air conditioning ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 4 of 3573

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

00 SERVICE INFORMATION

1A HEATING AND VENTILATION

1B AIR CONDITIONING

1D COMPRESSOR OVERHAUL

Page 16 of 3573

GENERAL REPAIR INSTRUCTIONS

1. Park the vehicle on level ground and chock the

front or rear wheels before lifting the vehicle.

2. Use covers on the vehicle body, seats, and

floor to prevent damage and/or

contaminations.

3. Disconnect the grounding cable from the

battery before performing service operations.

This will prevent cable damage or burning due

to shortcircuiting.

4. Raise the vehicle with a jack set against the

recommended lifting points (see ÒLifting

instructionsÓ in this section).

5. Support the vehicle on chassis stands.

6. Handle brake fluid and antifreeze solution with

great care.

Spilling these liquids on painted surfaces will

damage the paint.

7. The use of the proper tool(s) and special tool(s)

where specified is essential to efficient,

reliable, and safe service operations.

8. Always use genuine ISUZU replacement parts.

9. Discard used cotter pins, gasket, plastic clips,

O-rings, oil seals, lock washers, and self-

locking nuts at disassembly.

Normal function of these parts cannot be

guaranteed if they are reused.

10. Keep the disassembled parts neatly in groups.

This will facilitate smooth and correct

reassembly.11. Keep fixing nuts and bolts separate.

Fixing nuts and bolts vary in hardness and

design according to installation positions.

12. Clean all parts before inspection or

reassembly.

13. Clean the oil ports and other openings with

compressed air to make certain that they are

free of dirt and obstructions.

14. Lubricate the rotating and sliding faces of all

moving parts with oil or grease before

installation.

15. Use the recommended liquid gasket to prevent

leakage.

16. Carefully observe all nut and bolt torque

specifications.

17. When service operation is completed, make a

final check to be sure service has been done

properly and problem has been corrected.

18. When removing or replacing parts that require

refrigerant to be discharged from the air

conditioning system, be sure to use the

following tools to recover and recycle the

Refrigerant-134a (R-134a).

For 134a:

Use the R-134a Refrigerant Recovery/Recovery/

Recycling/Recharging/System (ACR

4) or its

equivalent to prevent the discharge of

refrigerant into the air.

0AÐ2 GENERAL INFORMATION

Page 26 of 3573

ABBREVIATIONS CHARTS

LIST OF AUTOMOTIVE ABBREVIATIONS WHICH MAY BE USED IN THIS MANUAL

A Ð Ampere(s)

ABS Ð Antilock Brake System

A/C Ð Air Conditioning

ACCEL Ð Accelerator

ACC Ð Accessary

Adj Ð Adjust

A/F Ð Air Fuel Ratio

AIR Ð Air Injection Reaction System

ALDL Ð Assembly Line Diagnostic Link

Alt Ð Altitude

AMP Ð Ampere(s)

ANT Ð Antenna

APS Ð Absolute Pressure Sensor

ASM Ð Assembly

A/T Ð Automatic Transmission/Transaxle

ATDC Ð After Top Dead Center

Auth Ð Authority

Auto Ð Automatic

BARO Ð Barometic

Bat Ð Battery

Bat+ Ð Battery Positive Terminal

Bbl Ð Barrel

BCM Ð Body Control Module

BHP Ð Brake Horsepower

BP Ð Back Pressure

BTDC Ð Before Top Dead Center

¡C ÐDegrees Celsius

Cat. Conv. Ð Catalytic Converter

cc Ð Cubic Centimeter

CCC Ð Computer Command Control

CCOT Ð Cycling Clutch Orifice Tube

CCP Ð Controlled Canister Purge

CID Ð Cubic Inch Displacement

CL Ð Closed Loop

CLCC Ð Closed Loop Carburetor Control

CO Ð Carbon Monoxide

Coax Ð Coaxial

Conn Ð Connector

Conv Ð Converter

CP Ð Canister Purge

CPS Ð Central Power Supply

Crank Ð Crankshaft

CTS Ð Coolant Temperature Sensor

Cu.In. Ð Cubic Inch

CV Ð Constant Velocity

Cyl Ð Cylinder(s)

C

3I Ð Computer Controlled Coil Ignition

DBM Ð Dual Bed Monolith

Diff Ð Differential

DIS Ð Direct Ignition System

Dist ÐDistributor

DOHC Ð Double Overhead Camshaft

DVM Ð Digital Voltmeter (10 meg.)

