engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1696 of 3573

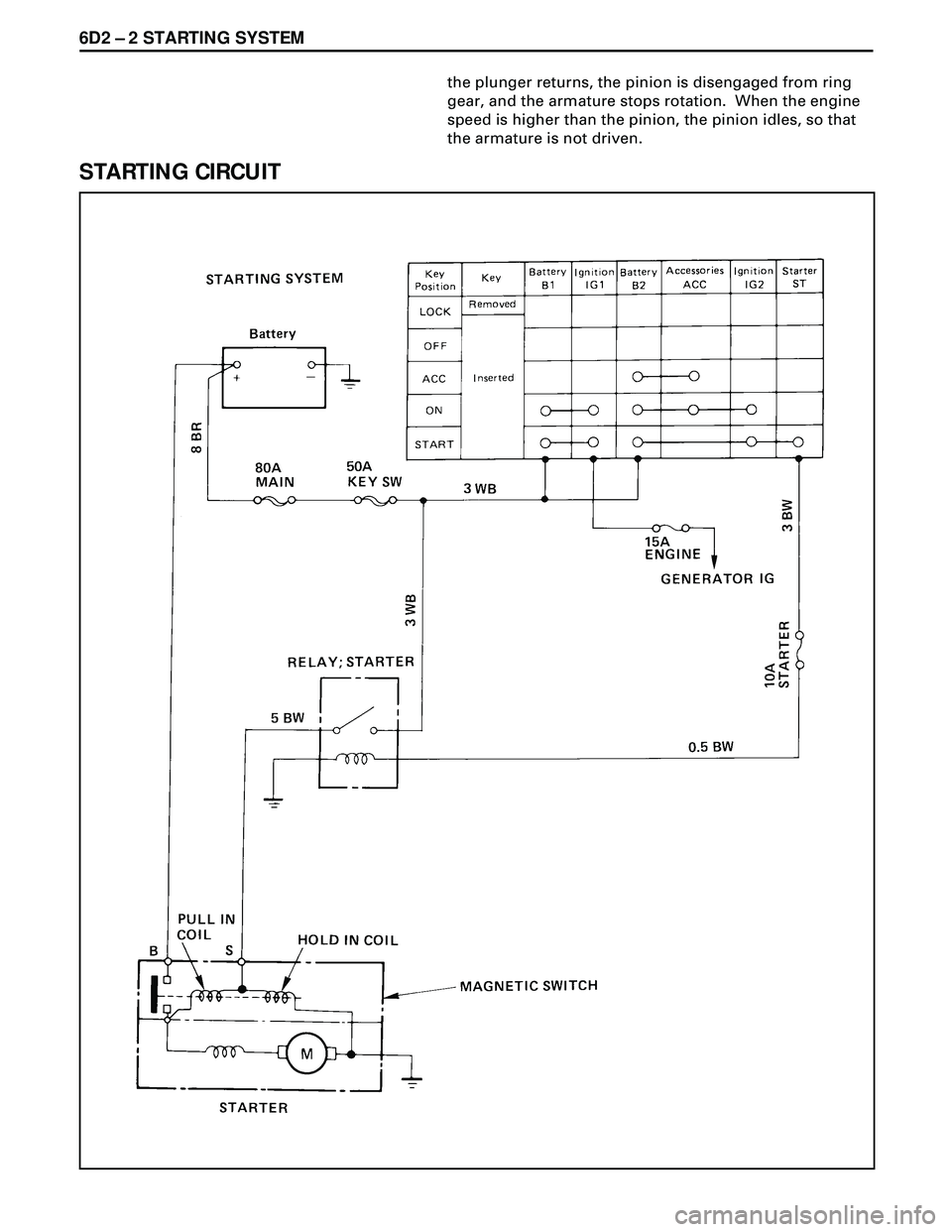

6D2 Ð 2 STARTING SYSTEM

the plunger returns, the pinion is disengaged from ring

gear, and the armature stops rotation. When the engine

speed is higher than the pinion, the pinion idles, so that

the armature is not driven.

