engine ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1666 of 3573

6B Ð 12 ENGINE COOLING

TENSION ADJUSTMENT

P/S oil pump and A/C compressor pulley belt.

·With P/S pump lock bolt loose, adjust belt tension

with adjust belt.

Cooling fan pulley belt

·With AC Generator mounting and lock bolts loose,

adjust belt tension with adjuster's adjust bolt.

AC generator fixing bolt40 (4.1/30) Torque StandardN·m(Kg·m/lb·ft)

Adjust plate fixing bolt24 (2.4/17)

Adjust plate lock bolt19 (1.9/14)

P/S oil pump adjustor lock bolt37 (3.8/27)

Page 1672 of 3573

6C Ð 6 FUEL SYSTEM

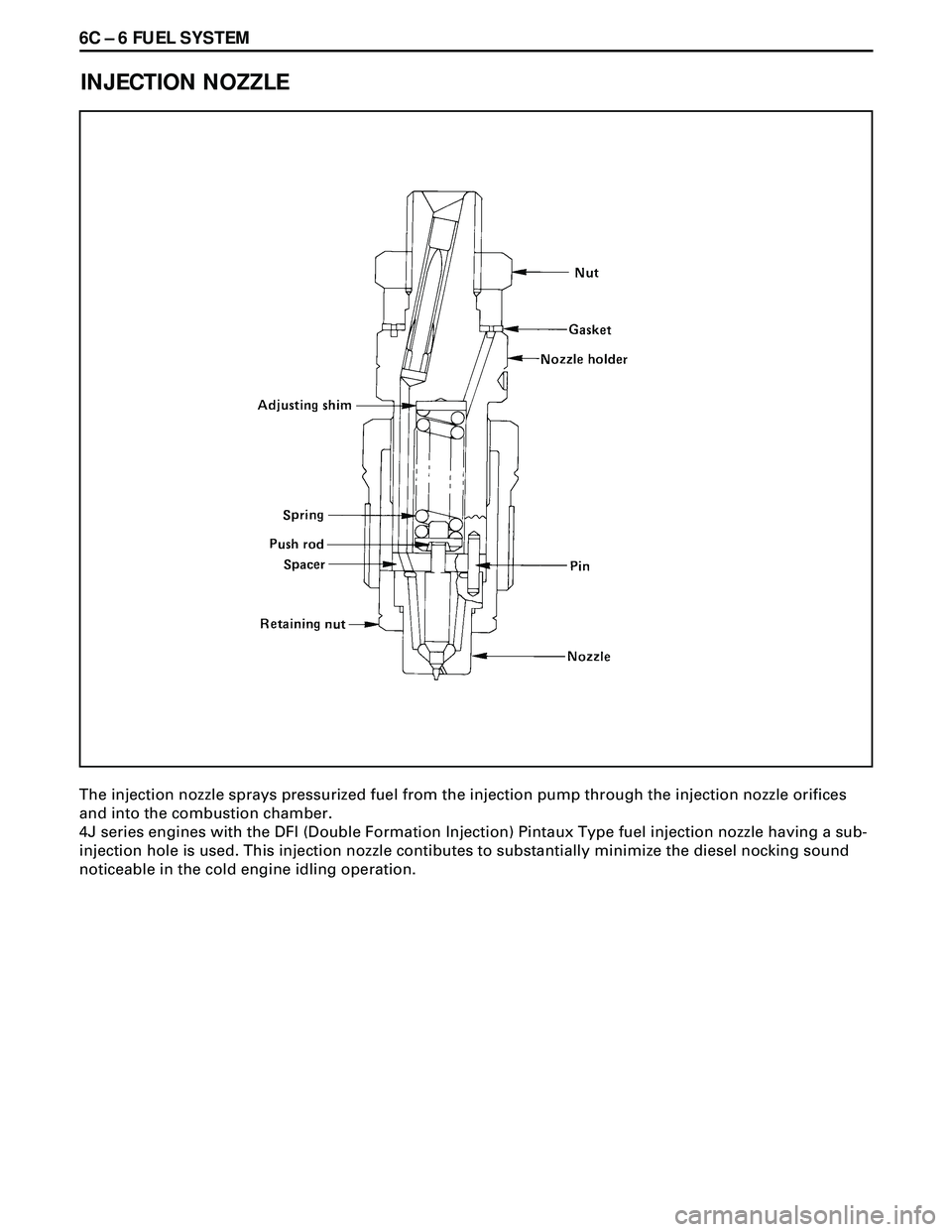

INJECTION NOZZLE

The injection nozzle sprays pressurized fuel from the injection pump through the injection nozzle orifices

and into the combustion chamber.

4J series engines with the DFI (Double Formation Injection) Pintaux Type fuel injection nozzle having a sub-

injection hole is used. This injection nozzle contibutes to substantially minimize the diesel nocking sound

noticeable in the cold engine idling operation.