DVOM Ð Digital Volt Ohmmeter

DVDV Ð Differential Vacuum Delay Valve

EAC ÐElectric Air Control

EAS Ð Electric Air Switching

EBCM Ð Electronic Brake Control Module

ECC Ð Electronic Climate Control

ECM Ð Electronic Control Module

ECU Ð Electronic Control Unit

Ð Engine Calibration Unit (PROM)

EECS Ð Evaporative Emission Control System

EFE Ð Early Fuel Evaporation

EFI Ð Electronic Fuel Injection

EGR Ð Exhaust Gas Recirculation

EGR/TVS Ð Exhaust Gas Recirculation/Thermostatic

Vacuum Switch

ELC Ð Electronic Level Control

ESC Ð Electronic Spark Control

EST Ð Electronic Spark Control

ETR Ð Electronically Tuned Receiver

EVRV Ð Electronic Vacuum Regulator Valve (EGR)

Exh Ð Exhaust

¡F Ð Degrees Fahrenheit

FF Ð Front Drive Front Engine

FL Ð Fusible Link

FLW Ð Fusible Link Wire

FRT ÐFront

FWD Ð Front Wheel Drive

4WD Ð Four Wheel Drive

4x4 Ð Four Wheel Drive

4 A/T Ð Four Speed Automatic Transmission/Transaxle

Gal Ð Gallon

Gen Ð Generator

Gov Ð Governor

g Ð Gram

Harn Ð Harness

HC Ð Hydrocarbons

HD ÐHeavy Duty

HEI Ð High Energy Ignition

Hg Ð Mercury

HiAlt Ð High Altitude

HVAC Ð Heater-Vent-Air Conditioning

IAC Ð Idle Air Control

IC Ð Integrated Circuit

ID Ð Identification

Ð Inside Diameter

IDI Ð Integrated Direct Ignition

IGN Ð Ignition

ILC Ð Idle Load Compensator

INJ ÐInjection

IP Ð Instrument Panel

IPC Ð Instrument Panel Cluster

INT Ð Intake

J/B Ð Junction Block

km Ð Kilometers

km/h Ð Kilometer per Hour

kPa Ð KiloPascals

KV Ð Kilovolts (thousands of volts)