STARTING CIRCUIT

Page 1710 of 3573

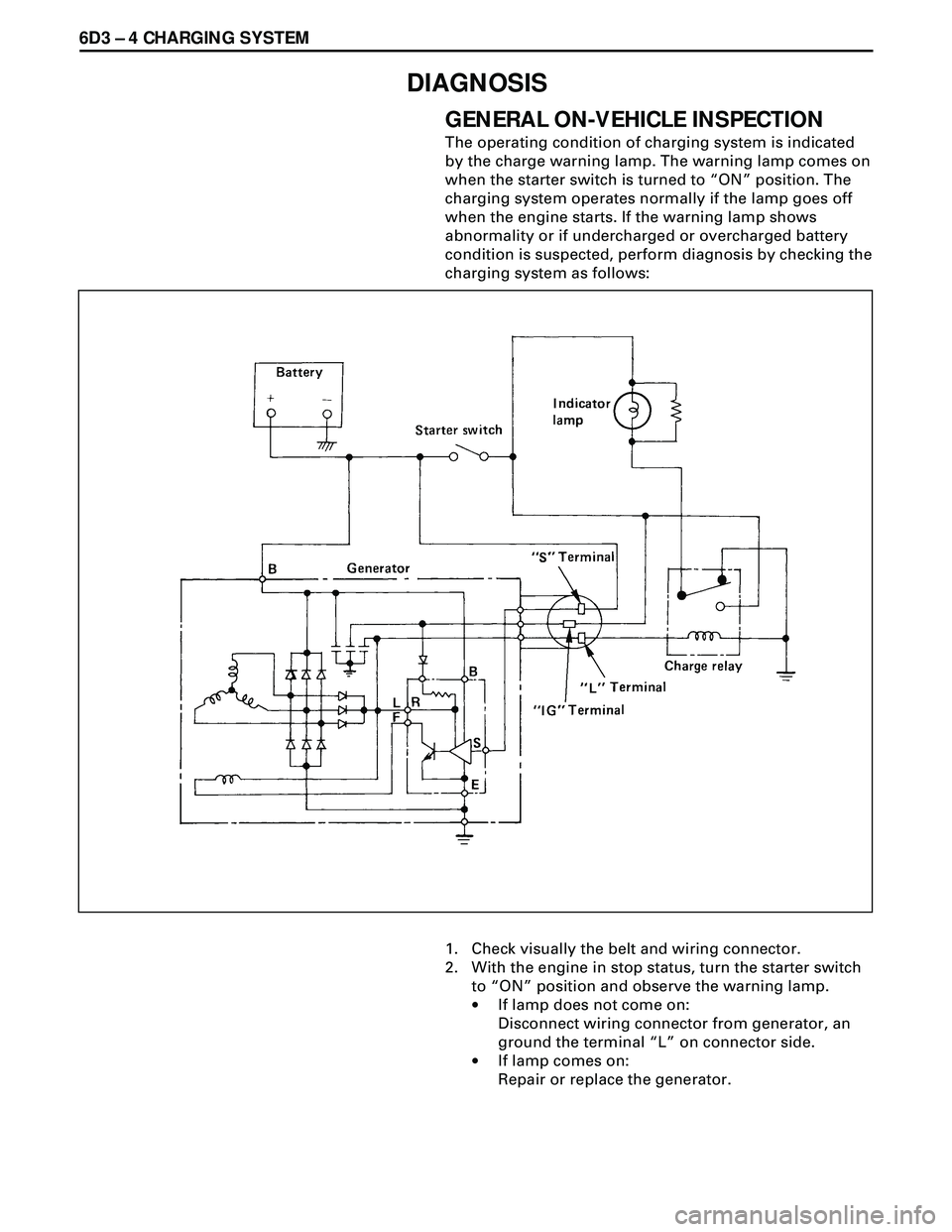

6D3 Ð 4 CHARGING SYSTEM

DIAGNOSIS

GENERAL ON-VEHICLE INSPECTION

The operating condition of charging system is indicated

by the charge warning lamp. The warning lamp comes on

when the starter switch is turned to ÒONÓ position. The

charging system operates normally if the lamp goes off

when the engine starts. If the warning lamp shows

abnormality or if undercharged or overcharged battery

condition is suspected, perform diagnosis by checking the

charging system as follows:

1. Check visually the belt and wiring connector.

2. With the engine in stop status, turn the starter switch

to ÒONÓ position and observe the warning lamp.

·If lamp does not come on:

Disconnect wiring connector from generator, an

ground the terminal ÒLÓ on connector side.

·If lamp comes on:

Repair or replace the generator.