Page 1674 of 3573

6C Ð 8 FUEL SYSTEM

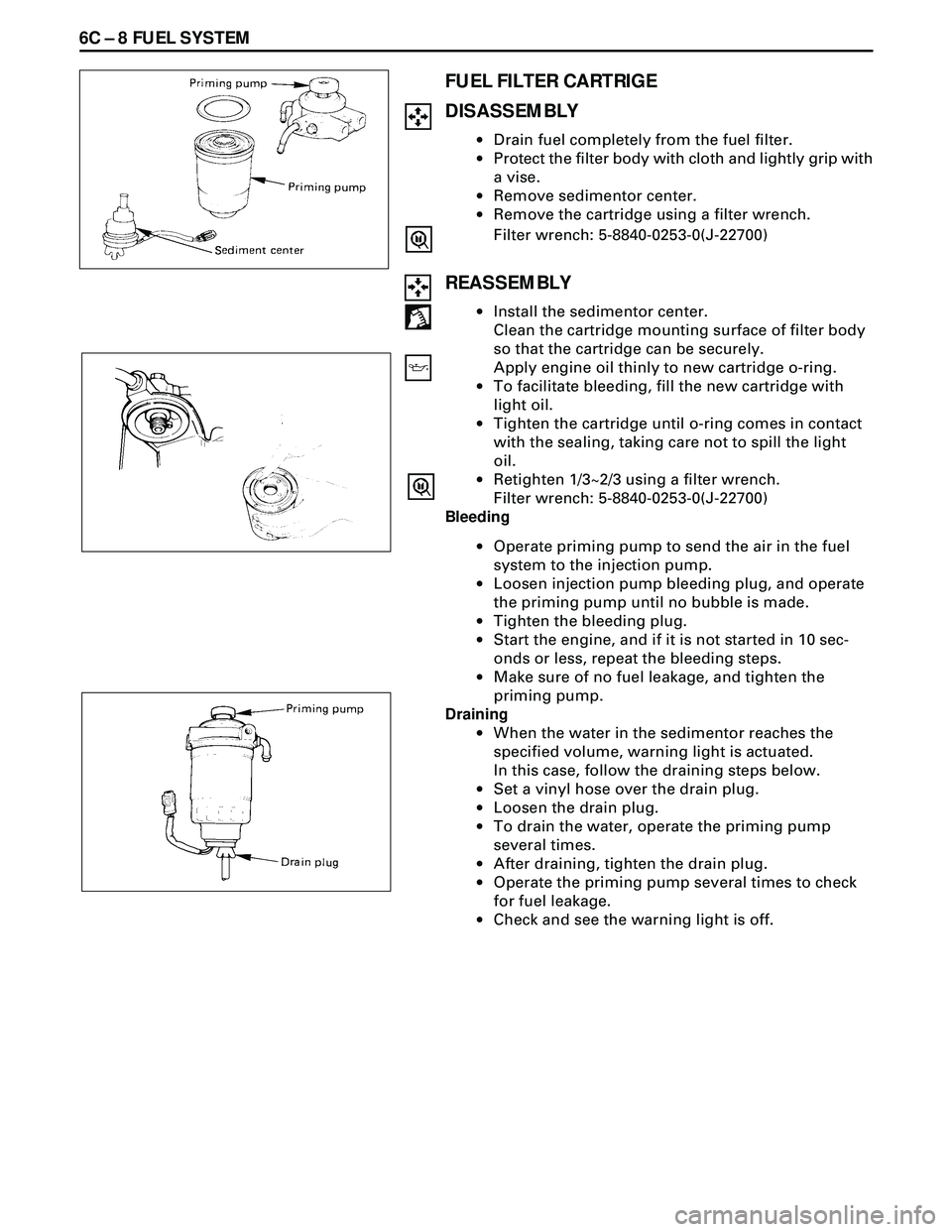

FUEL FILTER CARTRIGE

DISASSEMBLY

·Drain fuel completely from the fuel filter.

·Protect the filter body with cloth and lightly grip with

a vise.

·Remove sedimentor center.

·Remove the cartridge using a filter wrench.

Filter wrench: 5-8840-0253-0(J-22700)

REASSEMBLY

·Install the sedimentor center.

Clean the cartridge mounting surface of filter body

so that the cartridge can be securely.

Apply engine oil thinly to new cartridge o-ring.

·To facilitate bleeding, fill the new cartridge with

light oil.

·Tighten the cartridge until o-ring comes in contact

with the sealing, taking care not to spill the light

oil.

·Retighten 1/3~2/3 using a filter wrench.

Filter wrench: 5-8840-0253-0(J-22700)

Bleeding

·Operate priming pump to send the air in the fuel

system to the injection pump.

·Loosen injection pump bleeding plug, and operate

the priming pump until no bubble is made.

·Tighten the bleeding plug.

·Start the engine, and if it is not started in 10 sec-

onds or less, repeat the bleeding steps.

·Make sure of no fuel leakage, and tighten the

priming pump.

Draining

·When the water in the sedimentor reaches the

specified volume, warning light is actuated.

In this case, follow the draining steps below.

·Set a vinyI hose over the drain plug.

·Loosen the drain plug.

·To drain the water, operate the priming pump

several times.

·After draining, tighten the drain plug.

·Operate the priming pump several times to check

for fuel leakage.

·Check and see the warning light is off.