KW Ð Kilowatts

0AÐ12 GENERAL INFORMATION

Page 42 of 3573

SERVICE INFORMATION 00 Ð 3

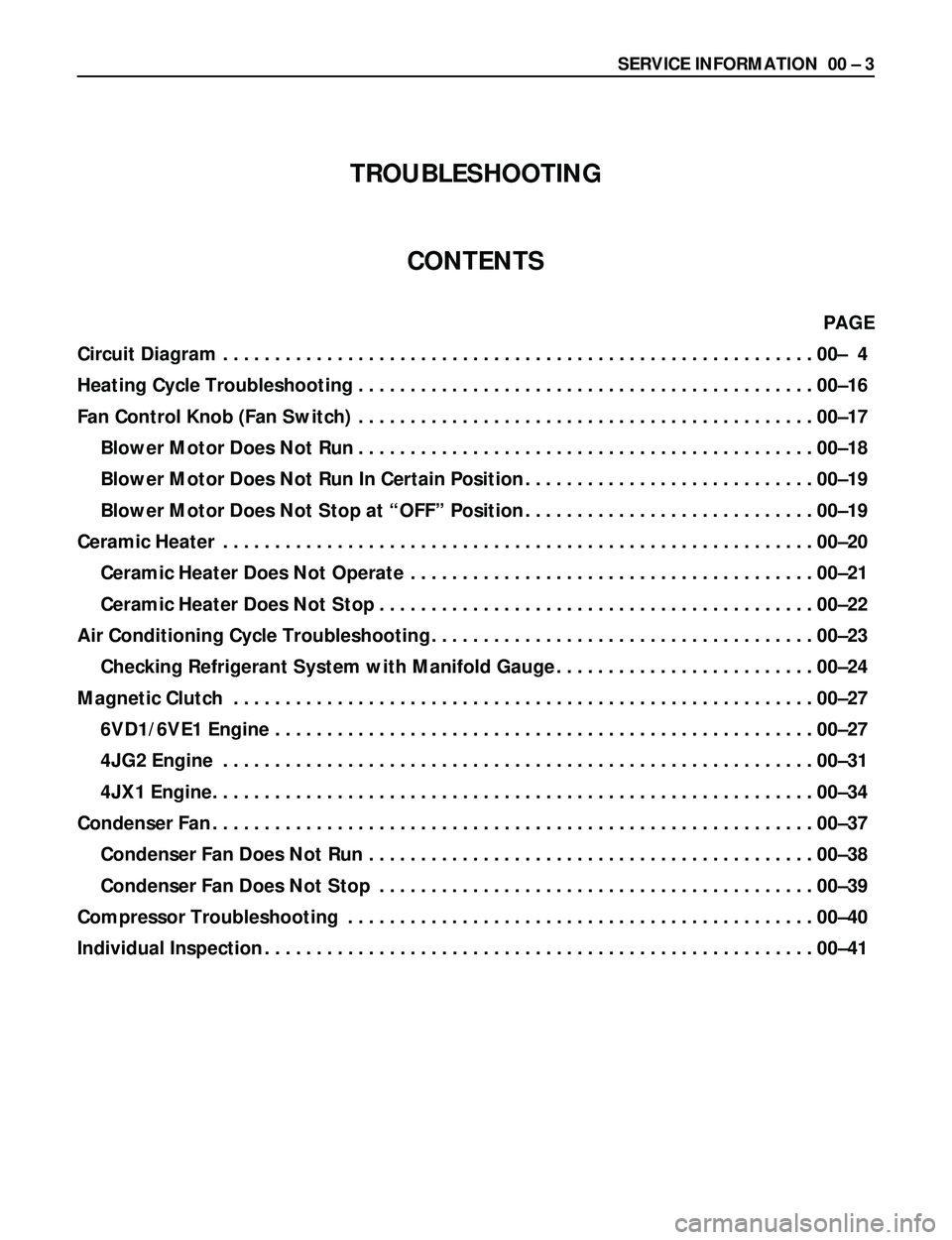

TROUBLESHOOTING

CONTENTS

PAGE

Circuit Diagram.........................................................00Ð 4

Heating Cycle Troubleshooting............................................00Ð16

Fan Control Knob (Fan Switch)............................................00Ð17

Blower Motor Does Not Run............................................00Ð18

Blower Motor Does Not Run In Certain Position............................00Ð19

Blower Motor Does Not Stop at ÒOFFÓ Position............................00Ð19

Ceramic Heater.........................................................00Ð20

Ceramic Heater Does Not Operate.......................................00Ð21

Ceramic Heater Does Not Stop..........................................00Ð22

Air Conditioning Cycle Troubleshooting.....................................00Ð23

Checking Refrigerant System with Manifold Gauge.........................00Ð24

Magnetic Clutch........................................................00Ð27

6VD1/6VE1 Engine....................................................00Ð27

4JG2 Engine.........................................................00Ð31

4JX1 Engine..........................................................00Ð34

Condenser Fan..........................................................00Ð37

Condenser Fan Does Not Run...........................................00Ð38

Condenser Fan Does Not Stop..........................................00Ð39

Compressor Troubleshooting.............................................00Ð40

Individual Inspection.....................................................00Ð41

Page 62 of 3573

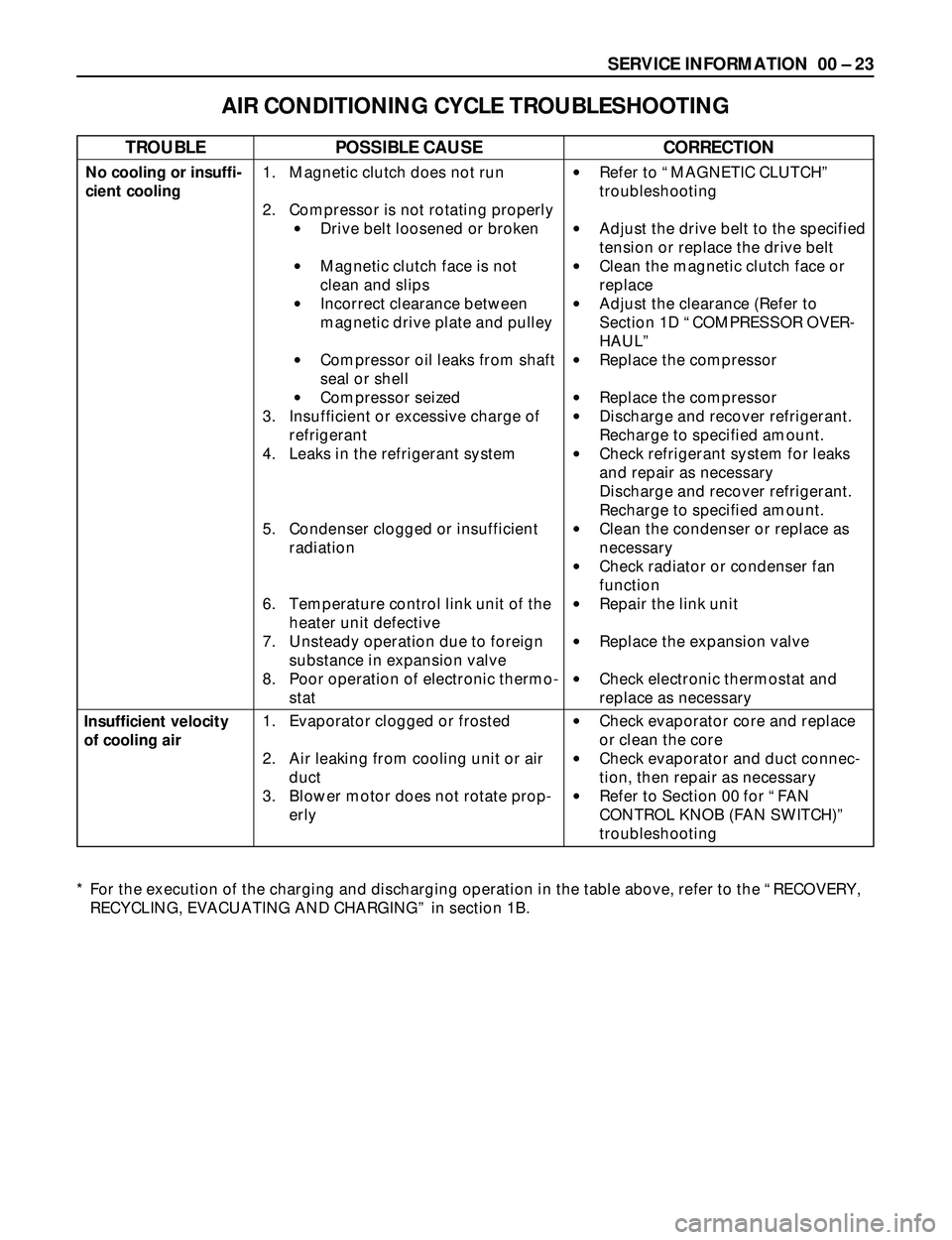

SERVICE INFORMATION 00 Ð 23

AIR CONDITIONING CYCLE TROUBLESHOOTING

