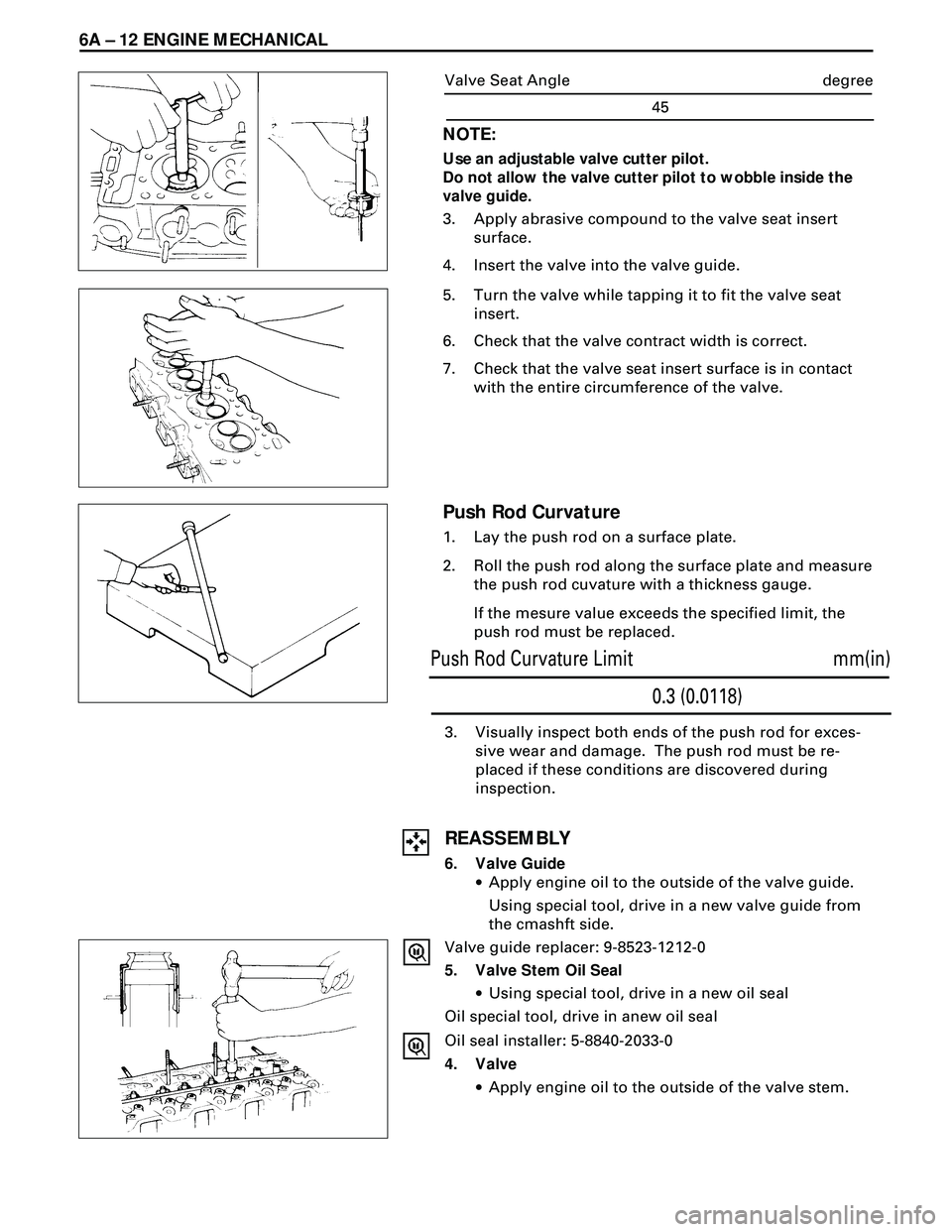

3. Visually inspect both ends of the push rod for exces-

sive wear and damage. The push rod must be re-

placed if these conditions are discovered during

inspection.

REASSEMBLY

6. Valve Guide

·Apply engine oil to the outside of the valve guide.

Using special tool, drive in a new valve guide from

the cmashft side.

Valve guide replacer: 9-8523-1212-0

5. Valve Stem Oil Seal

·Using special tool, drive in a new oil seal

Oil special tool, drive in anew oil seal

Oil seal installer: 5-8840-2033-0

4. Valve

·Apply engine oil to the outside of the valve stem.

Push Rod Curvature

1. Lay the push rod on a surface plate.

2. Roll the push rod along the surface plate and measure

the push rod cuvature with a thickness gauge.

If the mesure value exceeds the specified limit, the

push rod must be replaced.

NOTE:

Use an adjustable valve cutter pilot.

