JAGUAR S TYPE 1999 1.G Powertrain Manual

Manufacturer: JAGUAR, Model Year: 1999, Model line: S TYPE, Model: JAGUAR S TYPE 1999 1.GPages: 75, PDF Size: 3.4 MB

Page 41 of 75

V6 Engine AJ-V6/AJ28

36

Fail Safe Cooling System

A unique feature of the V6 engine is the use of a fail safe cooling strategy, controlled by the EMS, in the

event of coolant loss leading to rising engine temperatures. The principle of the strategy involves

switching off one or more fuel injectors to inhibit combustion and reduce heat, thus allowing the flow of

ambient intake air to further cool the selected cylinders. By cycling the selected cylinders, ie switching

different injectors off for a period and in a sequence determined by EMS parameters, overall engine

temperature can be controlled sufficiently to allow the vehicle to be driven, at reduced power, for a

short distance. Throughout the malfunction period, instrument panel messages and warnings advise the

driver of the current status of the cooling system as described below.

Driver Indication and EMS Action

The fail safe strategy moves though different stages depending on engine temperature:

¥ Temperatures below 122û C (250û F) are within the normal range. At high temperatures below this

level the temperature gauge pointer enters the red zone.

¥ If the temperature rises to between 122û C - 127û C (250û F to 260û F) no action is taken by the EMS

which affects engine running but the following indications appear:

Temperature gauge pointer in red zone

Message Centre HIGH ENGINE TEMPERATURE

Warning light TEMP

Priority light red

Audible indicator single chime sounded

¥ If the temperature rises to 127û C (260û F) or above, the fail safe strategy operates. At 127û C (260û F),

the EMS will cut out one cylinder (the selected cylinder is varied) and as the temperature continues

to rise, this will increase to a maximum of three cylinders cut (with cylinder cycling). The following

indications are given:

Temperature gauge pointer in red zone

Message Centre ENGINE POWER REDUCED

Warning light TEMP

Priority light red

Audible indicator three chimes sounded

¥ At 166û C (300û F) or above, the fail safe strategy continues as described but the following

indications are given:

Temperature gauge pointer in red zone

Message Centre PULL OFF ROAD SAFELY alternates with TURN OFF IGNITION

Warning light TEMP flashes

Priority light red

Audible indicator five chimes sounded

¥ EMS shuts the engine down.