No cooling or insuffi-

cient cooling

Insufficient velocity

of cooling air1. Magnetic clutch does not run

2. Compressor is not rotating properly

·Drive belt loosened or broken

·Magnetic clutch face is not

clean and slips

·Incorrect clearance between

magnetic drive plate and pulley

·Compressor oil leaks from shaft

seal or shell

·Compressor seized

3. Insufficient or excessive charge of

refrigerant

4. Leaks in the refrigerant system

5. Condenser clogged or insufficient

radiation

6. Temperature control link unit of the

heater unit defective

7. Unsteady operation due to foreign

substance in expansion valve

8. Poor operation of electronic thermo-

stat

1. Evaporator clogged or frosted

2. Air leaking from cooling unit or air

duct

3. Blower motor does not rotate prop-

erly·Refer to ÒMAGNETIC CLUTCHÓ

troubleshooting

·Adjust the drive belt to the specified

tension or replace the drive belt

·Clean the magnetic clutch face or

replace

·Adjust the clearance (Refer to

Section 1D ÒCOMPRESSOR OVER-

HAULÓ

·Replace the compressor

·Replace the compressor

·Discharge and recover refrigerant.

Recharge to specified amount.

·Check refrigerant system for leaks

and repair as necessary

Discharge and recover refrigerant.

Recharge to specified amount.

·Clean the condenser or replace as

necessary

·Check radiator or condenser fan

function

·Repair the link unit

·Replace the expansion valve

·Check electronic thermostat and

replace as necessary

·Check evaporator core and replace

or clean the core

·Check evaporator and duct connec-

tion, then repair as necessary

·Refer to Section 00 for ÒFAN

CONTROL KNOB (FAN SWITCH)Ó

troubleshooting

* For the execution of the charging and discharging operation in the table above, refer to the ÒRECOVERY,

RECYCLING, EVACUATING AND CHARGINGÓ in section 1B.