Do not allow the valve cutter pilot to wobble inside the

valve guide.

3. Apply abrasive compound to the valve seat insert

surface.

4. Insert the valve into the valve guide.

5. Turn the valve while tapping it to fit the valve seat

insert.

6. Check that the valve contract width is correct.

7. Check that the valve seat insert surface is in contact

with the entire circumference of the valve.

mm(in)

0.3 (0.0118) Push Rod Curvature Limit

degree

45 Valve Seat Angle

Page 1563 of 3573

ENGINE MECHANICAL 6A Ð 13

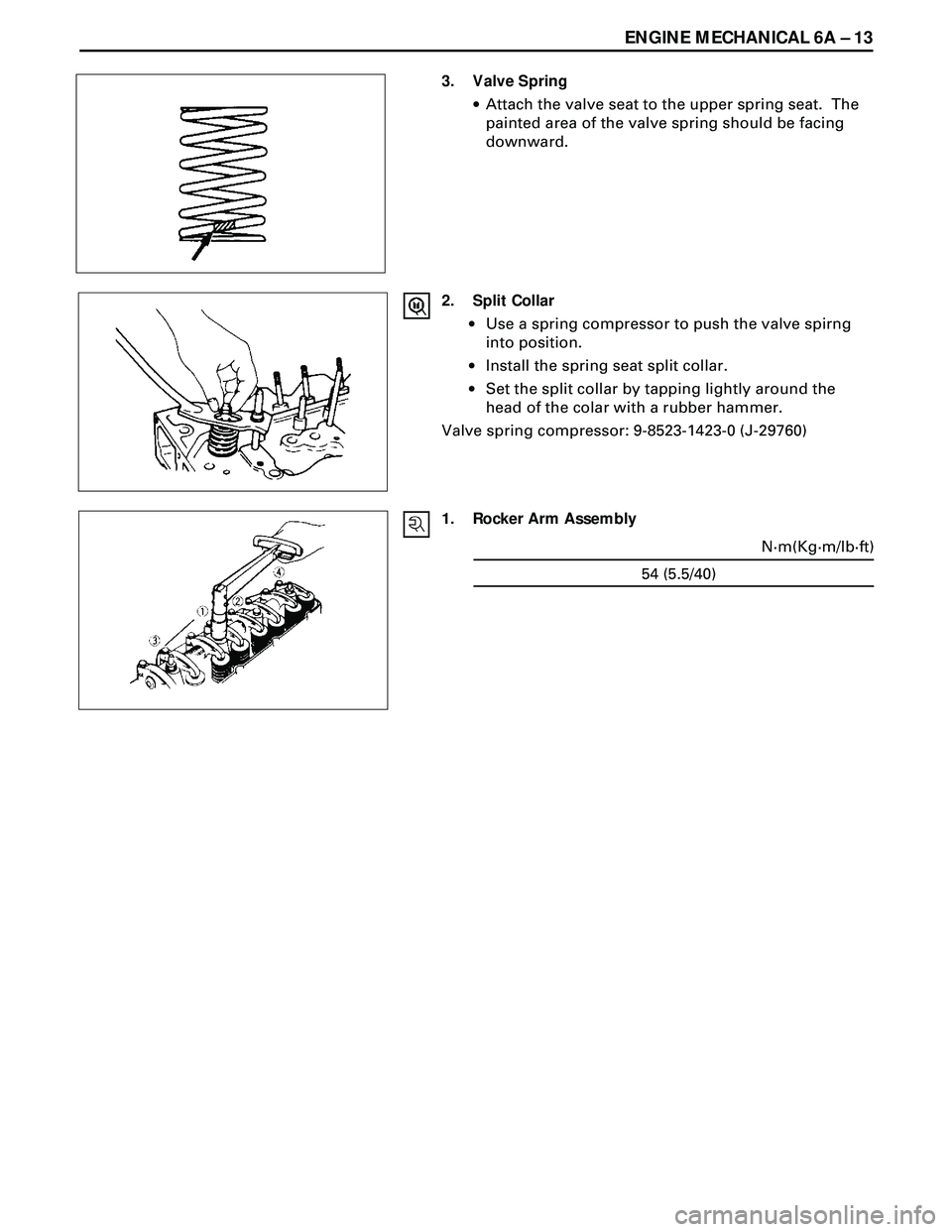

3. Valve Spring

·Attach the valve seat to the upper spring seat. The

painted area of the valve spring should be facing

downward.

2. Split Collar

·Use a spring compressor to push the valve spirng

into position.

·Install the spring seat split collar.

·Set the split collar by tapping lightly around the

head of the colar with a rubber hammer.