Page 1681 of 3573

FUEL SYSTEM 6C Ð 15

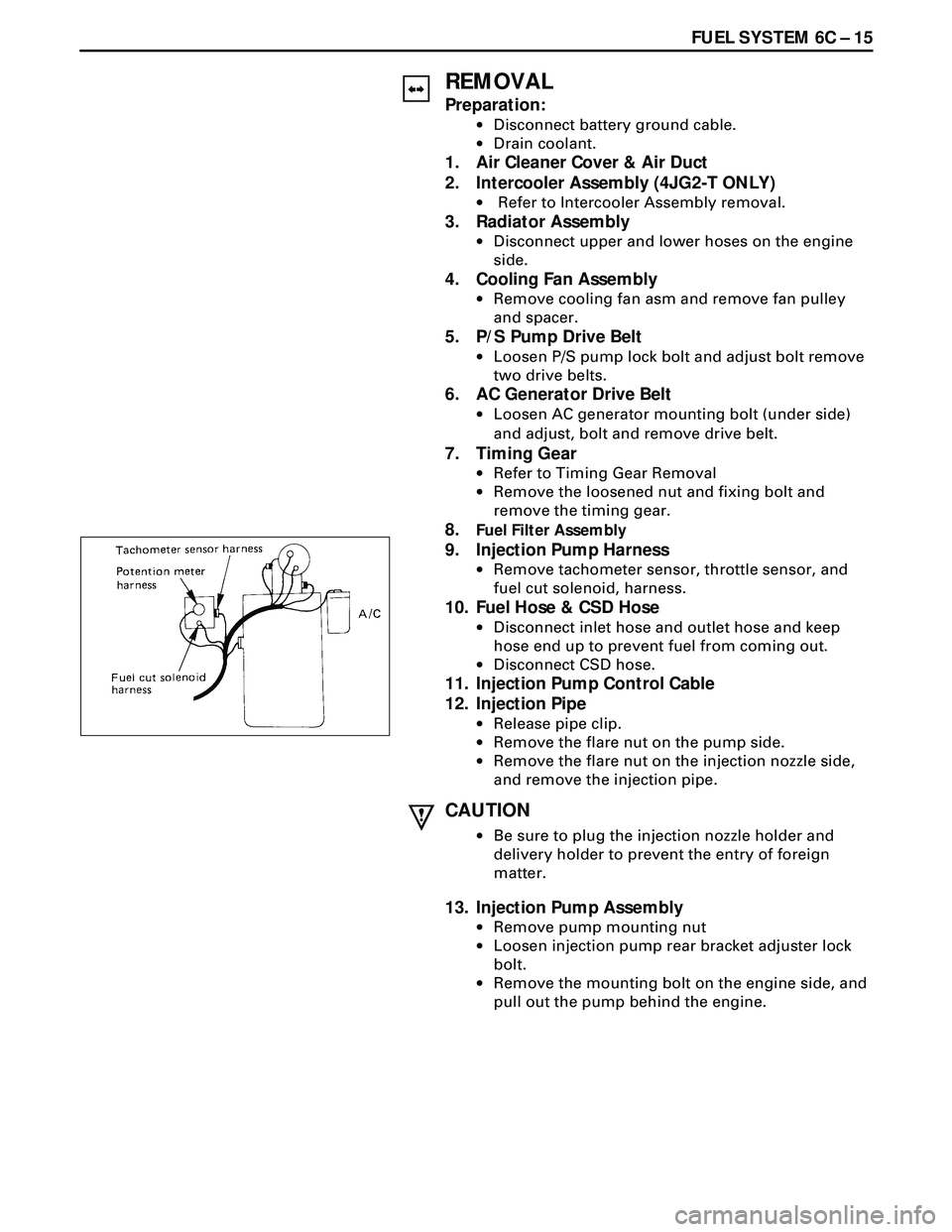

REMOVAL

Preparation:

·Disconnect battery ground cable.

·Drain coolant.

1. Air Cleaner Cover & Air Duct

2. Intercooler Assembly (4JG2-T ONLY)

· Refer to Intercooler Assembly removal.

3. Radiator Assembly

·Disconnect upper and lower hoses on the engine

side.

4. Cooling Fan Assembly

·Remove cooling fan asm and remove fan pulley

and spacer.

5. P/S Pump Drive Belt

·Loosen P/S pump lock bolt and adjust bolt remove

two drive belts.

6. AC Generator Drive Belt

·Loosen AC generator mounting bolt (under side)

and adjust, bolt and remove drive belt.

7. Timing Gear

·Refer to Timing Gear Removal

·Remove the loosened nut and fixing bolt and

remove the timing gear.

8.Fuel Filter Assembly

9. Injection Pump Harness

·Remove tachometer sensor, throttle sensor, and

fuel cut solenoid, harness.

10. Fuel Hose & CSD Hose

·Disconnect inlet hose and outlet hose and keep

hose end up to prevent fuel from coming out.

·Disconnect CSD hose.

11. Injection Pump Control Cable

12. Injection Pipe

·Release pipe clip.

·Remove the flare nut on the pump side.

·Remove the flare nut on the injection nozzle side,

and remove the injection pipe.

CAUTION

·Be sure to plug the injection nozzle holder and

delivery holder to prevent the entry of foreign

matter.

13. Injection Pump Assembly

·Remove pump mounting nut

·Loosen injection pump rear bracket adjuster lock

bolt.

·Remove the mounting bolt on the engine side, and

pull out the pump behind the engine.