Page 1717 of 3573

CHARGING SYSTEM 6D3 Ð 11

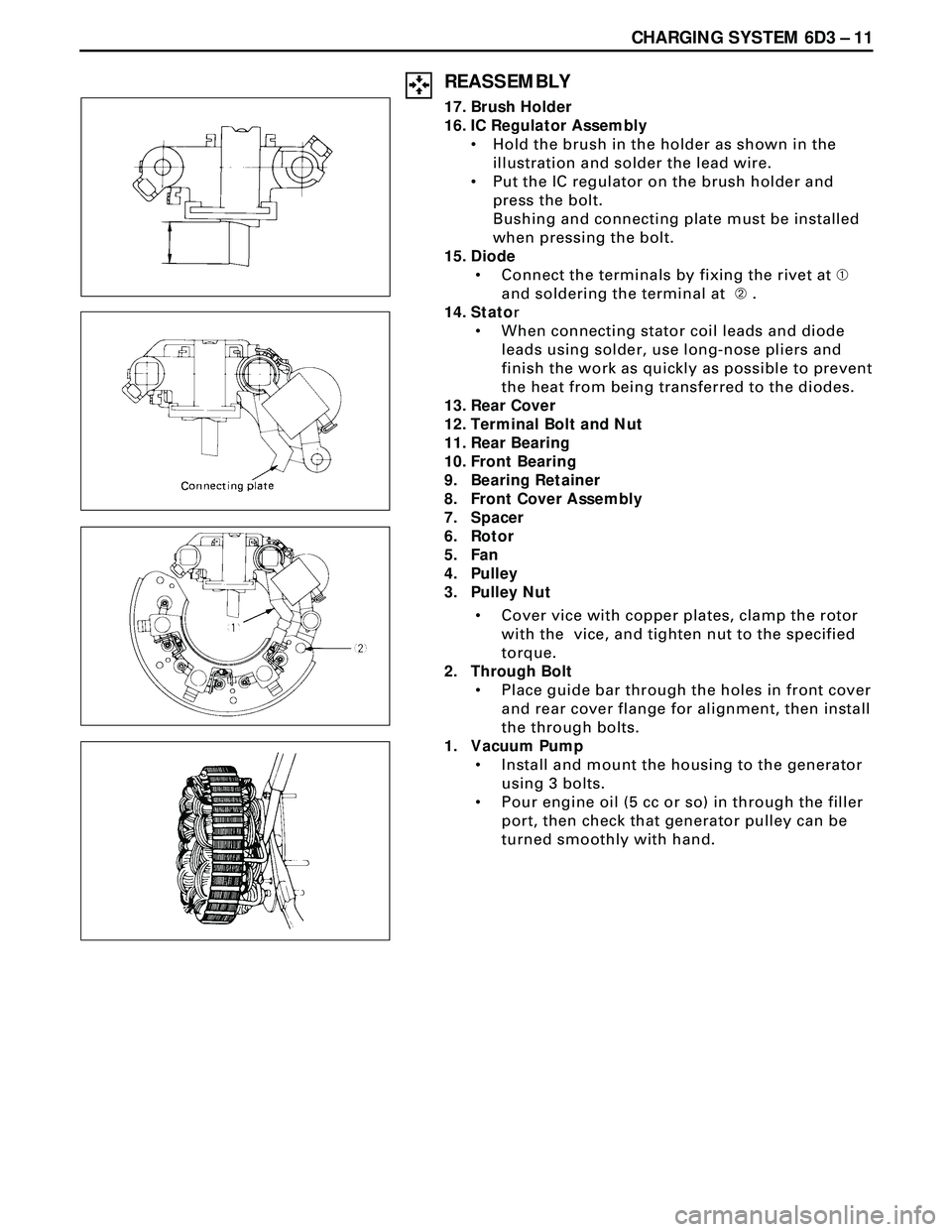

REASSEMBLY

17. Brush Holder

16. IC Regulator Assembly

¥ Hold the brush in the holder as shown in the

illustration and solder the lead wire.

¥ Put the IC regulator on the brush holder and

press the bolt.

Bushing and connecting plate must be installed

when pressing the bolt.

15. Diode

¥ Connect the terminals by fixing the rivet at À

and soldering the terminal at Á .

14. Stator

¥ When connecting stator coil leads and diode

leads using solder, use long-nose pliers and

finish the work as quickly as possible to prevent

the heat from being transferred to the diodes.

13. Rear Cover

12. Terminal Bolt and Nut

11. Rear Bearing

10. Front Bearing

9. Bearing Retainer

8. Front Cover Assembly

7. Spacer

6. Rotor

5. Fan

4. Pulley

3. Pulley Nut

¥ Cover vice with copper plates, clamp the rotor

with the vice, and tighten nut to the specified

torque.