Page 42 of 75

V6 EngineAJ-V6/AJ28

37

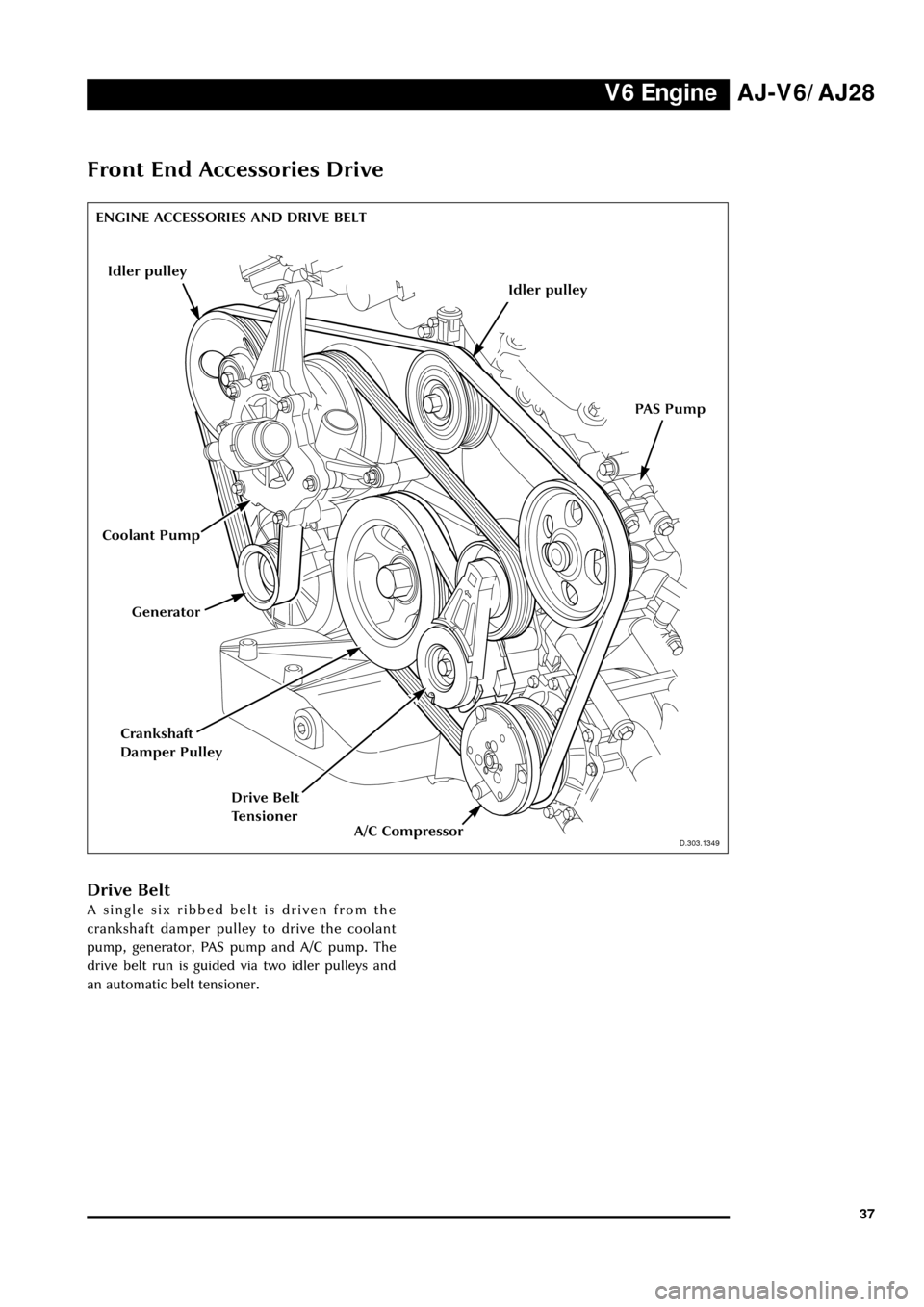

Front End Accessories Drive

D.303.1349

Drive Belt

A single six ribbed belt is driven from the

crankshaft damper pulley to drive the coolant

pump, generator, PAS pump and A/C pump. The

drive belt run is guided via two idler pulleys and

an automatic belt tensioner.

PAS Pump

Generator

D.303.1349

ENGINE ACCESSORIES AND DRIVE BELT

Coolant Pump

A/C Compressor

Drive Belt

Tensioner

Crankshaft

Damper Pulley

Idler pulley

Idler pulley

Page 43 of 75

V6 Engine AJ-V6/AJ28

38

J.303.1348

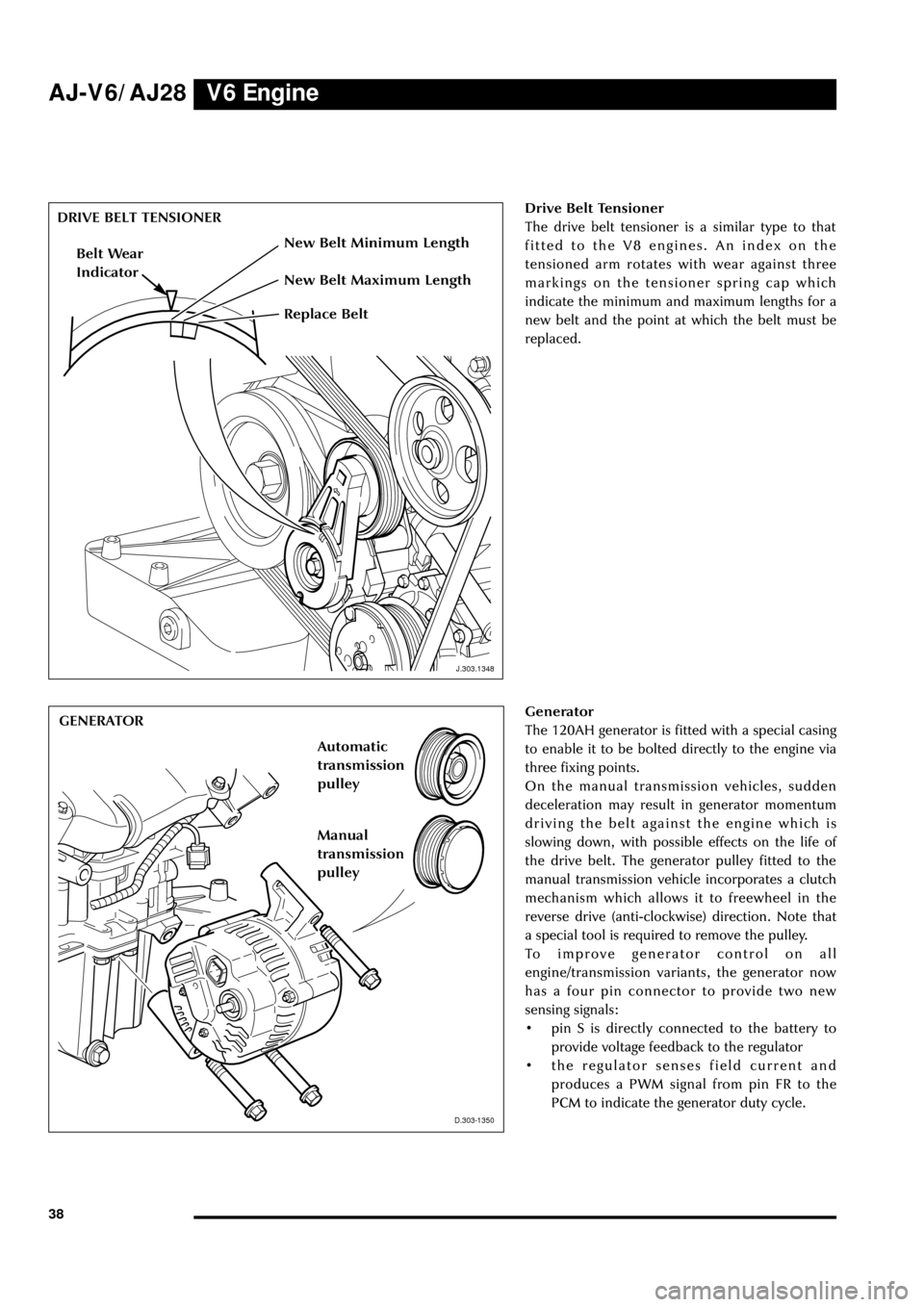

Generator

The 120AH generator is fitted with a special casing

to enable it to be bolted directly to the engine via

three fixing points.