Page 1682 of 3573

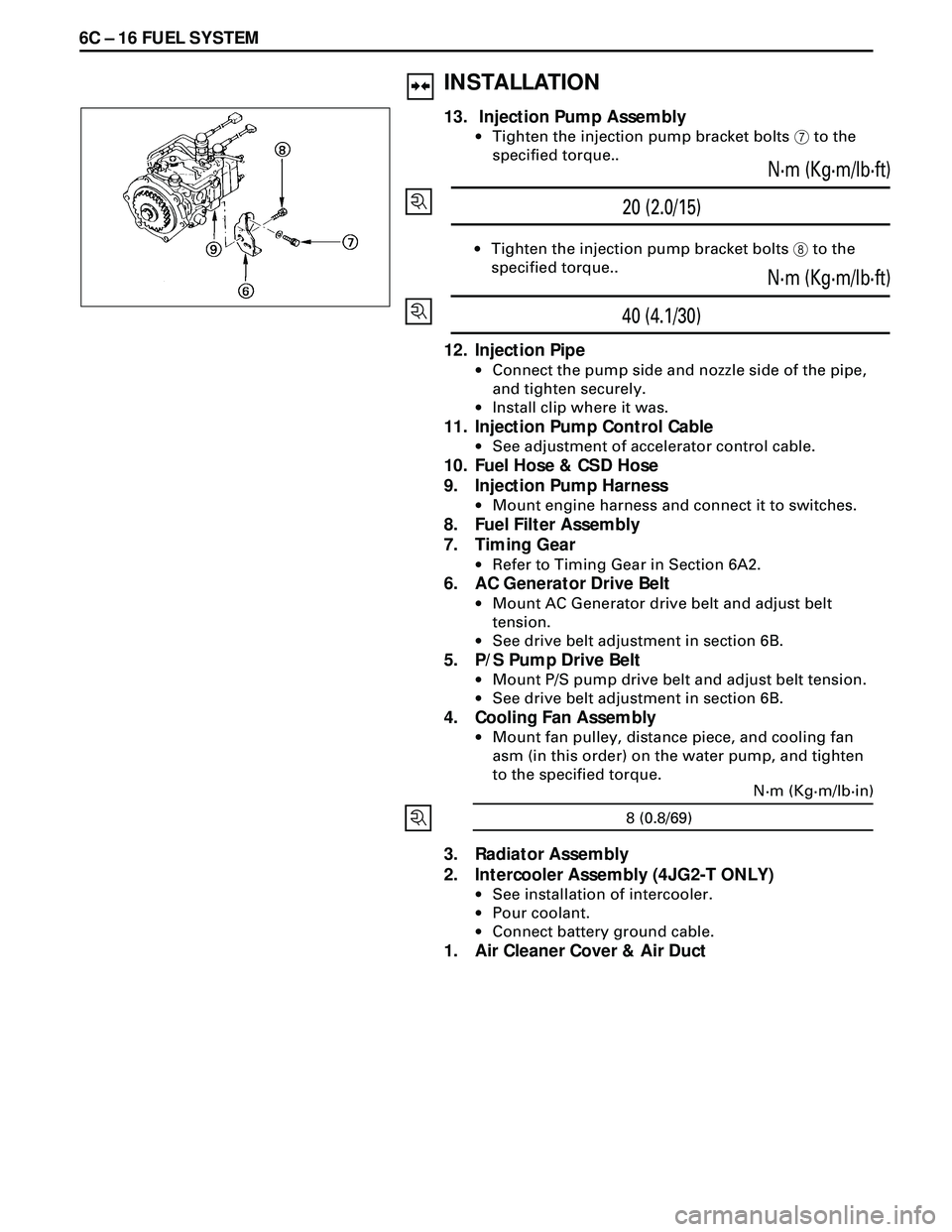

6C Ð 16 FUEL SYSTEM

20 (2.0/15)N·m (Kg·m/lb·ft)

·Tighten the injection pump bracket bolts 8 to the

specified torque..

40 (4.1/30)N·m (Kg·m/lb·ft)

12. Injection Pipe

·Connect the pump side and nozzle side of the pipe,

and tighten securely.

·Install clip where it was.

11. Injection Pump Control Cable

·See adjustment of accelerator control cable.

10. Fuel Hose & CSD Hose

9. Injection Pump Harness

·Mount engine harness and connect it to switches.

8. Fuel Filter Assembly

7. Timing Gear

·Refer to Timing Gear in Section 6A2.

6. AC Generator Drive Belt

·Mount AC Generator drive belt and adjust belt

tension.

·See drive belt adjustment in section 6B.

5. P/S Pump Drive Belt

·Mount P/S pump drive belt and adjust belt tension.

·See drive belt adjustment in section 6B.

4. Cooling Fan Assembly

·Mount fan pulley, distance piece, and cooling fan

asm (in this order) on the water pump, and tighten

to the specified torque.

3. Radiator Assembly

2. Intercooler Assembly (4JG2-T ONLY)

·See installation of intercooler.

·Pour coolant.

·Connect battery ground cable.

1. Air Cleaner Cover & Air Duct

INSTALLATION

13. Injection Pump Assembly

·Tighten the injection pump bracket bolts 7 to the

specified torque..

8 (0.8/69)N·m (Kg·m/lb·in)

Page 1691 of 3573

ENGINE ELECTRICAL 6D1 Ð 1

SECTION 6D

ENGINE ELECTRICAL

CONTENTS

Battery................................................................................................................................... Section 6D1

Starting System ................................................................................................................... Section 6D2

Charging System.................................................................................................................. Section 6D3

QOS-IIIPreheating System ................................................................................................. Section 6D6

SECTION 6D1

BATTERY

CONTENTS

General Description ......................................... 6D1Ð1

Diagnosis .......................................................... 6D1Ð1

On-Vehicle Service........................................... 6D1Ð3

Battery Charging .......................................... 6D1Ð3Jump Starting .............................................. 6D1Ð3

Removal and Installation of Battery .......... 6D1Ð4

GENERAL DESCRIPTION

There are six battery fluid caps at the top of the

battery. These are covered by a paper label.

The battery is completely sealed except for the six

small vent holes at the side. These vent holes per-

mit the escape of small amounts of gas generated

by the battery.

This type of battery has the following advantages

over conventional batteries:1. There is no need to add water during the entire

service life of the battery.

2. The battery protects itself against overcharging.

The battery will refuse to accept an excessive

charge.

(A conventional battery will accept an excessive

charge, resulting in gassing and loss of battery

fluid.)

3. The battery is much less vulnerable to self-

discharge than a conventional type battery.

DIAGNOSIS

1. VISUAL INSPECTION

Inspect the battery for obvious physical damage,

such as a cracked or broken case, which would

permit electrolyte loss.

Replace the battery if obvious physical damage is

discovered during inspection.

Check for any other physical damage and correct it

as necessary. If not, proceed to Step 2.