Valve spring compressor: 9-8523-1423-0 (J-29760)

1. Rocker Arm Assembly

N·m(Kg·m/lb·ft)

54 (5.5/40)

Page 1564 of 3573

6A Ð 14 ENGINE MECHANICAL

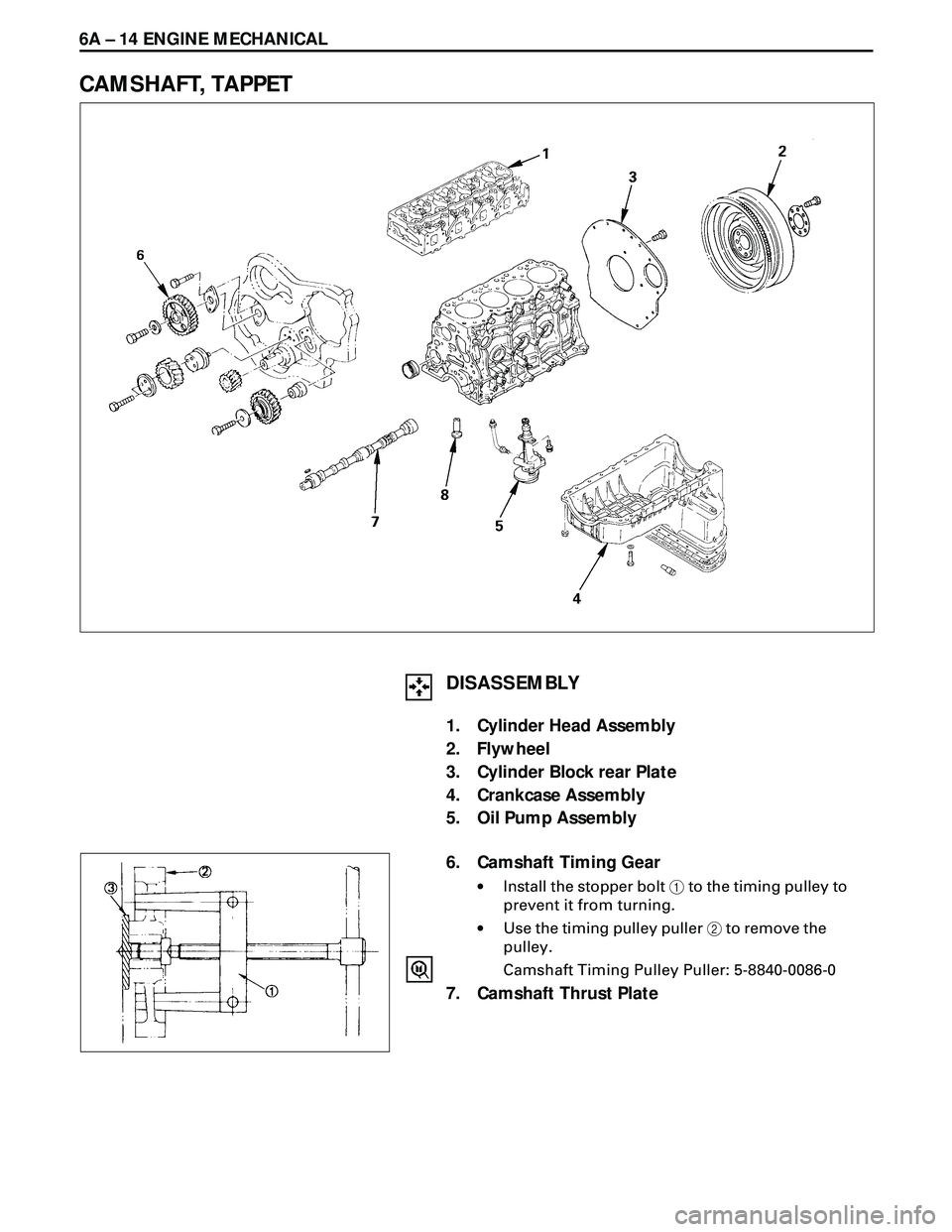

CAMSHAFT, TAPPET

6. Camshaft Timing Gear

·Install the stopper bolt 1 to the timing pulley to

prevent it from turning.

·Use the timing pulley puller 2 to remove the

pulley.