2. Through Bolt

¥ Place guide bar through the holes in front cover

and rear cover flange for alignment, then install

the through bolts.

1. Vacuum Pump

¥ Install and mount the housing to the generator

using 3 bolts.

¥ Pour engine oil (5 cc or so) in through the filler

port, then check that generator pulley can be

turned smoothly with hand.

Page 1719 of 3573

QOS III PREHEATING SYSTEM 6D6 Ð 1

PAGE

General Description ........................................................................................................ 6D6- 1

System Diagram .............................................................................................................. 6D6- 2

GENERAL DESCRIPTION

QOS III preheating system features a quick-on glow

plug with thermometer control of the glowing time

and the afterglow time function.

The system consists of a controller, indicator lamp,

thermosensor, vehicle speedsensor, dropping

resistor, relay (2 pcs), and temperature self-control

type glow plug (4 pcs).With the employment of the thermosensor, the

glow time changes according to the engine coolant

temperature, thus allowing optimum starting

conditions to be obtained.

The afterglow time function is controlled by

thermosensor, vehicle speed sensor, and the

engine runstall sensor (charge relay).

SECTION 6D6

QOSIII PREHEATING SYSTEM

CONTENTS

Page 1720 of 3573

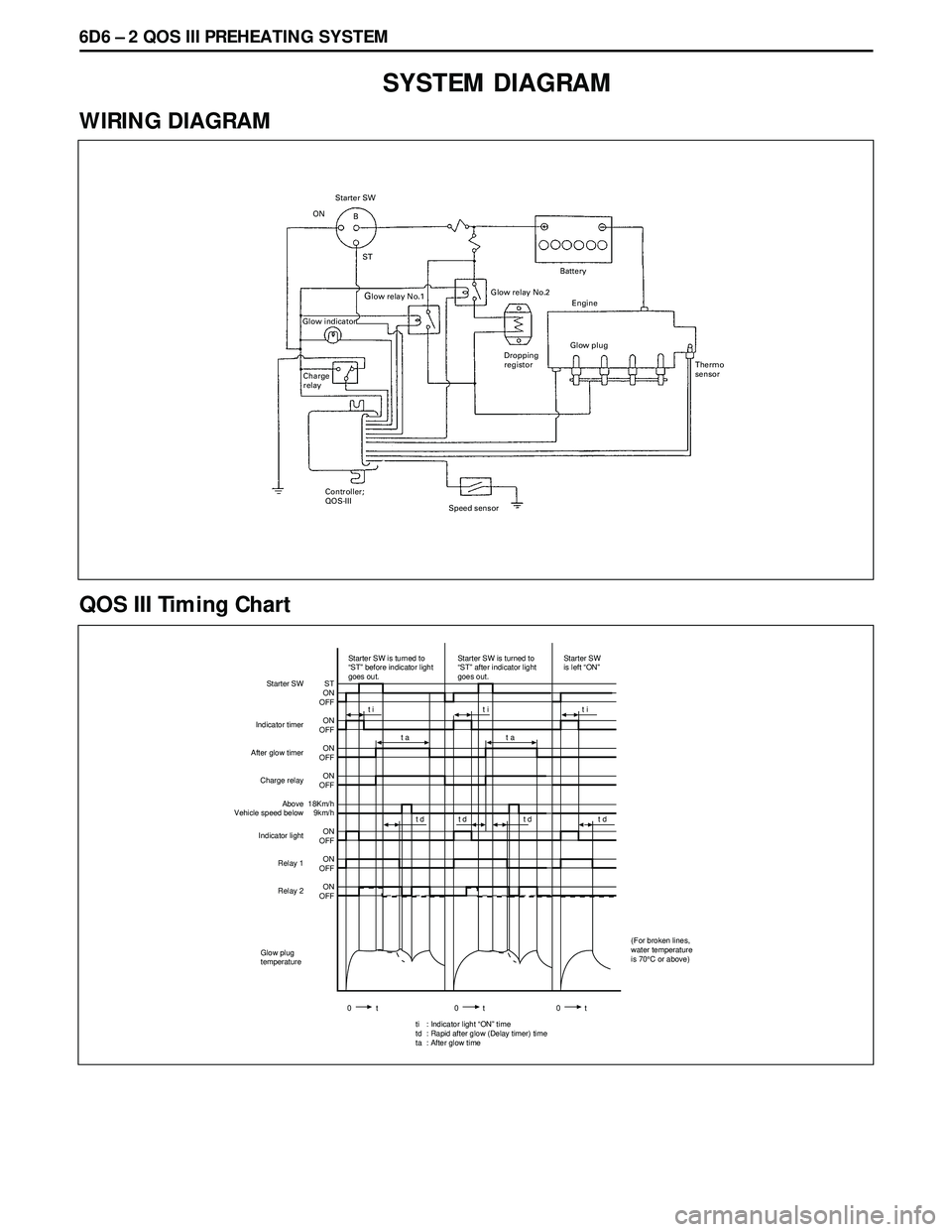

6D6 Ð 2 QOS III PREHEATING SYSTEM

SYSTEM DIAGRAM

WIRING DIAGRAM

ON

B

ST

Glow relay No.1 Starter SW

Battery

Engine Glow relay No.2

Glow indicator

Charge

relayGlow plug

Thermo

sensor

Controller;

QOS-III

Speed sensorDropping

registor

QOS III Timing Chart

ST

ON

OFF

ON

OFF

ON

OFF

ON

OFF

18Km/h

9km/h

ON

OFF

ON

OFF

ON

OFF Starter SW

Starter SW is turned to

“ST” before indicator light

goes out.Starter SW is turned to

“ST” after indicator light

goes out.Starter SW

is left “ON”

Indicator timer

After glow timer

Charge relay

Indicator light

Relay 1

Relay 2Above

Vehicle speed below

t i t i t i

t a t a

t d t d t d t d

Glow plug

temperature

0t 0t 0t

: Indicator light “ON” time

: Rapid after glow (Delay timer) time

: After glow time

ti

td

ta

(For broken lines,

water temperature

is 70¡C or above)