On the manual transmission vehicles, sudden

deceleration may result in generator momentum

driving the belt against the engine which is

slowing down, with possible effects on the life of

the drive belt. The generator pulley fitted to the

manual transmission vehicle incorporates a clutch

mechanism which allows it to freewheel in the

reverse drive (anti-clockwise) direction. Note that

a special tool is required to remove the pulley.

To improve generator control on all

engine/transmission variants, the generator now

has a four pin connector to provide two new

sensing signals:

¥ pin S is directly connected to the battery to

provide voltage feedback to the regulator

¥ the regulator senses field current and

produces a PWM signal from pin FR to the

PCM to indicate the generator duty cycle.

D.303.1350

DRIVE BELT TENSIONER

GENERATOR

D.303-1350

Drive Belt Tensioner

The drive belt tensioner is a similar type to that

fitted to the V8 engines. An index on the

tensioned arm rotates with wear against three

markings on the tensioner spring cap which

indicate the minimum and maximum lengths for a

new belt and the point at which the belt must be

replaced.

Replace Belt

Belt Wear

Indicator

New Belt Maximum Length

New Belt Minimum Length

Manual

transmission

pulleyAutomatic

transmission

pulley

J.303.1348

Page 44 of 75

V6 EngineAJ-V6/AJ28

39

D.303.1351D.303.1352

PAS PUMPA/C COMPRESSOR

D.303.1352

D.303.1369

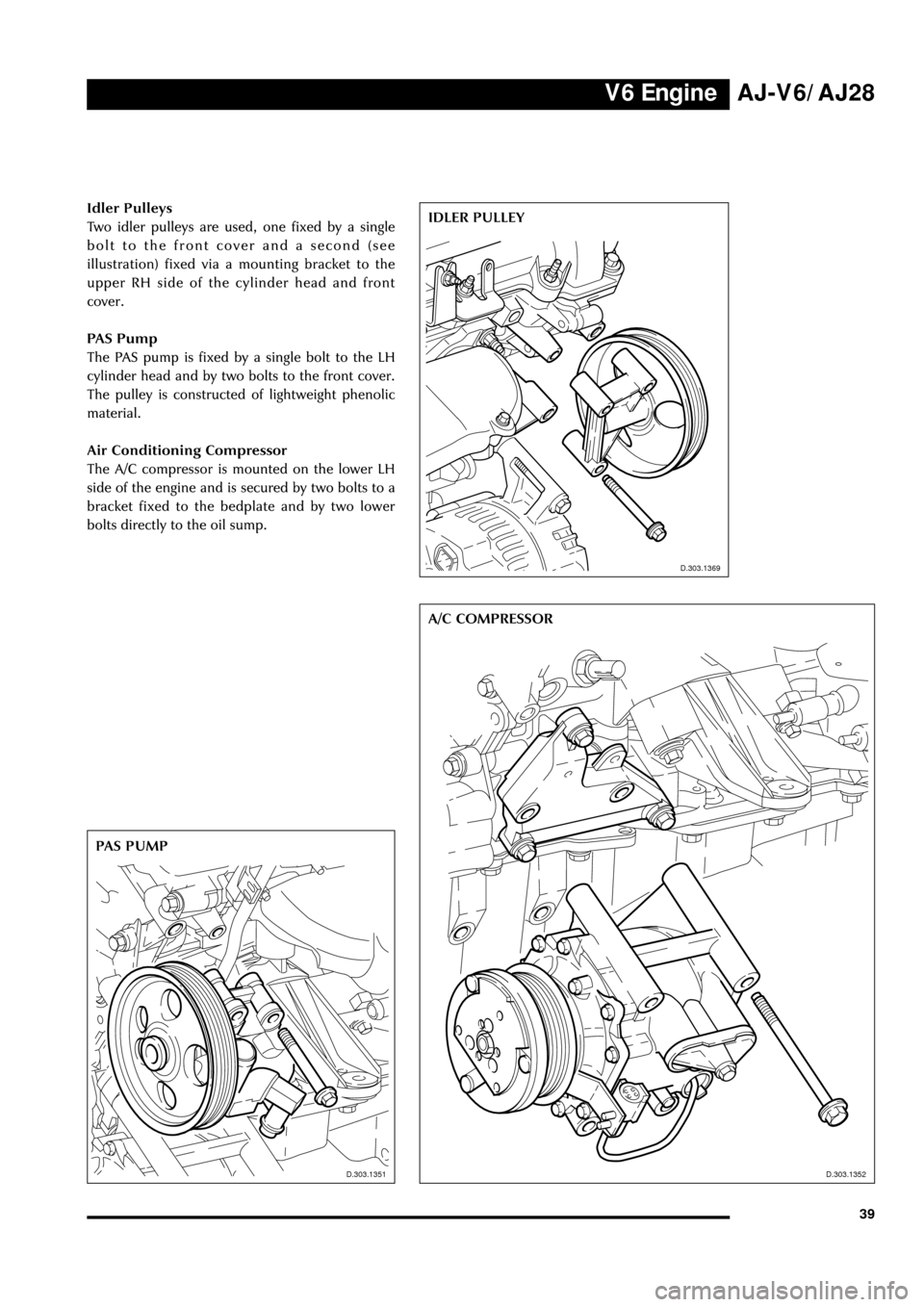

Idler Pulleys

Two idler pulleys are used, one fixed by a single

bolt to the front cover and a second (see

illustration) fixed via a mounting bracket to the

upper RH side of the cylinder head and front

cover.