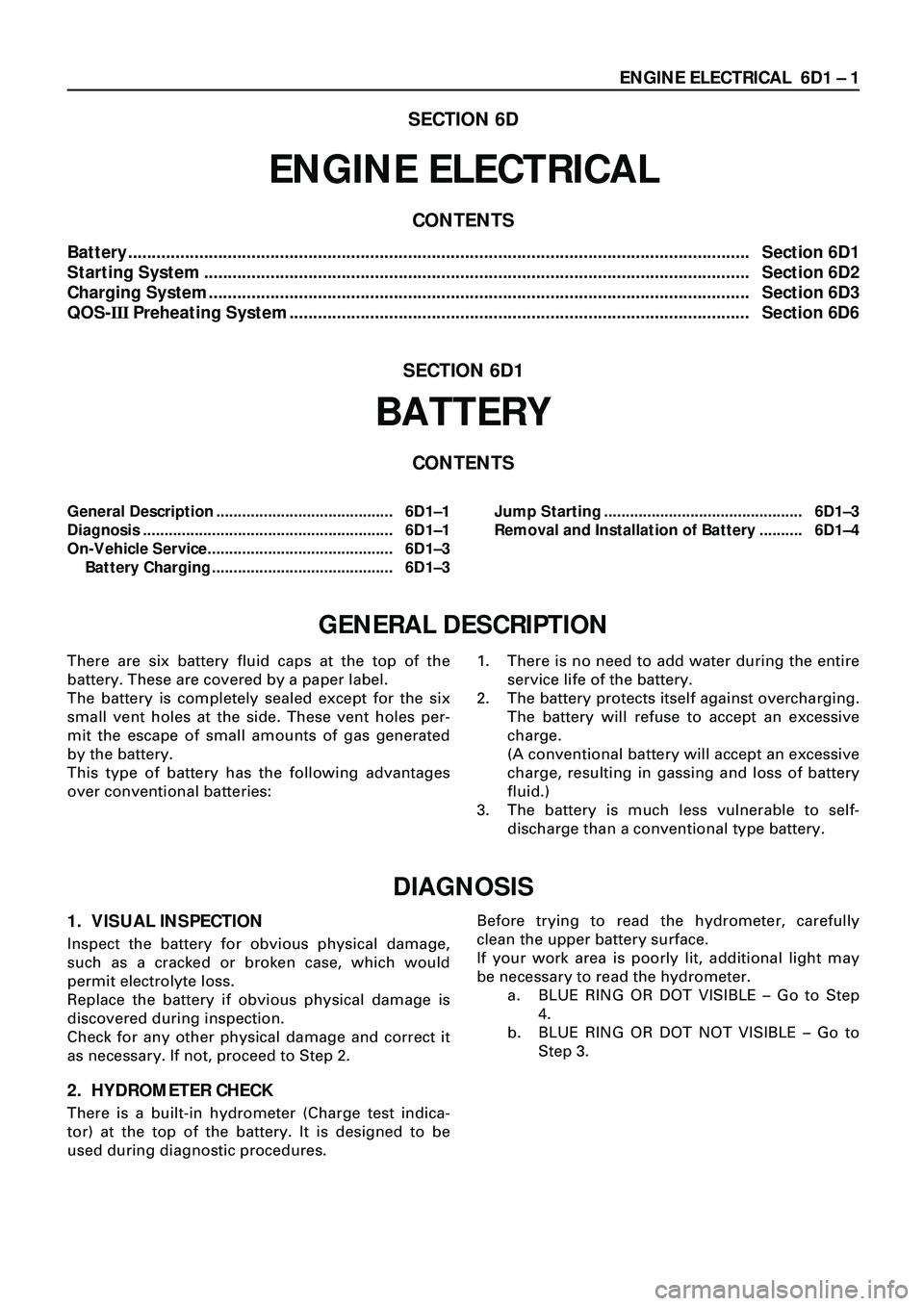

2. HYDROMETER CHECK

There is a built-in hydrometer (Charge test indica-

tor) at the top of the battery. It is designed to be

used during diagnostic procedures.Before trying to read the hydrometer, carefully

clean the upper battery surface.

If your work area is poorly lit, additional light may

be necessary to read the hydrometer.

a. BLUE RING OR DOT VISIBLE Ð Go to Step

4.

b. BLUE RING OR DOT NOT VISIBLE Ð Go to

Step 3.

Page 1692 of 3573

6D1 Ð 2 ENGINE ELECTRICAL

3. FLUID LEVEL CHECK

The fluid level should be between the upper level

line and lower level line on side of the battery.

a. CORRECT FLUID LEVEL Ð Charge the bat-

tery.

b. BELOW LOWER LEVEL Ð Replace battery.

4. VOLTAGE CHECK

(1) Put voltmeter test leads to battery terminals.

a. VOLTAGE IS 12.4V OR ABOVE Ð Go to

Step 5.

b. VOLTAGE IS UNDER 12.4V Ð Go to proce-

dure (2) below.

(2) Determine fast charge amperage from specifi-

cation. (See Main Data and Specifications in

this section).

Fast charge battery for 30 minutes at amperage

rate no higher than specified value.

Take voltage and amperage readings after

charge.

a. VOLTAGE IS ABOVE 16V AT BELOW 1/3 OF

AMPERAGE RATE Ð Replace battery.

b. VOLTAGE IS ABOVE 16V AT ABOVE 1/3 OF

AMPERAGE RATE Ð Drop charging voltage

to 15V and charge for 10 - 15 hours.

Then go to Step 5.

c. VOLTAGE IS BETWEEN 12V AND 16V Ð

Continue charging at the same rate for an

additional 3-1/2 hours. Then go to Step 5.

d. VOLTAGE IS BELOW 12V Ð Replace battery.