Camshaft Timing Pulley Puller: 5-8840-0086-0

7. Camshaft Thrust Plate

DISASSEMBLY

1. Cylinder Head Assembly

2. Flywheel

3. Cylinder Block rear Plate

4. Crankcase Assembly

5. Oil Pump Assembly

Page 1565 of 3573

ENGINE MECHANICAL 6A Ð 15

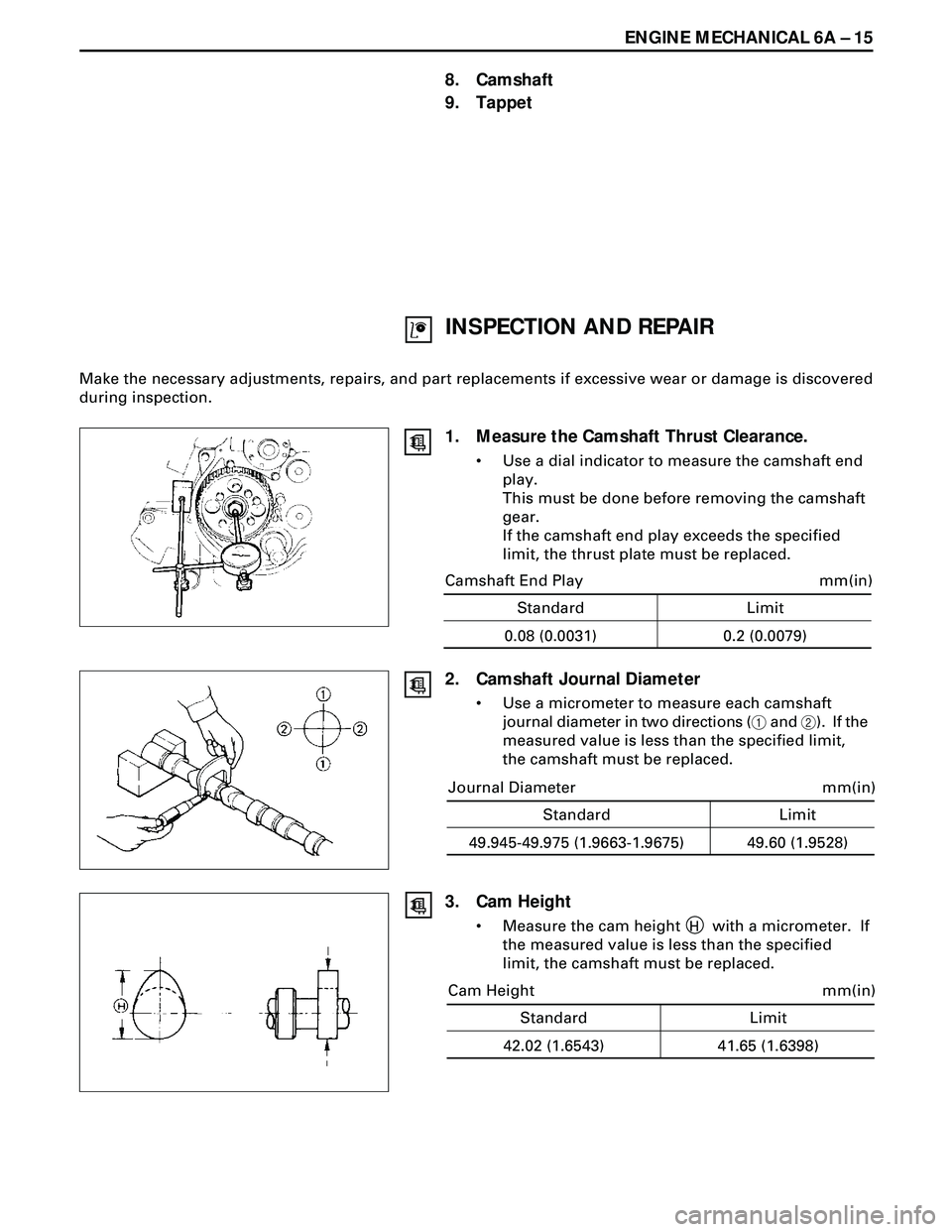

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered

during inspection.

8. Camshaft

9. Tappet

1. Measure the Camshaft Thrust Clearance.

¥ Use a dial indicator to measure the camshaft end

play.

This must be done before removing the camshaft

gear.

If the camshaft end play exceeds the specified

limit, the thrust plate must be replaced.

2. Camshaft Journal Diameter

¥ Use a micrometer to measure each camshaft

journal diameter in two directions (1 and 2). If the

measured value is less than the specified limit,

the camshaft must be replaced.

3. Cam Height

¥ Measure the cam height H with a micrometer. If

the measured value is less than the specified

limit, the camshaft must be replaced.

Standard Limit

mm(in)

49.945-49.975 (1.9663-1.9675) 49.60 (1.9528) Journal Diameter

Standard Limit

mm(in)

42.02 (1.6543) 41.65 (1.6398) Cam Height

Standard Limit

mm(in)

0.08 (0.0031) 0.2 (0.0079) Camshaft End Play