PAS Pump

The PAS pump is fixed by a single bolt to the LH

cylinder head and by two bolts to the front cover.

The pulley is constructed of lightweight phenolic

material.

Air Conditioning Compressor

The A/C compressor is mounted on the lower LH

side of the engine and is secured by two bolts to a

bracket fixed to the bedplate and by two lower

bolts directly to the oil sump.IDLER PULLEY

D.303.1351

D.303.1369

Page 45 of 75

V6 Engine AJ-V6/AJ28

40

Engine Management Sensors

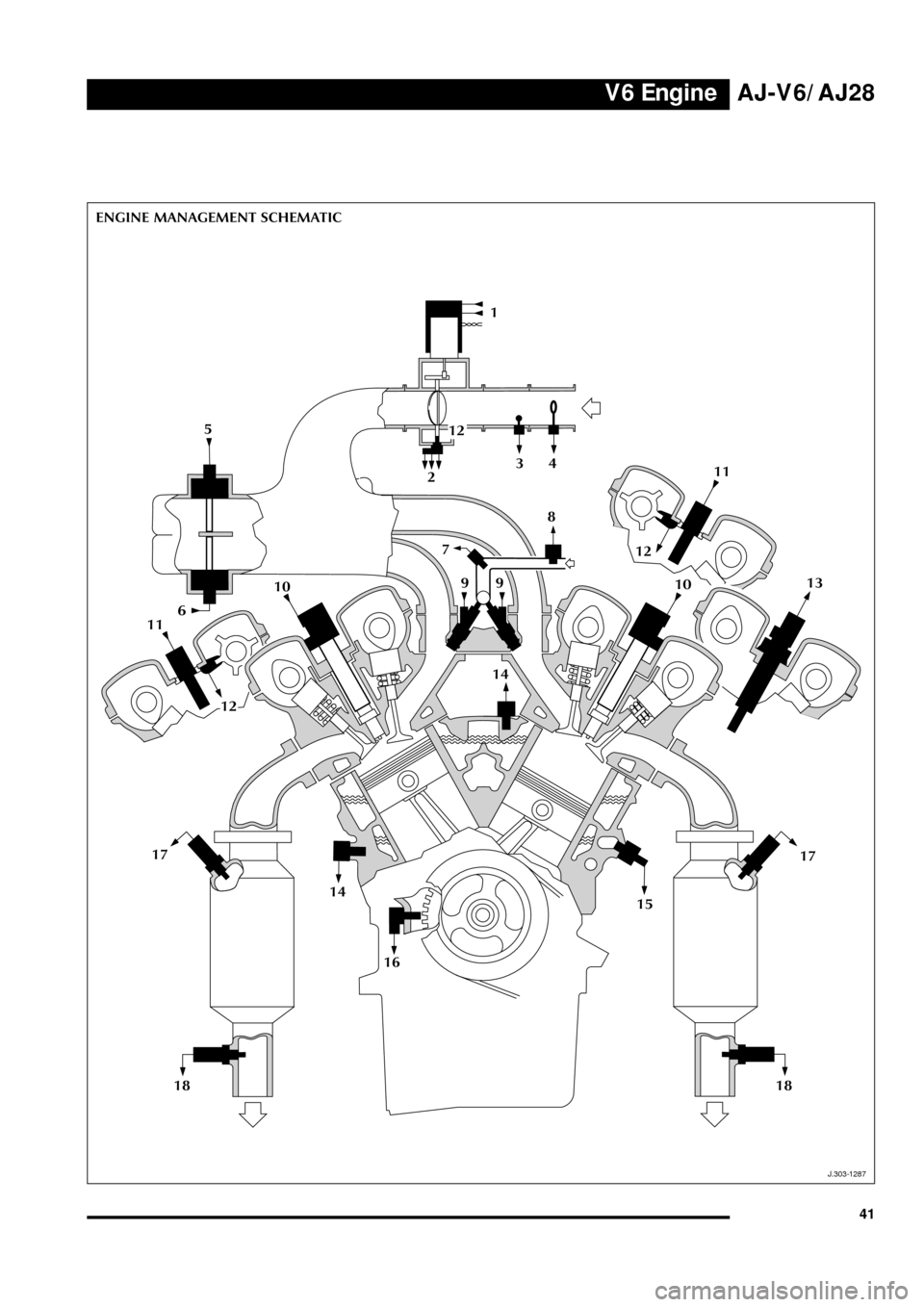

Key to illustration on page 41:

1. Throttle motor

2. TP sensor

3. IAT sensor

4. MAF sensor

5. Top IMT valve

6. Bottom IMT valve

7. EFT sensor

8. IP sensor

9. Fuel injectors

10. Coil-on-plug units

11. VVT shuttle valve

12. CMP sensor

13. CHT sensor

14. KS sensors

15. EOT sensor

16. CKP sensor

17. HO2 sensors

18. HO2 sensors (catalyst monitors)

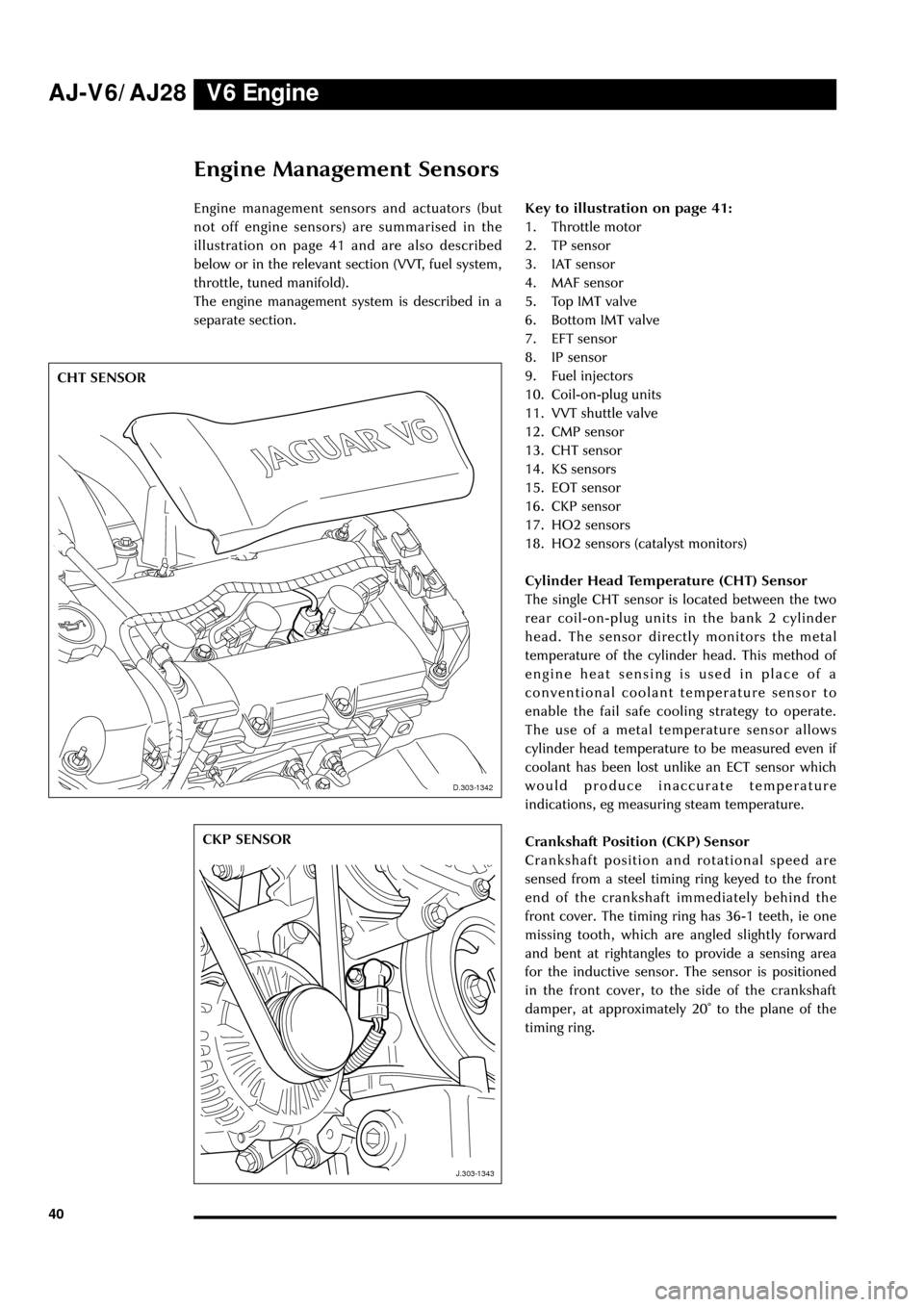

Cylinder Head Temperature (CHT) Sensor

The single CHT sensor is located between the two

rear coil-on-plug units in the bank 2 cylinder

head. The sensor directly monitors the metal

temperature of the cylinder head. This method of

engine heat sensing is used in place of a

conventional coolant temperature sensor to

enable the fail safe cooling strategy to operate.

The use of a metal temperature sensor allows

cylinder head temperature to be measured even if

coolant has been lost unlike an ECT sensor which

would produce inaccurate temperature

indications, eg measuring steam temperature.

Crankshaft Position (CKP) Sensor

Crankshaft position and rotational speed are

sensed from a steel timing ring keyed to the front

end of the crankshaft immediately behind the

front cover. The timing ring has 36-1 teeth, ie one

missing tooth, which are angled slightly forward

and bent at rightangles to provide a sensing area

for the inductive sensor. The sensor is positioned

in the front cover, to the side of the crankshaft

damper, at approximately 20û to the plane of the

timing ring.

D.303.1342

J.303.1343

CHT SENSOR

CKP SENSOR

D.303-1342

J.303-1343

Engine management sensors and actuators (but

not off engine sensors) are summarised in the

illustration on page 41 and are also described

below or in the relevant section (VVT, fuel system,

throttle, tuned manifold).