Page 1723 of 3573

QOS III PREHEATING SYSTEM 6D6 Ð 5

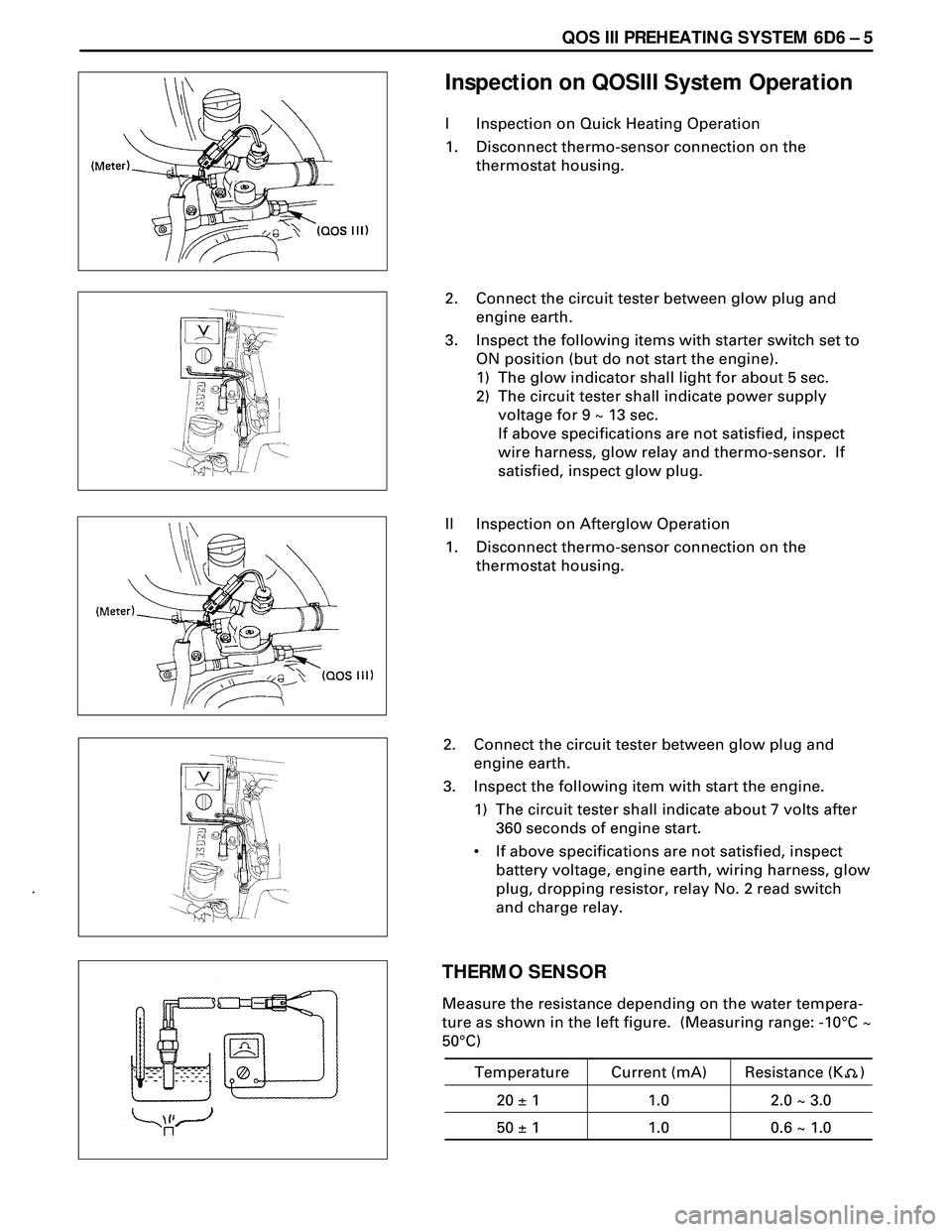

Inspection on QOSIII System Operation

I Inspection on Quick Heating Operation

1. Disconnect thermo-sensor connection on the

thermostat housing.

2. Connect the circuit tester between glow plug and

engine earth.

3. Inspect the following items with starter switch set to

ON position (but do not start the engine).

1) The glow indicator shall light for about 5 sec.

2) The circuit tester shall indicate power supply

voltage for 9 ~ 13 sec.

If above specifications are not satisfied, inspect

wire harness, glow relay and thermo-sensor. If

satisfied, inspect glow plug.

II Inspection on Afterglow Operation

1. Disconnect thermo-sensor connection on the

thermostat housing.

2. Connect the circuit tester between glow plug and

engine earth.

3. Inspect the following item with start the engine.

1) The circuit tester shall indicate about 7 volts after

360 seconds of engine start.

¥ If above specifications are not satisfied, inspect

battery voltage, engine earth, wiring harness, glow

plug, dropping resistor, relay No. 2 read switch

and charge relay.

THERMO SENSOR

Measure the resistance depending on the water tempera-

ture as shown in the left figure. (Measuring range: -10¡C ~

50¡C)

Current (mA)

20 ± 1 1.0

50 ± 1Resistance (K )

1.0

2.0 ~ 3.0

0.6 ~ 1.0 Temperature

Page 1725 of 3573

ENGINE EXHAUST 6F Ð 1

SECTION 6F

ENGINE EXHAUST

CAUTION:

overheating of the floor pan and possible damage

to the passenger compartment, insulation and trim

materials. Exhaust system components must have enough

clearance from the underbody to prevent

CONTENTS

PAGE

General Description ........................................................................................................ 6F-2

Hangers ........................................................................................................................6F-2

Gasket .......................................................................................................................... 6F-2

On-Vehicle Service .......................................................................................................... 6F-3

Front Exhaust Pipe ...................................................................................................... 6F-3

Center Exhaust Pipe .................................................................................................... 6F-5

Exhaust Silencer .......................................................................................................... 6F-7

Rear Exhaust Pipe ....................................................................................................... 6F-9