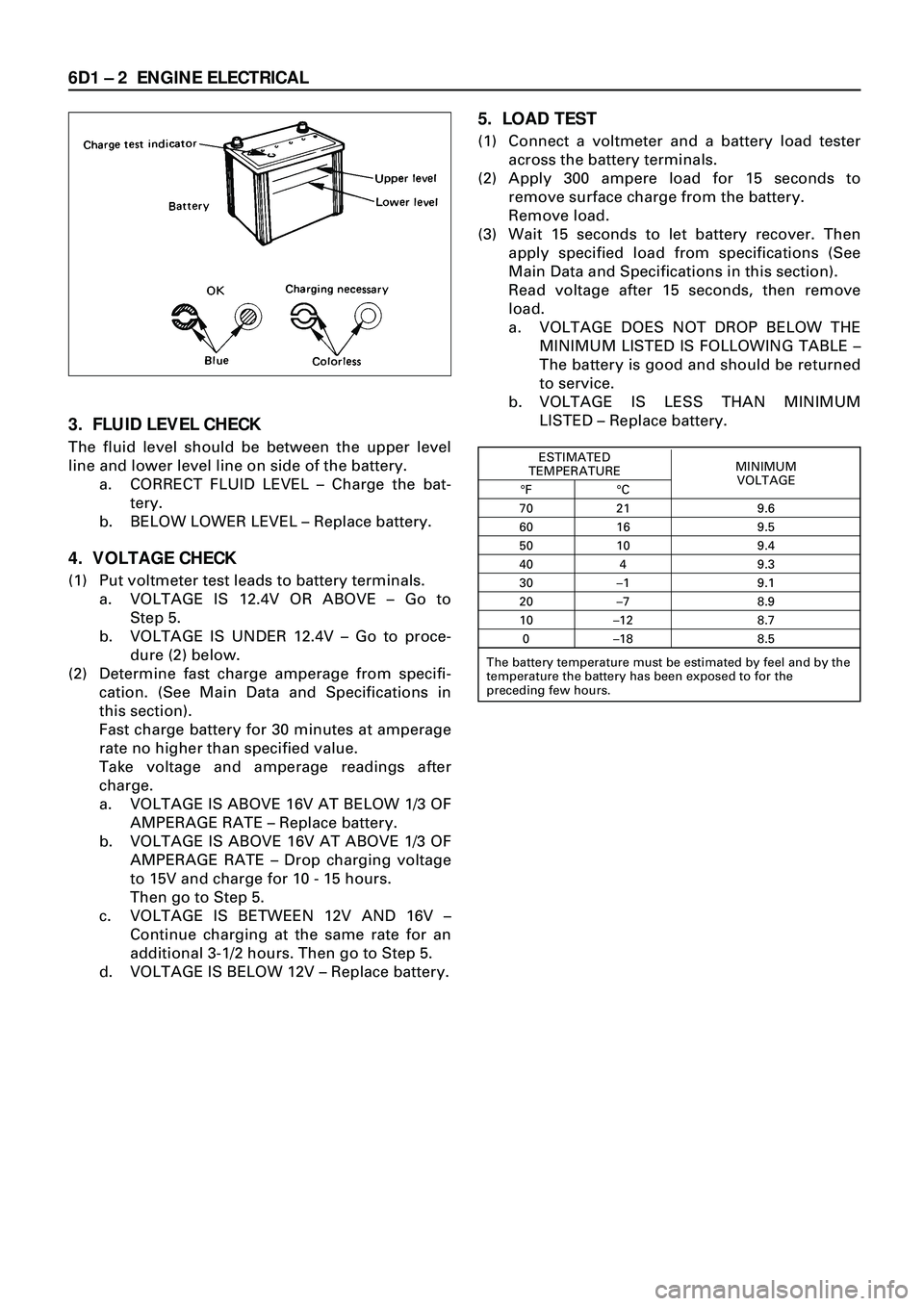

5. LOAD TEST

(1) Connect a voltmeter and a battery load tester

across the battery terminals.

(2) Apply 300 ampere load for 15 seconds to

remove surface charge from the battery.

Remove load.

(3) Wait 15 seconds to let battery recover. Then

apply specified load from specifications (See

Main Data and Specifications in this section).

Read voltage after 15 seconds, then remove

load.

a. VOLTAGE DOES NOT DROP BELOW THE

MINIMUM LISTED IS FOLLOWING TABLE Ð

The battery is good and should be returned

to service.

b. VOLTAGE IS LESS THAN MINIMUM

LISTED Ð Replace battery.

ESTIMATED

MINIMUM

TEMPERATURE

VOLTAGE

¡F ¡C

70 21 9.6

60 16 9.5

50 10 9.4

40 4 9.3

30 Ð1 9.1

20 Ð7 8.9

10 Ð12 8.7

0 Ð18 8.5

The battery temperature must be estimated by feel and by the

temperature the battery has been exposed to for the

preceding few hours.

Page 1693 of 3573

ENGINE ELECTRICAL 6D1 Ð 3

BATTERY CHARGING

Observe the following safety precautions when

charging the battery:

1. Never attempt to charge the battery when the

fluid level is below the lower level line on the

side of the battery. In this case, the battery

must be replaced.

2. Pay close attention to the battery during the

charging procedure.

Battery charging should be discontinued or the

rate of charge reduced if the battery feels hot to

the touch.

Battery charging should be discontinued or the

rate of charge reduced if the battery begins to

gas or spew electrolyte from the vent holes.

3. In order to more easily view the hydrometer

blue dot or ring, it may be necessary to jiggle or

tilt the battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be

either quick-charged or slow-charged in the

same manner as other batteries.

Whichever method you decide to use, be sure

that you completely charge the battery. Never

partially charge the battery.

JUMP STARTING

JUMP STARTING WITH AN AUXILIARY

(BOOSTER) BATTERY

CAUTION:

Never push or tow the vehicle in an attempt to

start it. Serious damage to the emission system

as well as other vehicle parts will result.