The engine management system is described in a

separate section.

Page 46 of 75

V6 EngineAJ-V6/AJ28

41

J.303.1287

ENGINE MANAGEMENT SCHEMATIC

1

324 5

12

6

8

14

15 7

9

111013

16

J.303-1287

9

1011

12

1214

18 17

1817

Page 47 of 75

V6 Engine AJ-V6/AJ28

42

J.303.1291

KS SENSORS

J.303-1291

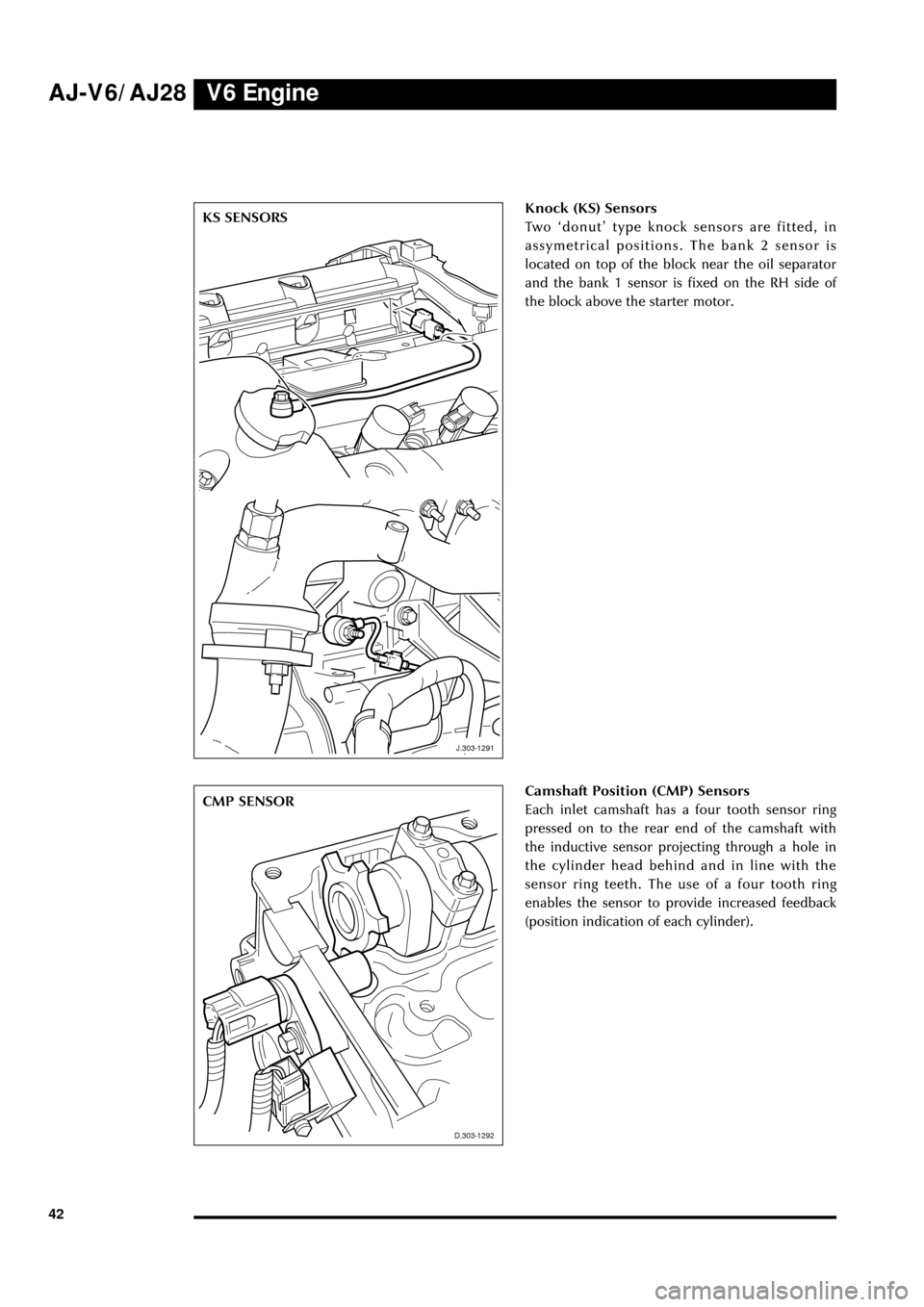

Knock (KS) Sensors

Two ÔdonutÕ type knock sensors are fitted, in

assymetrical positions. The bank 2 sensor is

located on top of the block near the oil separator

and the bank 1 sensor is fixed on the RH side of

the block above the starter motor.

D.303.1292

CMP SENSOR

D.303-1292

Camshaft Position (CMP) Sensors

Each inlet camshaft has a four tooth sensor ring

pressed on to the rear end of the camshaft with

the inductive sensor projecting through a hole in

the cylinder head behind and in line with the

sensor ring teeth. The use of a four tooth ring

enables the sensor to provide increased feedback

(position indication of each cylinder).