TROUBLEPOSSIBLE CAUSECORRECTION

Page 64 of 3573

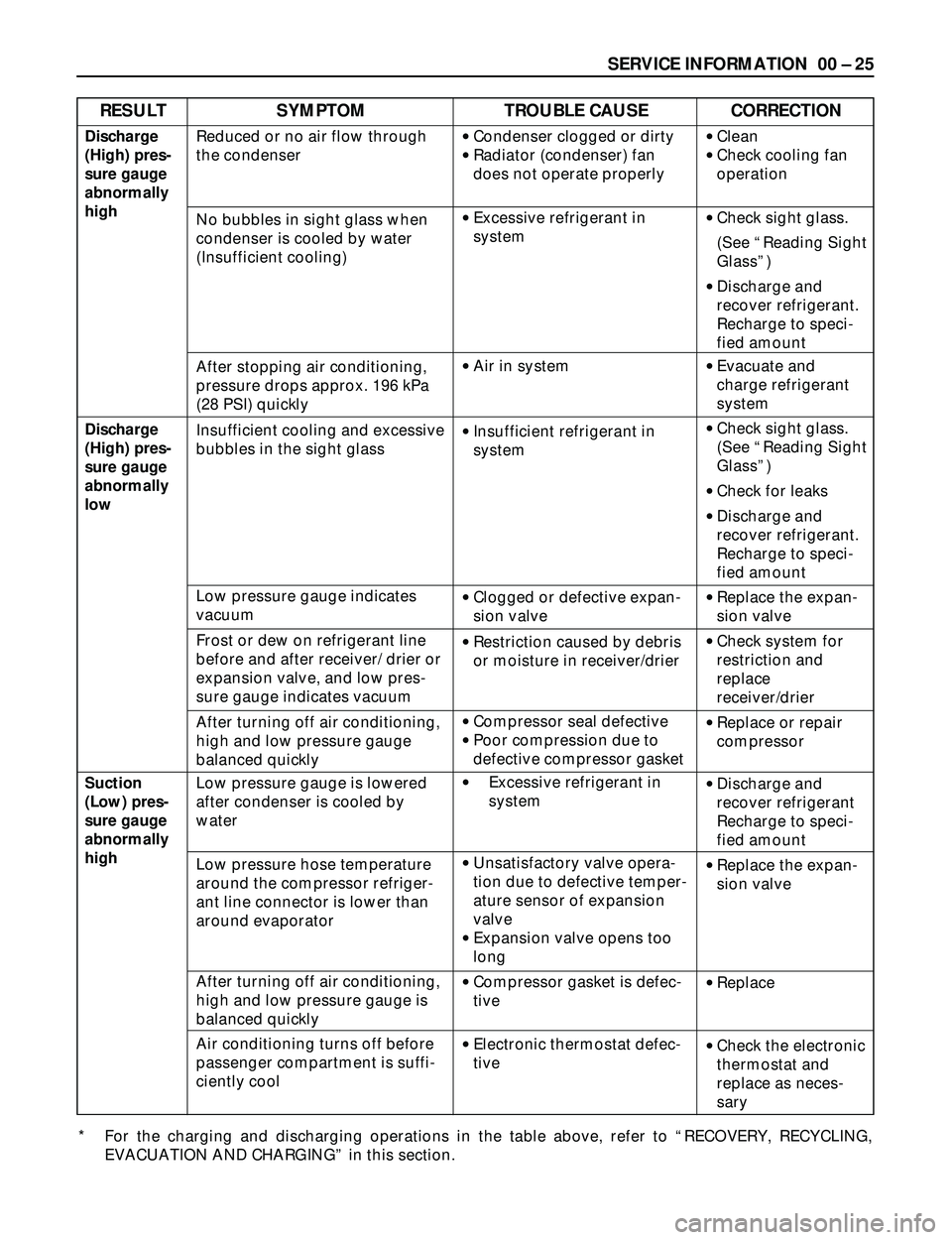

RESULT SYMPTOM TROUBLE CAUSE CORRECTION

SERVICE INFORMATION 00 Ð 25

Reduced or no air flow through

the condenser

No bubbles in sight glass when

condenser is cooled by water

(Insufficient cooling)

After stopping air conditioning,

pressure drops approx. 196 kPa

(28 PSI) quickly

Insufficient cooling and excessive

bubbles in the sight glass

Low pressure gauge indicates

vacuum

Frost or dew on refrigerant line

before and after receiver/ drier or

expansion valve, and low pres-

sure gauge indicates vacuum

After turning off air conditioning,

high and low pressure gauge

balanced quickly

Low pressure gauge is lowered

after condenser is cooled by

water

Low pressure hose temperature

around the compressor refriger-

ant line connector is lower than

around evaporator

After turning off air conditioning,

high and low pressure gauge is

balanced quickly

Air conditioning turns off before

passenger compartment is suffi-

ciently cool·Condenser clogged or dirty

·Radiator (condenser) fan

does not operate properly

·Excessive refrigerant in

system

·Air in system

·Insufficient refrigerant in

system

·Clogged or defective expan-

sion valve

·Restriction caused by debris

or moisture in receiver/drier

·Compressor seal defective

·Poor compression due to

defective compressor gasket

·Excessive refrigerant in

system

·Unsatisfactory valve opera-

tion due to defective temper-

ature sensor of expansion

valve

·Expansion valve opens too

long

·Compressor gasket is defec-

tive

·Electronic thermostat defec-

tive·Clean

·Check cooling fan

operation

·Check sight glass.

(See ÒReading Sight

GlassÓ)

·Discharge and

recover refrigerant.

Recharge to speci-

fied amount

·Evacuate and

charge refrigerant

system

·Check sight glass.

(See ÒReading Sight

GlassÓ)

·Check for leaks

·Discharge and

recover refrigerant.

Recharge to speci-

fied amount

·Replace the expan-

sion valve

·Check system for

restriction and

replace

receiver/drier

·Replace or repair

compressor

·Discharge and

recover refrigerant

Recharge to speci-

fied amount

·Replace the expan-

sion valve

·Replace

·Check the electronic

thermostat and

replace as neces-

saryDischarge

(High) pres-

sure gauge

abnormally

high

Discharge

(High) pres-

sure gauge

abnormally

low

Suction

(Low) pres-

sure gauge

abnormally

high

* For the charging and discharging operations in the table above, refer to ÒRECOVERY, RECYCLING,

EVACUATION AND CHARGINGÓ in this section.