Treat both the discharged battery and the

booster battery with great care when using

jumper cables. Carefully follow the jump

starting procedure, being careful at all times to

avoid sparking.

WARNING:

Failure to carefully follow the jump starting

procedure could result in the following:

1. Serious personal injury, particulaly to

your eyes.

2. Property damage from a battery explo-

sion, battery acid, or an electrical fire.

3. Damage to the electronic components of

one or both vehicles particularly. Never expose the battery to an open flame or elec-

trical spark. Gas generated by the battery may catch

fire or explode.

Remove any rings, watches, or other jewelry before

working around the battery. Protect your eyes by

wearing an approved set of goggles.

Never allow battery fluid to come in contact with

your eyes or skin.

Never allow battery fluid to come in contact with

fabrics or painted surfaces.

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your

eyes, skin, fabric, or a painted surface, immediately

and thoroughly rinse the affected area with clean

tap water.

Never allow metal tools or jumper cables to come

in contact with the positive battery terminal, or any

other metal surface of the vehicle. This will protect

against a short circuit.

Always keep batteries out of the reach of young

children.

JUMP STARTING PROCEDURE

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector lever in the

ÒPARKÓ position.

If the vehicle is equipped with a manual trans-

mission place the shift lever in the ÒNEUTRALÓ

position.

Turn ÒOFFÓ the ignition.

Turn ÒOFFÓ all lights and any other accessory

requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer

is completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the posi-

tive terminal of the booster battery.

Attach the other end of the same cable to the

positive terminal of the discharged battery.

Do not allow the vehicles to touch each other.

This will cause a ground connection, effectively

neutralizing the charging procedure.

Be sure that the booster battery has a 12 volt

rating.

4. Attach one end of the remaining cable to the

negative terminal of the booster battery.

Attach the other end of the same cable to a

solid engine ground (such as the A/C com-

pressor bracket or the generator mounting

bracket) of the vehicle with the discharged bat-

tery.

This ground connection must be at least 450

mm (18 in) from the battery of the vehicle

whose battery is being charged.

ON-VEHICLE SERVICE

Page 1694 of 3573

6D1 Ð 4 ENGINE ELECTRICAL

WARNING:

Never attach the end of the jumper cable

directly to the negative terminal of the dead

battery.

5. Start the engine of the vehicle with the good

battery.

Make sure that all unnecessary electrical acces-

sories have been turned ÒOFFÓ.

6. Start the engine of the vehicle with the dead

battery.

7. To remove the jumper cables, follow the above

directions in the reverse order.

Be sure to first disconnect the negative cable

from the vehicle with the discharged battery.