Page 48 of 75

V6 EngineAJ-V6/AJ28

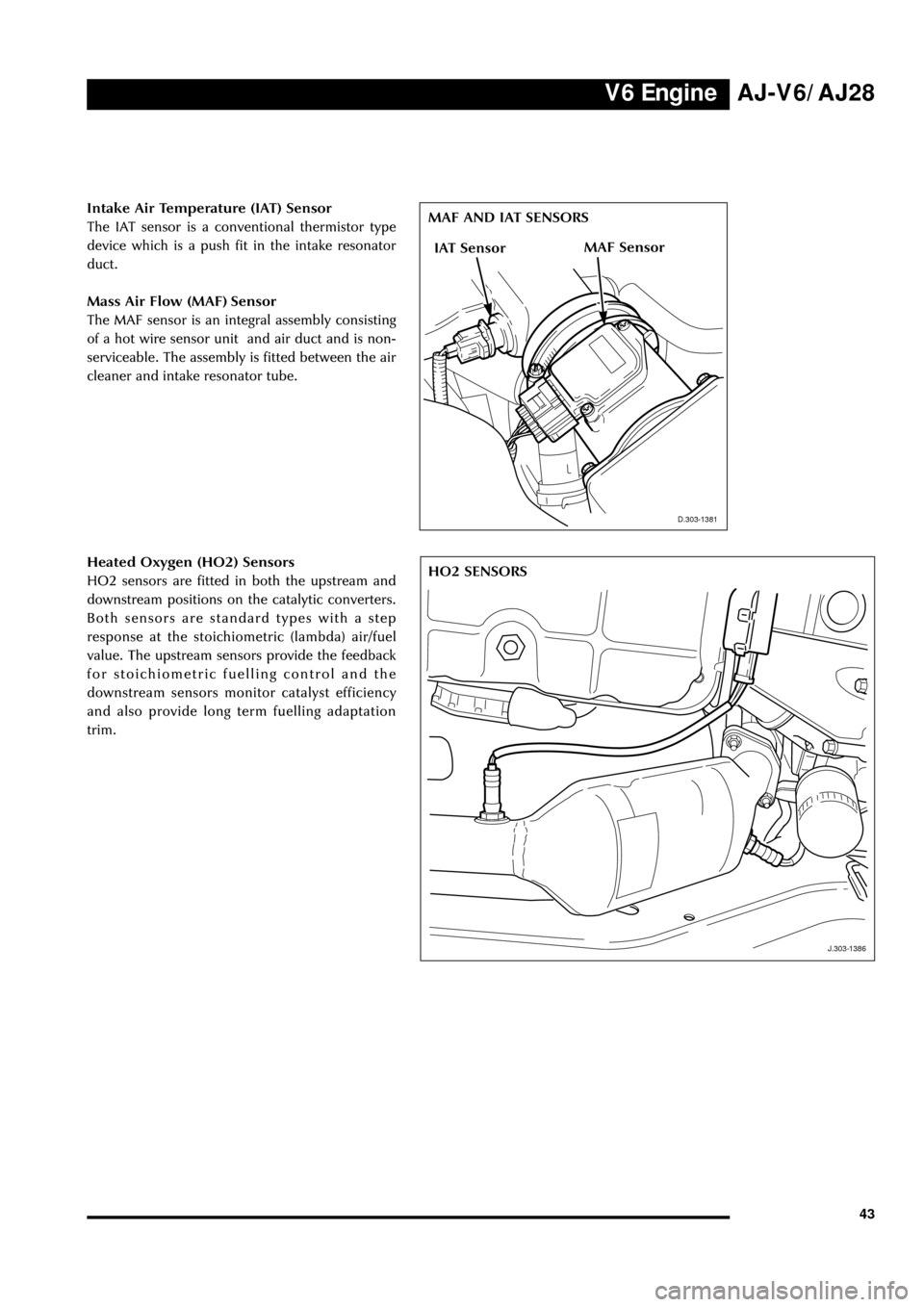

43 Intake Air Temperature (IAT) Sensor

The IAT sensor is a conventional thermistor type

device which is a push fit in the intake resonator

duct.

Mass Air Flow (MAF) Sensor

The MAF sensor is an integral assembly consisting

of a hot wire sensor unit and air duct and is non-

serviceable. The assembly is fitted between the air

cleaner and intake resonator tube.

D.303.1381

MAF AND IAT SENSORS

D.303-1381

J.303.1386

HO2 SENSORS

J.303-1386

Heated Oxygen (HO2) Sensors

HO2 sensors are fitted in both the upstream and

downstream positions on the catalytic converters.

Both sensors are standard types with a step

response at the stoichiometric (lambda) air/fuel

value. The upstream sensors provide the feedback

for stoichiometric fuelling control and the

downstream sensors monitor catalyst efficiency

and also provide long term fuelling adaptation

trim.

MAF SensorIAT Sensor

Page 49 of 75

Notes AJ-V6/AJ28

44

Page 50 of 75

V8 EngineAJ-V6/AJ28

45

Introduction

The AJ28 engine is a variant of the 4.0L 90û V8 units fitted to the XJ and XK range of vehicles. The AJ28

shares some of the changes incorporated in the current AJ27 engine: both engines are derived from the

original AJ26 unit. A number of features are unique to the AJ28 or are shared with the AJ-V6 engine also

described in this publication.