Page 66 of 3573

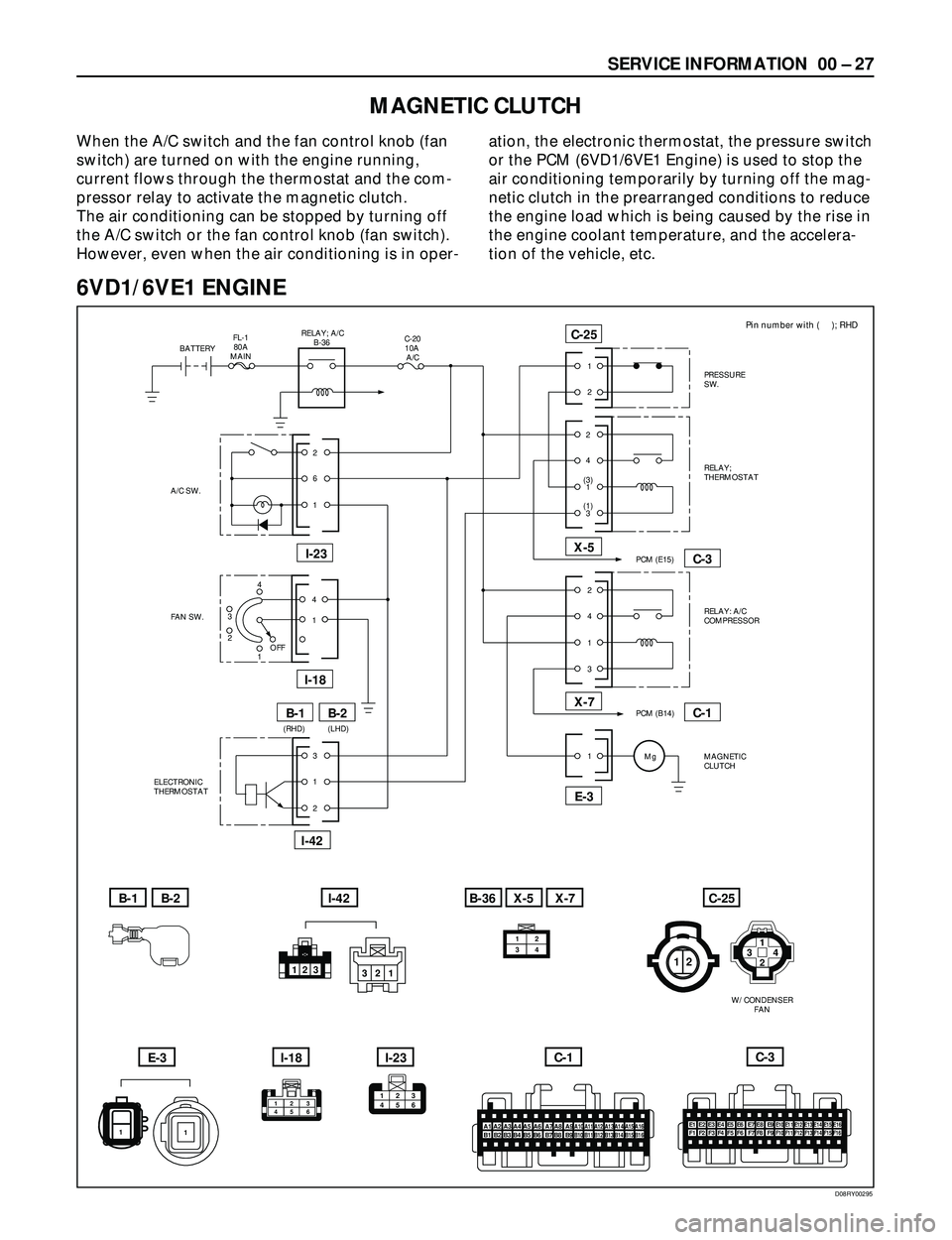

SERVICE INFORMATION 00 Ð 27

MAGNETIC CLUTCH

When the A/C switch and the fan control knob (fan

switch) are turned on with the engine running,

current flows through the thermostat and the com-

pressor relay to activate the magnetic clutch.

The air conditioning can be stopped by turning off

the A/C switch or the fan control knob (fan switch).

However, even when the air conditioning is in oper-ation, the electronic thermostat, the pressure switch

or the PCM (6VD1/6VE1 Engine) is used to stop the

air conditioning temporarily by turning off the mag-

netic clutch in the prearranged conditions to reduce

the engine load which is being caused by the rise in

the engine coolant temperature, and the accelera-

tion of the vehicle, etc.

123

45 6

RELAY; A/C

B-36C-20

10A

A/C FL-1

80A

MAIN

1

2

B-2

C-25

2

4

X-5

1

3 (3)

(1)

4

13

24

1

A/C SW.

FAN SW.

I-23

PRESSURE

SW.

RELAY;

THERMOSTAT

B-2

X-7 C-25

C-1C-3E-3I-23

BATTERY

X-7

RELAY: A/C

COMPRESSOR

1

E-3

MAGNETIC

CLUTCHMg

OFF

I-18

2

6

1

321123

12

3412

11

213

5 46

I-18

X-5

B-1(LHD) (RHD)

B-1

1

2 34

W/ CONDENSER

FAN

2

4

1

3

C-3PCM (E15)

C-1PCM (B14)

3

1

2

ELECTRONIC

THERMOSTAT

I-42

I-42B-36

Pin number with ( ); RHD

A1 A2 A3 A4 A5 A6 A7 A8 A9A10 A11 A12 A13 A14 A15 A16B1 B2 B3 B4 B5 B6 B7 B8 B9B10 B11 B12 B13 B14 B15 B16E1 E2 E3 E4 E5 E6 E7 E8 E9E10 E11 E12 E13 E14 E15 E16F1 F2 F3 F4 F5 F6 F7 F8 F9F10 F11 F12 F13 F14 F15 F16