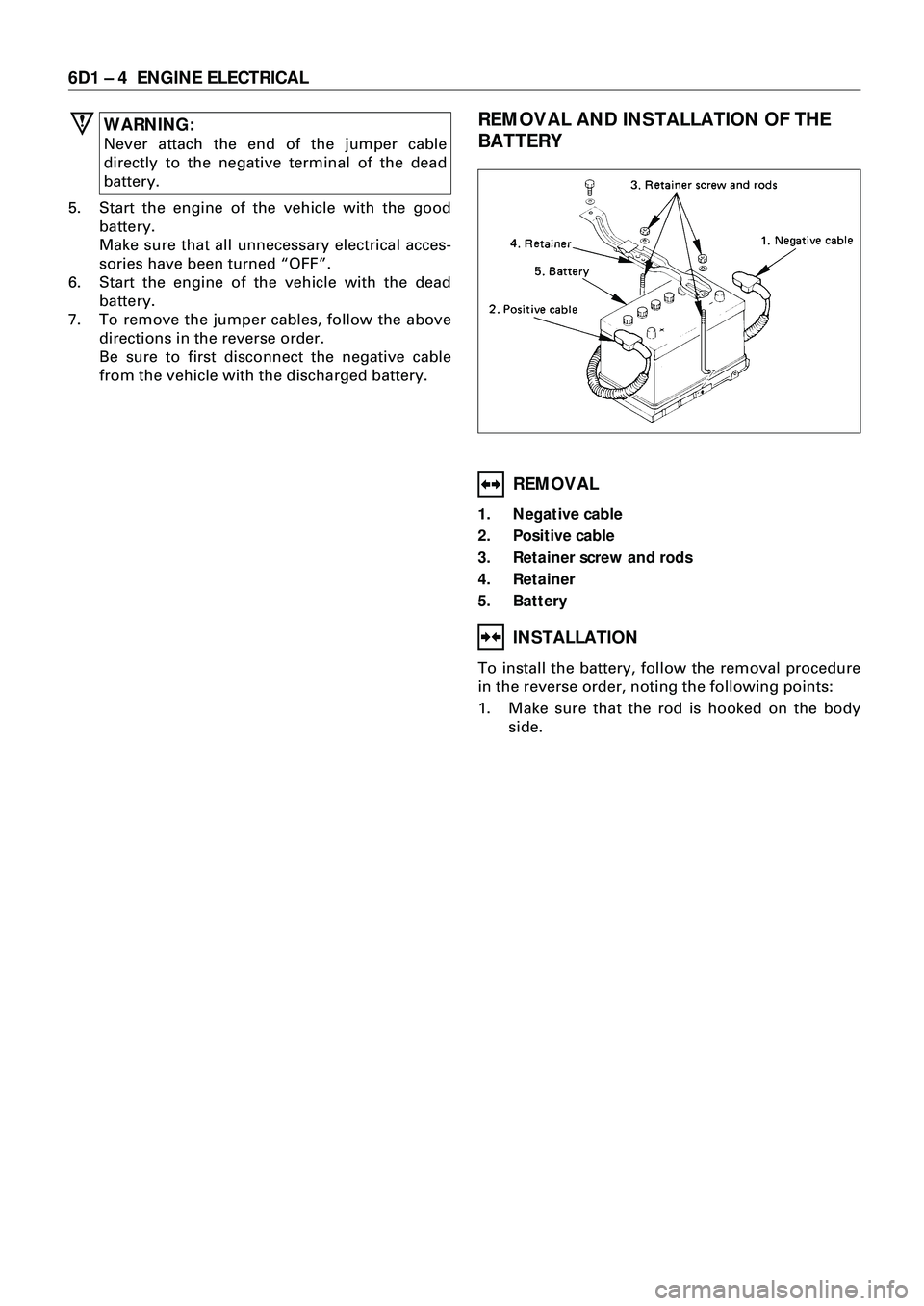

REMOVAL AND INSTALLATION OF THE

BATTERY

REMOVAL

1. Negative cable

2. Positive cable

3. Retainer screw and rods

4. Retainer

5. Battery

INSTALLATION

To install the battery, follow the removal procedure

in the reverse order, noting the following points:

1. Make sure that the rod is hooked on the body

side.

Page 1695 of 3573

STARTING SYSTEM 6D2 Ð 1

SECTION 6D2

STARTING SYSTEM

CONTENTS

PAGE

General Description .................................................................................................................. 6D2- 1

On-Vehicle Service .................................................................................................................... 6D2- 3

Unit Repair ................................................................................................................................. 6D2- 5

GENERAL DESCRIPTION

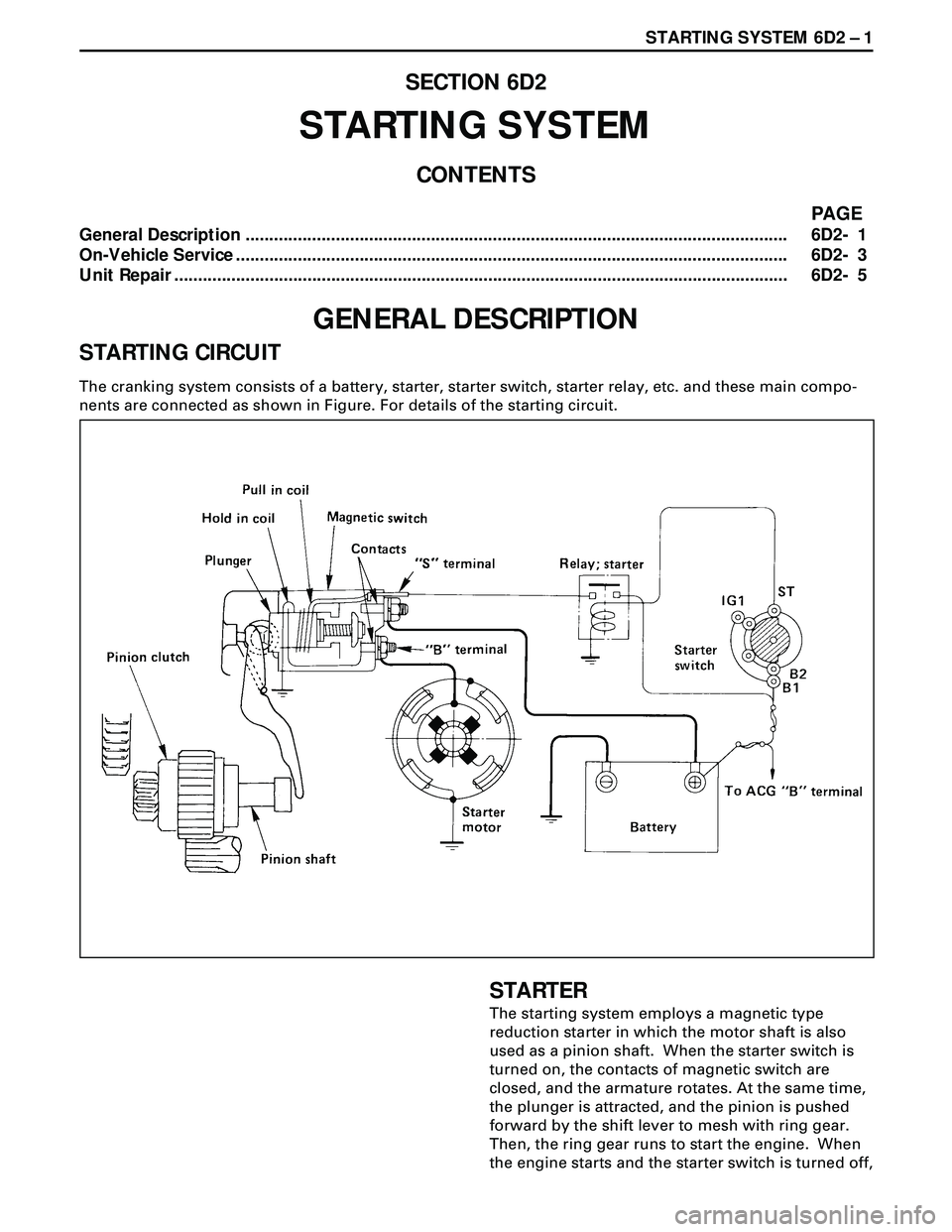

STARTING CIRCUIT

The cranking system consists of a battery, starter, starter switch, starter relay, etc. and these main compo-

nents are connected as shown in Figure. For details of the starting circuit.

STARTER

The starting system employs a magnetic type

reduction starter in which the motor shaft is also

used as a pinion shaft. When the starter switch is

turned on, the contacts of magnetic switch are

closed, and the armature rotates. At the same time,

the plunger is attracted, and the pinion is pushed

forward by the shift lever to mesh with ring gear.

Then, the ring gear runs to start the engine. When

the engine starts and the starter switch is turned off,