Page 1726 of 3573

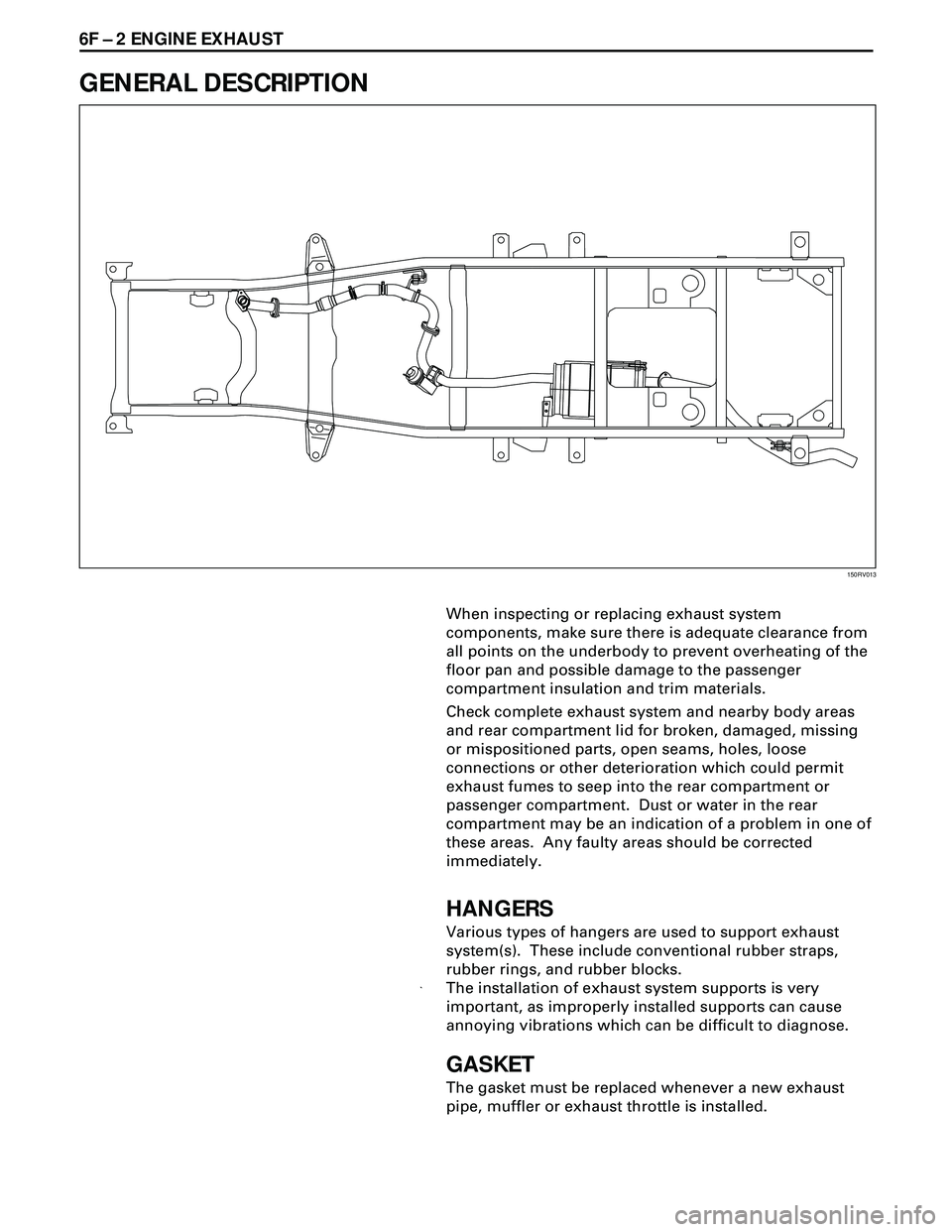

6F Ð 2 ENGINE EXHAUST

GENERAL DESCRIPTION

150RV013

When inspecting or replacing exhaust system

components, make sure there is adequate clearance from

all points on the underbody to prevent overheating of the

floor pan and possible damage to the passenger

compartment insulation and trim materials.

Check complete exhaust system and nearby body areas

and rear compartment lid for broken, damaged, missing

or mispositioned parts, open seams, holes, loose

connections or other deterioration which could permit

exhaust fumes to seep into the rear compartment or

passenger compartment. Dust or water in the rear

compartment may be an indication of a problem in one of

these areas. Any faulty areas should be corrected

immediately.

HANGERS

Various types of hangers are used to support exhaust

system(s). These include conventional rubber straps,

rubber rings, and rubber blocks.

The installation of exhaust system supports is very

important, as improperly installed supports can cause

annoying vibrations which can be difficult to diagnose.

GASKET

The gasket must be replaced whenever a new exhaust

pipe, muffler or exhaust throttle is installed.

Page 1727 of 3573

ENGINE EXHAUST 6F Ð 3

ON-VEHICLE SERVICE

Rattles and noise vibrations in the exhaust system

are usually caused by misalignment of parts. When

aligning the system, leave all bolts or nuts loose

until all parts are properly aligned; then tighten,

working from front to rear.

1. Check connections for looseness or damage,

especially for exhaust gas leakage.2. Check clamps and rubbers for weakness, cracks

or damage.

3. If any part of the converter heat shield is

damaged or dented to the extent that it contacts

the catalyst, repair or replace.

4. Check for dents or damage and for any holes or

cracks caused by corrosion.