Features of the AJ28 engine are:

¥ Continuously variable inlet valve timing over a 48û

+

-2û crank angle: as fitted to the AJ27 engine

¥ Full authority cable-less electronic throttle control: as fitted to the AJ-V6 engine

¥ Air assisted fuel injection: similar to system used on the AJ27 engine

¥ Unique induction manifold with centrally mounted throttle body

¥ Returnless fuel system: similar to AJ-V6 engine

¥ Twin wall exhaust manifold

¥ Engine management system as used on the AJ-V6

¥ New sensors

¥ Modified sump and oil cooler

¥ Modified front end ancillary drive and components

Engine Specification

Maximum power DIN - 209 kW (281 BHP) at 6100 RPM

EEC - 203 kW (276 PS) at 6100 RPM

Maximum torque DIN - 390 Nm (287 lbft) at 4300 RPM

EEC - 278 Nm (279 lbft) at 4300 RPM

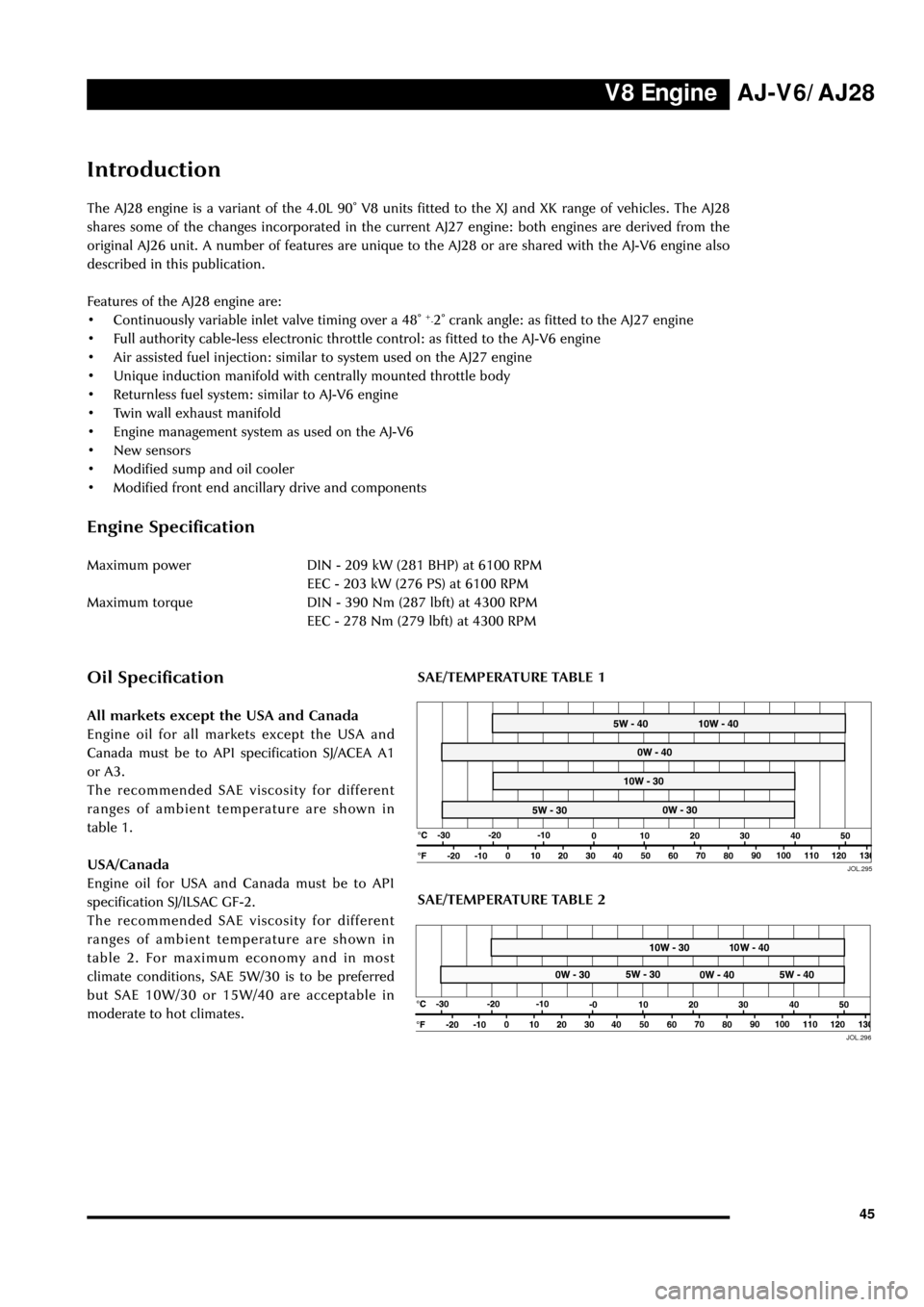

Oil Specification

All markets except the USA and Canada

Engine oil for all markets except the USA and

Canada must be to API specification SJ/ACEA A1

or A3.

The recommended SAE viscosity for different

ranges of ambient temperature are shown in

table 1.

USA/Canada

Engine oil for USA and Canada must be to API

specification SJ/ILSAC GF-2.

The recommended SAE viscosity for different

ranges of ambient temperature are shown in

table 2. For maximum economy and in most

climate conditions, SAE 5W/30 is to be preferred

but SAE 10W/30 or 15W/40 are acceptable in

moderate to hot climates.

JOL.29550

50JOL.296

SAE/TEMPERATURE TABLE 2

SAE/TEMPERATURE TABLE 1