6VD1/6VE1 ENGINE

D08RY00295

Page 89 of 3573

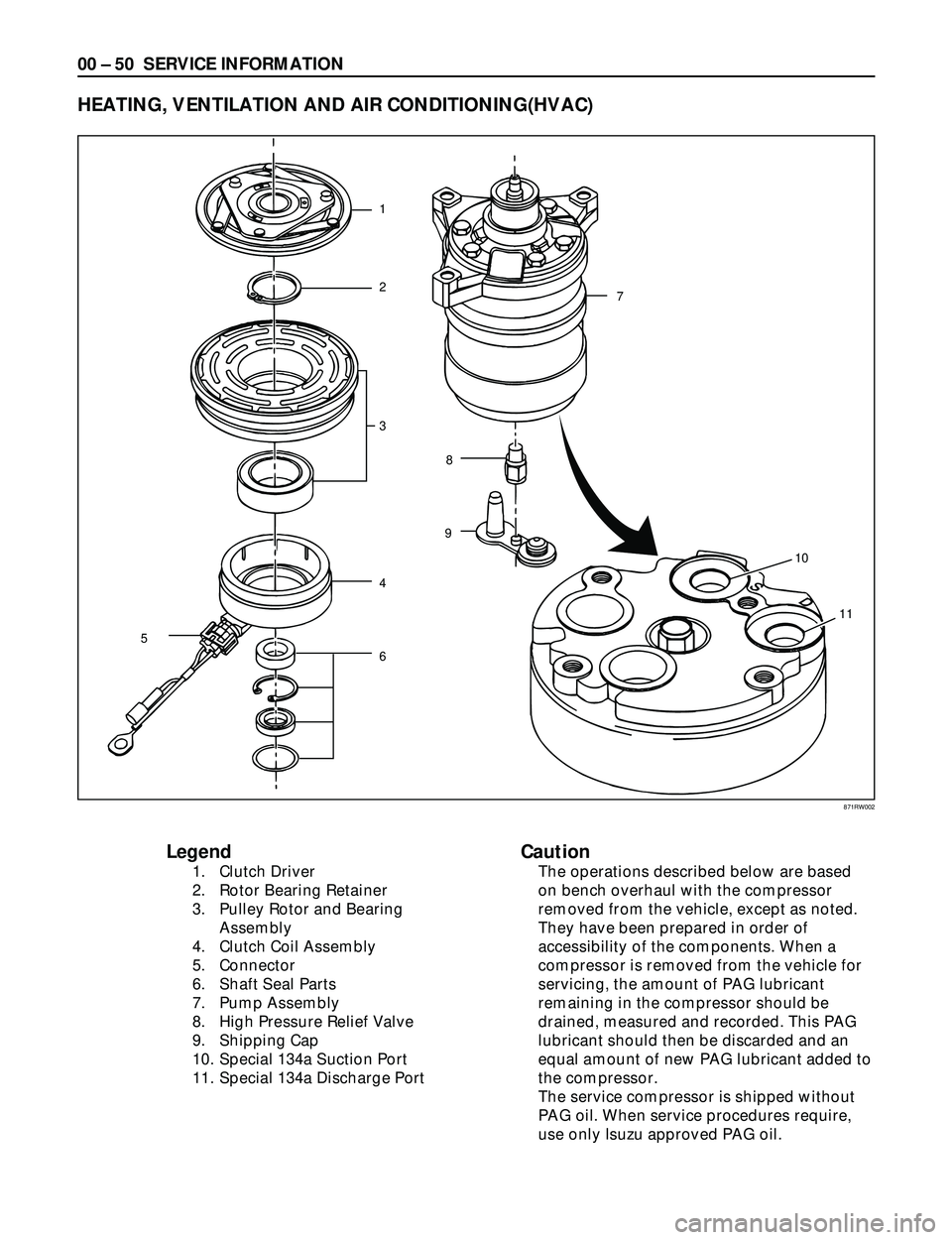

00 Ð 50 SERVICE INFORMATION

Legend

1. Clutch Driver

2. Rotor Bearing Retainer

3. Pulley Rotor and Bearing

Assembly

4. Clutch Coil Assembly

5. Connector

6. Shaft Seal Parts

7. Pump Assembly

8. High Pressure Relief Valve

9. Shipping Cap

10. Special 134a Suction Port

11. Special 134a Discharge Port

Caution

The operations described below are based

on bench overhaul with the compressor

removed from the vehicle, except as noted.

They have been prepared in order of

accessibility of the components. When a

compressor is removed from the vehicle for

servicing, the amount of PAG lubricant

remaining in the compressor should be

drained, measured and recorded. This PAG

lubricant should then be discarded and an

equal amount of new PAG lubricant added to

the compressor.

The service compressor is shipped without

PAG oil. When service procedures require,

use only Isuzu approved PAG oil.

HEATING, VENTILATION AND AIR CONDITIONING(HVAC)