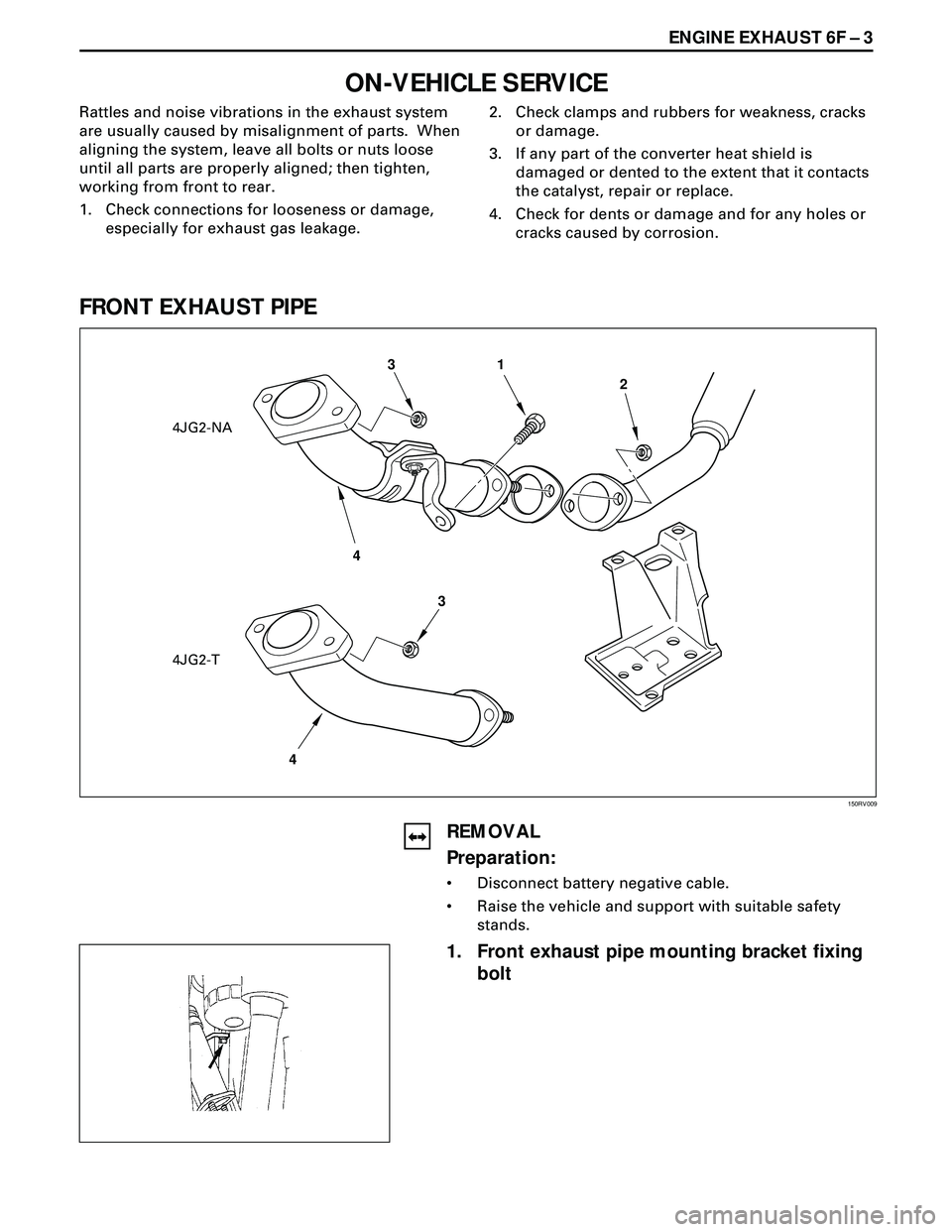

REMOVAL

Preparation:

¥ Disconnect battery negative cable.

¥ Raise the vehicle and support with suitable safety

stands.

1. Front exhaust pipe mounting bracket fixing

bolt

150RV009

FRONT EXHAUST PIPE

4JG2-NA

4JG2-T3

31

4

42

Page 1728 of 3573

6F Ð 4 ENGINE EXHAUST

2. Front exhaust pipe fixing nuts

¥ Remove two bolts fixed from front pipe and center

pipe A.

3. Exhaust manifold fixing nuts

¥ Remove two fixing nuts from exhaust manifold and

front pipe.

4. Front exhaust pipe

INSTALLATION

4. Front exhaust pipe

3. Exhaust manifold fixing nuts

¥ Tighten the fixing nuts to the specified torque.

67 (6.8/49)N·m (Kg·m/lb·ft)

2. Front exhaust pipe fixing nuts

¥ Tighten the fixing nuts to the specified torque

43 (4.4/32)N·m (Kg·m/lb·ft)

1. Front exhaust pipe mounting bracket fixing

bolt

¥ Tighten the fixing nuts to the specified torque

40 (4.1/30)N·m (Kg·m/lb·ft)