1

2

3

4

5

68

97

10

11

871RW002

Page 97 of 3573

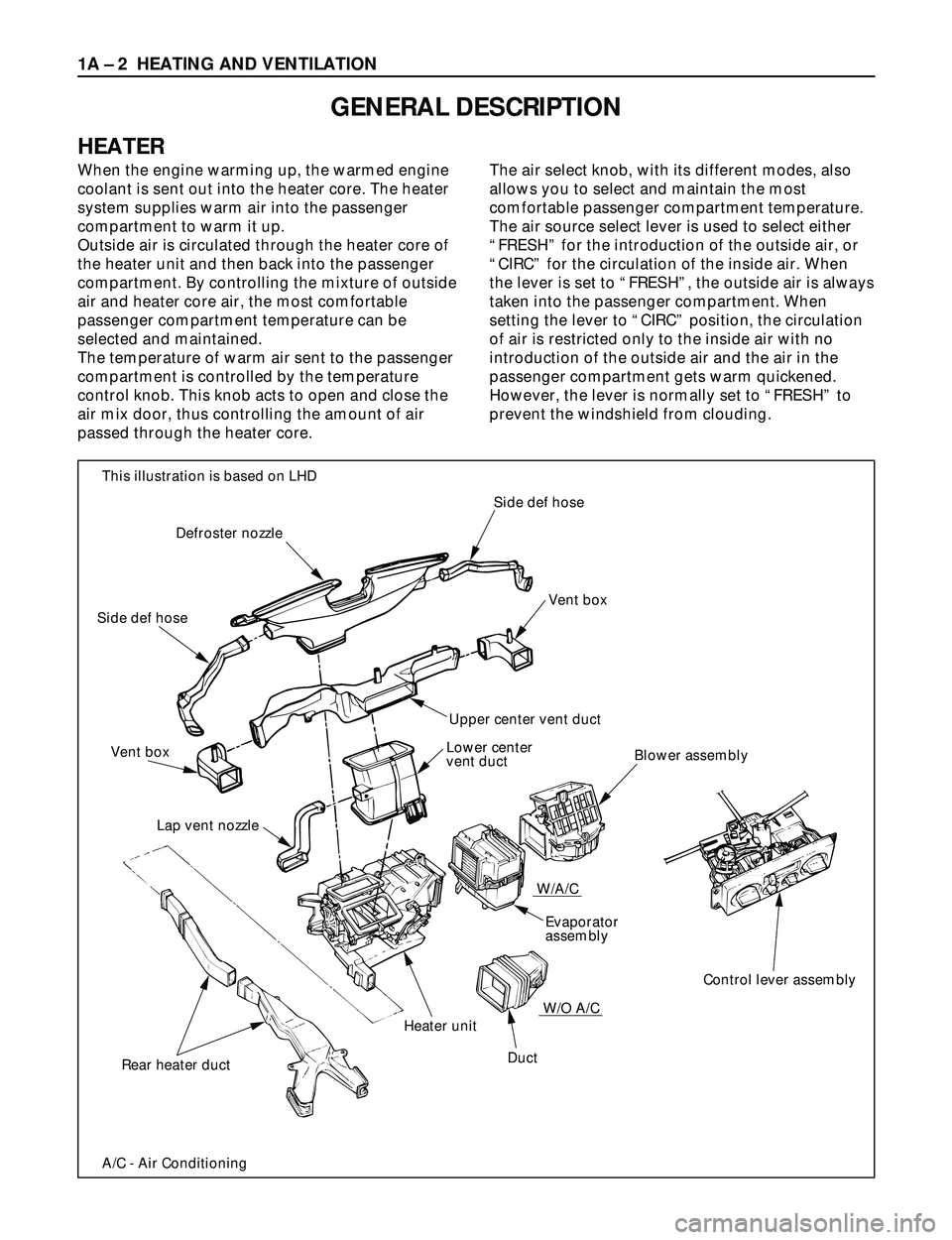

When the engine warming up, the warmed engine

coolant is sent out into the heater core. The heater

system supplies warm air into the passenger

compartment to warm it up.

Outside air is circulated through the heater core of

the heater unit and then back into the passenger

compartment. By controlling the mixture of outside

air and heater core air, the most comfortable

passenger compartment temperature can be

selected and maintained.

The temperature of warm air sent to the passenger

compartment is controlled by the temperature

control knob. This knob acts to open and close the

air mix door, thus controlling the amount of air

passed through the heater core.The air select knob, with its different modes, also

allows you to select and maintain the most

comfortable passenger compartment temperature.

The air source select lever is used to select either

ÒFRESHÓ for the introduction of the outside air, or

ÒCIRCÓ for the circulation of the inside air. When

the lever is set to ÒFRESHÓ, the outside air is always

taken into the passenger compartment. When

setting the lever to ÒCIRCÓ position, the circulation

of air is restricted only to the inside air with no

introduction of the outside air and the air in the

passenger compartment gets warm quickened.

However, the lever is normally set to ÒFRESHÓ to

prevent the windshield from clouding.

1A Ð 2 HEATING AND VENTILATION

GENERAL DESCRIPTION

HEATER

Side def hose

Vent box

Upper center vent duct

Lower center

vent ductBlower assembly

Control lever assembly Evaporator

assembly W/A/C

W/O A/C

Duct Heater unit

Lap vent nozzle Vent box Side def hoseDefroster nozzle

Rear heater duct

A/C - Air Conditioning This illustration is based on LHD

Page 102 of 3573

HEATING AND VENTILATION 1A Ð 7

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. When handling the ECM and the control unit, be

careful not to make any improper connection of the

connectors.

2. Adjust control lever assembly cables.

Refer to ÒCONTROL LEVER ASSEMBLYÓ installation

steps in this section.

3. When installing the heater unit, defroster nozzle and

center vent duct, be sure that proper seal is made,

without any gap between then.

REMOVAL

Preparation:

·Disconnect the battery ground cable

·Drain engine coolant

·Discharge and recover refrigerant (W/A/C)

(Refer to Section 1B ÒREFRIGERANT RECOVERYÓ)

1. Instrument Panel Assembly

Refer to Section 10 ÒBODYÓ for INSTRUMENT PANEL

ASSEMBLY removal procedure.

2. Water Hose

Disconnect water hoses at heater unit.

3. Resistor Connector

4. Duct

4a. Evaporator Assembly

Refer to Section 1B ÒAIR CONDITIONINGÓ for

Evaporator Assembly removal procedure.

5. Instrument panel center bracket

6. Rear Heater Duct

7. Heater Unit

8. Lap vent nozzle

9. Center ventilation lower duct